Lithium battery and preparation method thereof

A lithium battery and cathode technology, applied in the field of lithium battery and lithium battery preparation, can solve the problem that the battery cannot meet the requirements of high rate discharge and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

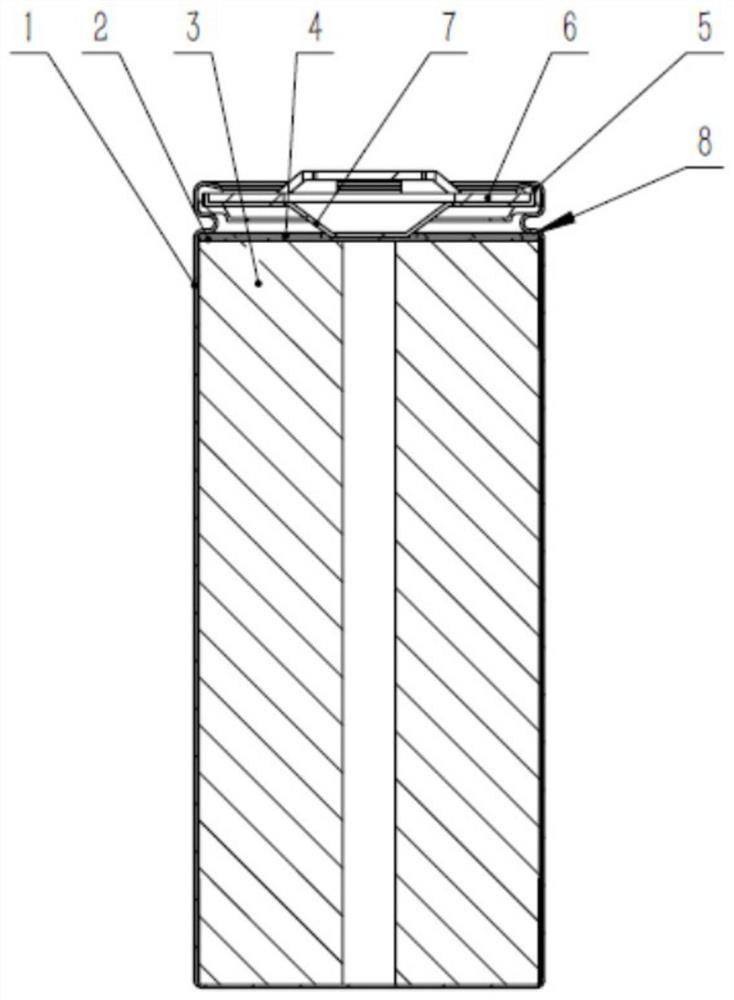

[0063] In the second aspect, a method for preparing a lithium battery as described above according to an embodiment of the present invention includes the steps of:

[0064] Prepare the positive electrode sheet and the negative electrode sheet. Specifically, the preparation of the positive electrode sheet specifically includes positive electrode homogenization → positive electrode coating → positive electrode spreading → positive electrode cutting to prepare the positive electrode sheet. The preparation of the negative electrode sheet specifically includes negative electrode homogenization → negative electrode coating → Negative electrode stretching → negative electrode slitting to prepare negative electrode sheets;

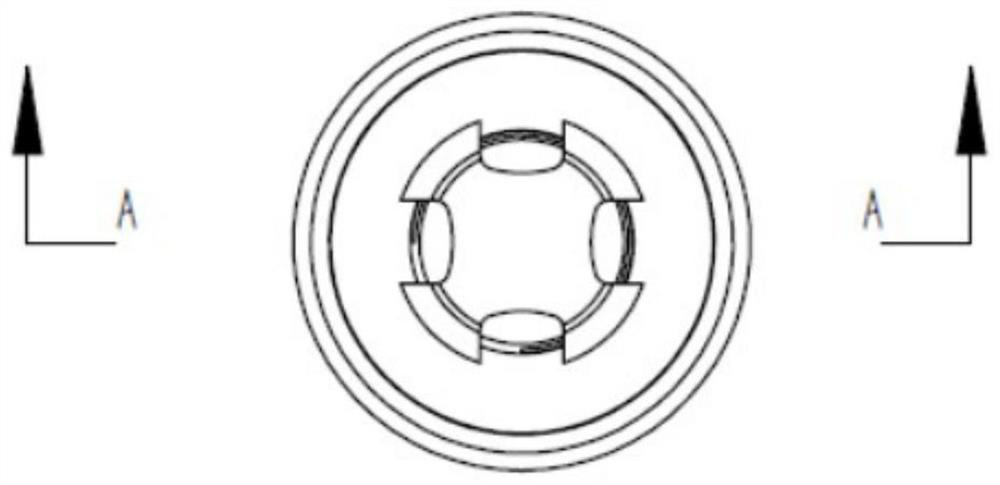

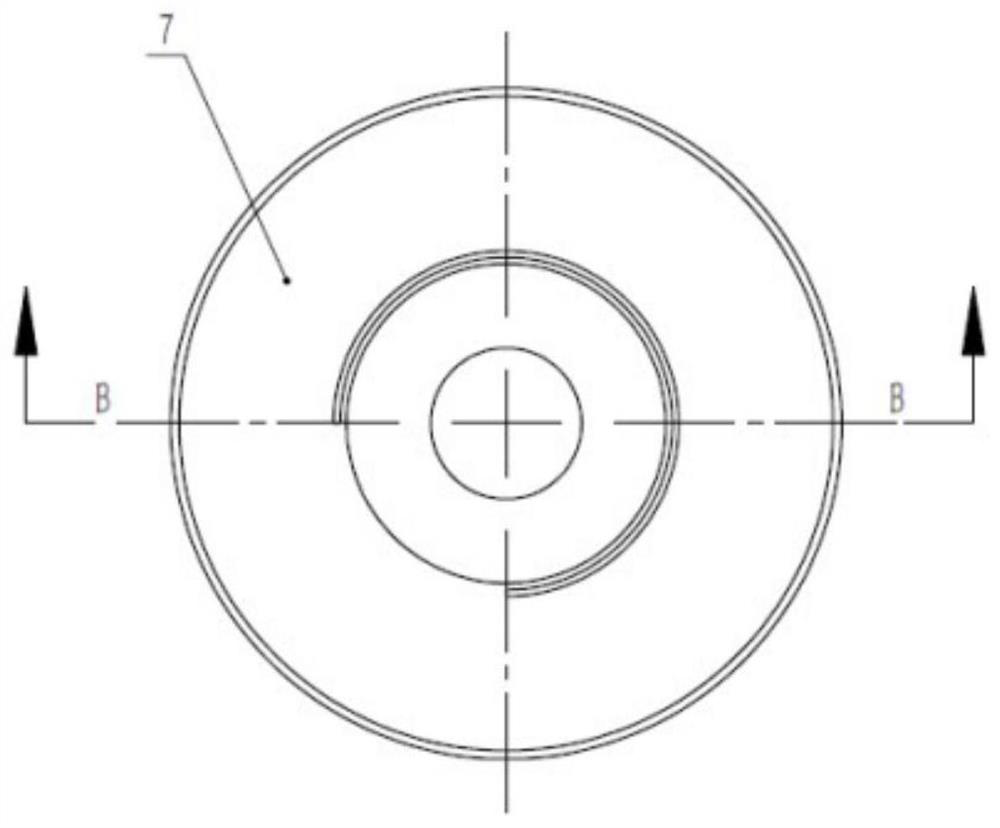

[0065] Winding the prepared positive electrode sheet, negative electrode sheet, and separator, so that the negative electrode sheet wraps the positive electrode sheet, and the separator wraps the negative electrode sheet to prepare a core 3;

[0066] The winding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com