Stack silicon-base miniature fuel celles and manufacturing method

A fuel cell stack and fuel cell technology, applied in the direction of fuel cell groups, fuel cells, chemical instruments and methods, etc., can solve the problems of low output voltage of a single cell, small range of output current density, large packaging volume ratio, etc., and achieve battery The effect of small internal resistance, large performance improvement, and small package volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

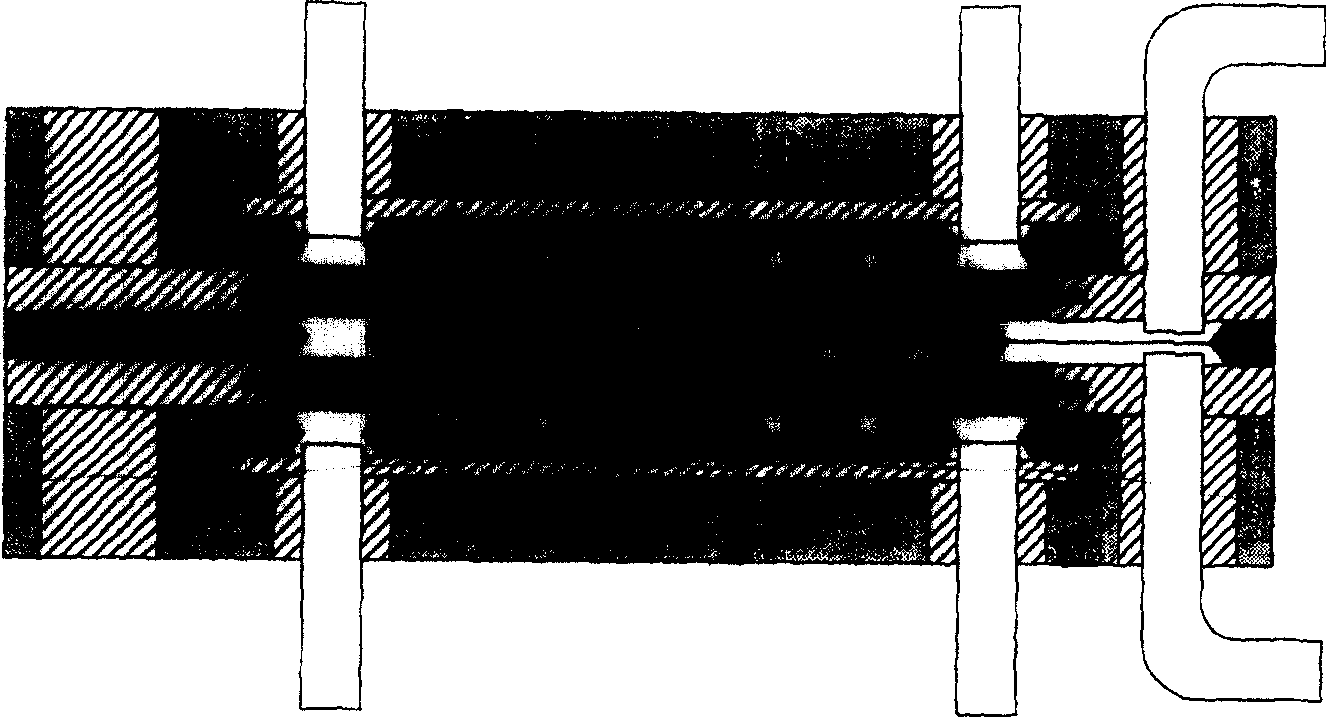

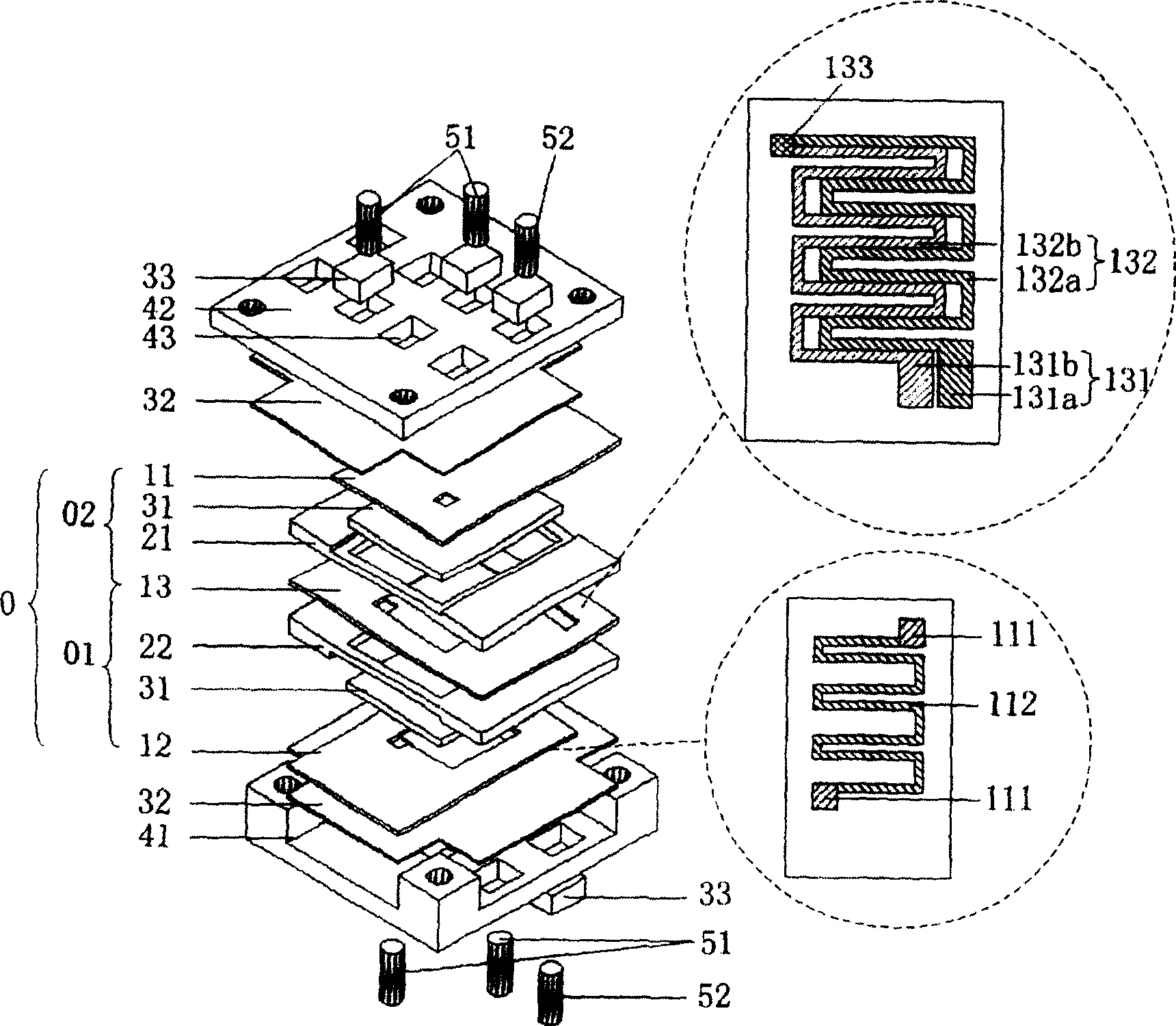

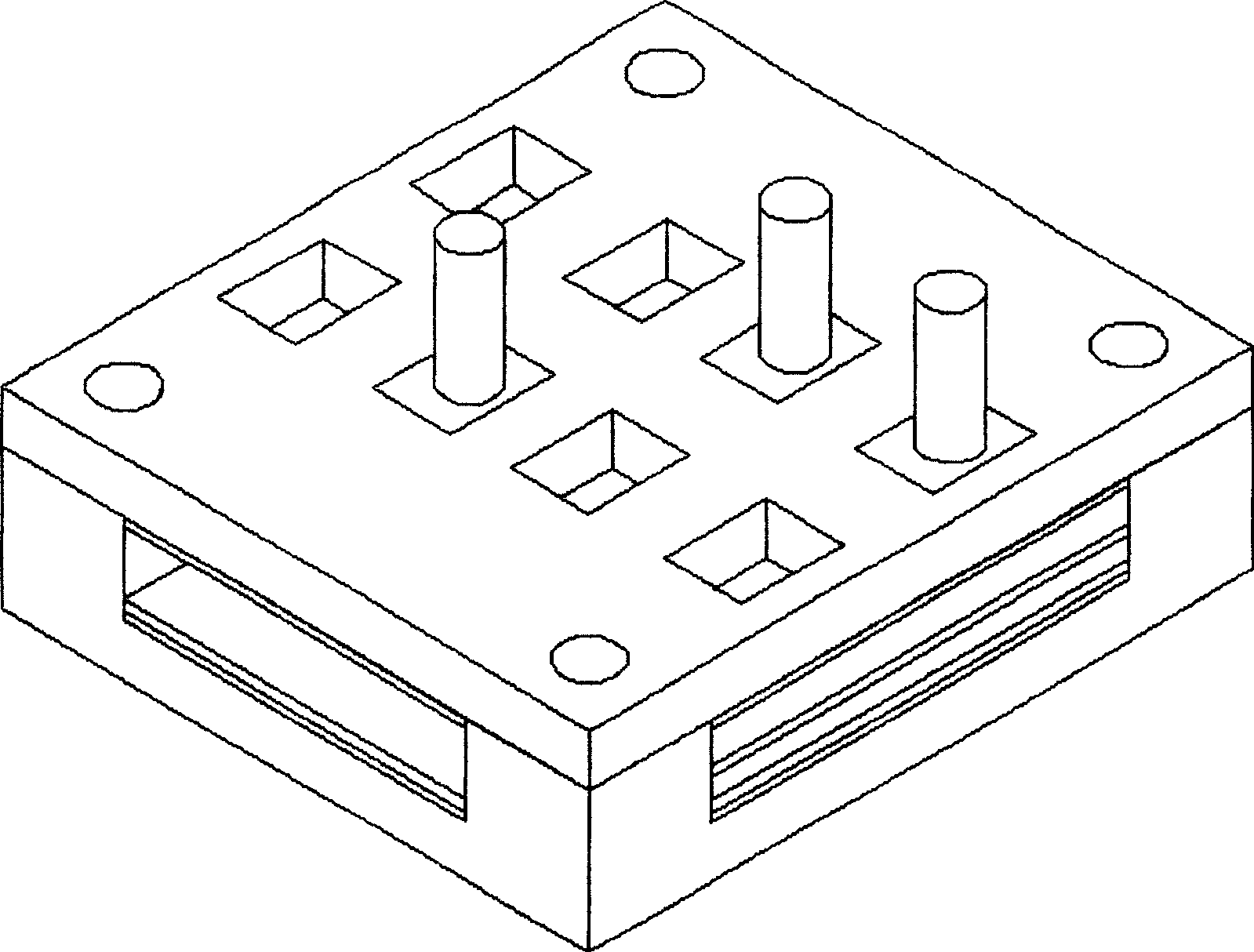

[0033] The cross-sectional structure of a typical embodiment of the silicon-based micro-fuel cell stack to which the present invention belongs is as follows: figure 1 As shown, the split structure of each component is as follows figure 2 shown. A stacked silicon-based micro fuel cell stack, including a single cell stack composed of two fuel cell single cells, a sealing assembly, a clamp assembly and a fluid conduit. The two fuel cells include three silicon plates and two membrane electrodes, the outer plate (11), the inner plate (13) and the membrane electrode (21) to form a single cell (01), the outer plate ( 12), the inner pole plate (13) and the membrane electrode (22) form a single cell (02), wherein the inner pole plate (13) is shared by two fuel cell single cells, and the single cell (01) and the single cell (02) form a single cell stack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com