Nitrogen-selenium co-doped porous carbon sphere, sodium ion battery negative electrode material, and preparation methods and applications thereof

A sodium ion battery and negative electrode material technology, applied in the field of materials science, can solve the problems of reducing cycle stability, limiting material application, poor material conductivity, etc., and achieves easy large-scale industrial production, increasing active sites, and increasing contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

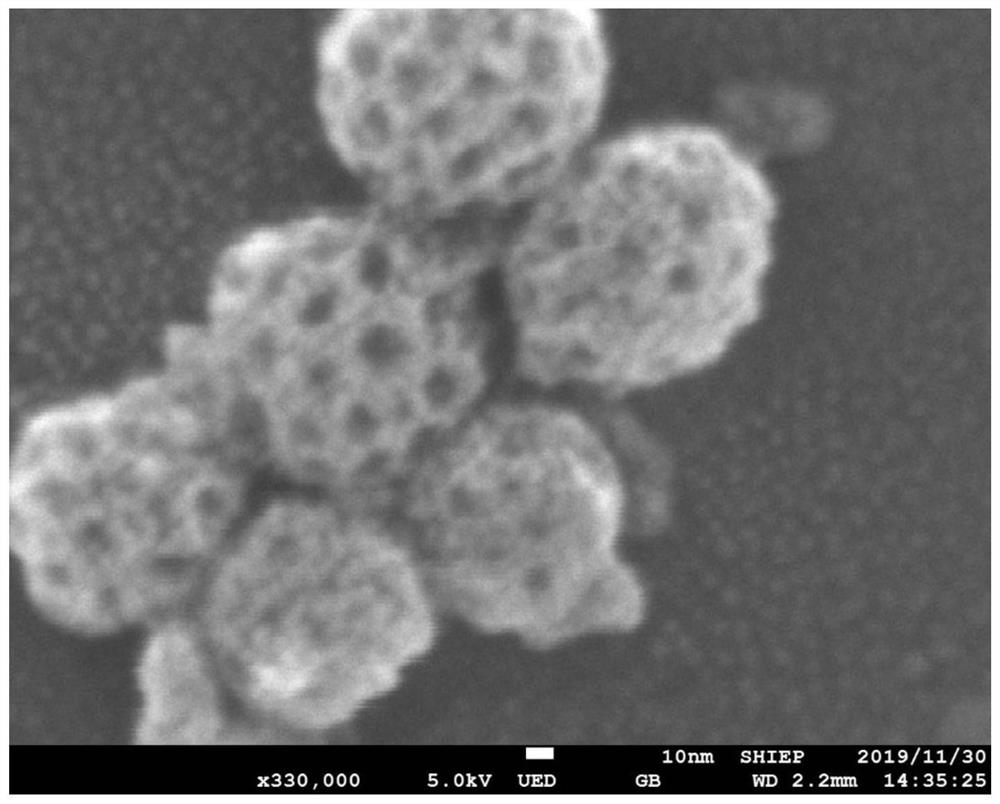

[0030] A method for preparing nitrogen-selenium co-doped porous carbon spheres provided by the present invention specifically comprises the following steps:

[0031] Step S1, dissolving F127 and dopamine hydrochloride in a mixed solution of water and ethanol, stirring until the solution is clear, then adding mesitylene and stirring, and then adding ammonia water to obtain a black solution.

[0032] Step S2, mixing and stirring the black solution and ethanol at a volume ratio of 1:1-1:4, centrifuging, and taking out the lower sediment.

[0033] Step S3, calcining the precipitate at 300° C.-900° C. under an inert atmosphere, and cooling to obtain a powder, namely nitrogen-doped porous carbon spheres.

[0034] Step S4, under an inert atmosphere, place selenium powder and nitrogen-doped porous carbon spheres on both ends of the porcelain boat respectively, keep warm at 300°C-600°C for a period of time, and cool to obtain the final product, that is, black powdery nitrogen-selenium ...

Embodiment 1

[0043] The invention provides a method for preparing a negative electrode energy storage material of a sodium ion battery, which specifically includes the following steps:

[0044] Step S1, dissolve 2g of F127 and 1g of dopamine hydrochloride in 200mL of a mixed solution of water and ethanol at a ratio of 1:1, stir at 35°C for 30min until the solution is clear; then add 3mL of mesitylene and stir for 30min, then add 10mL of 25% Ammonia was stirred for 30 min, and finally a black solution was obtained.

[0045] Step S2, mix the black solution and ethanol at a volume ratio of 1:2, stir, centrifuge at 16,000 rpm for 5 min, and take out the lower sediment.

[0046] Step S3, heating the lower precipitate to 800°C for calcination under a nitrogen atmosphere at a heating rate of 3°C / min, keeping it for 2 hours, cooling to room temperature and collecting powder to obtain nitrogen-doped porous carbon spheres.

[0047] Step S4, preparing porous carbon spheres co-doped with nitrogen and...

Embodiment 2

[0053] The invention provides a method for preparing a negative electrode energy storage material of a sodium ion battery, which specifically includes the following steps:

[0054] Step S1, dissolve 3g of F127 and 1.5g of dopamine hydrochloride in 250mL of a mixed solution of water and ethanol at a ratio of 1:1, stir at 35°C for 40min until the solution is clear; then add 3ml of mesitylene and stir for 40min, then add 10ml of % ammonia water was stirred for 40min, and finally a black solution was obtained.

[0055] Step S2, mix the black solution and ethanol at a volume ratio of 1:3, stir, centrifuge at 15,000 rpm for 5 min, and take out the lower sediment.

[0056] In step S3, the lower precipitate is then heated to 800° C. for calcination under a nitrogen atmosphere at a heating rate of 3° C. / min, kept for 2 hours, and cooled to room temperature to collect powder to obtain nitrogen-doped porous carbon spheres.

[0057] Step S4, preparing porous carbon spheres co-doped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com