Preparation technology of photovoltaic battery front-face electrode

A front electrode and photovoltaic cell technology, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of restricting the improvement of photovoltaic cell efficiency, restricting the manufacturing cost of photovoltaic cells, increasing the fragmentation rate of printed cells, etc., to achieve The effect of low cost, small electrode resistance, and large electrode aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation process for a front electrode of a photovoltaic cell, comprising the following steps:

[0032] (1) Preparation of conductive paste: metal powder, metal or non-metallic oxide, organic binder, organic solvent and additives are mixed and stirred evenly to obtain conductive paste; in the described conductive paste, the mass percentage of metal powder The content is 70-90%, the mass percentage of metal or non-metal oxide is 1-10%, the mass percentage of organic binder is 1-10%, and the mass percentage of organic solvent is 1-10% %, the mass percentage of additives is 1-5%;

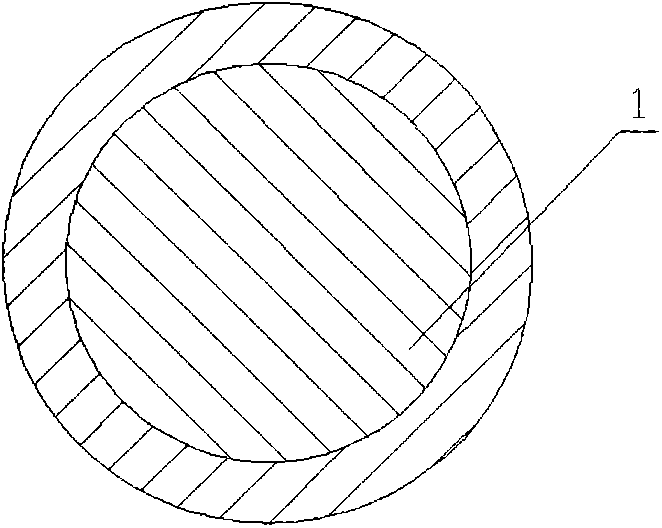

[0033] (2) Preparation of composite electrode material: the conductive paste is evenly coated on the surface of the conductive wire 1 and dried and cured. The drying and curing temperature of the conductive paste is 50°C-200°C;

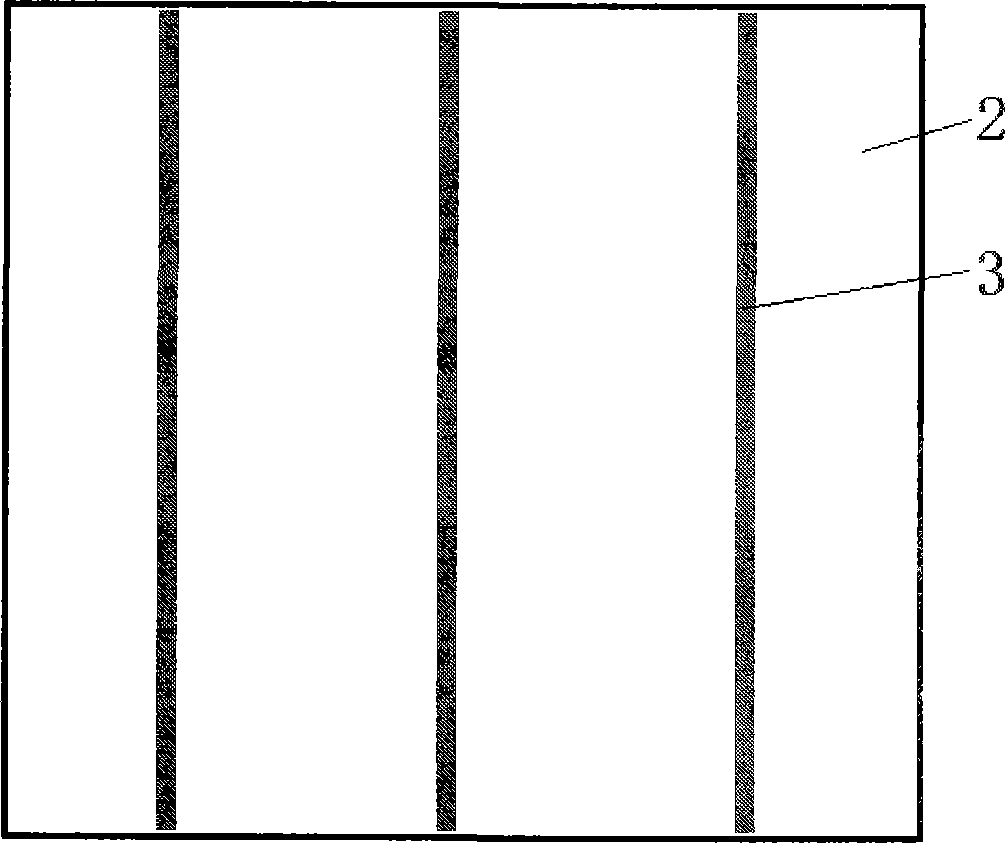

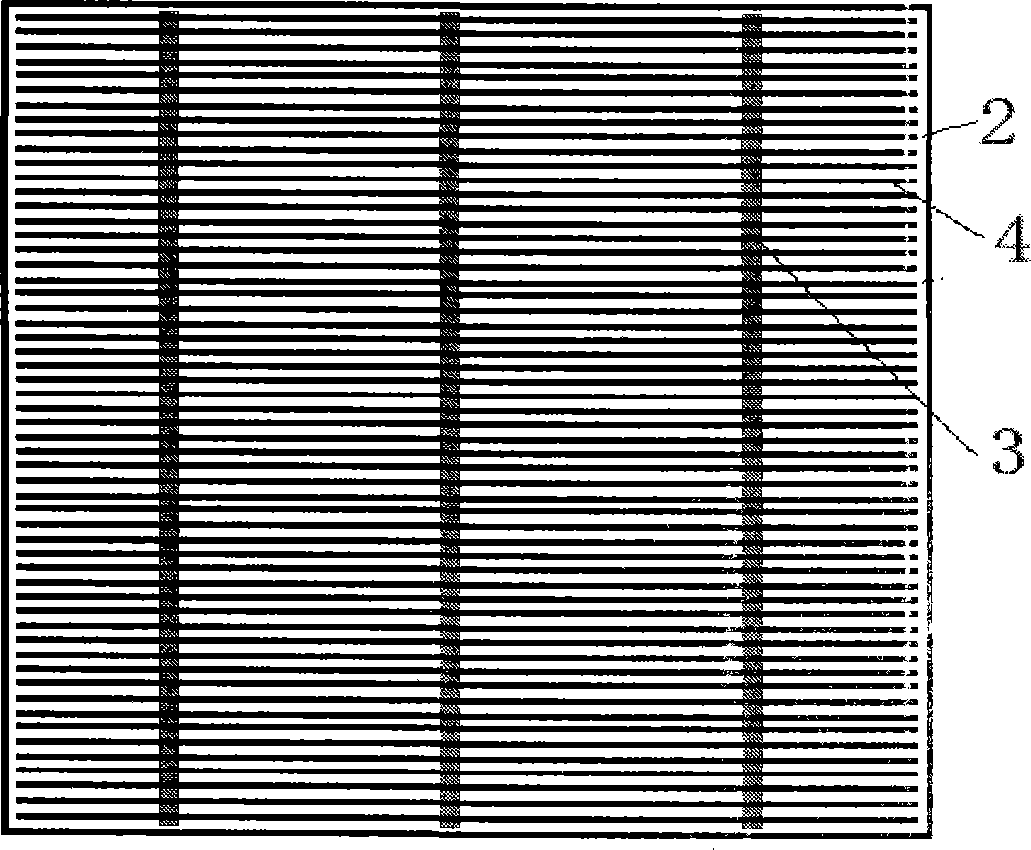

[0034] (3) Heat the battery sheet 2 or the composite electrode material 4 at 100°C-500°C, lay the composite electrode material 4 on the front surface of the batte...

Embodiment 1

[0044] For the front electrode of the photovoltaic cell, follow the steps below:

[0045] (1) Preparation of conductive paste: mix and stir metal powder, metal or non-metallic oxide, organic binder, organic solvent and additives evenly to obtain conductive paste; in the conductive paste used, the metal powder is silver powder, conductive According to the weight percentage of the conductive silver paste in the silver paste, metal or non-metal oxide accounts for 5%, organic binder accounts for 5%, organic solvent accounts for 5%, additive accounts for 1%, and the rest is silver powder, the particle size of silver powder The range is 0.1-2μm;

[0046] (2) Preparation of composite electrode material: The conductive paste is evenly coated on the surface of copper wire with a diameter of 10-20 microns, and it is dried and cured. The drying and curing temperature of the conductive paste is 50°C-200°C. The thickness after drying and curing is 5 microns to 10 microns;

[0047](3) Hea...

Embodiment 2

[0053] Photovoltaic battery positive electrode, according to the step with embodiment 1, difference is in the conductive silver paste in embodiment 2 by the weight percentage of conductive silver paste, metal or nonmetallic oxide accounts for 8%, and organic binder accounts for 5%, Organic solvents account for 5%, additives account for 2%, and the rest is silver powder; the number of busbars is 5;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com