Electrode pad for graphene-based supercapacitor and preparation method of electrode pad

A technology of supercapacitors and electrode pole pieces, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of detachment of active materials from current collectors, insufficient bonding strength of binders, and shortened cycle life. Achieve strong electrolyte adsorption and storage capacity, improve high-rate discharge performance, and reduce battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for an electrode pole piece of a graphene-based supercapacitor comprises the following steps:

[0039] 1) Prepare layered graphene slurry: 2.5g graphene and 0.5g carbon nanotube prepared by physical exfoliation are dispersed in 50ml water to form slurry;

[0040] 2) Prepare porous graphene slurry: 25g graphene, 5g carbon nanotubes, 50g potassium hydroxide prepared by chemical oxidation method are dispersed in 100ml water to form slurry;

[0041] 3) Preparation of electrode pole piece: Brush the mixed slurry obtained in steps 1) and 2) successively on the substrate, heat at 800°C for 2h in an inert atmosphere, soak the obtained sample in 1M hydrochloric acid for 2h for cleaning, and then Wash with water, dry at 100°C for 10 hours, and roll the dried sample directly to obtain the electrode sheet.

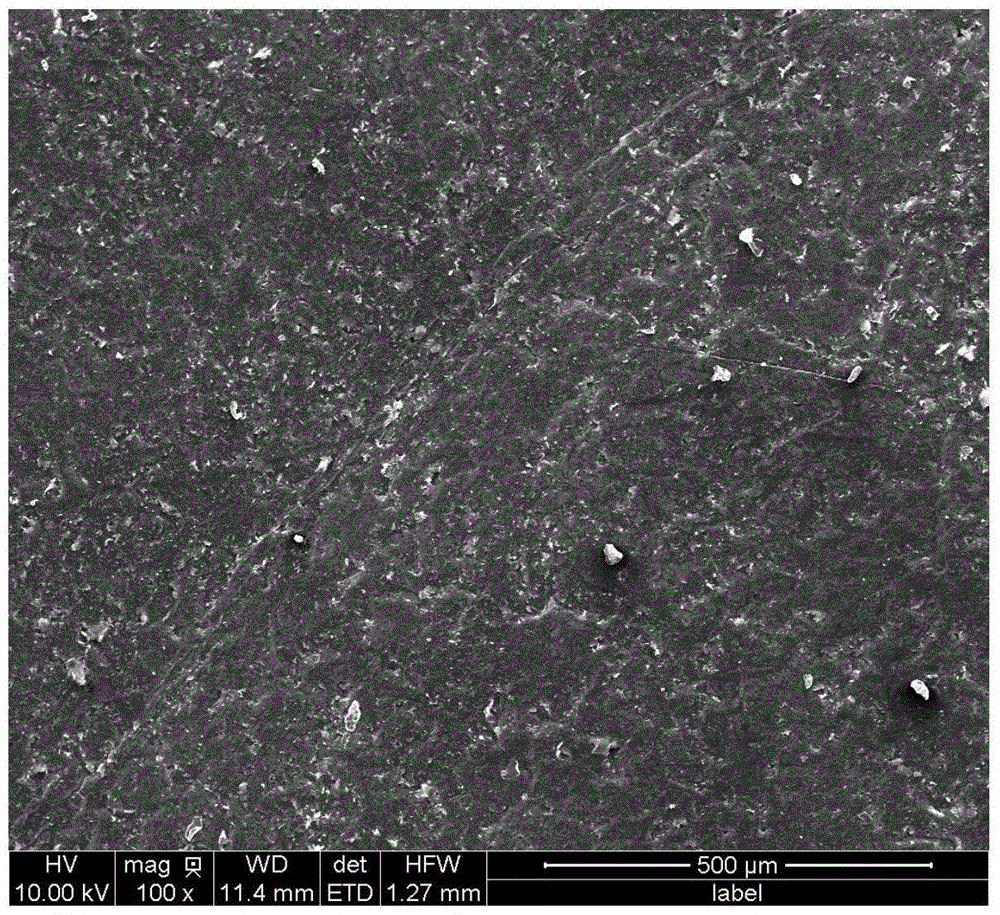

[0042] figure 1 Shown is the laminated graphene layer (current collector layer), and it can be seen that the surface of the laminated graphene layer is u...

Embodiment 2

[0048] A preparation method for an electrode pole piece of a graphene-based supercapacitor comprises the following steps:

[0049] 1) Prepare laminated graphene slurry: disperse 5g of graphene and 0.5g of carbon nanotubes prepared by physical exfoliation in 80ml of water to form a slurry;

[0050] 2) Preparation of porous graphene slurry: disperse 30g of graphene, 5g of carbon nanotubes, and 70g of sodium hydroxide prepared by chemical oxidation into 200ml of water to form a slurry;

[0051] 3) Preparation of electrode pole piece: brush the mixed slurry obtained in steps 1) and 2) on the substrate successively, heat at 1000° C. for 1 h in an inert atmosphere, and soak the obtained sample in 1M hydrochloric acid for 2 h for cleaning. Then wash with water, dry at 100°C for 10 hours, and roll the dried sample directly to obtain the electrode sheet.

Embodiment 3

[0053] A preparation method for an electrode pole piece of a graphene-based supercapacitor comprises the following steps:

[0054] 1) Prepare stacked graphene slurry: disperse 5 g of graphene and 0.5 g of carbon nanotubes prepared by physical exfoliation in 90 ml of water to form a slurry;

[0055] 2) Preparation of porous graphene slurry: disperse 100g of graphene, 5g of carbon nanotubes, and 400g of cobalt particles prepared by chemical oxidation into 900ml of water to form a slurry;

[0056] 3) Preparation of electrode pole piece: brush the mixed slurry obtained in steps 1) and 2) successively on the substrate, heat at 500°C for 8 hours in an inert atmosphere, soak the obtained sample in 1M hydrochloric acid for 2 hours, and then Wash with water, dry at 100°C for 10 hours, and roll the dried sample directly to obtain the electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com