Vanadium phosphate sodium composite nano porous cathode material and method for preparing material by using freeze drying method

A composite cathode material, freeze-drying technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the limitations of the popularization and application of sodium vanadium phosphate composite cathode materials, high current charge and discharge performance and problems such as low rate performance, to achieve the effect of reducing polarization and battery internal resistance, facilitating wetting, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

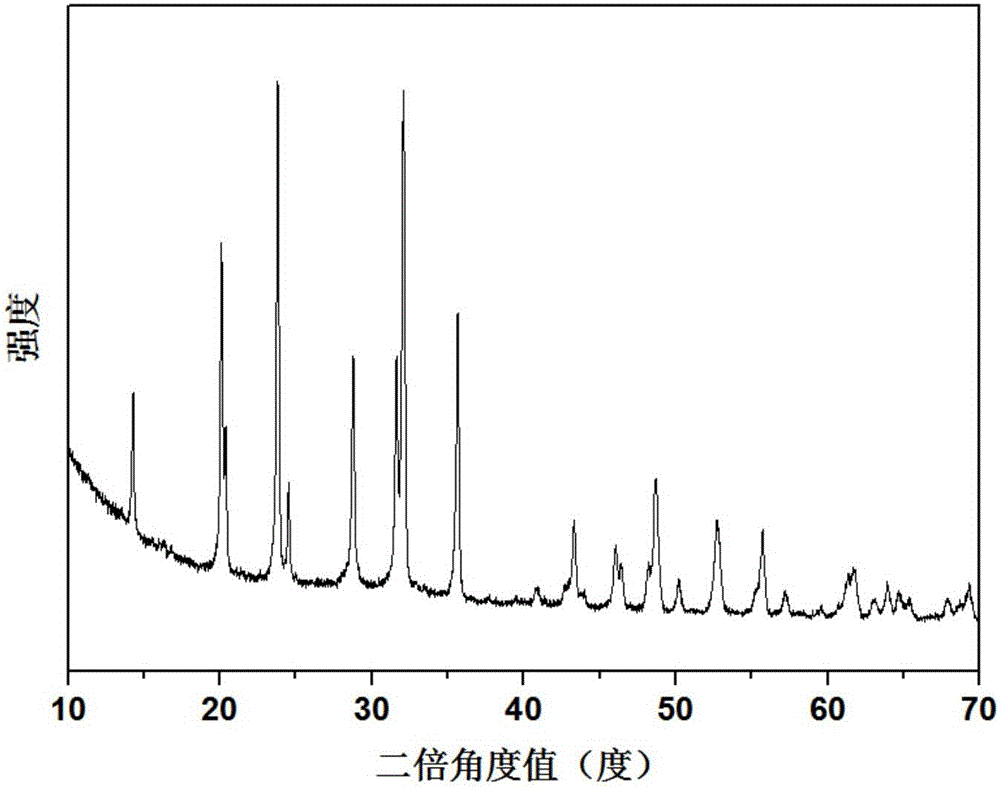

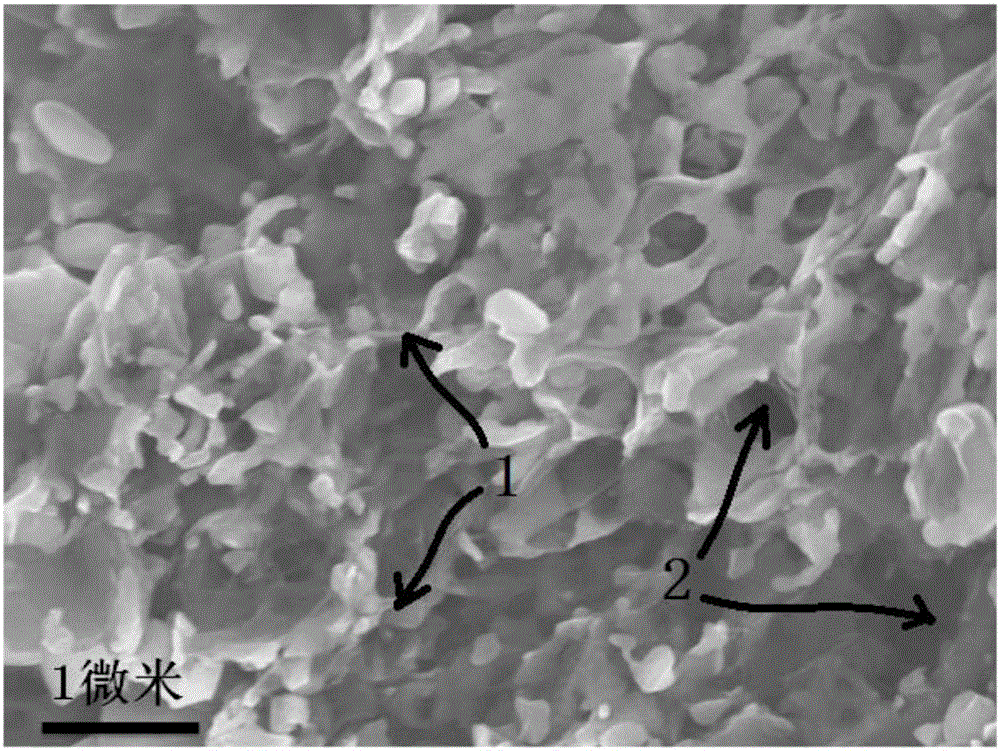

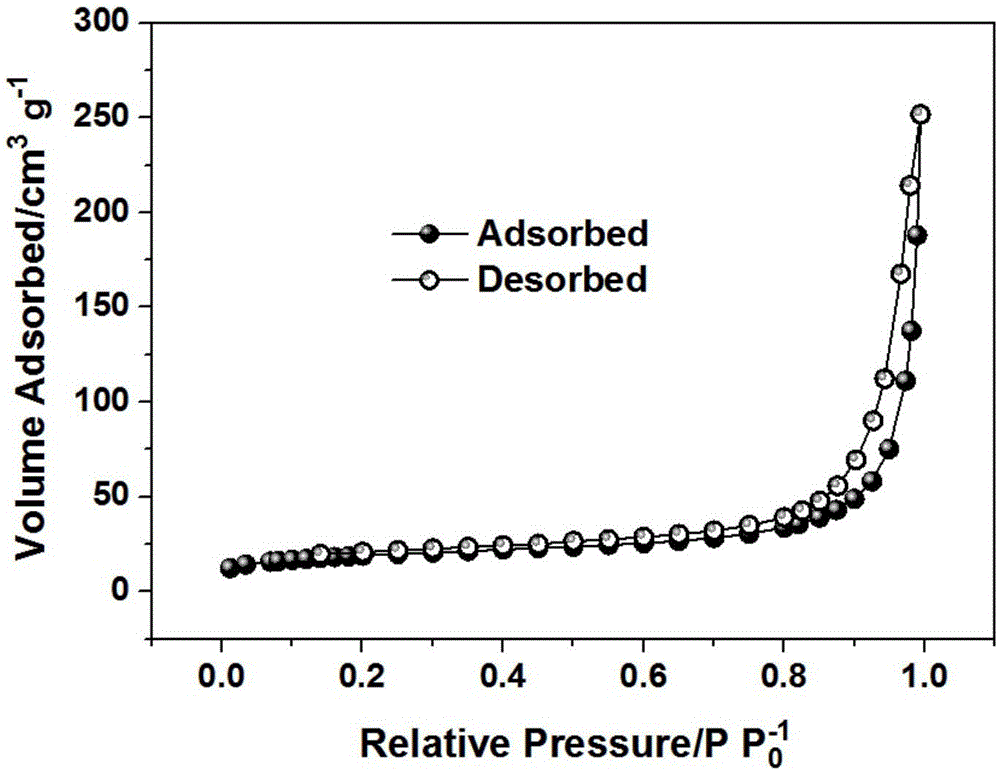

Embodiment 1

[0036]Accurately weigh 181.9 mg (1 mmol) of vanadium pentoxide, add it to a mixed solvent consisting of 5 mL of hydrogen peroxide and 50 mL of deionized water, stir and dissolve for 1 hour, then add 246.1 mg (3 mmol) of sodium acetate and 345.1 mg (3 mmol) of phosphoric acid Ammonium dihydrogen and 50 mg graphene oxide were stirred for 12 hours to obtain a mixed solution. Next, the mixed solution was placed in liquid nitrogen at -196°C for 30 minutes and frozen into a solid, and then vacuum-dried in a vacuum freeze dryer for 48 hours to obtain a sodium vanadium phosphate precursor. Finally, the freeze-dried precursor was placed in an atmosphere tube furnace and sintered at 750°C for 8 hours under a mixed gas atmosphere of argon and hydrogen (accounting for 5 wt% of the mixed gas) to obtain sodium vanadium phosphate / graphene Composite cathode material. Mix the sodium vanadium phosphate / composite material prepared in this example with carbon powder and binder in a weight ratio ...

Embodiment 2

[0043] Accurately weigh 23.4 mg (0.2 mmol) of ammonium metavanadate, add it into a mixed solvent composed of 1 mL of hydrogen peroxide and 50 mL of deionized water, stir and dissolve for 1 hour, then add 25.5 mg (0.3 mmol) of sodium nitrate, 29.4 mg (0.3 mmol) phosphoric acid and 4.6 mg carbon nanotubes, and continued stirring for 12 hours to obtain a mixed solution. Next, the mixed solution was placed in liquid nitrogen at -196°C for 30 minutes and frozen into a solid, and then vacuum-dried in a vacuum freeze dryer for 48 hours to obtain a sodium vanadium phosphate precursor. Finally, the freeze-dried precursor was placed in an atmosphere tube furnace and sintered at 700°C for 24 hours under a mixed gas atmosphere of argon and hydrogen (5wt%) to obtain a three-dimensional porous framework structure of sodium vanadium phosphate / carbon Nanotube composite cathode materials.

Embodiment 3

[0045] Accurately weigh 16.6g (200mmol) vanadium dioxide, add it into a mixed solvent composed of 50mL hydrogen peroxide and 50mL deionized water, stir and dissolve for 12 hours, then add 21.3g (150mmol) sodium sulfate, 29.4mg (0.3mmol) phosphoric acid Diammonium hydrogen and 22.8g sucrose were stirred for 24 hours to obtain a mixed solution. Next, the mixed solution was placed in liquid nitrogen at -196°C for 30 minutes and frozen into a solid, and then vacuum-dried in a vacuum freeze dryer for 48 hours to obtain a sodium vanadium phosphate precursor. Finally, the freeze-dried precursor was placed in an atmosphere tube furnace and sintered at 900°C for 6 hours under a mixed gas atmosphere of argon and hydrogen (5wt%) to obtain a three-dimensional porous framework structure of sodium vanadium phosphate / carbon Composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com