Dimesize dynamic piezoresistance, pressure sensor, and manufacturing method

A pressure sensor, dynamic piezoresistive technology, applied in chemical instruments and methods, fluid pressure measurement by changing ohmic resistance, measurement of fluid pressure, etc., to achieve excellent anti-light interference, protection against destructive impact, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

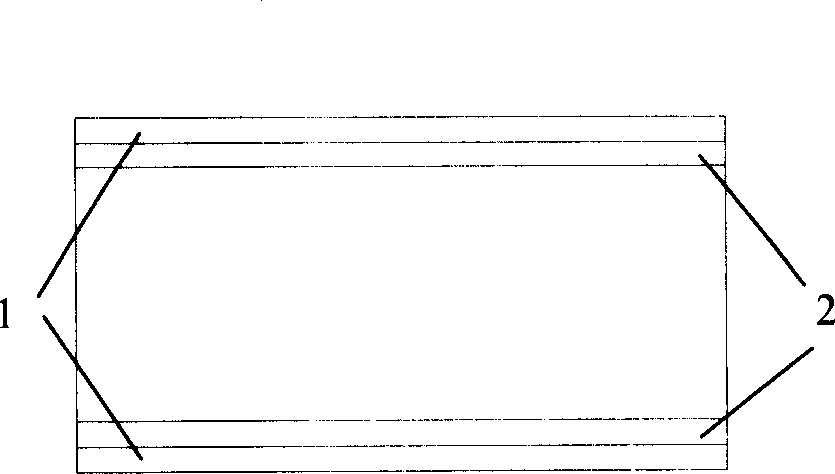

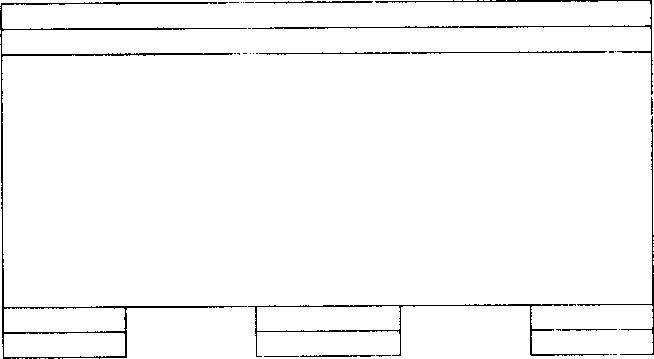

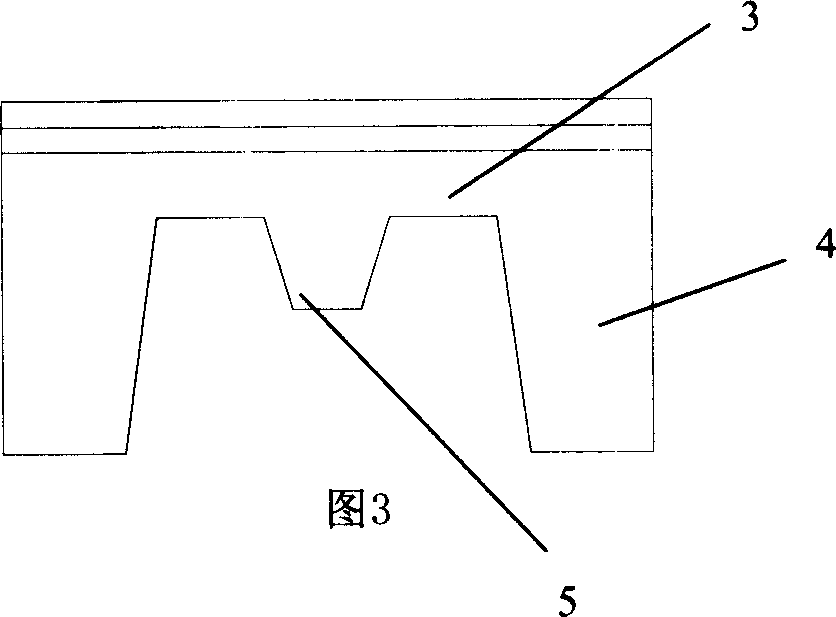

[0054] Using MEMS silicon micromachining technology to manufacture miniature pressure sensitive chips, the unit size of the chip is 1.5×1.5, the size of the sensitive diaphragm is 1.0×1.0, and an island-shaped hard core is left in the center of the diaphragm, and the size of the hard core is 0.7 ×0.7, the force-sensitive detection resistor is distributed on the film between the hard core and the boundary hard frame, and the position is determined according to the design method of the E-type sensitive chip. The implementation steps are as follows Figure 1 to Figure 5 The implementation shown:

[0055] figure 1 The double-sided polished silicon wafer used as an elastic element is covered with 1 μm thick SiO on both sides by traditional thermal oxidation technology in MEMS technology processing. 2 Layer 2, and then use standard LPCVD method to cover 3000A thick Si on both sides 3 N 4 Layer 1, use two photolithography techniques to etch away the Si on the back of the silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com