Hydraulic oil type high-stability pressure sensor

A pressure sensor and hydraulic oil technology, applied in the field of sensors, can solve the problems of uneven pressure-sensitive diaphragm force surface, inaccurate pressure detection, and poor working stability of the sensor, so as to ensure dynamic frequency response characteristics and stable structure , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

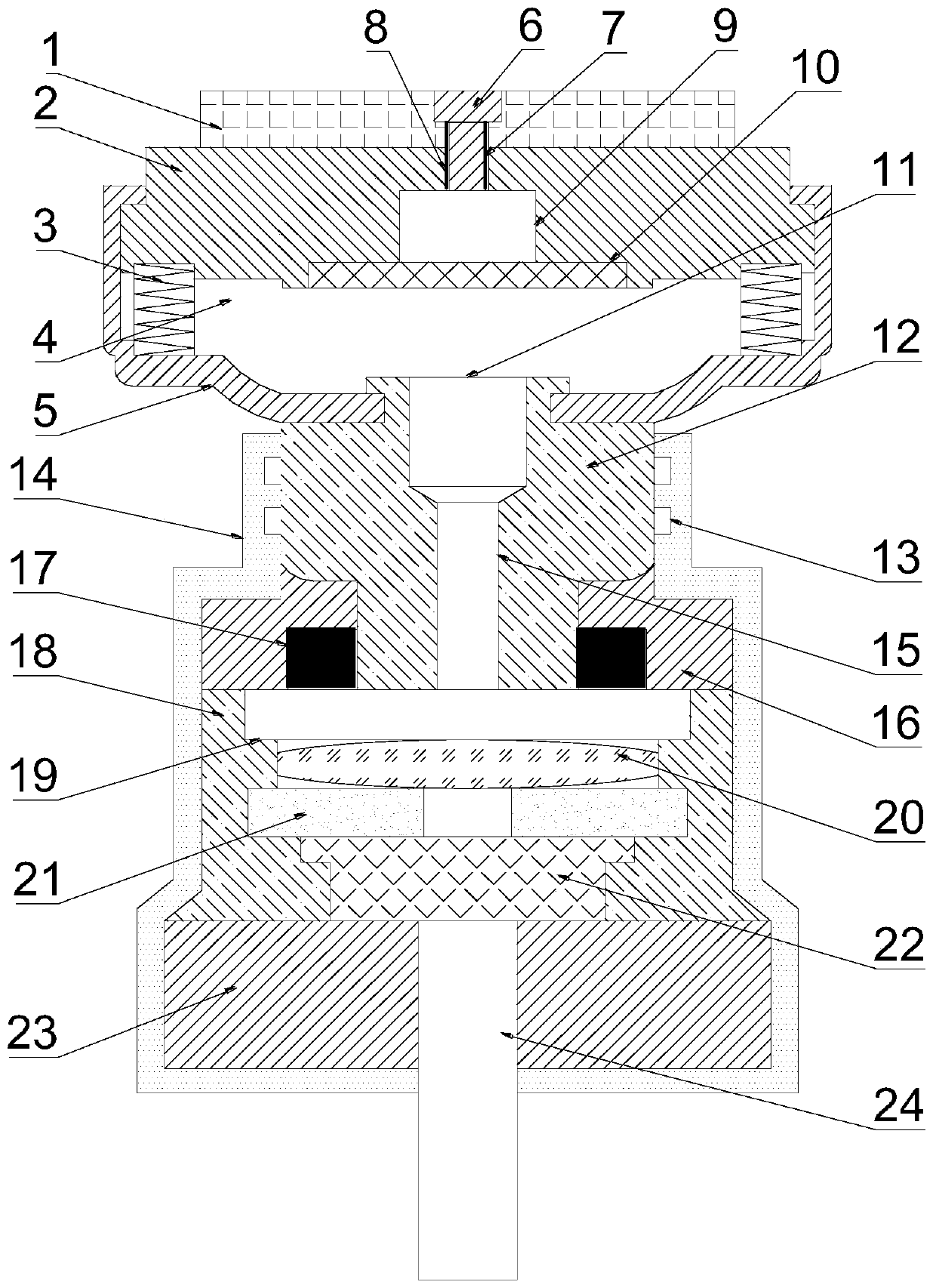

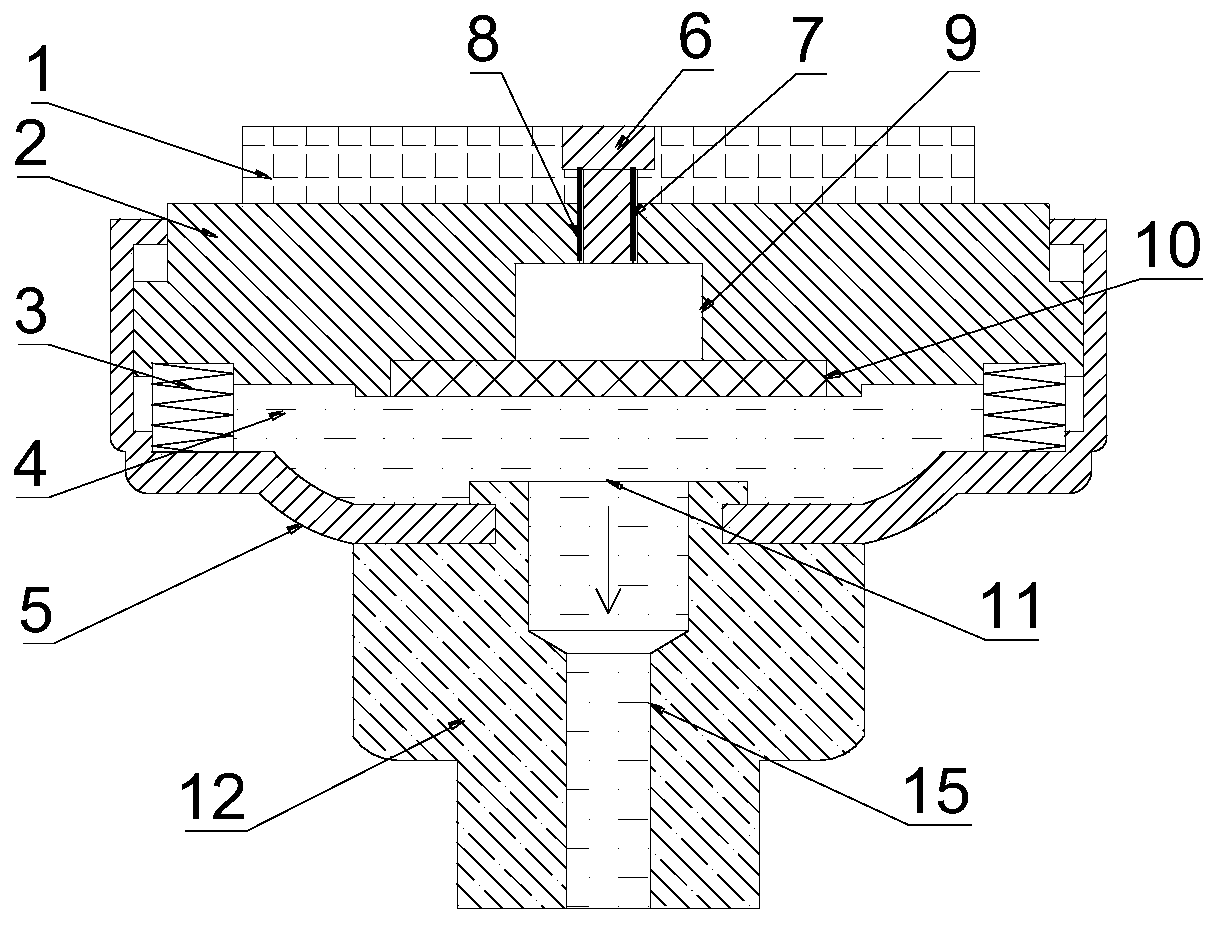

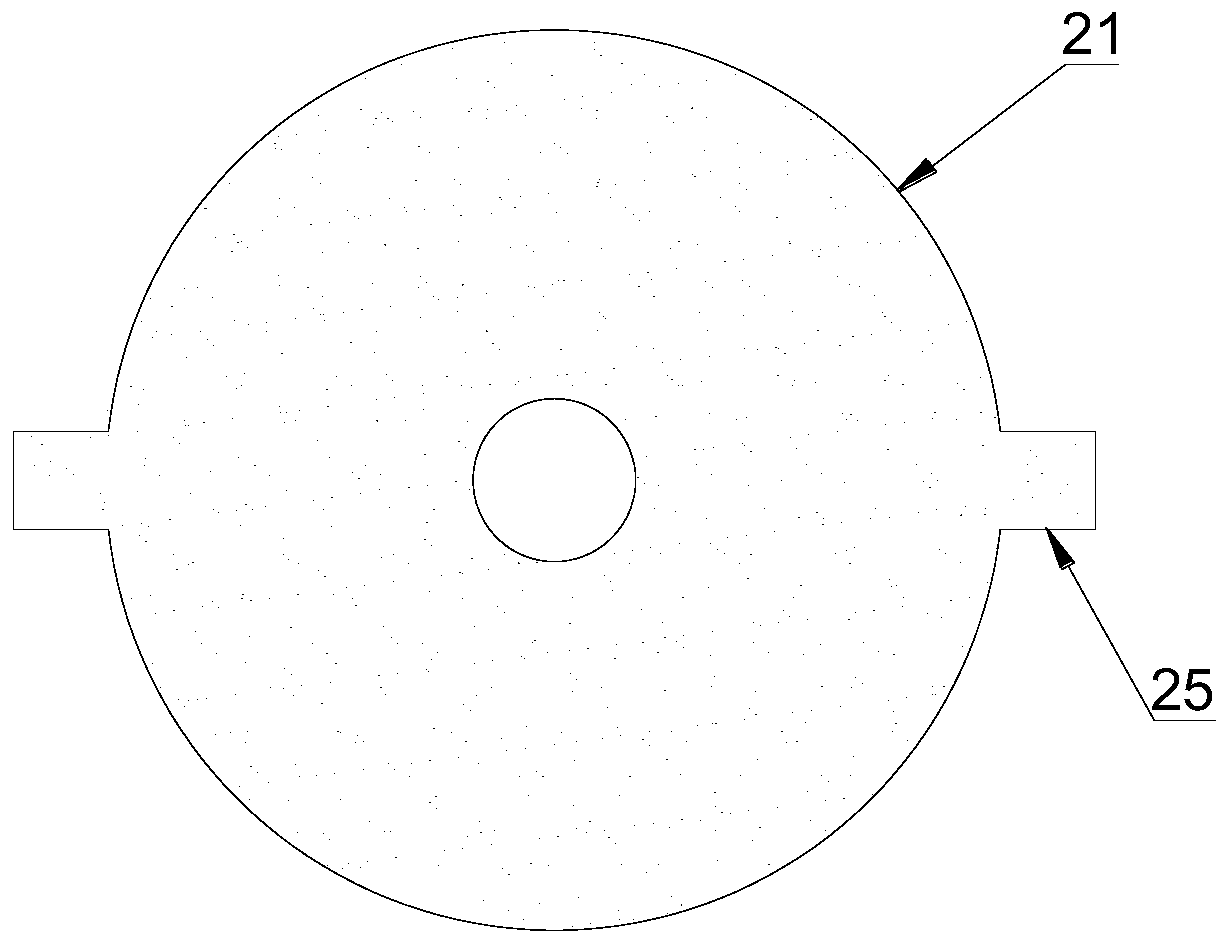

[0025] see Figure 1 ~ Figure 3 , in this embodiment, a hydraulic oil-type high-stability pressure sensor includes a lower pressure block 2, a sensor upper housing 5, a hydraulic column 12 and a sensor lower housing 14, and the middle part of the bottom end of the sensor upper housing 5 is fixed Connect the hydraulic column 12, the bottom side of the hydraulic column 12 is connected to the lower housing 14 of the sensor through the threaded part 13, the threaded part 13 includes an external thread arranged on the side wall of the hydraulic column 12 and an internal thread arranged on the inner wall of the lower sensor housing 14, the external thread and the internal thread are engaged with each other, so as to realize the connection between the hydraulic column 12 and the lower housing 14 of the sensor.

[0026] The upper end of the sensor upper housing 5 is provided with a lower pressing block 2 inside, the lower pressing block 2 is slidably arranged in the sensor upper housi...

Embodiment 2

[0033] see Figure 1 ~ Figure 3 , in this embodiment, a hydraulic oil type high stability pressure sensor also includes a spring 3, the spring 3 is installed in the hydraulic oil chamber 4, and the spring 3 is installed between the bottom wall of the sensor upper housing 5 and the lower pressure block 2 , The spring 3 is used to assist the reset action of the lower pressing block 2, and the rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com