Piezoresistance type high-frequency dynamic high voltage sensing device

A high-voltage sensor, high-frequency dynamic technology, applied in the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problems of flat packaging and other problems, and achieve the effect of avoiding small signal noise and large noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

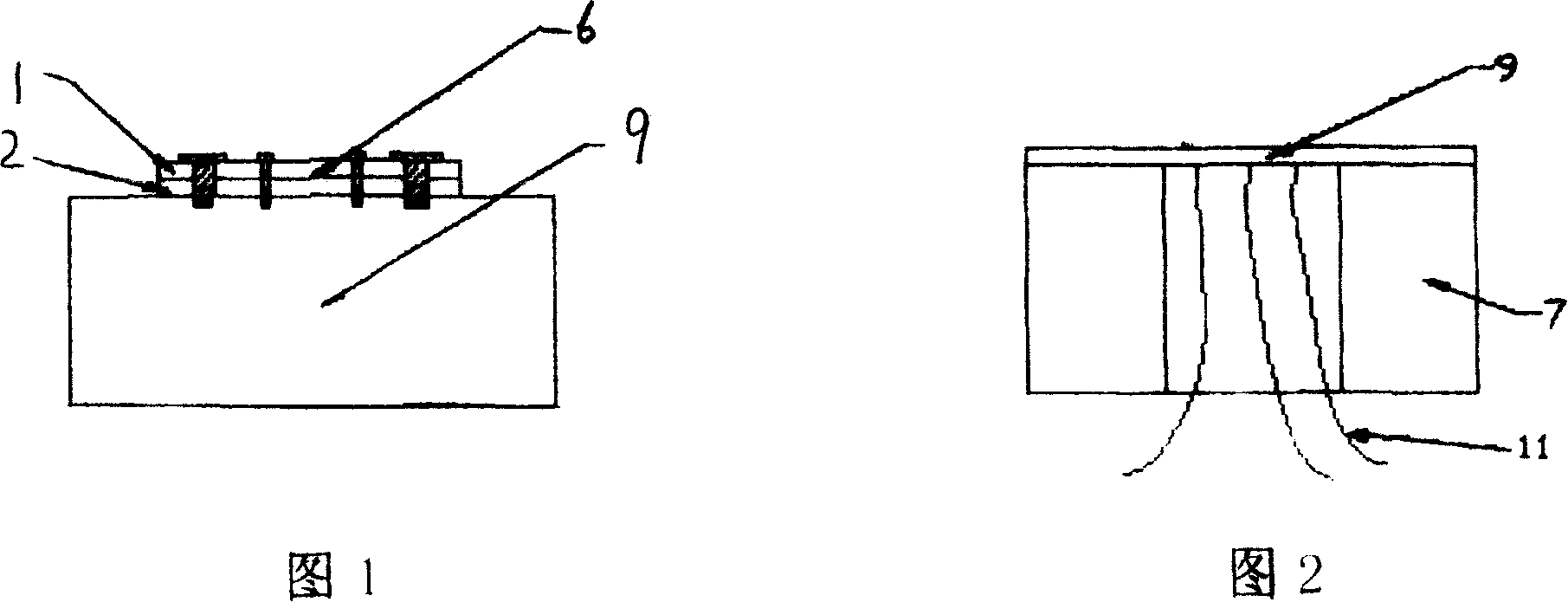

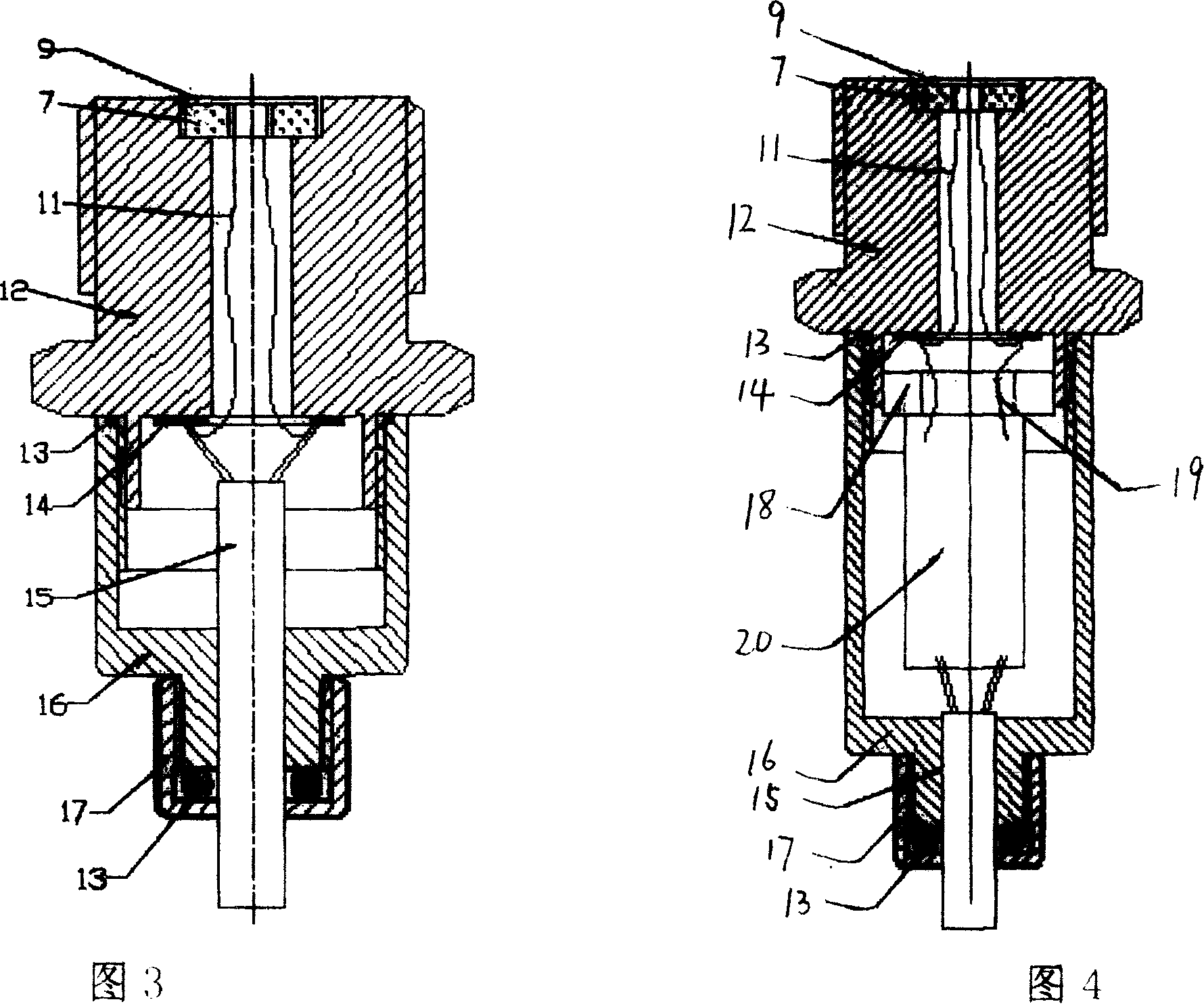

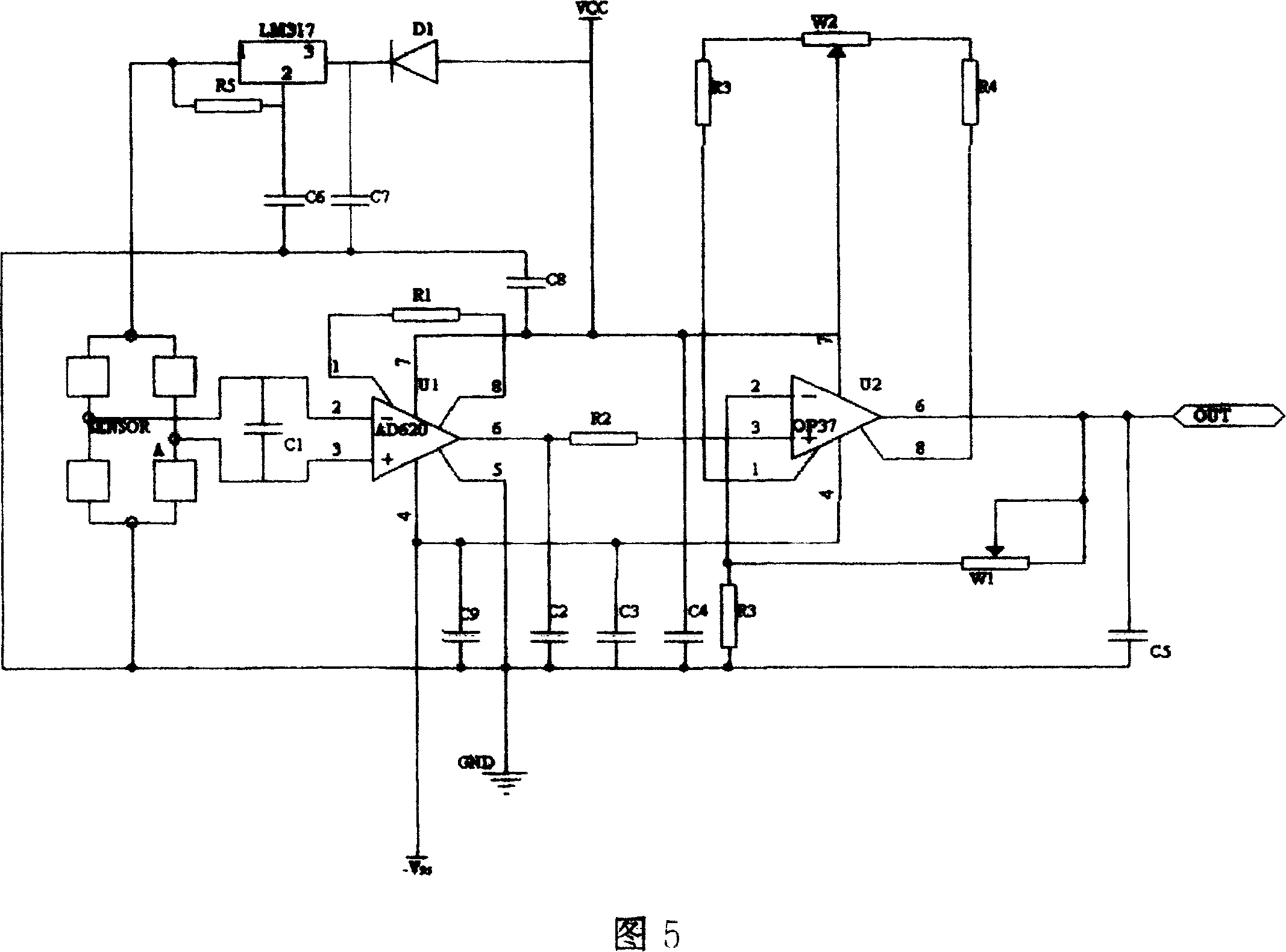

[0028] The high-frequency dynamic high-voltage sensor adopts the MEMS silicon micromachining process to make the round flat membrane fixed and supported by the flush package, which eliminates the influence of the lumen effect on the dynamic test and realizes the real-time measurement of the dynamic pressure. It adopts a high-frequency broadband amplifier , while ensuring a high enough frequency response, it also avoids the weakness of small signal and large noise. The implementation steps are realized as shown in Figure 1 to Figure 5:

[0029] Figure 1 is a circular flat silicon diaphragm with a circular force-sensitive area. The double-sided polished silicon wafer used as an elastic element is firstly covered with 1 μm thick SiO on both sides by traditional thermal oxidation technology in MEMS technology processing. 2 Layer 2, and then use standard LPCVD method to cover 3000A thick Si on both sides 3 N 4 Layer 1: use two photolithography techniques to etch away the Si on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com