Miniature dynamic piezoresistive pressure sensor and manufacturing method thereof

A pressure sensor, dynamic piezoresistive technology, applied in the measurement of fluid pressure by changing ohmic resistance, the manufacture of microstructure devices, microstructure technology, etc., to achieve the effect of protection against destructive impact, improved ability, and excellent resistance to light interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

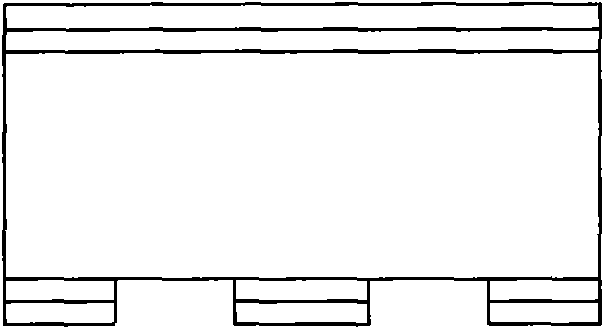

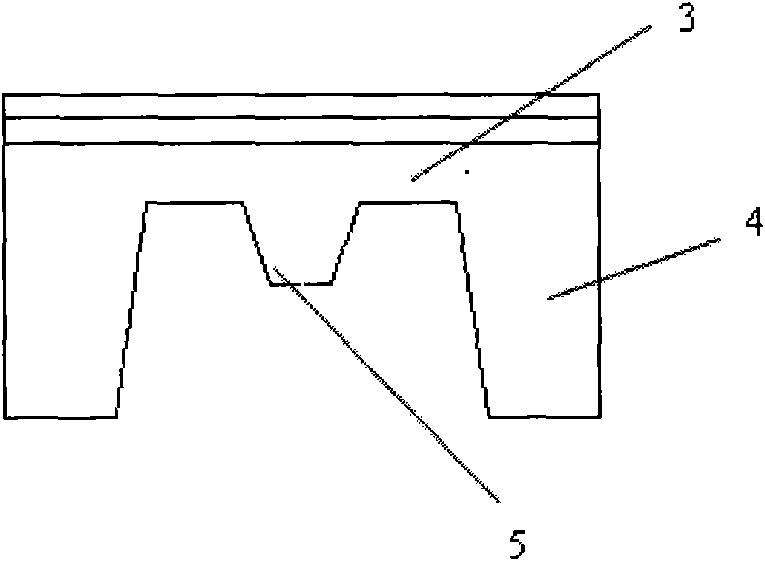

[0054] The micro pressure sensitive chip is manufactured by MEMS silicon micromachining technology. The unit size of the chip is 1.5×1.5mm, the size of the sensitive diaphragm is 1.0×1.0mm, and an island-shaped hard core is left in the center of the diaphragm. The size of the hard core is It is 0.7×0.7mm, and the force-sensitive detection resistor is distributed on the film between the hard core and the boundary hard frame, and the position is determined according to the design method of the E-type sensitive chip. The implementation steps are as follows Figure 1 to Figure 5 The implementation shown:

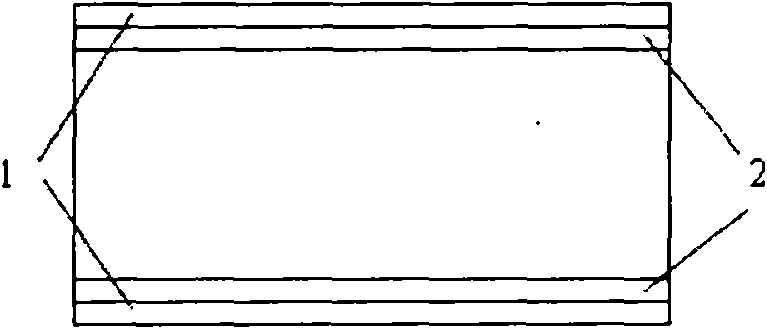

[0055] figure 1 The double-sided polished silicon wafer used as an elastic element is covered with 1 μm thick SiO on both sides by traditional thermal oxidation technology in MEMS technology processing. 2 Layer 2, and then use standard LPCVD method to cover 3000A thick Si on both sides 3 N 4 Layer 1, use two photolithography techniques to etch away the Si on the back of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com