Metal-silicon compound cantilever beam type microelectronic mechanical system probe card and manufacture method thereof

A technology of micro-electronic machinery and composite cantilever beams, which is applied to the components of TV systems, generators/motors, metal material coating processes, etc., can solve the problems of high cost, complicated preparation process, and difficulty in obtaining three-dimensional suspended electroplating metal probes structure and other issues, to achieve the effect of low cost, simplified processing technology and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

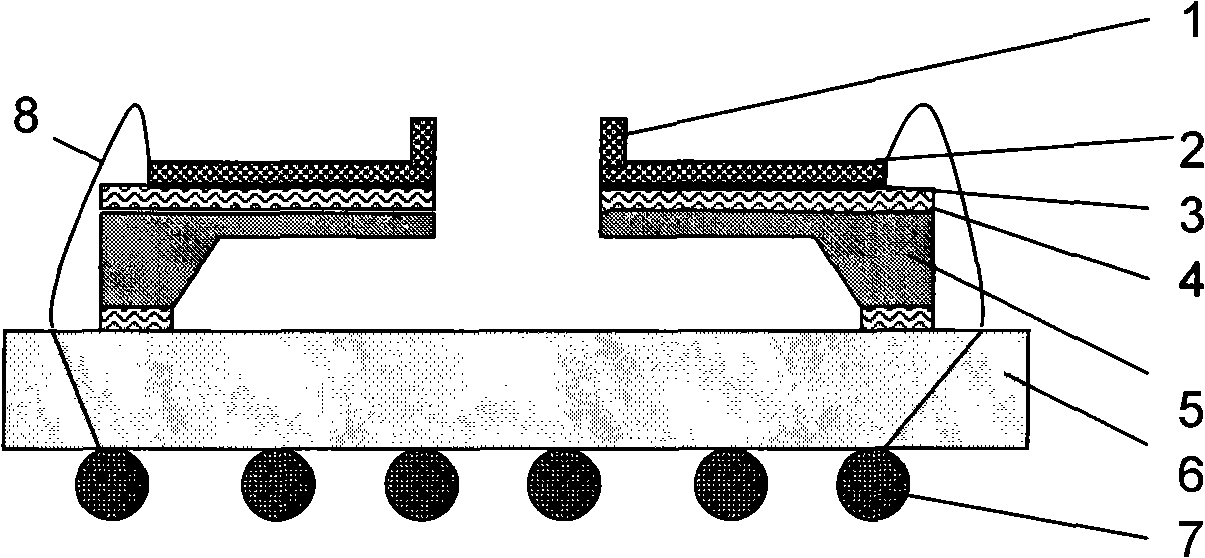

[0026] The structural parameters of the composite cantilever beam probe card are selected as follows: beam length 700μm, silicon layer width 80μm, thickness 20μm, copper layer width 60μm, thickness 10μm, nickel pillar diameter 20μm, height 20μm.

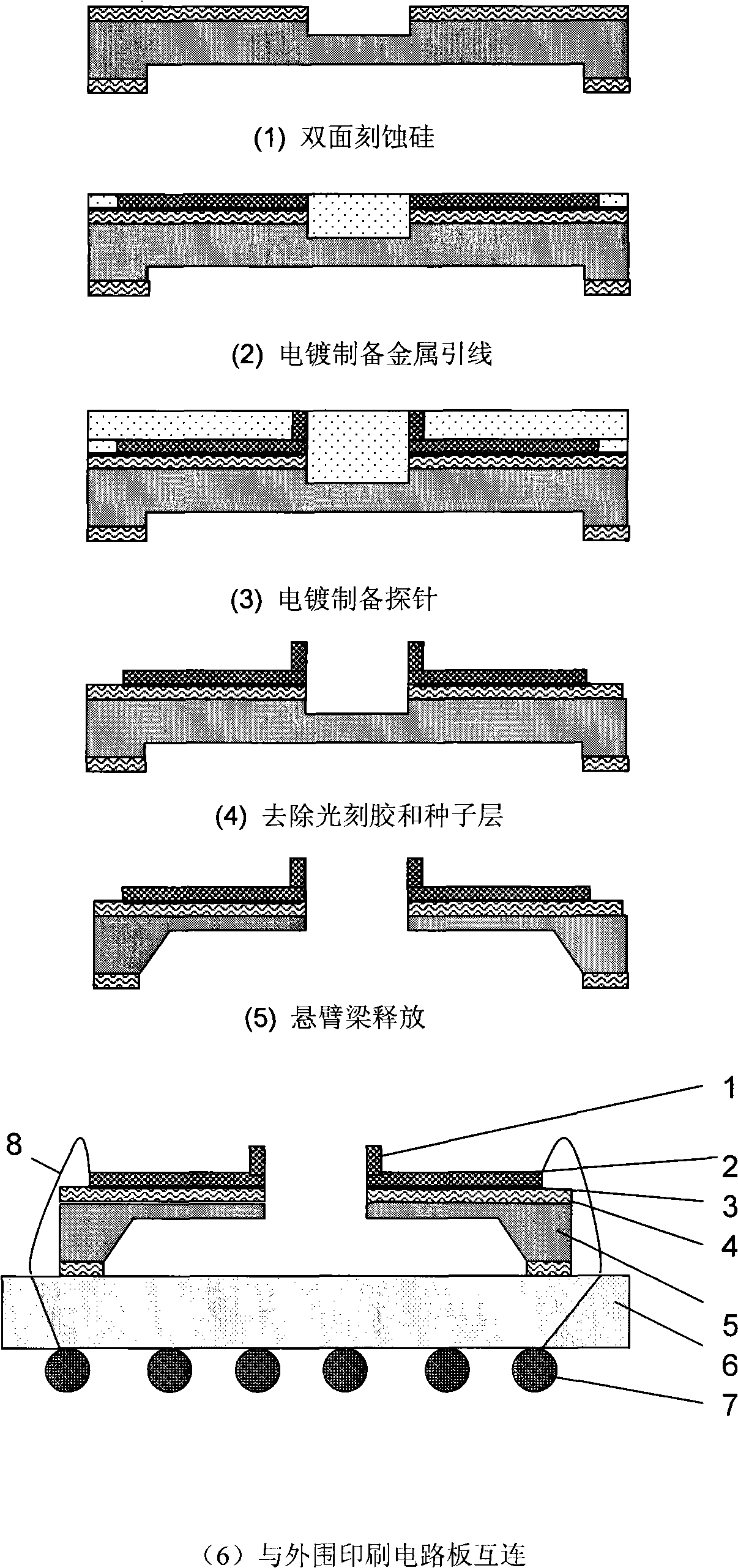

[0027] (1) Double-sided etching silicon wafers: use (100) single crystal silicon wafers with a thickness of 450μm, clean with sulfuric acid and then deionized water, and bake in an oven at 180°C for 3 hours; use thermal oxidation to prepare dioxide with a thickness of about 2μm The silicon layer; the oxide layer is used as the mask layer for the subsequent wet-etching silicon process; firstly, 3μm positron glue AZ4620 is cast on the first side, and dried in a vacuum oven at 90°C for 1 hour, and then 3μm positron glue AZ4620 is also cast on the backside, 90°C vacuum Bake in an oven for 1 hour; Expose a 700μm long and 80μm wide cantilever pattern on the front for 50 seconds, develop for 1 minute, then engrave the back window pattern, expos...

Embodiment 2

[0034] The structural parameters of the composite cantilever beam probe card are selected as follows: beam length 2000μm, silicon layer width 100μm, thickness 50μm, copper layer width 80μm, thickness 20μm, nickel pillar diameter 8μm, height 15μm.

[0035] (1) Double-sided etching of silicon wafers: using (100) single crystal silicon wafers with a thickness of 450μm, cleaning with sulfuric acid and then deionized water, baking in an oven at 180°C for 3 hours; thermal oxidation is used to generate thicknesses of about 2μm on both sides Silicon dioxide; the oxide layer is used as the mask layer for the subsequent wet-etching silicon process; firstly, 3μm positron glue AZ4620 is cast on the first side, and dried in a vacuum oven at 90°C for 1 hour, and then 3μm positron glue AZ4620 is also cast on the backside, 90°C Bake in a vacuum oven for 1 hour; Expose a cantilever pattern with a front length of 2000 μm and a width of 100 μm for 50 seconds, develop for 30 seconds, then engrave the...

Embodiment 3

[0042] The structural parameters of the composite cantilever beam probe card are selected as follows: beam length 100μm, silicon layer width 10μm, thickness 5μm, copper layer width 8μm, thickness 2μm, nickel pillar diameter 5μm, height 10μm.

[0043] (1) Double-sided etching of silicon wafers: using (100) single crystal silicon wafers with a thickness of 450μm, cleaning with sulfuric acid and then deionized water, baking in an oven at 180°C for 3 hours; thermal oxidation is used to generate thicknesses of about 2μm on both sides Silicon dioxide; the oxide layer is used as the mask layer for the subsequent wet-etching silicon process; firstly, 3μm positron glue AZ4620 is cast on the first side, and dried in a vacuum oven at 90°C for 1 hour, and then 3μm positron glue AZ4620 is also cast on the backside, 90°C Bake in a vacuum oven for 1 hour; expose a 100μm long and 10μm wide cantilever pattern for 50 seconds on the front side, develop for 30 seconds, then engrave the back window pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com