High compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere and preparation method thereof

A technology of octadecyl methacrylate copolymer resin and octadecyl methacrylate, which is applied in the field of high-pressure-resistant polystyrene-co-stearyl methacrylate copolymer resin microspheres and the preparation thereof, and can solve the problem of inapplicability and other problems, to achieve the effect of saving time, obvious effect and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

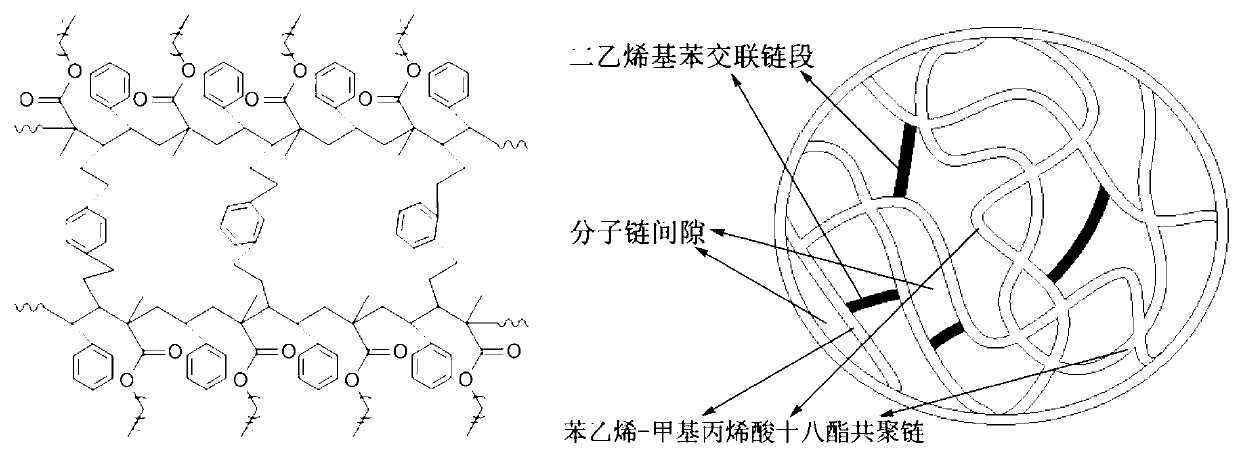

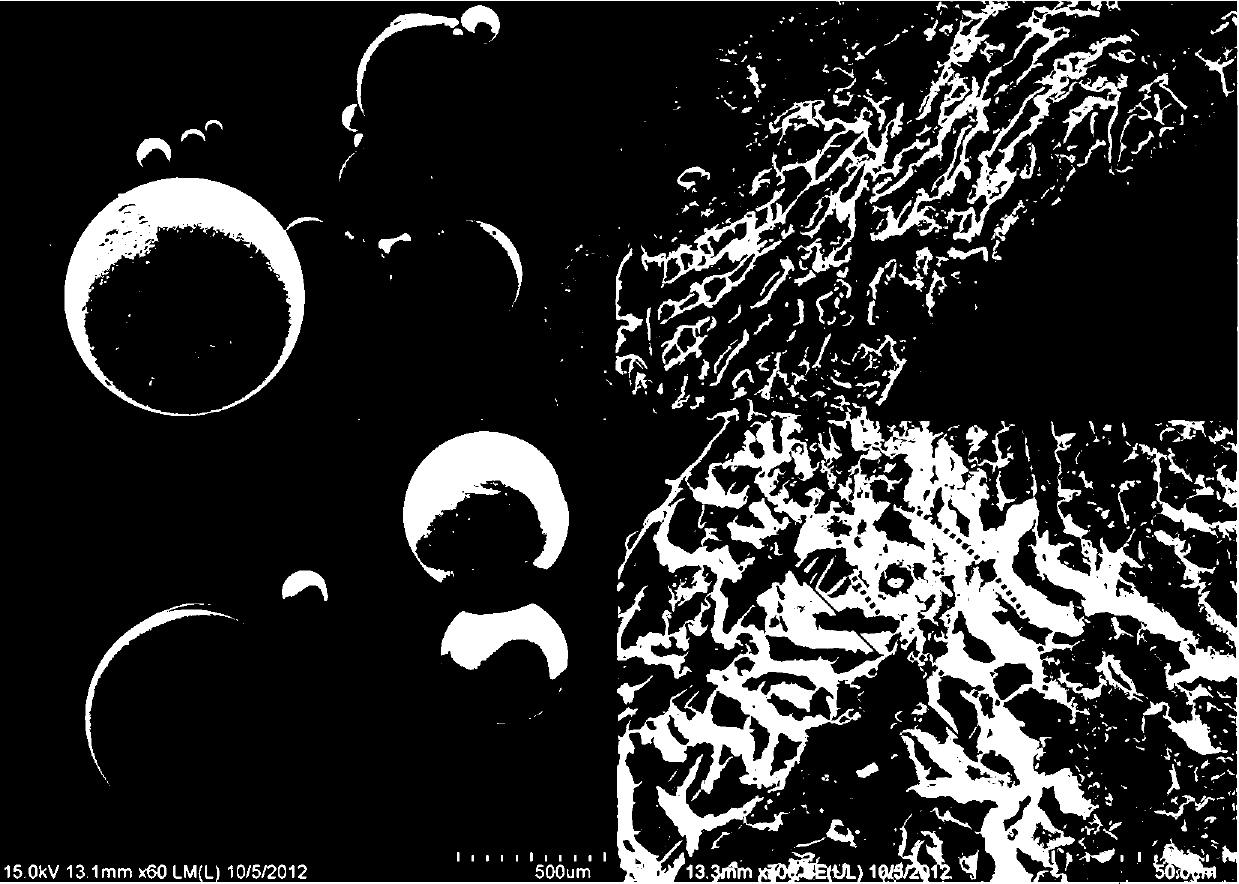

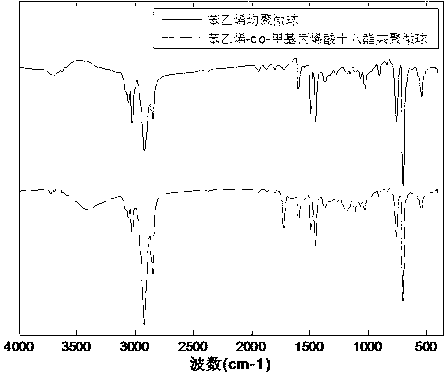

[0040] A high-pressure polystyrene-co-octadecyl methacrylate copolymer resin microsphere, which uses styrene as the first monomer, octadecyl methacrylate as the second monomer, and divinylbenzene as the Cross-linking agent, and the cross-linked copolymer prepared by adding porogen. In the case where the first monomer styrene is the main body, the second monomer octadecyl methacrylate is introduced as a comonomer, and the molar ratio of the first monomer to the second monomer is 1: 0.08; the degree of crosslinking Based on the mass percentage of the cross-linking agent in the comonomer, the value range is 5%; the mass of the porogen accounts for 20% of the mass of the comonomer.

[0041] The preparation method of the high compressive polystyrene-co-stearyl methacrylate copolymer resin microsphere described in the present embodiment comprises the following steps:

[0042] Step 1: Preparation of comonomer oil phase

[0043] According to the molar ratio of styrene and stearyl me...

Embodiment 2

[0054] A high-pressure polystyrene-co-octadecyl methacrylate copolymer resin microsphere, which uses styrene as the first monomer, octadecyl methacrylate as the second monomer, and divinylbenzene as the Cross-linking agent, and the cross-linked copolymer prepared by adding porogen. When the first monomer styrene is the main body, introducing the second monomer octadecyl methacrylate is a comonomer, and the relative molar percentage of the first monomer introduced by the second monomer is 7%; the degree of crosslinking is as follows: The crosslinking agent divinylbenzene accounts for 10% of the mass percentage of the comonomer; the mass of the porogen accounts for 30% of the mass of the comonomer.

[0055] The preparation method of the high compressive polystyrene-co-stearyl methacrylate copolymer resin microsphere described in the present embodiment comprises the following steps:

[0056] Step 1: Preparation of comonomer oil phase

[0057] According to the molar ratio of sty...

Embodiment 3

[0068] A high-pressure polystyrene-co-octadecyl methacrylate copolymer resin microsphere, which uses styrene as the first monomer, octadecyl methacrylate as the second monomer, and divinylbenzene as the Cross-linking agent, and the cross-linked copolymer prepared by adding porogen. When the first monomer styrene is the main body, introducing the second monomer octadecyl methacrylate is a comonomer, and the relative molar percentage of the first monomer introduced by the second monomer is 4%; the degree of crosslinking is as follows: The crosslinking agent divinylbenzene accounts for 12% by mass of the comonomer; the mass of the porogen accounts for 10% by mass of the comonomer.

[0069] The preparation method of the high compressive polystyrene-co-stearyl methacrylate copolymer resin microsphere described in the present embodiment comprises the following steps:

[0070] Step 1: Preparation of comonomer oil phase

[0071] According to the molar ratio of styrene and stearyl me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com