A heating-free direct rolling system and method for continuous casting slabs of wire and rod

A heating-free, continuous casting slab technology, applied in the direction of metal rolling, etc., can solve the problems of slab cutting or shearing time requirements, huge economic investment and production cost, continuous casting machine casting speed and secondary cooling control improvement, etc. , to achieve the effect of reducing plant area and transportation equipment, improving labor intensity and saving metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

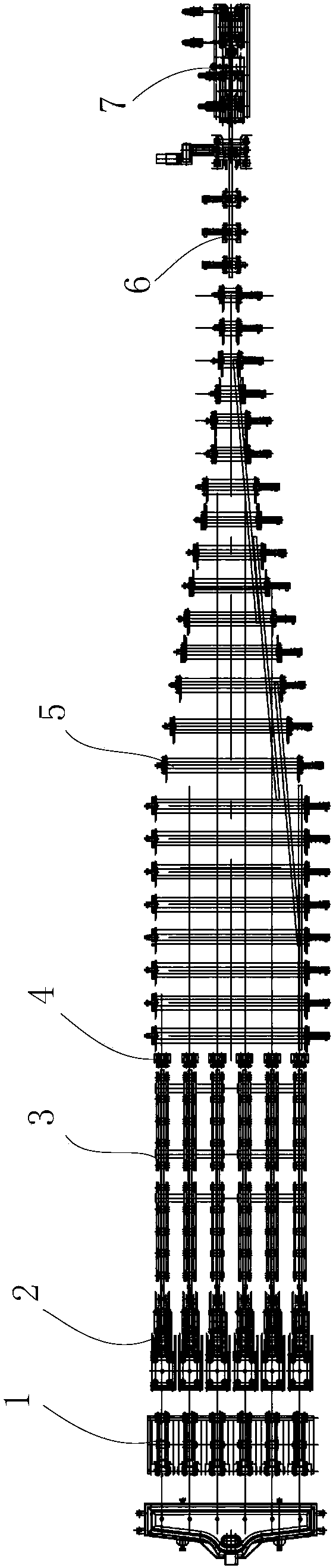

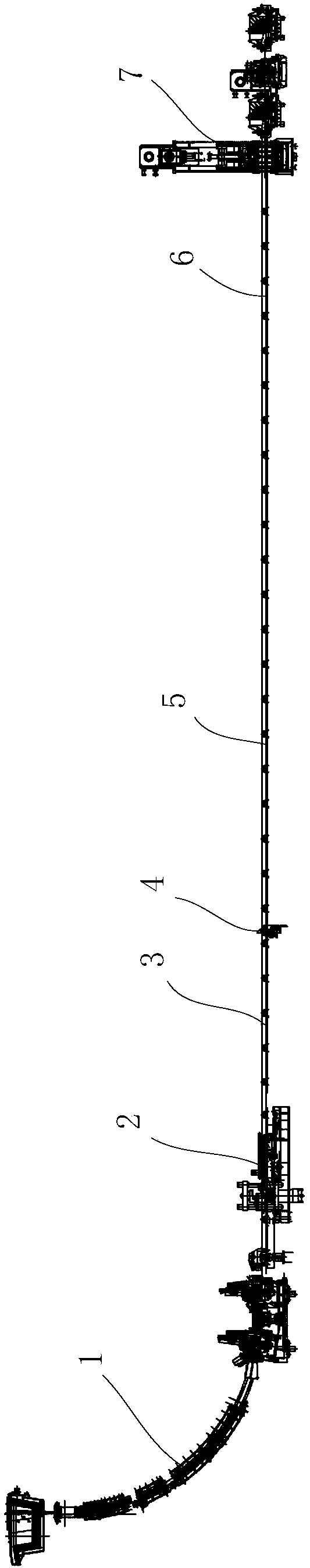

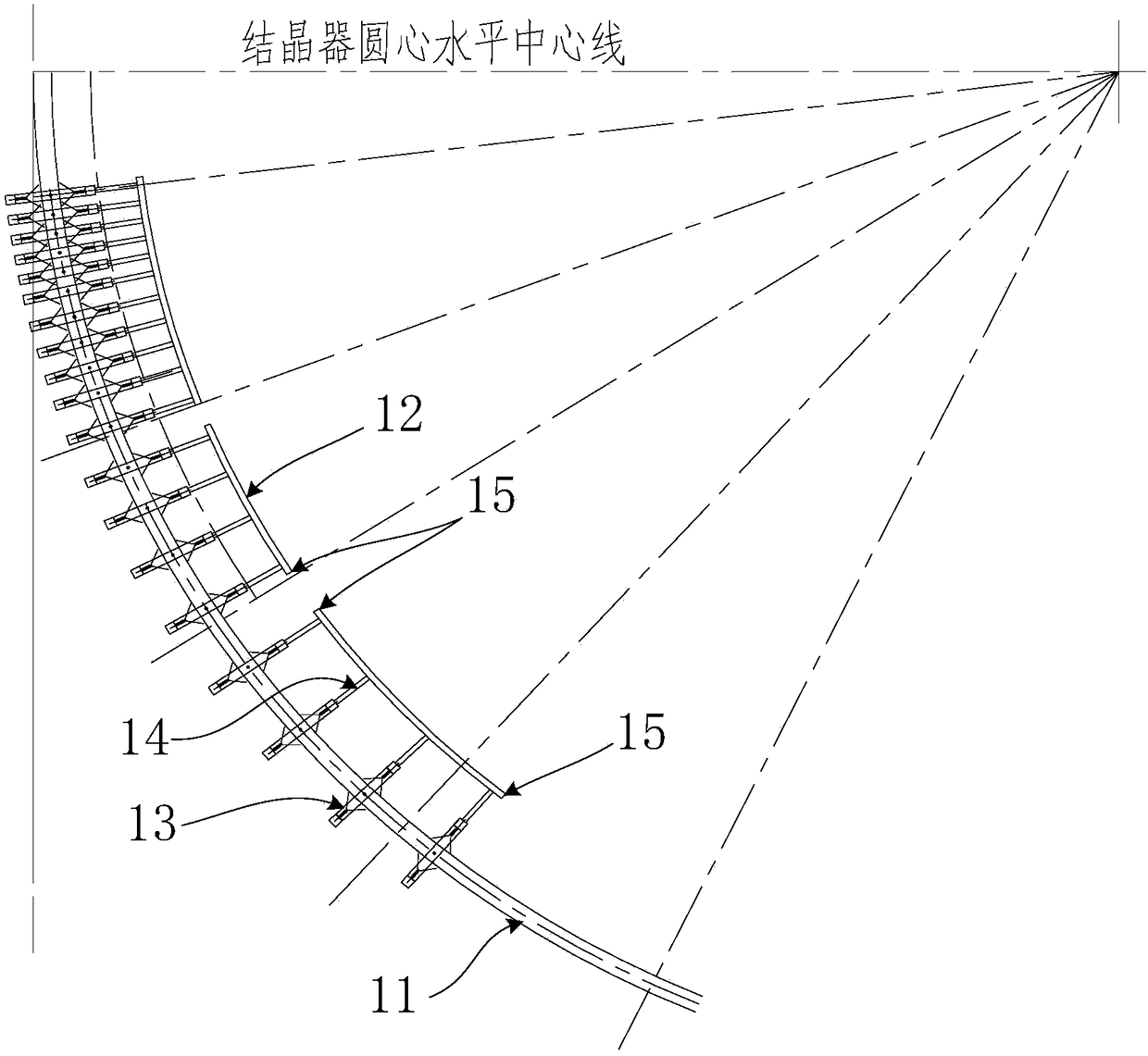

[0059] Such as figure 1 with figure 2 As shown, a heating-free direct rolling system for continuous casting of wire and rod is mainly used in the production process of wire and rod, including small radius high-speed continuous casting machine 1, rapid hydraulic shear 2, shear The rear roller table 3, the high-speed slab flow converging roller table 5, the high-speed transport hot-feeding roller table 6 and the wire bar mill 7; the post-cutting roller table 3 and the high-speed slab flow converging roller table 5 are provided for blocking the slab The gate mechanism 4 for entering and releasing. When the gate is raised, it can prevent the slab from entering the high-speed slab flow converging roller table 5. When it is lowered, the slab in the current flow is released to enter the slab flow converging roller table, which plays a role in the slab transportation. The role of sequence regulation. After the slab is pulled out at a high speed, the high-temperature slab is cut to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com