Machine tool fixture for thin-wall workpiece

A technology for machine tool fixtures and thin-walled workpieces, which is applied in the field of workpiece clamping devices, can solve problems such as heat deformation and thin-walled workpieces are easily deformed by force, and achieve the effects of not easily deforming workpieces, accelerating melting speed, and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

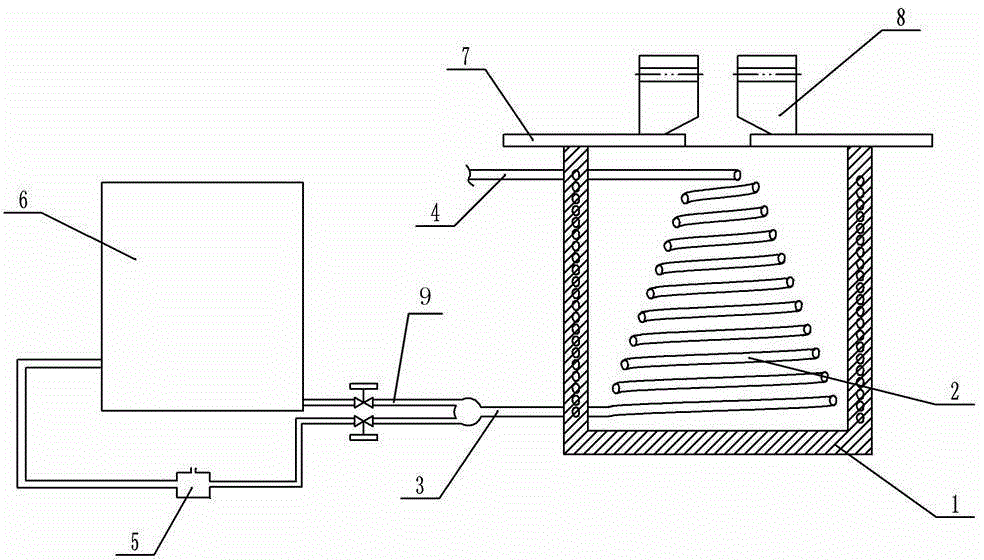

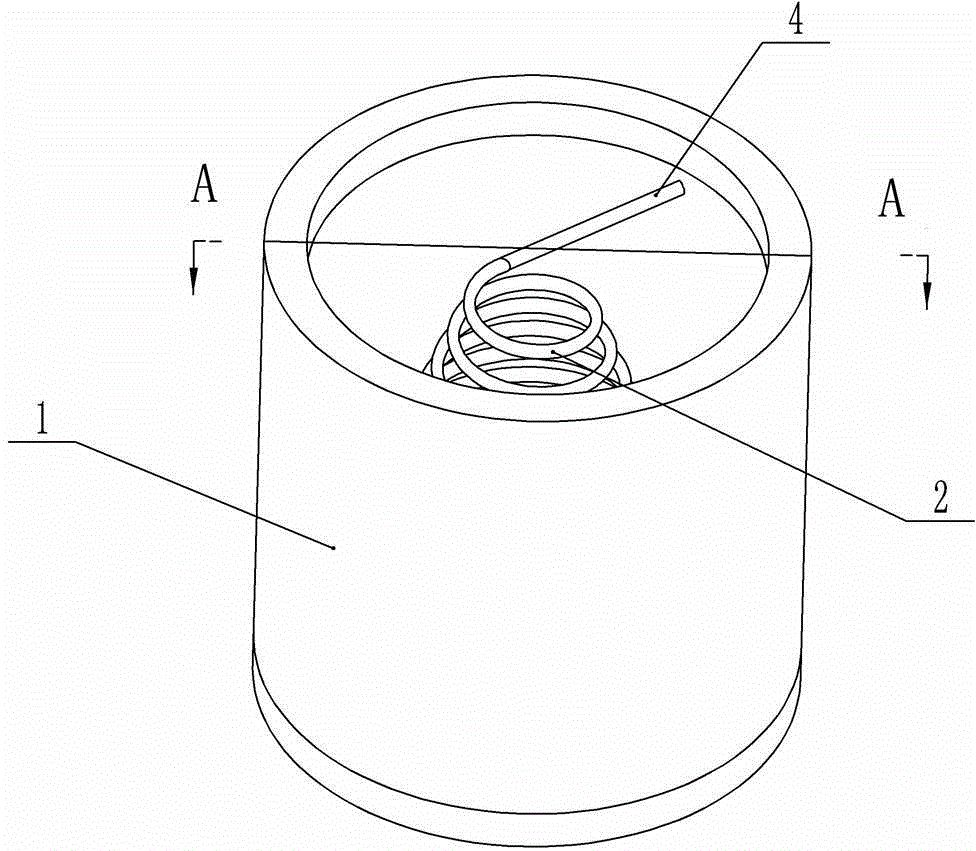

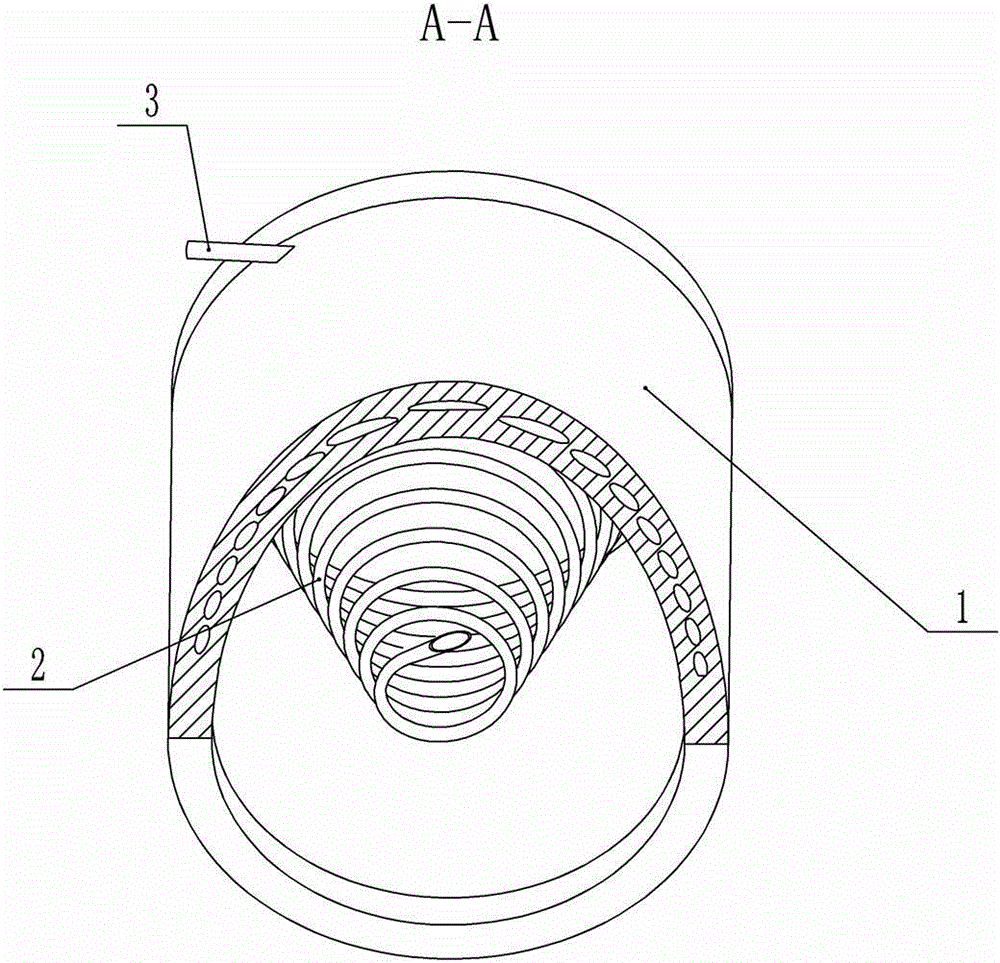

[0019] The reference signs in the drawings of the description include: material cylinder 1, cooling pipe 2, air inlet pipe 3, air outlet pipe 4, vortex pipe 5, heat preservation tank 6, slide rail 7, locking block 8, and thawing pipe 9.

[0020] The embodiment is basically as attached figure 1 Shown: a machine tool fixture for thin-walled workpieces, including a material cylinder 1, a cooling pipe 2, an air inlet pipe 3, an air outlet pipe 4, a vortex tube 5, and an insulation tank 6; the material cylinder 1 is a hollow cylinder, and the material cylinder 1 is made of aluminum alloy, and the cylinder is filled with an aqueous solution. The volume of the aqueous solution is about nine tenths of the volume of the cylinder, so as to prevent the material cylinder 1 from bursting due to volume expansion when the aqueous solution freezes, and the wall of the material cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com