Refining device and method for controlling nitrogen content of molten steel

A refining device and molten steel nitrogen technology, applied in the field of continuous steel, can solve problems such as difficult application, major hidden dangers buried in production safety, splashing of molten steel and steel slag, etc., and achieve the effect of easy operation, small investment, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

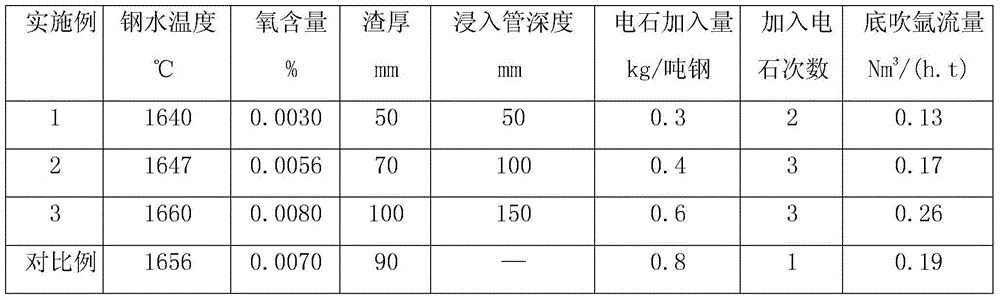

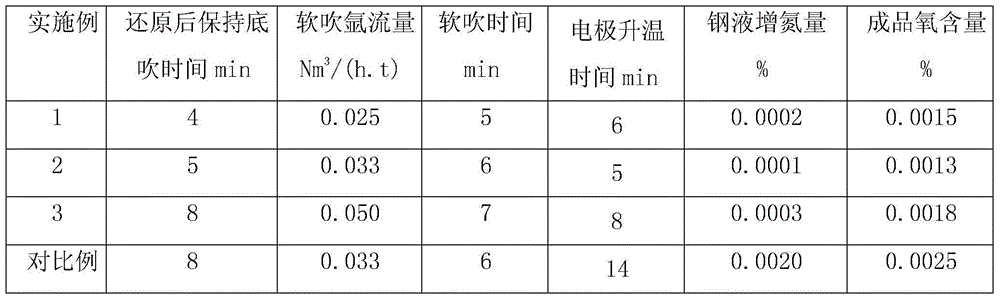

Examples

Embodiment Construction

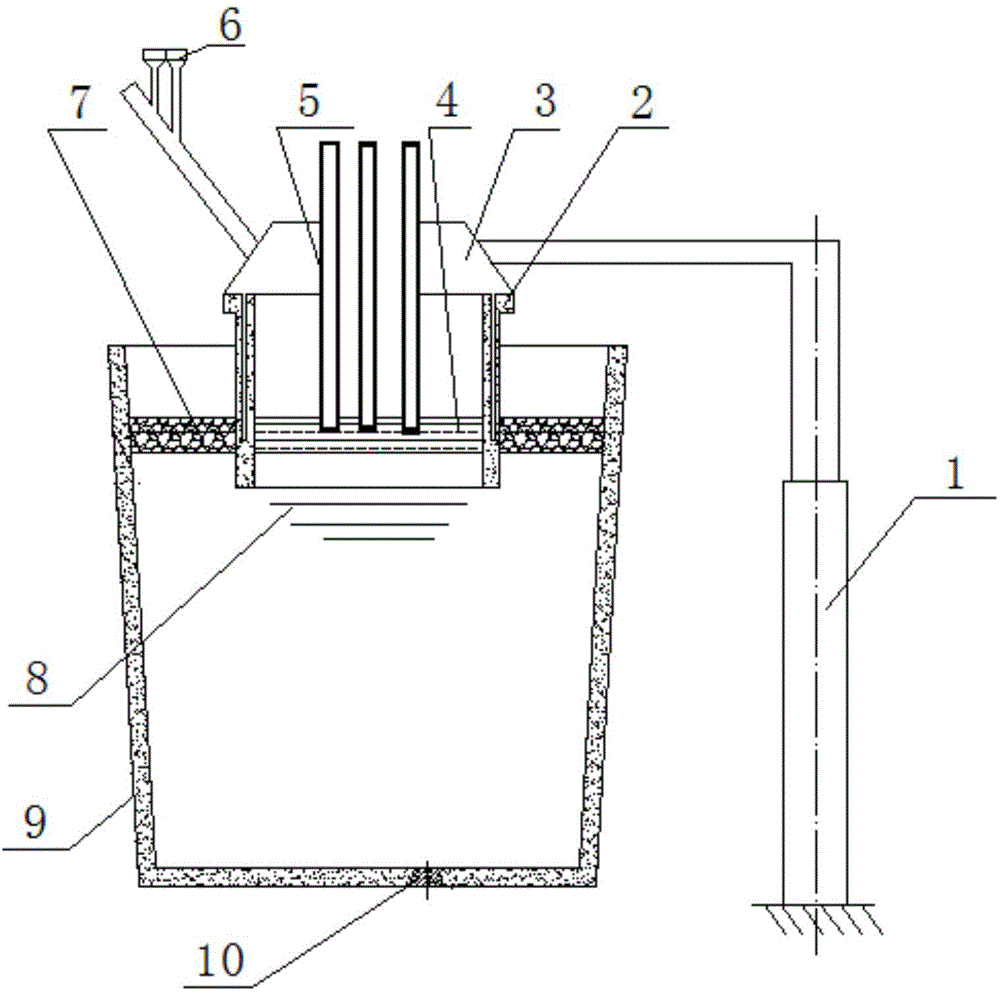

[0028] Depend on figure 1 It can be seen that the refining device for controlling the nitrogen content of molten steel in the present invention is mainly composed of a lifting hydraulic cylinder 1 , an immersion tube 2 , a furnace cover 3 , an electrode 5 , a feed bin 6 and a ladle 9 . The lifting hydraulic cylinder 1 is fixed on the ground, and the front end of the piston rod of the lifting hydraulic cylinder 1 is fixed horizontally with a connecting rod. There is a silo 6 above the feed inlet, and the immersion tube 2 made of refractory material is fixed on the steel structure under the furnace cover 3. The diameter of the furnace cover 3 is 1 / 3 to 1 / 2 of the diameter of the ladle 9, so the furnace cover 3 Lift and hang on the top of the ladle 9 by the lifting hydraulic cylinder 1 and the connecting rod.

[0029] The concrete steps of the present invention's control molten steel nitrogen content method are:

[0030] 1. Preheat the immersion tube 2 under the furnace cover 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com