Copper powder and method for manufacturing same

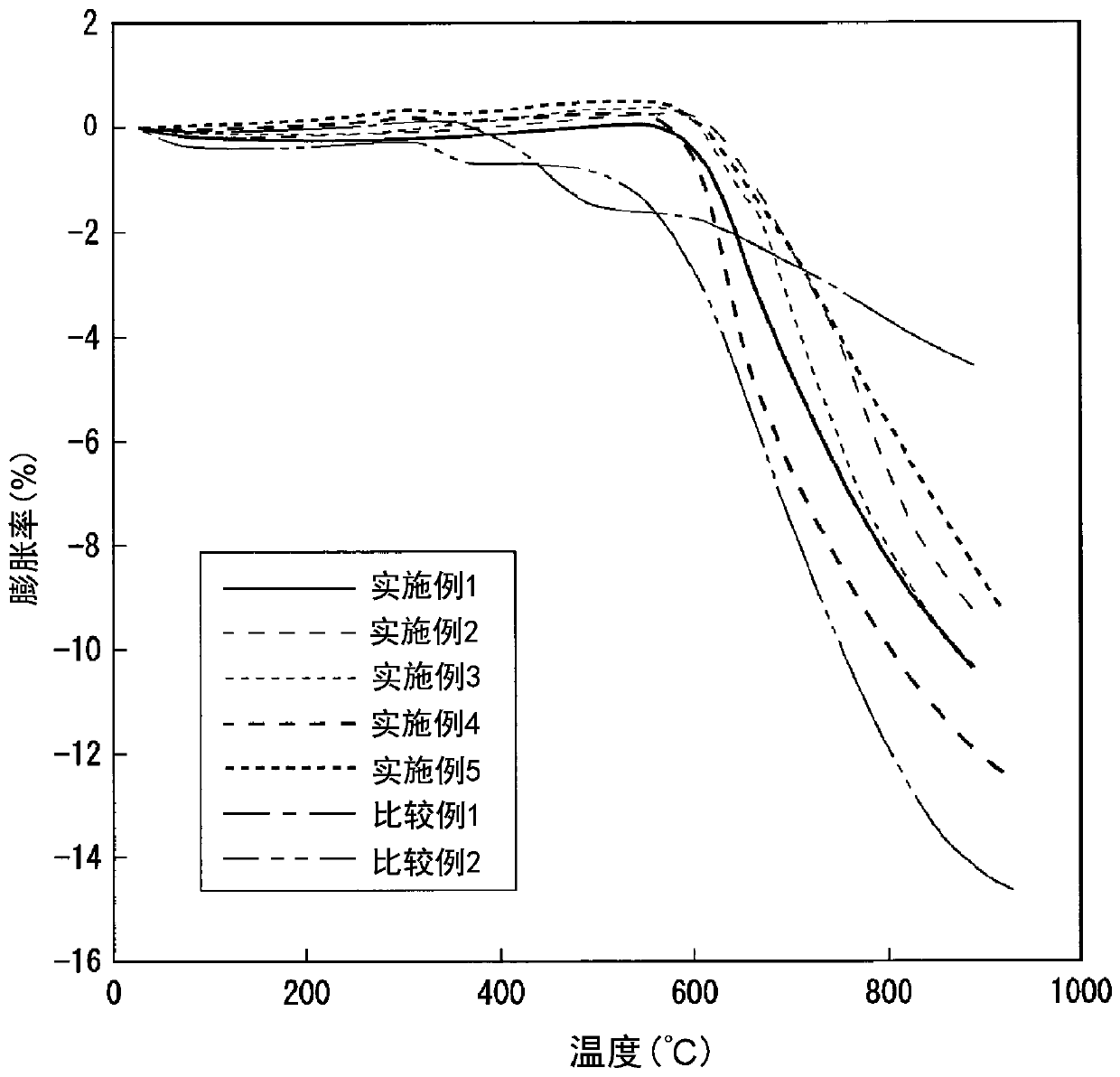

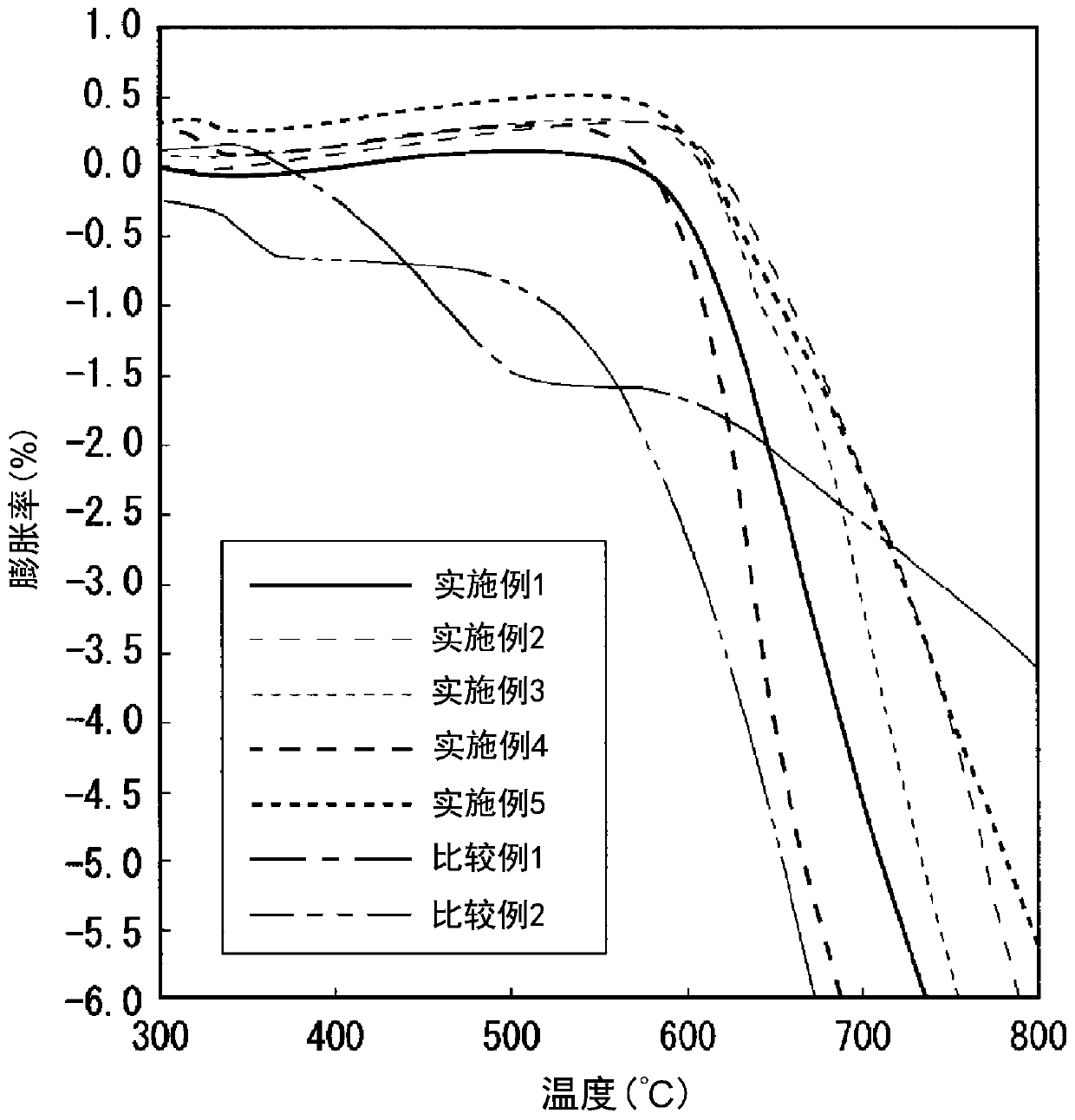

A manufacturing method and technology of copper powder, applied to the conductive layer on the insulating carrier, conductor, transportation and packaging, etc., can solve the problems of copper layer peeling, excessive difference, copper layer cracks, etc., and achieve high shrinkage initiation temperature, The effect of low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] While the oxygen-free copper balls are heated to 1600°C in a nitrogen atmosphere and the melt is dripping from the lower part of the casting tray in a nitrogen atmosphere, high-pressure water (pH value 10.3 Alkaline water) to make it freeze and solidify rapidly, separate the solid and liquid of the obtained paste, wash the solid with water, dry, disintegrate, and classify by wind to obtain copper powder.

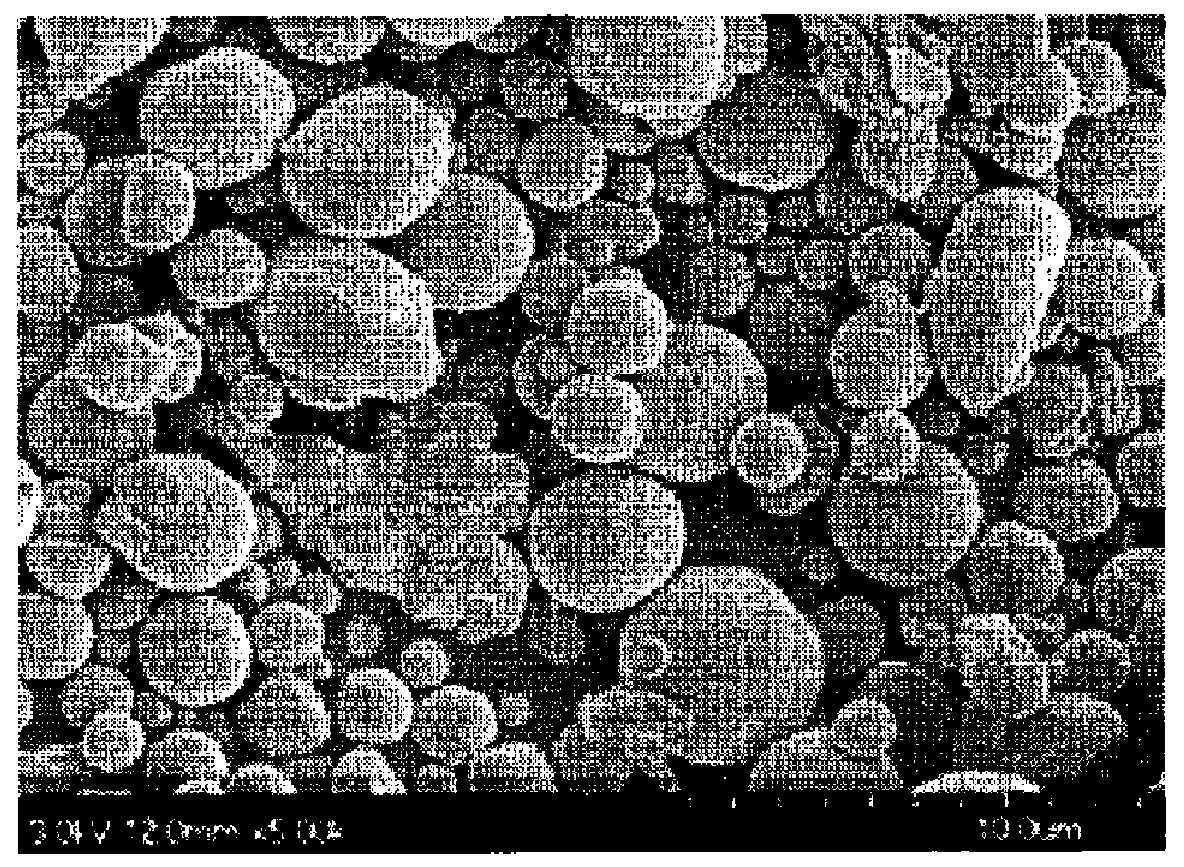

[0052] The BET specific surface area, tap density, oxygen content, carbon content, and particle size distribution of the copper powder thus obtained were determined.

[0053] The BET specific surface area is measured by using a BET specific surface area measuring device (4 Sorbe US manufactured by Yuasa Ionix Co., Ltd. (Yuasa Ionix Co., Ltd.)), and degassing the measuring device by flowing nitrogen gas at 105° C. for 20 minutes. , in a mixture of nitrogen and helium (N 2 : 30% by volume, He: 70% by volume) and measured by the BET one-point method. As a result, the B...

Embodiment 2

[0062] Except that the water pressure is 106MPa and the water yield is 165L / min, the copper powder is obtained by the same method as in Example 1, and the BET specific surface area, tap density, oxygen content, carbon content, particle size distribution, and particle size distribution are obtained for the copper powder obtained. Grain size (Dx) and roundness coefficient mean values, and thermomechanical analysis (TMA) of copper powder was carried out.

[0063]As a result, the BET specific surface area is 0.28m 2 / g, the tap density is 4.9g / cm 3 . The oxygen content is 0.12% by mass, and the ratio of the oxygen content of the copper powder to the BET specific surface area (O / BET) is 0.43% by mass g / m 2 , the carbon content is 0.004% by mass. Cumulative 10% particle size (D 10 ) is 1.4μm, cumulative 50% particle size (D 50 ) is 3.8μm, cumulative 90% particle size (D 90 ) is 7.9 μm. The crystallite diameter (Dx) was 136.9 nm for the (111) plane, 47.2 nm for the (200) plane...

Embodiment 3

[0065] Except that the water pressure is 105MPa and the water yield is 163L / min, the copper powder is obtained by the same method as in Example 1, and the BET specific surface area, tap density, oxygen content, carbon content, particle size distribution, and particle size distribution are obtained for the copper powder obtained. Grain size (Dx) and roundness coefficient mean values, and thermomechanical analysis (TMA) of copper powder was carried out.

[0066] As a result, the BET specific surface area is 0.31m 2 / g, the tap density is 4.8g / cm 3 . The oxygen content is 0.12% by mass, and the ratio of the oxygen content of the copper powder to the BET specific surface area (O / BET) is 0.38% by mass g / m 2 , the carbon content is 0.007% by mass. Cumulative 10% particle size (D 10 ) is 1.4μm, cumulative 50% particle size (D 50 ) is 3.7μm, cumulative 90% particle size (D 90 ) is 6.8 μm. The crystallite diameter (Dx) was 140.1 nm for the (111) plane, 50.2 nm for the (200) plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com