Composite curing agent for MUF resin adhesive, and application of composite curing agent in production of medium-high density fiberboards

A composite curing agent and resin adhesive technology, applied in the direction of adhesive additives, adhesives, non-polymer adhesive additives, etc., can solve the problem of few patents on MUF curing agents, achieve excellent latent properties, superior curing performance, Promotes fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation of composite curing agent for MUF resin adhesive:

[0024] 1. Weigh each component according to the following weight:

[0025] Ammonium persulfate: 5.5kg, hexamethylenetetramine: 4.5kg, p-toluenesulfonic acid: 5kg, ethanolamine: 5kg.

[0026] 2. Add the above components into the reaction kettle one by one, and stir evenly.

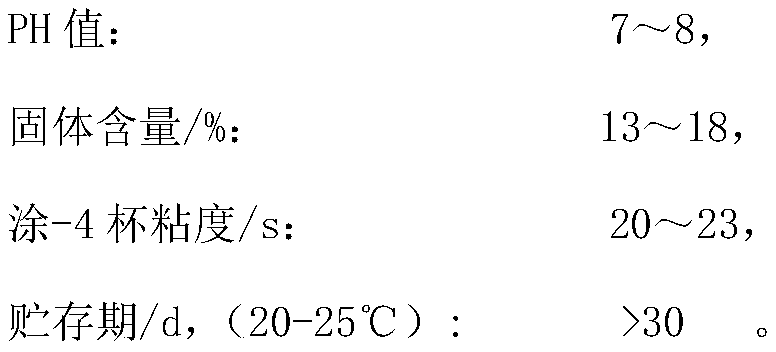

[0027] The main technical indicators of the obtained composite MUF resin curing agent are as follows:

[0028]

Embodiment 2

[0030] A kind of preparation of composite curing agent for MUF resin adhesive:

[0031] 1. Weigh each component according to the following weight:

[0032] Ammonium persulfate: 4.5kg, hexamethylenetetramine: 5.5kg, p-toluenesulfonic acid: 5kg, ethanolamine: 5kg.

[0033] 2. Add the above components into the reaction kettle one by one, and stir evenly.

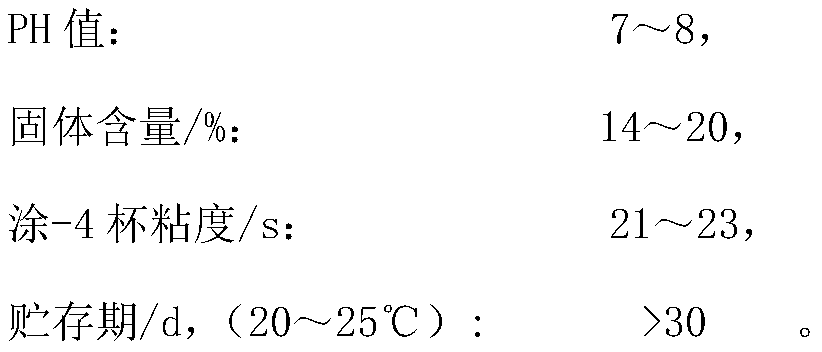

[0034] The main technical indicators of the obtained composite MUF resin curing agent are as follows:

[0035]

Embodiment 3

[0037] A kind of preparation of composite curing agent for MUF resin adhesive:

[0038] 1. Weigh each component according to the following weight:

[0039] Ammonium persulfate: 5kg, hexamethylenetetramine: 5kg, p-toluenesulfonic acid: 5kg, ethanolamine: 5kg.

[0040] 2. Add the above components into the reaction kettle one by one, and stir evenly.

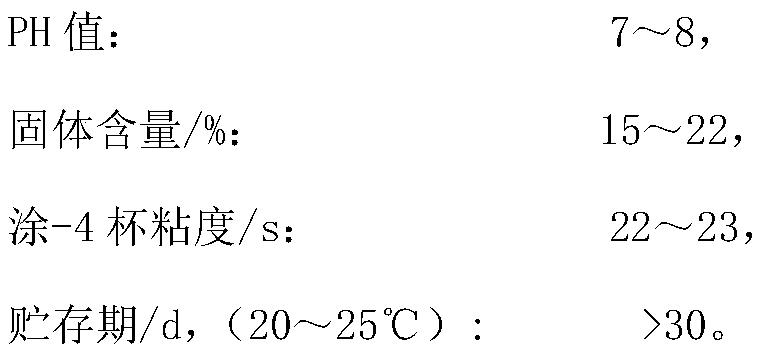

[0041] The main technical indicators of the obtained composite MUF resin curing agent are as follows:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com