Preparation method of tin oxide composite tricobalt tetroxide photothermal catalyst and its application in thermal catalysis

A technology of tricobalt tetroxide light and tin oxide, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low thermal catalytic activity and achieve cheap and easy raw materials The effect of obtaining, not easy to inactivate, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

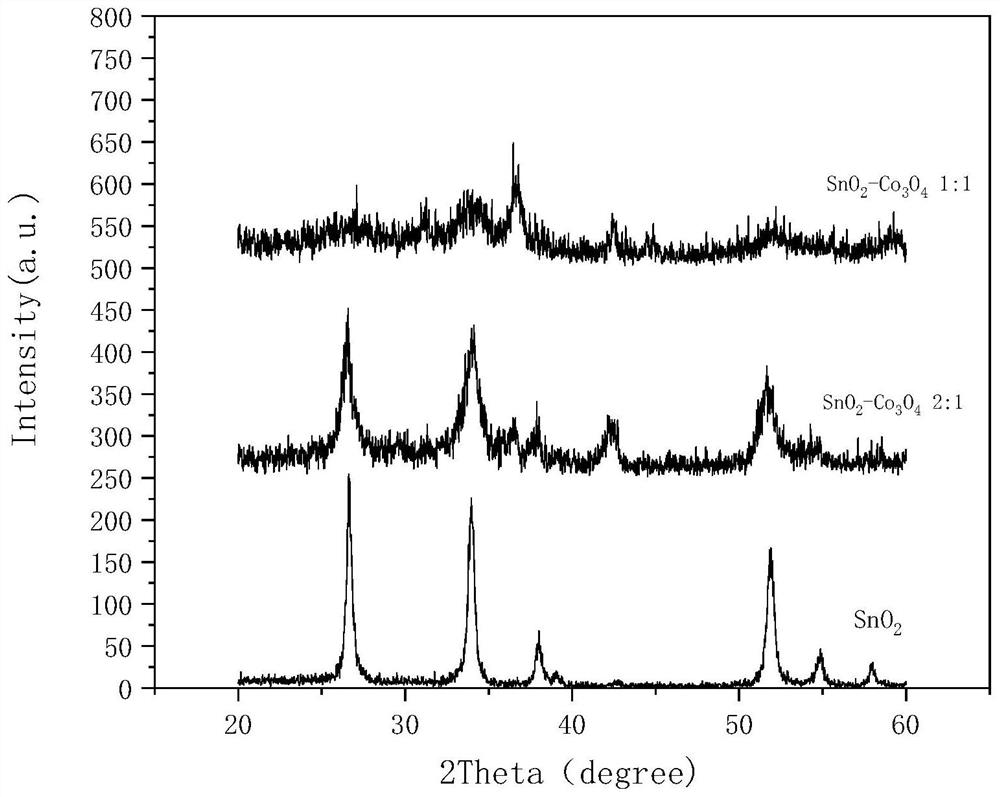

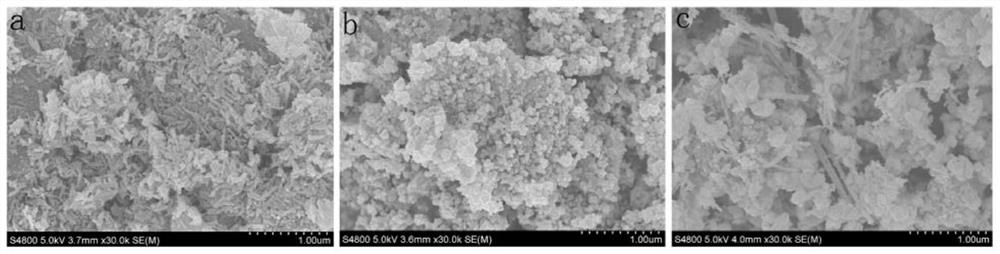

[0026] (1) Tin Oxide Composite Cobalt Tetroxide Photothermal Catalyst SnO 2 -Co 3 o 4

[0027] The preparation method is as follows:

[0028] 1. Cobalt tetraoxide Co 3 o 4 preparation of

[0029] 0.212g Na 2 CO 3 Add it to a mixed solution of 25ml of concentrated ammonia water (concentration: 28wt%) and 40ml of ethylene glycol, stir for 1 hour, and make it fully dissolve to obtain a mixed solvent. 1.45515g Co(NO 3 ) 2 .6H 2 O was added to the mixed solvent, and after stirring for 20 min, the resulting mixture was poured into a hydrothermal reaction kettle and kept at 170°C for 16 h. After natural cooling, centrifuge, put in an oven, dry at 60°C, grind the obtained solid, send it into a high-temperature furnace, heat up to 230°C at a heating rate of 5°C / min, and perform high-temperature calcination for 3 hours, cool, and grind to obtain co 3 o 4 .

[0030] 2. SnO 2 -Co 3 o 4 preparation of

[0031] 0.482g (0.002mol) Co 3 o 4 Dissolve in a mixture of 30mL et...

Embodiment 2

[0037] Example 2 application

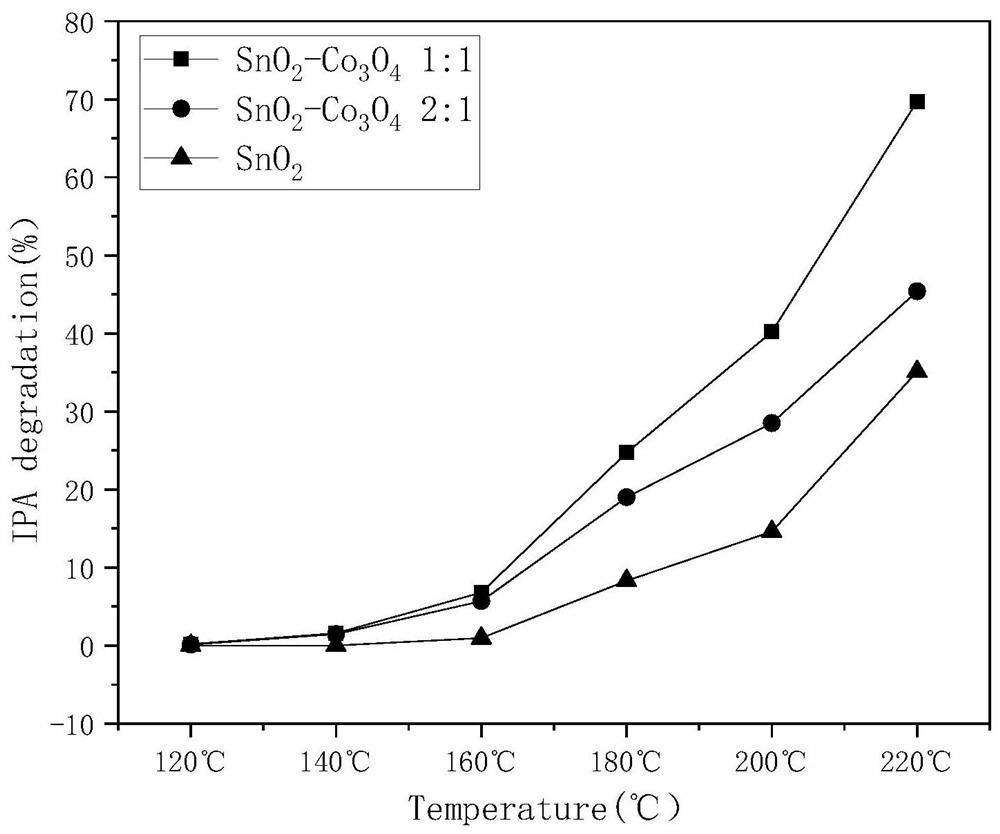

[0038] (1) Effects of catalysts with different molar ratios on catalytic degradation of isopropanol under heating conditions

[0039] In the flow reaction device, under normal pressure, the tin oxide composite tricobalt tetroxide photothermal catalyst SnO with different molar ratios prepared in Example 1 was 2 -Co 3 o 4 Put into the reactor, feed isopropanol, carry out catalytic decomposition to isopropanol, flow gas is air (90ml / min), the reactor is heated up to 120 ℃, then starts to heat up, adopts thermocouple to measure temperature. The generated acetone was analyzed by gas chromatography with an FID detector (GC1690, Jiedao Technology Co., Ltd.). Record the peak area of degrading isopropanol to generate acetone, and obtain the concentration change point line diagram of degrading isopropanol to generate acetone through calculation.

[0040] Depend on image 3 Visible, the SnO of the present invention 2 -Co 3 o 4 The concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com