Patents

Literature

49results about How to "Achieving Green Chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

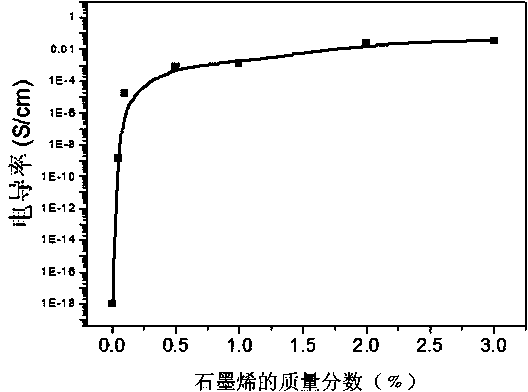

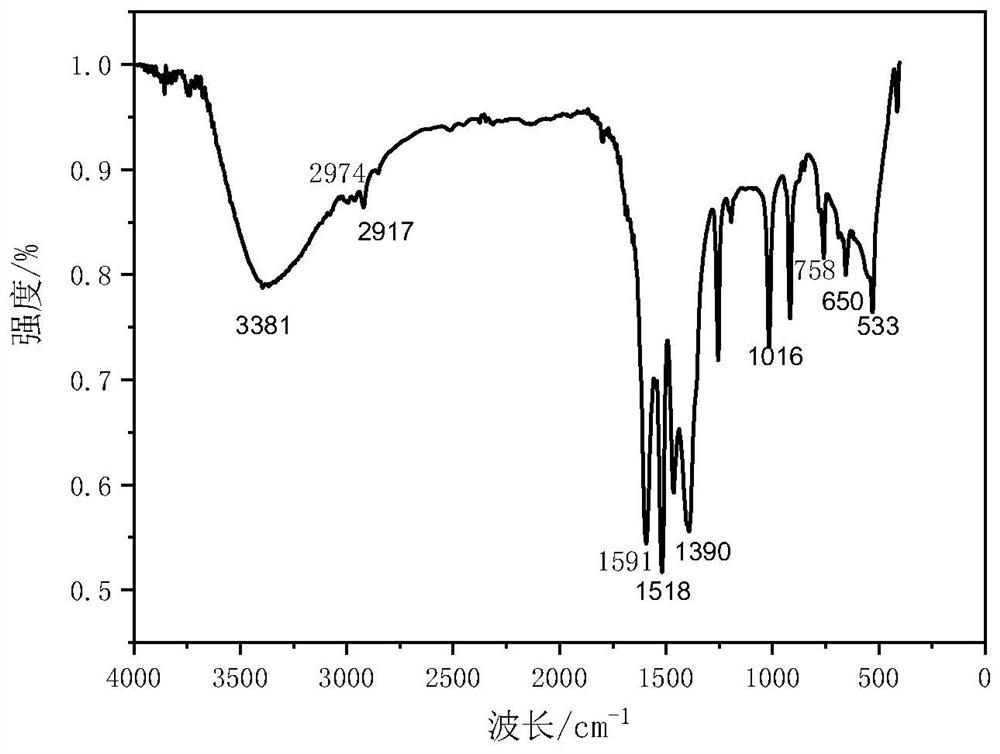

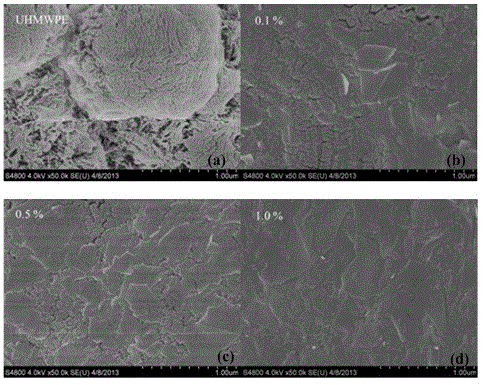

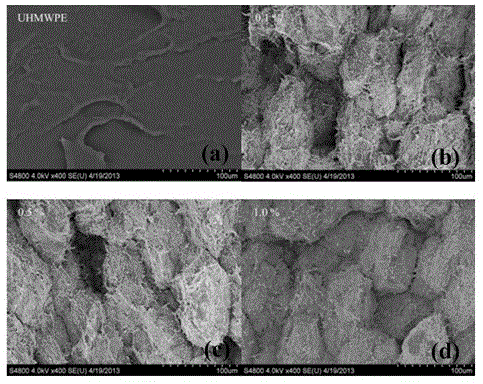

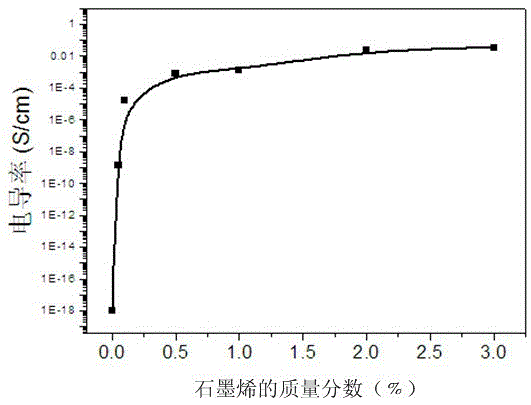

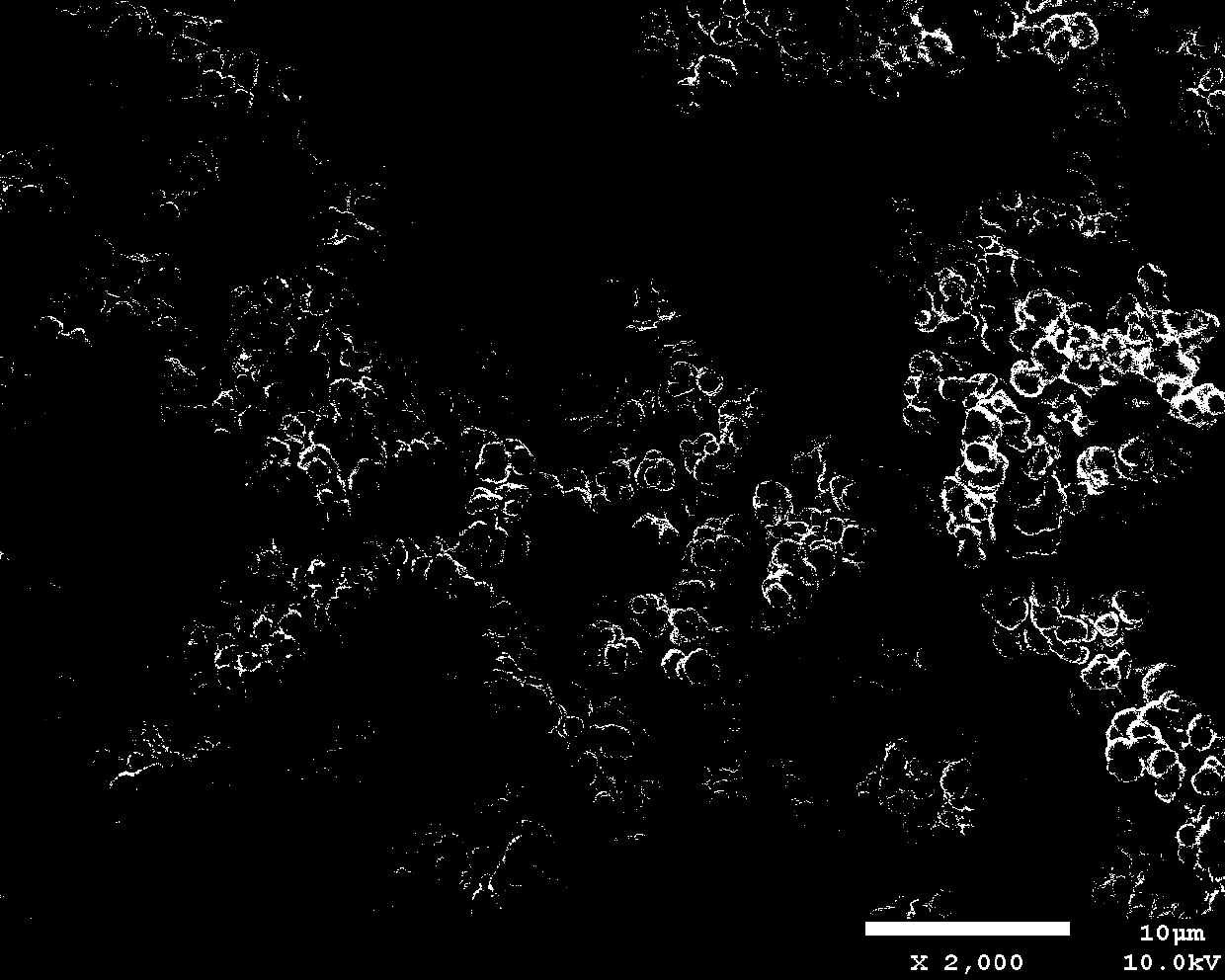

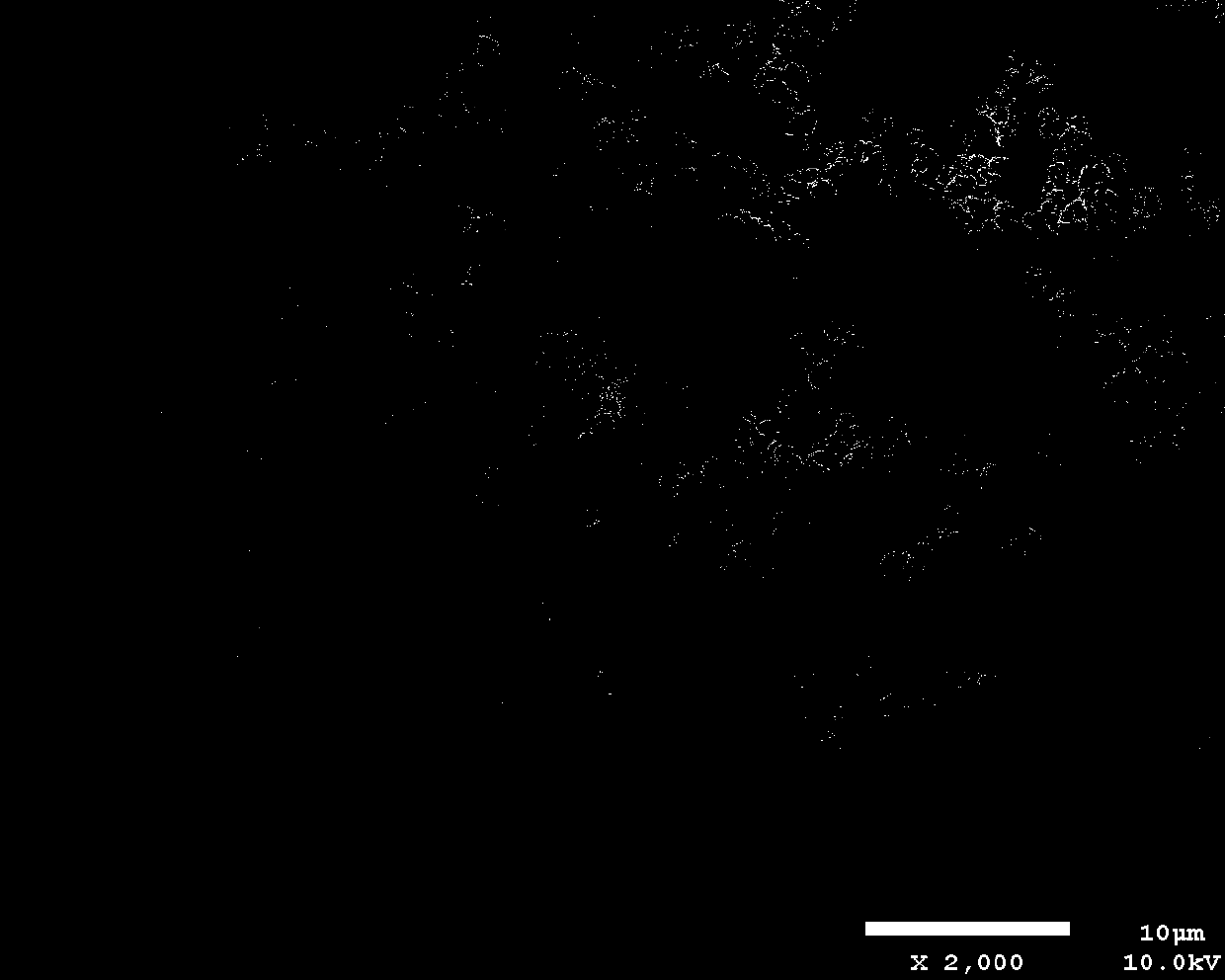

Preparation method of antistatic ultra-high molecular weight polyethylene (UHMWPE)/graphene composite material

The invention relates to a preparation method of an antistatic ultra-high molecular weight polyethylene (UHMWPE) / graphene composite material. The method comprises the following steps: putting UHMWPE and graphene powder in a high-speed stirrer to be stirred to obtain UHMWPE / graphene composite particles, wherein the graphene powder is added to the high-speed stirrer in 2-50 times and the materials are stirred for 10-30 seconds each time at a speed of 10000-30000r / min; preheating the UHMWPE / graphene composite particles at 180-240 DEG C for 5-10 minutes, and then carrying out hot pressing for 30 minutes under the conditions of the same temperature and 10MPa, thus obtaining the UHMWPE / graphene material. The method has the beneficial effects that solvents are not involved in the method; the required antistatic composite material is prepared through electrostatic adsorption and hot press molding; the prepared material has a three-dimensional net structure; the percolation value of the material is slightly higher than that of the material prepared by a solution method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

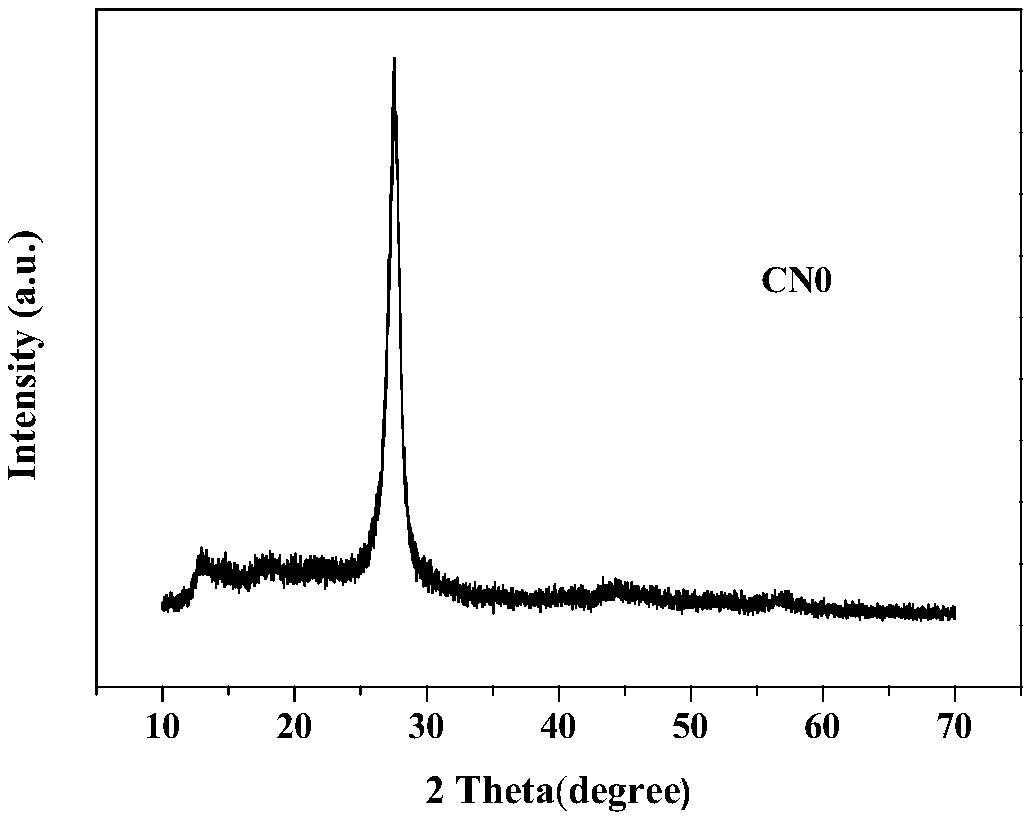

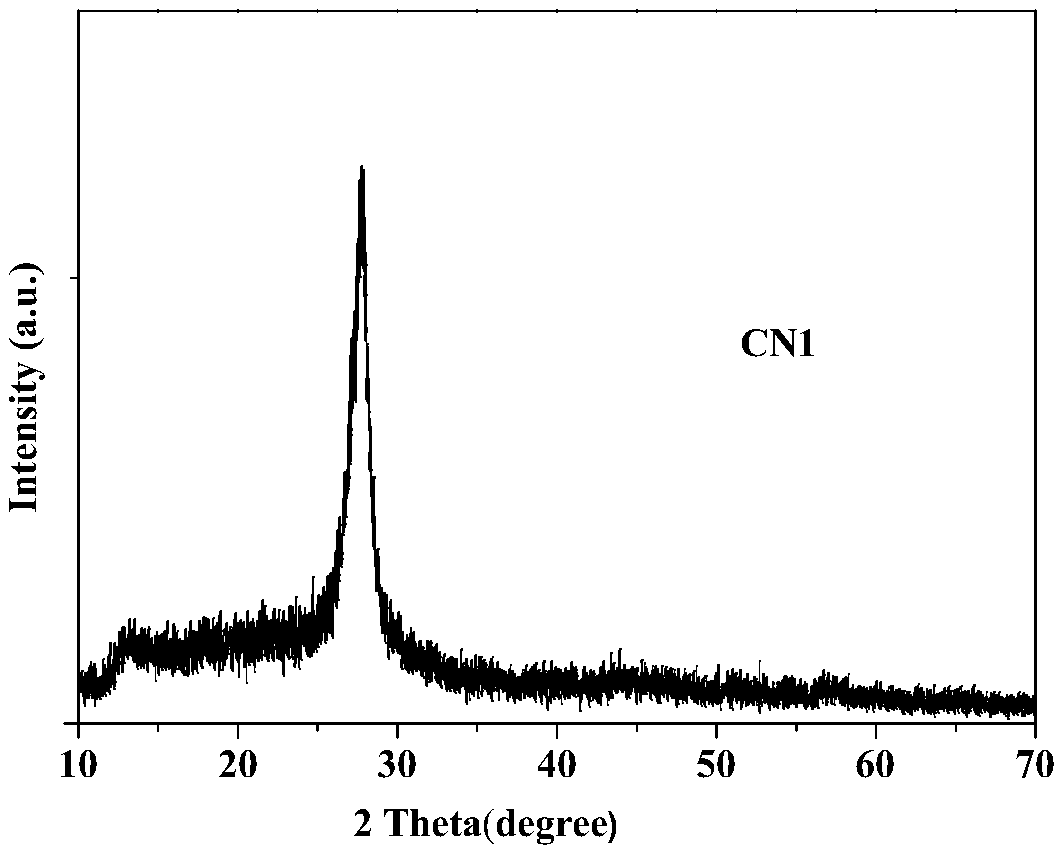

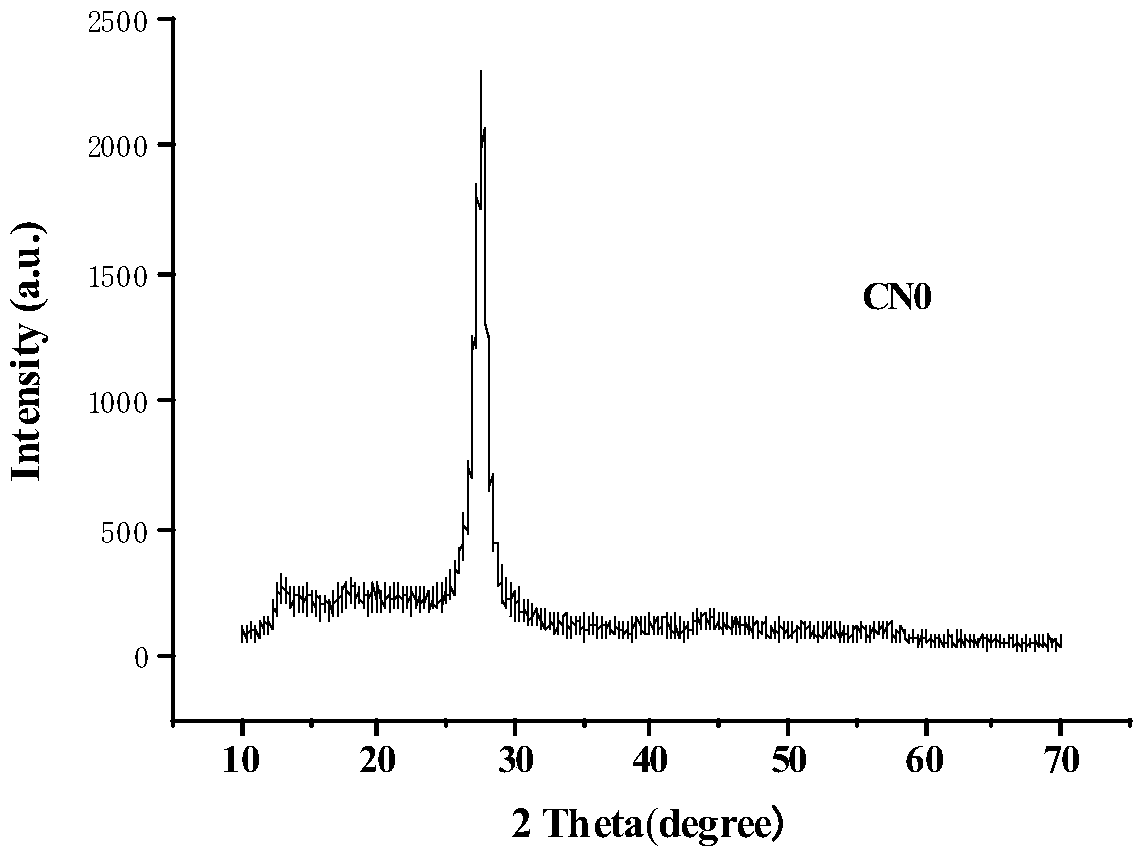

Oxygen-doped porous g-C3N4 photocatalyst, preparation method thereof and application of the photocatalyst

ActiveCN108568307AFor the purpose of dopingLarge specific surface areaOrganic compound preparationPreparation by dehydrogenationAir atmosphereMelamine

The invention discloses a preparation method of an oxygen-doped porous g-C3N4 photocatalyst. The method comprises dissolving melamine in deionized water, adding an organic substance containing an aldehyde group dropwise under heating and stirring conditions, putting the obtained solution into an oven, drying the solution at 80-150 DEG C to obtain a precursor, grinding the precursor, calcining theprecursor in an inert gas atmosphere to obtain an intermediate product, and calcining the intermediate product in an air atmosphere to obtain a target product. The porous oxygen-doped g-C3N4 nanometermaterial prepared by the method of the invention can effectively promote electron transfer, reduce the recombination rate and increase photocatalytic activity, and precursor treatment in this mannercan not only change the structure but also introduce useful foreign atoms. Moreover, the method is cheaper than conventional oxygen doping methods and is simple and convenient to operate. The photocatalyst can effectively degrade organic pollutants under visible light irradiation.

Owner:LIAONING UNIVERSITY

New technology for catalytically cracking light diesel oil from waste motor oil

InactiveCN101531948AEliminate pollutionReduce pollutionCatalytic crackingLubricant compositionDistillationPulp and paper industry

The invention belongs to the diesel oil refining technology, especially a new technology for catalytically cracking light diesel fuel from waste motor oil. Currently, the drawbacks of the prior technology for refining the waste motor oil into diesel oil are that: the cetane number falls short of national standard and the chroma is deep and opaque, the recovery is low and the technology is complex. The new technology comprises the following steps: adding waste motor oil into a reaction kettle; adding a hone-made good catalyst accounting for 1 / 1000 of the weight of the waste motor oil; heating to 300-500 DEG C to make the waste motor oil catalytically crack, finally obtaining distillation product; putting the distillation product into a condenser, making the condensed liquid-sate light diesel oil and the tail gas through an oil-gas splitter, making the tail gas into a gas collector; split diesel oil flowing into a treatment tank, adding high efficiency treating agent with concentration of 5 / 10000 into the treatment tank, treating the diesel oil using a backflow spray head; finally layering and filtering the treated light diesel oil by an oil water splitter, namely the yellow transparent light diesel oil with flash point >55 DEG C is obtained, with recovery of higher 80%.

Owner:熊道陵 +2

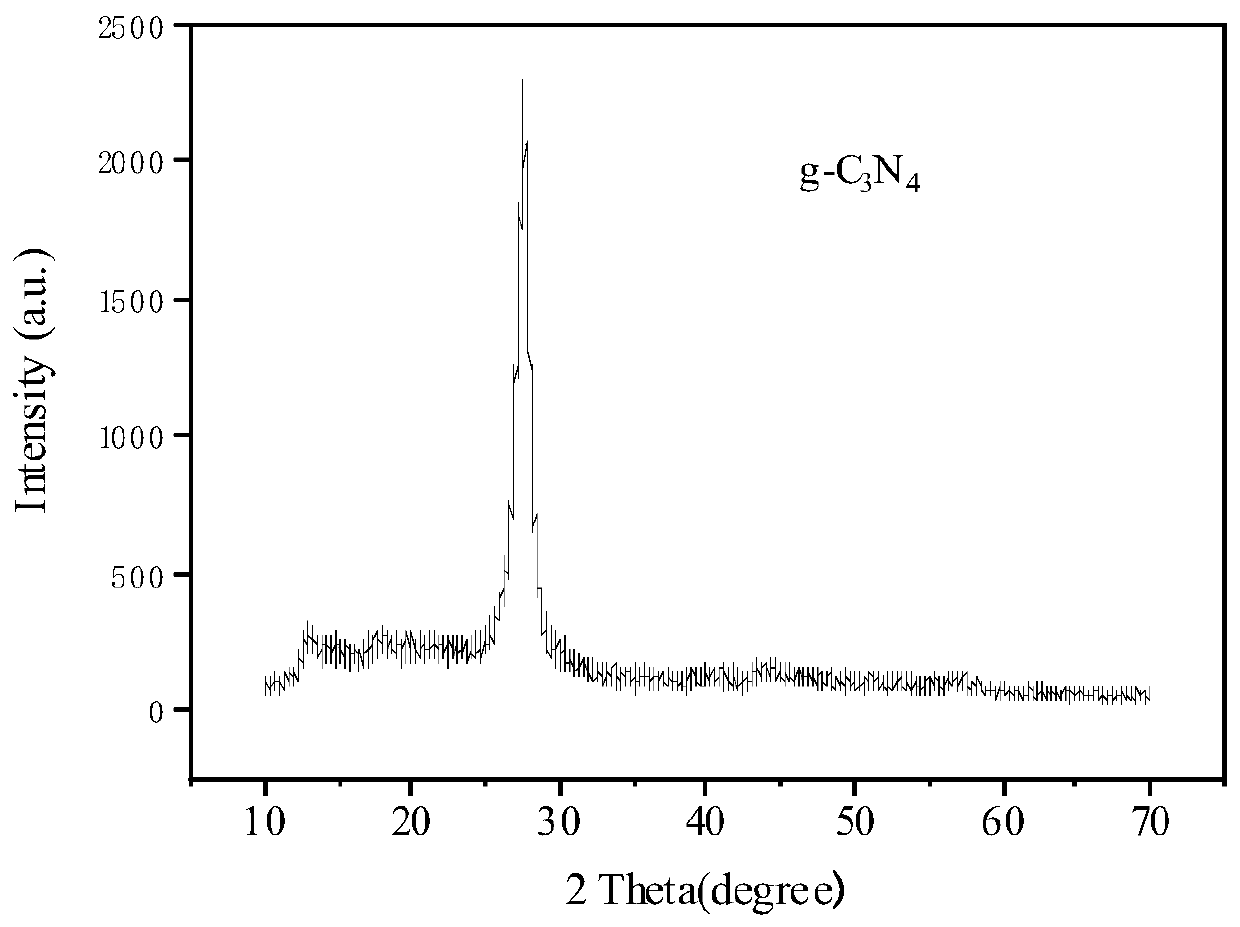

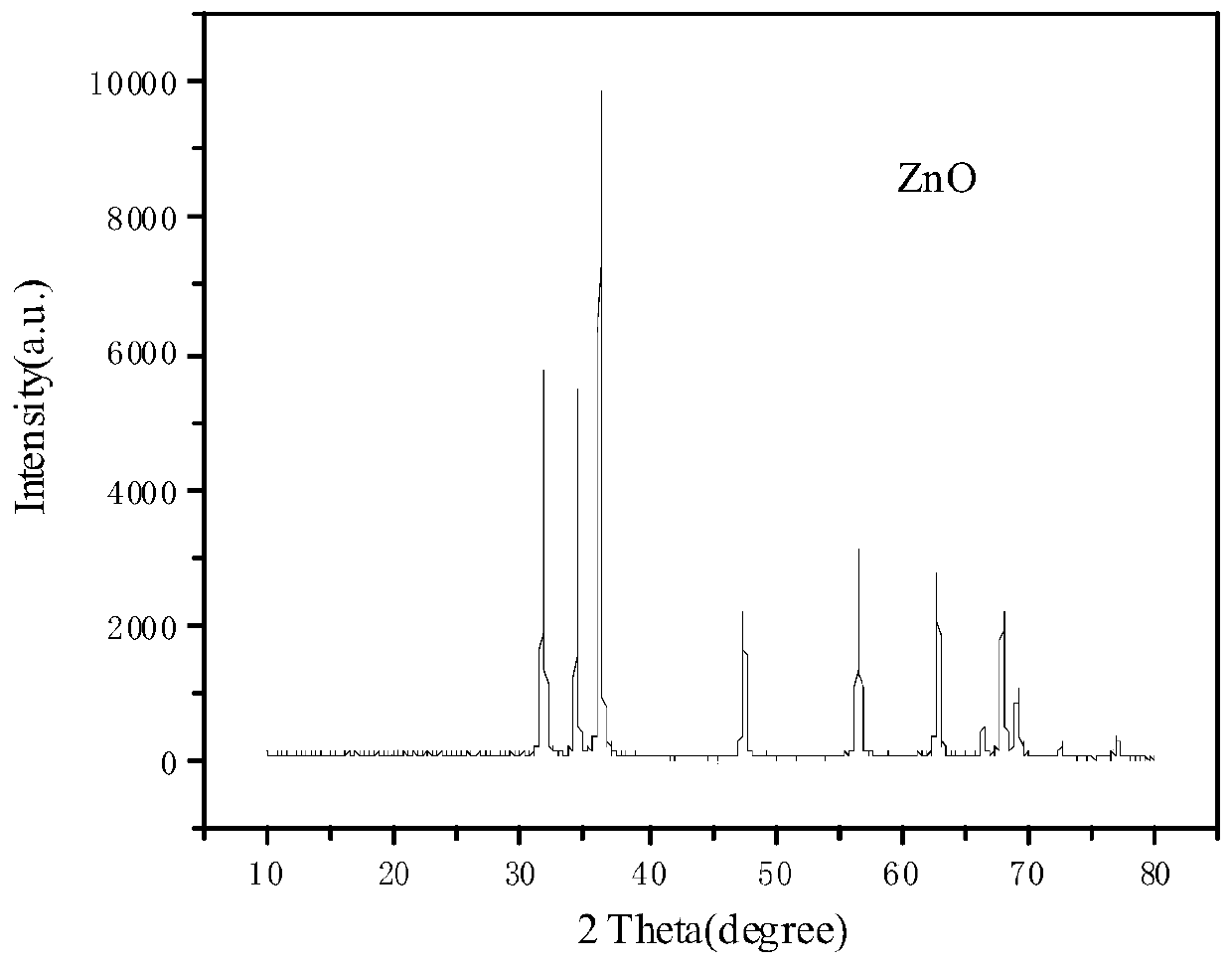

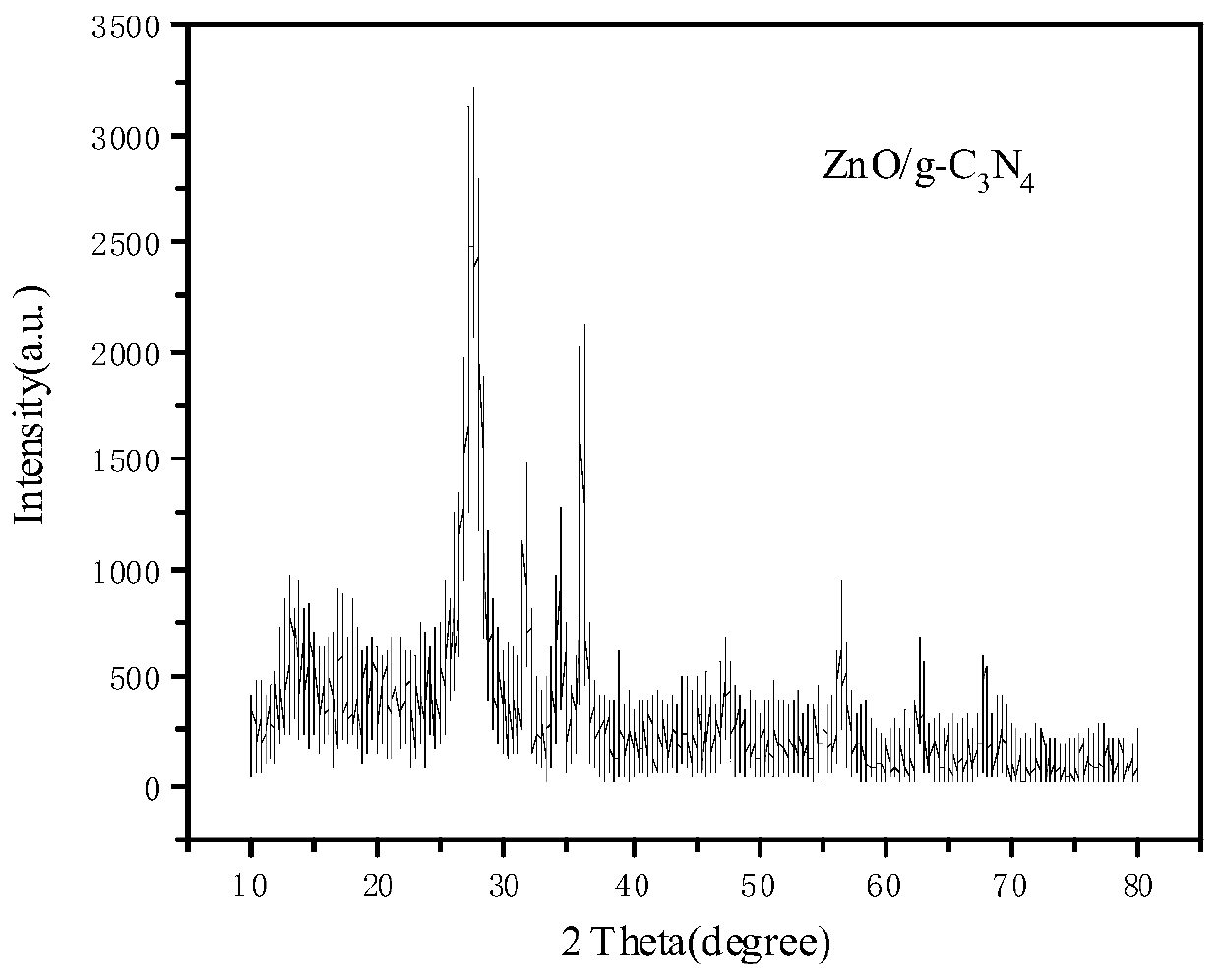

ZnO/g-C3N4 composite photocatalyst as well as preparation method and application thereof

InactiveCN110124723AEfficient separationReduce recombination rateGas treatmentPhysical/chemical process catalystsElectron holeWater baths

The invention discloses a ZnO / g-C3N4 composite photocatalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing nitrogen-rich organicmatter and deionized water, performing heating in a water bath at 30-90 DEG C, after full stirring is performed, putting the stirred material into an oven, performing drying, performing grinding, performing primary high-temperature calcination on the obtained precursor A in a nitrogen environment, performing secondary high-temperature calcination in an air environment, performing cooling, and performing grinding to obtain g-C3N4; dissolving zinc acetate into methanol, performing titration by using an alkaline solution, after a precipitate is completely precipitated, performing centrifugation,performing washing, performing drying, and performing high-temperature calcination on the obtained precursor B to obtain ZnO; and performing ultrasonic mixing on the ZnO and the g-C3N4 for 0.5-3 h, adjusting the pH of the solution to 4-10 to form the ZnO / g-C3N4 composite photocatalyst. According to the method provided by the invention, the ZnO / g-C3N4 composite photocatalyst prepared by the methodcan effectively separate electron hole pairs and reduce a recombination rate of electron holes, so that the photocatalytic activity is effectively improved.

Owner:LIAONING UNIVERSITY

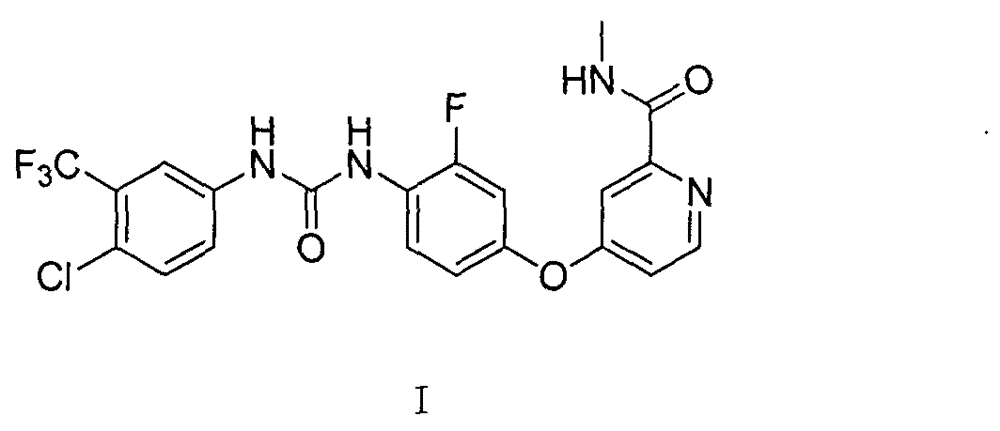

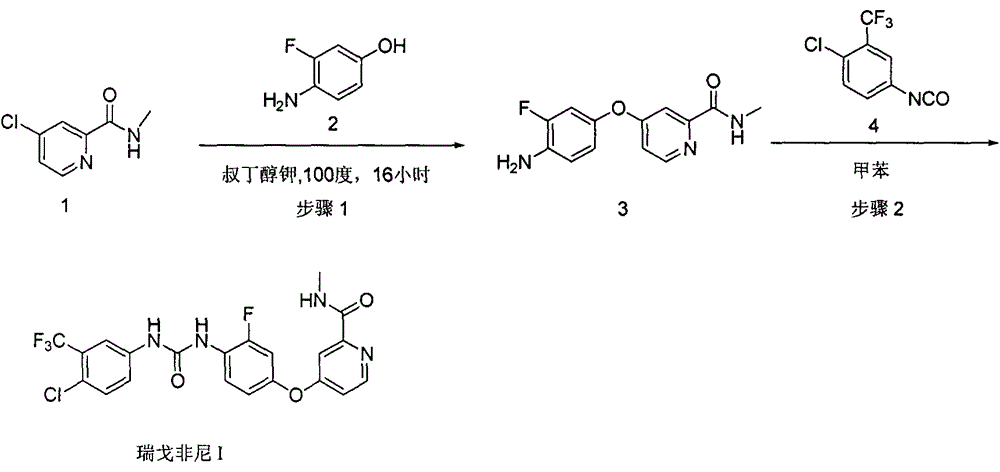

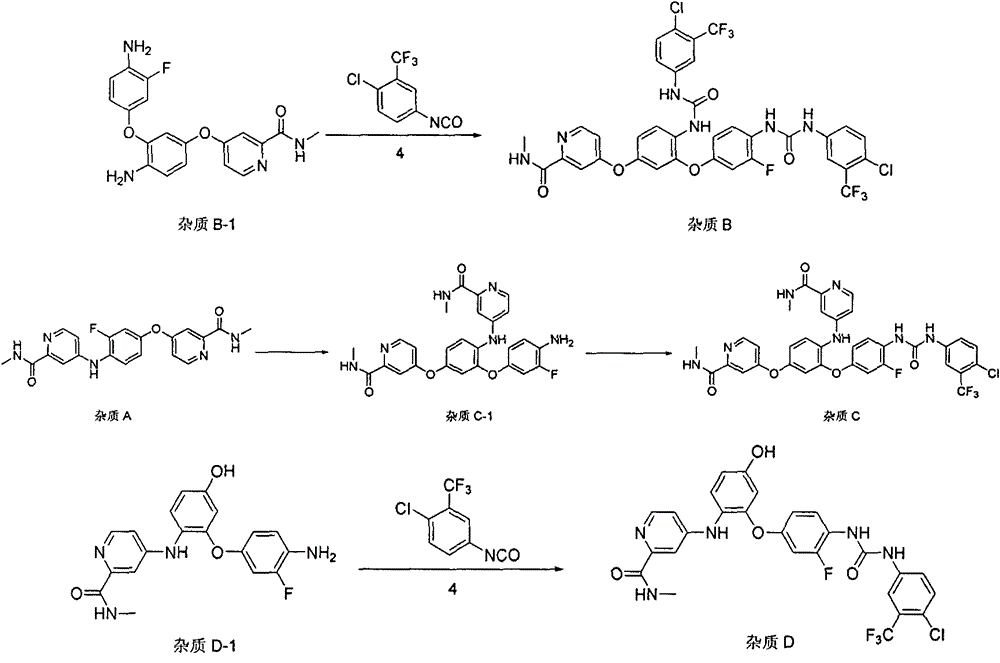

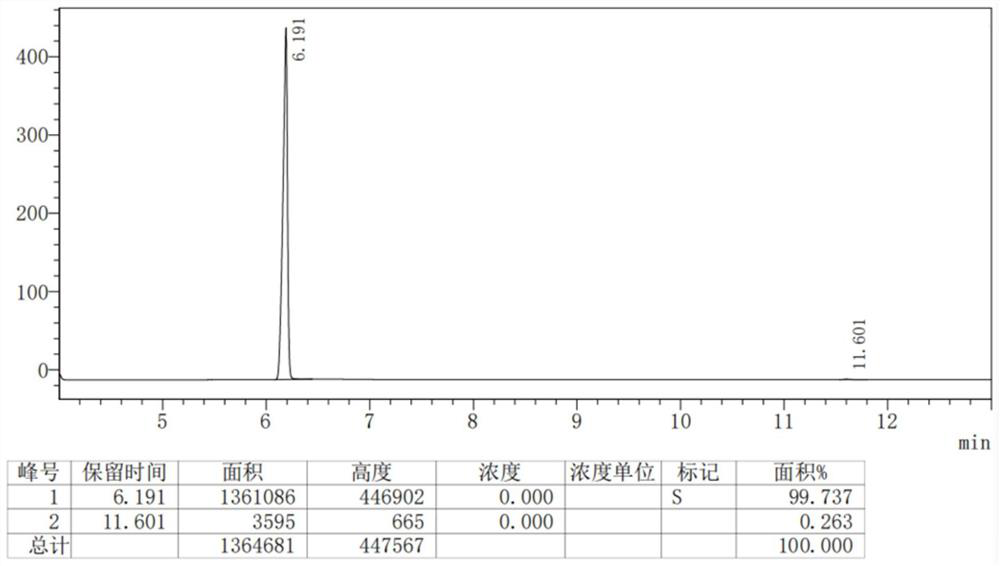

Preparation method for high-purity regorafenib

InactiveCN105218440ALower reaction conditionsAvoid demandingOrganic chemistryRegorafenibPhase-transfer catalyst

The invention discloses an improved preparation method for high-purity regorafenib (a compound I), particularly a preparation method for a compound 3 (a regorafenib intermediate) with the structure shown in the description, wherein the compound 3 is further used for industrial preparation of regorafenib with extremely excellent purity. By adopting a phase transfer catalyst, the method is simple and convenient to operate and environmental-friendly, can effectively inhibit generation of impurities, is low in requirement on equipment and is suitable for industrial production of high-purity regorafenib on a large scale.

Owner:HENAN UNIV OF CHINESE MEDICINE

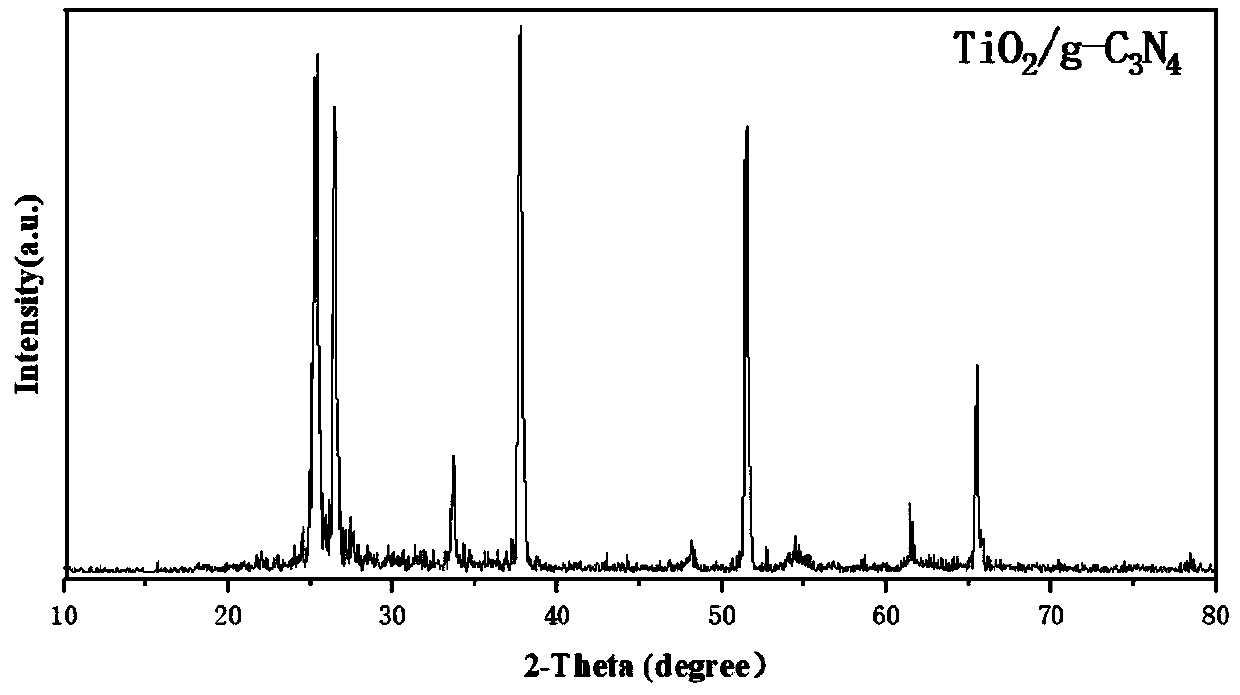

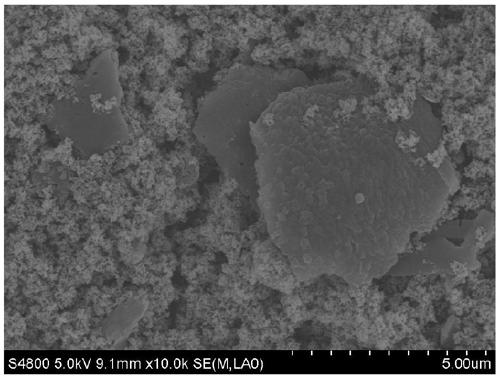

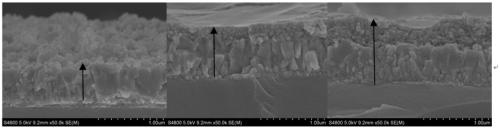

Preparation method and application of TiO2/g-C3N4 photoanode nanocomposite

InactiveCN109626422AGood photochemical propertiesReduce energy consumptionMaterial nanotechnologyElectrophoretic coatingsRoom temperaturePhotoelectrochemistry

The invention relates to the field of photoelectrochemistry, and discloses a TiO2 / g-C3N4 photoanode nanocomposite. The preparation method includes the following steps that melamine and tetrabutyl titanate are mixed in ethanol, stirring is performed to make the mixture evenly dispersed, a hydrothermal method is adopted, centrifugal filtration is performed, and after drying, powder is annealed at high temperature, cooled to room temperature and ground to obtain the TiO2 / g-C3N4 photoanode nanocomposite. The invention further provides the application of the photoanode nanocomposite in preparationof a TiO2 / g-C3N4 photo-electrode film. The TiO2 / g-C3N4 photoanode nanocomposite and the photo-electrode film have good photochemical properties, and the preparation method has the advantages that theenergy consumption is low, the conditions are simple and large-scale preparation is easy to achieve.

Owner:LIAONING UNIVERSITY

Sulfur-doped graphite-phase carbon nitride nanosheet photocatalyst and preparation method and application thereof

InactiveCN109364977AEfficient separationReduce recombination rateMaterial nanotechnologyGas treatmentSulfur containingCalcination

The invention discloses a sulfur-doped graphite-phase carbon nitride nanosheet photocatalyst and a preparation method and application thereof. The preparation method comprises the following steps that1, a nitrogen-enriched organic matter is placed in a crucible, high-temperature calcination treatment is conducted at 300-500 DEG C, the temperature is maintained for 1-10 h, and cooling is conductedto obtain a precursor A; 2, a sulfur-containing nitrogen-enriched organic matter is ground, and is dissolved in water, oxalic acid is added, and after being fully stirred, a mixture is placed in an oven, and is heated for drying at 60-120 DEG C to obtain a precursor B; 3, the precursor A and the precursor B are mixed, and are subjected to high-temperature calcination subsequently to obtain the product sulfur-doped graphite-phase carbon nitride nanosheet photocatalyst. A sulfur-doped graphite-phase carbon nitride nanometer material can provide more catalytic reaction sites, meanwhile, a builtsulfur-doped structure can trap photo-induced electrons, the photo-induced electrons and photo-induced holes are effectively separated, the recombination rate is reduced, and the photocatalytic activity is improved. The photocatalyst can effectively degrade organic pollutants when irradiated by visible light.

Owner:LIAONING UNIVERSITY

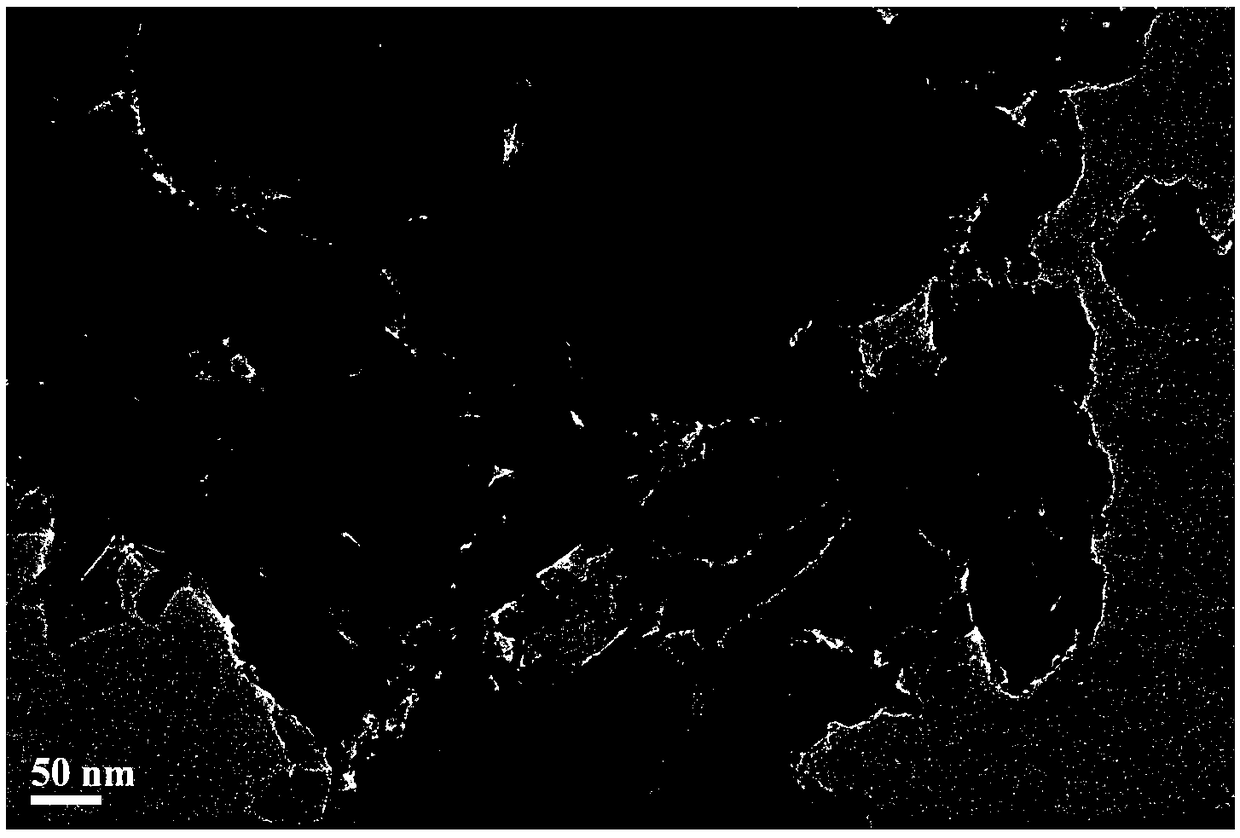

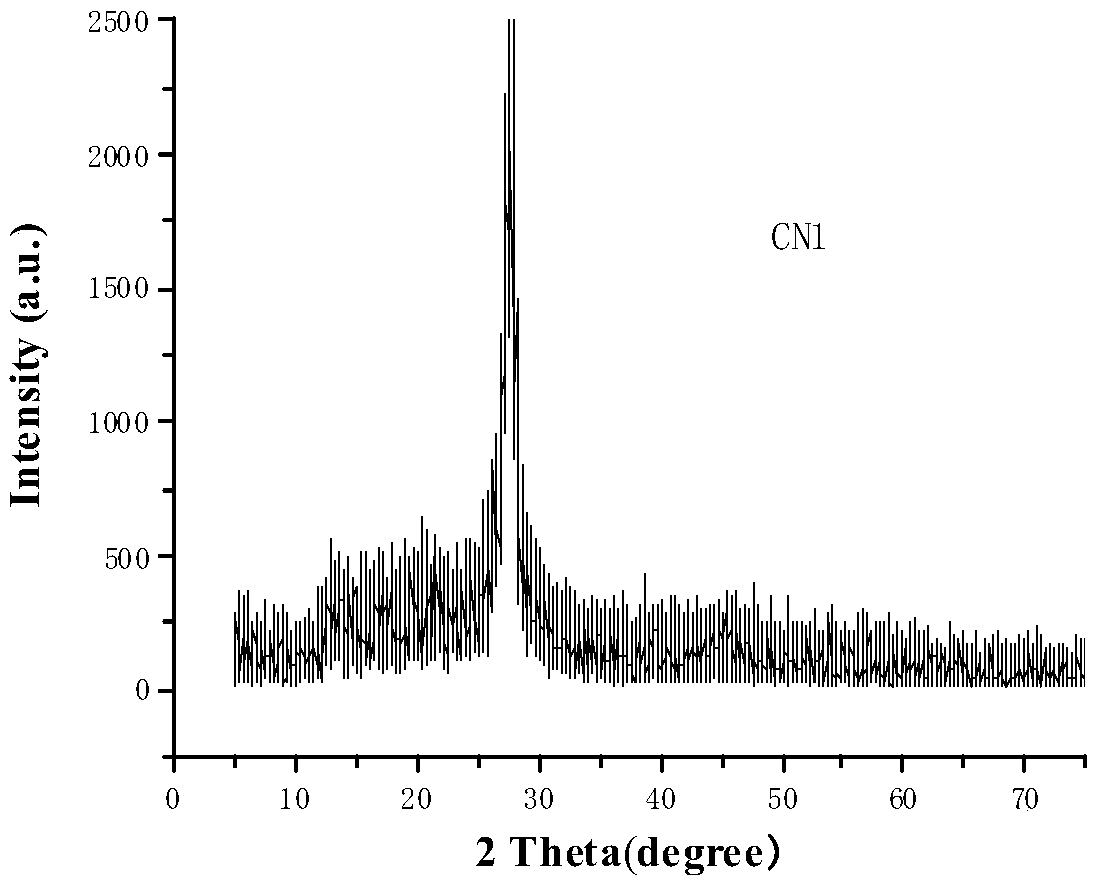

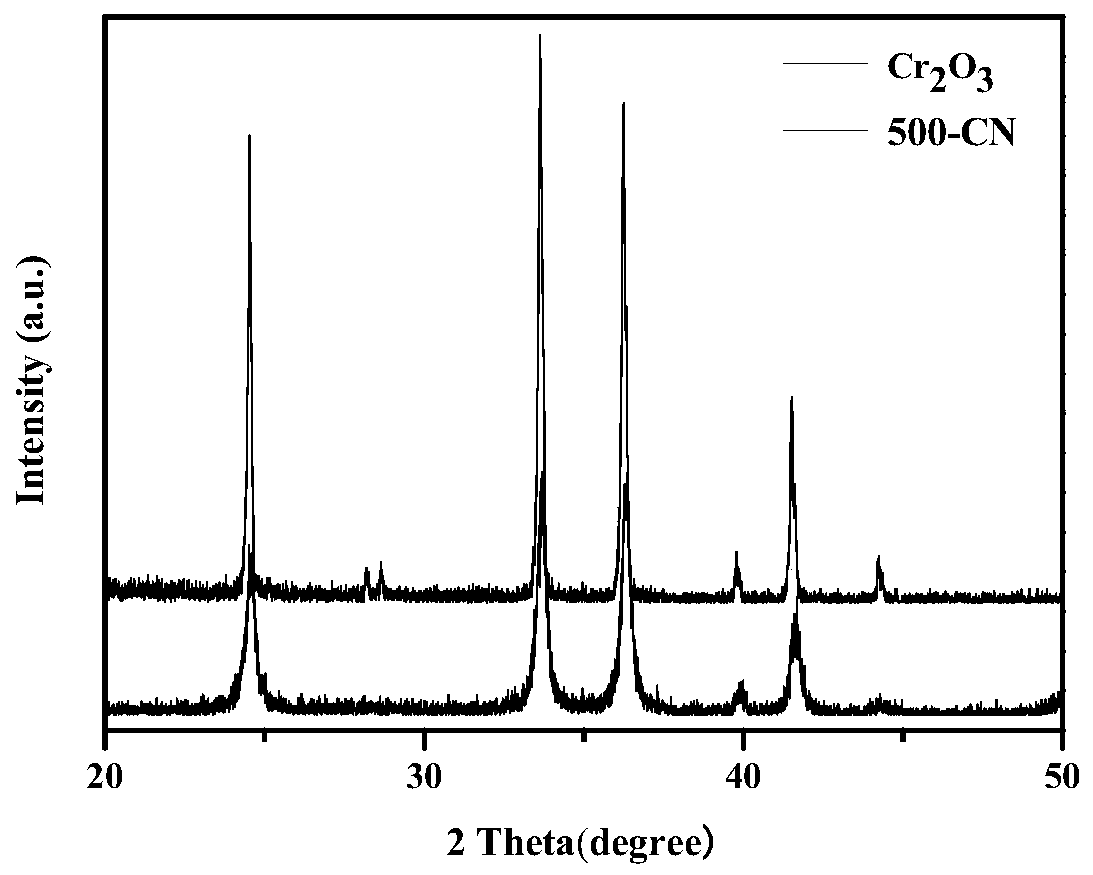

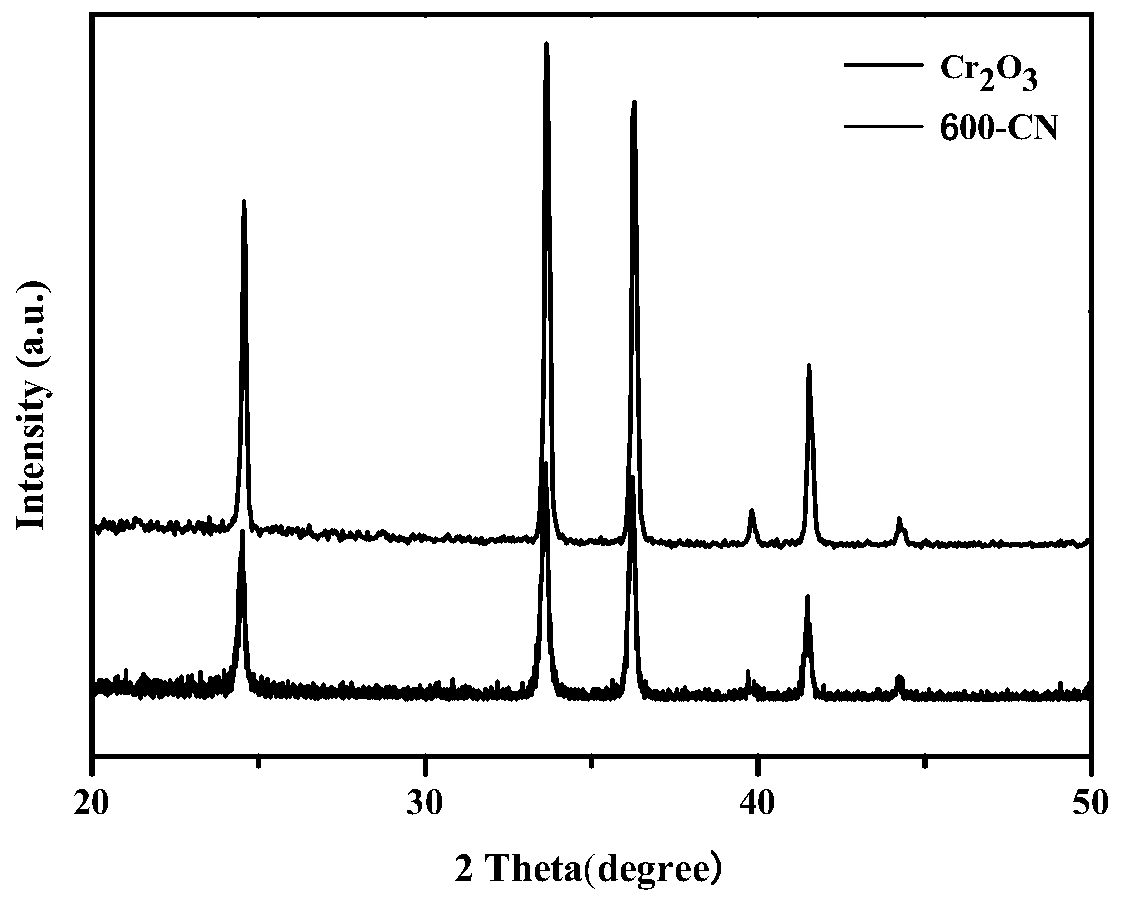

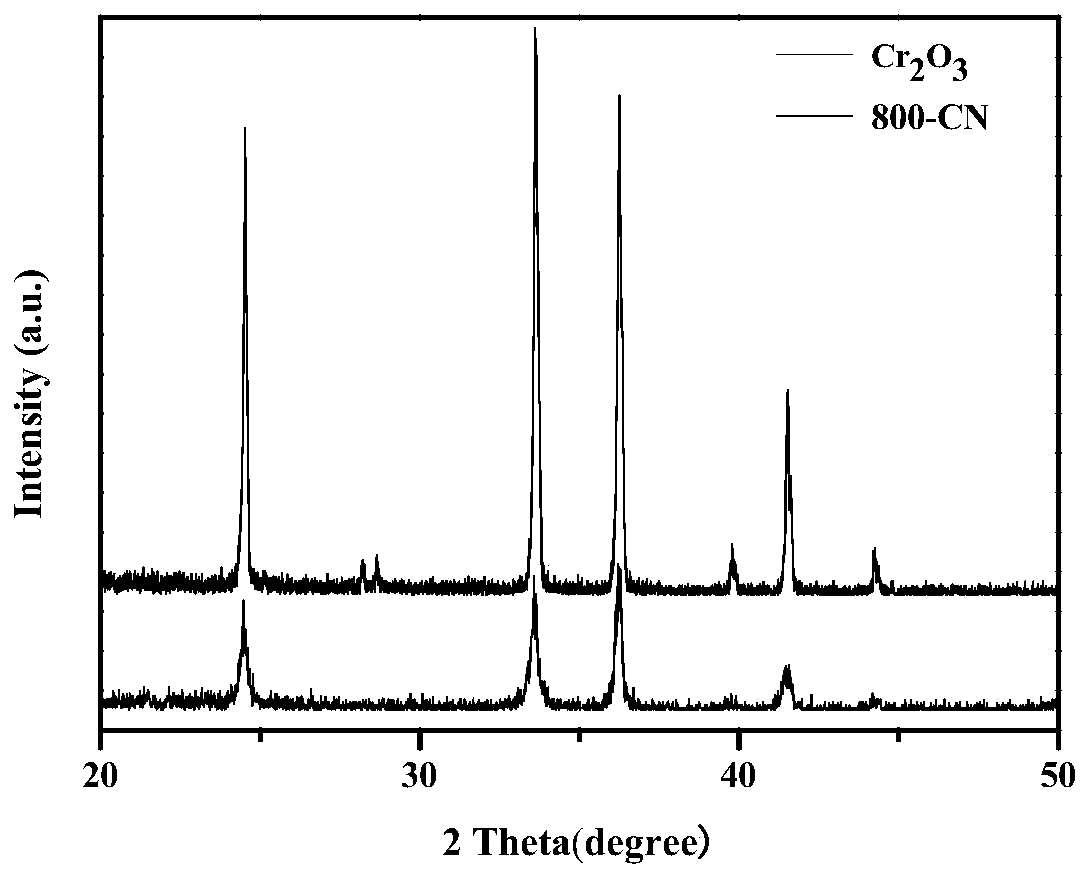

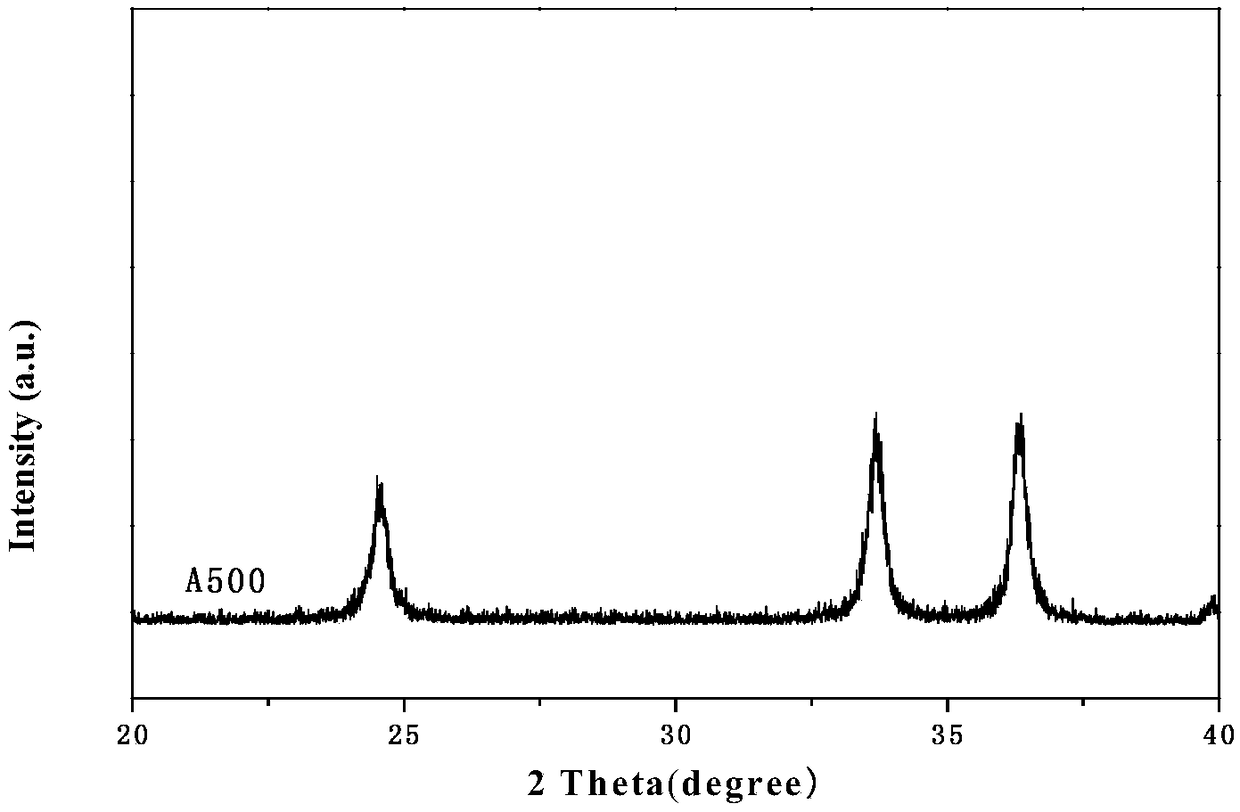

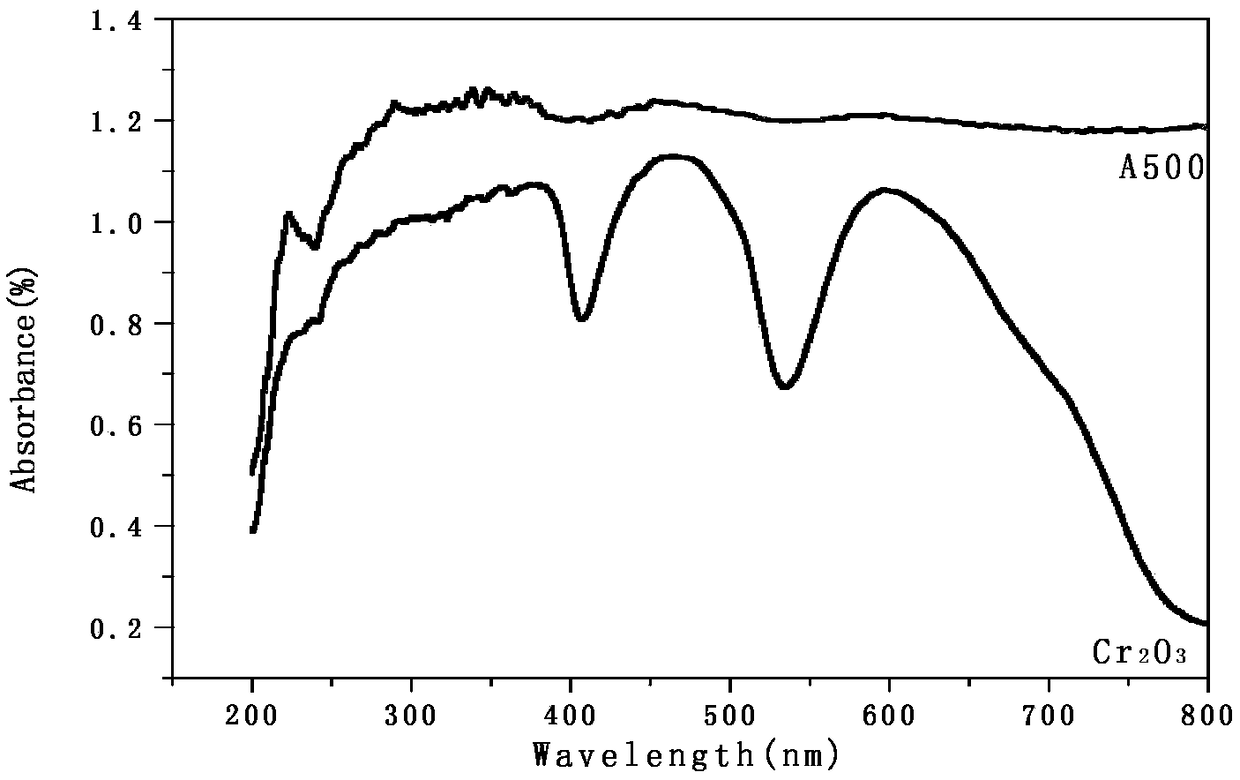

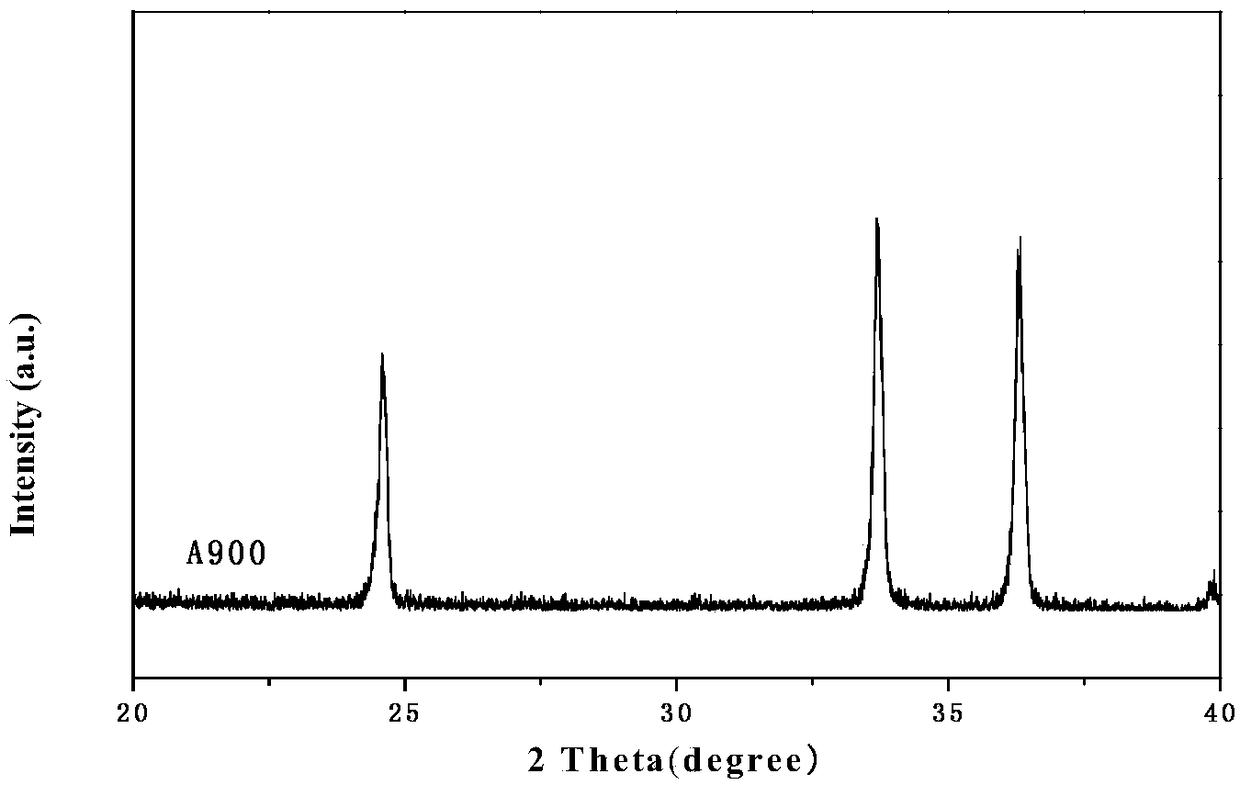

Carbon nitride compounded chromium sesquioxide oxygen-vacancy-containing photo-thermal catalyst as well as preparation method and application thereof

ActiveCN110152713AEfficient degradationInhibitory complexPhysical/chemical process catalystsDispersed particle separationChromium sesquioxideOxygen vacancy

The invention discloses a carbon nitride compounded chromium sesquioxide oxygen-vacancy-containing photo-thermal catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: putting a nitrogen-containing organic matter and a chromium salt input deionized water, stirring and keeping for 0.5-5 hours, and drying so as to obtain a precursor; grinding the precursor, carrying out calcining in an inert gas environment or an air environment, and carrying out natural cooling so as to obtain the carbon nitride compounded chromium sesquioxide oxygen-vacancy-containing photo-thermal catalyst of which the carbon nitride content is 1-5%, wherein the calcining temperature is 200-800 DEG C, and the calcining time is 1-10 hours. By adopting a carbon nitride compounded chromium sesquioxide oxygen-vacancy-containing material prepared by using the method disclosed by the invention, electrons or holes caused by thermal activation can be captured byvirtue of oxygen defects, and carrier recombination can be effectively inhibited, so that photo-thermal catalytic activity can be improved. By adopting the obtained photo-thermal catalyst, organic pollutants can be effectively degraded.

Owner:LIAONING UNIVERSITY

Cr2O3 thermal catalyst with oxygen defect, and preparation method and application of Cr2O3 thermal catalyst

ActiveCN109364909AImprove thermocatalytic activitySave raw materialsGas treatmentDispersed particle separationChemistryPollutant

The invention discloses a Cr2O3 thermal catalyst with an oxygen defect material, and a preparation method and application of the Cr2O3 thermal catalyst. The preparation method comprises the followingsteps that an oxygen-enriched chromium-containing compound is put into a crucible to be subjected to be high-temperature calcination treatment in an inert gas environment or an air environment, then cooled and ground, and thus a Cr2O3 thermal catalyst product with the oxygen defect is obtained. A chromium oxide material with the oxygen defect is prepared through the preparation method, the oxygendefect can effectively adsorb pollutants to be subjected to an oxidizing reaction, thus thermocatalytic activity is improved, and in addition, the higher the concentration of the oxygen defect is, thebetter the organic pollutant degrading effect at the same temperature is. By utilizing the obtain the thermal catalyst, the gaseous organic pollutants can be effectively degraded at the low temperature.

Owner:LIAONING UNIVERSITY

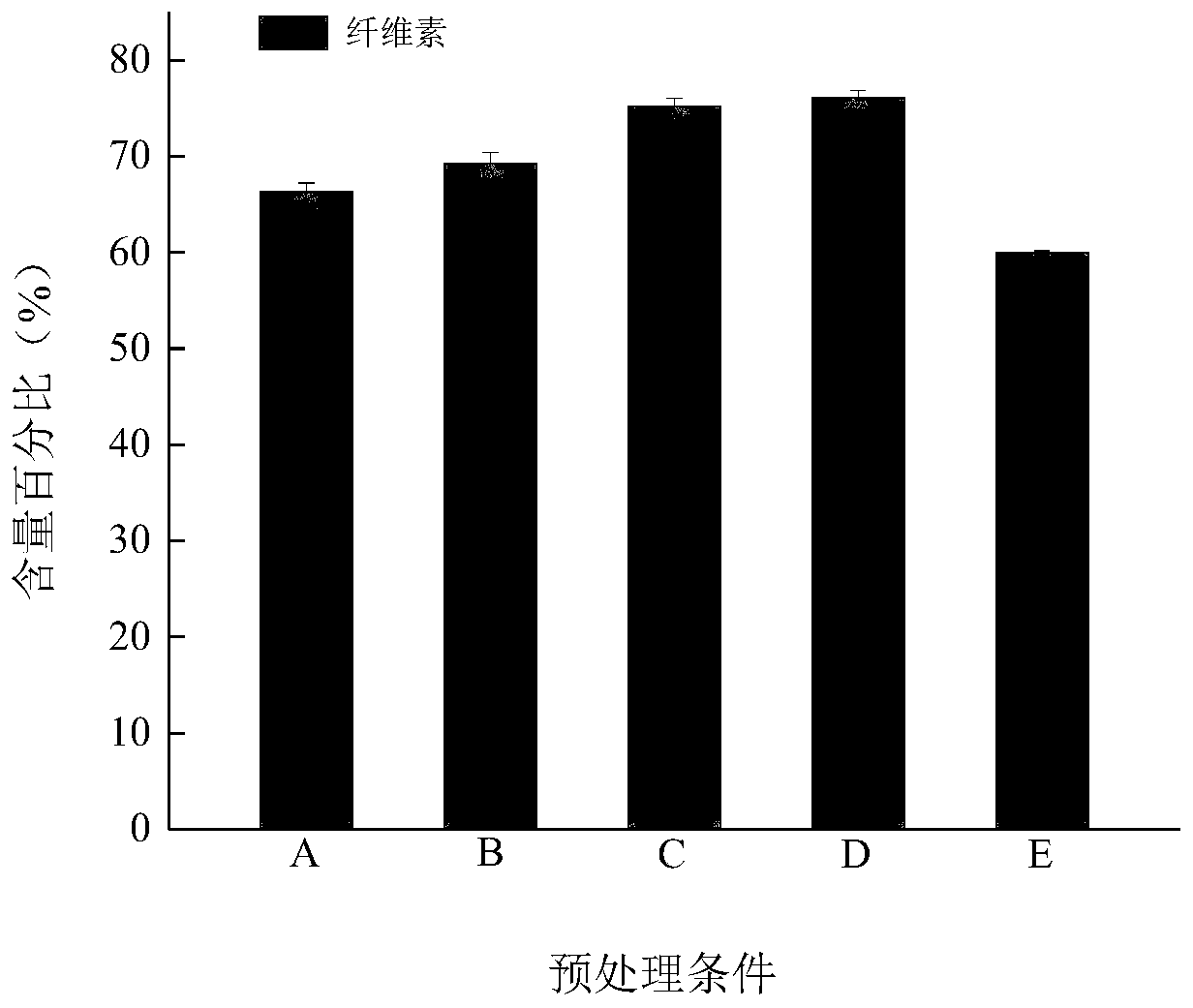

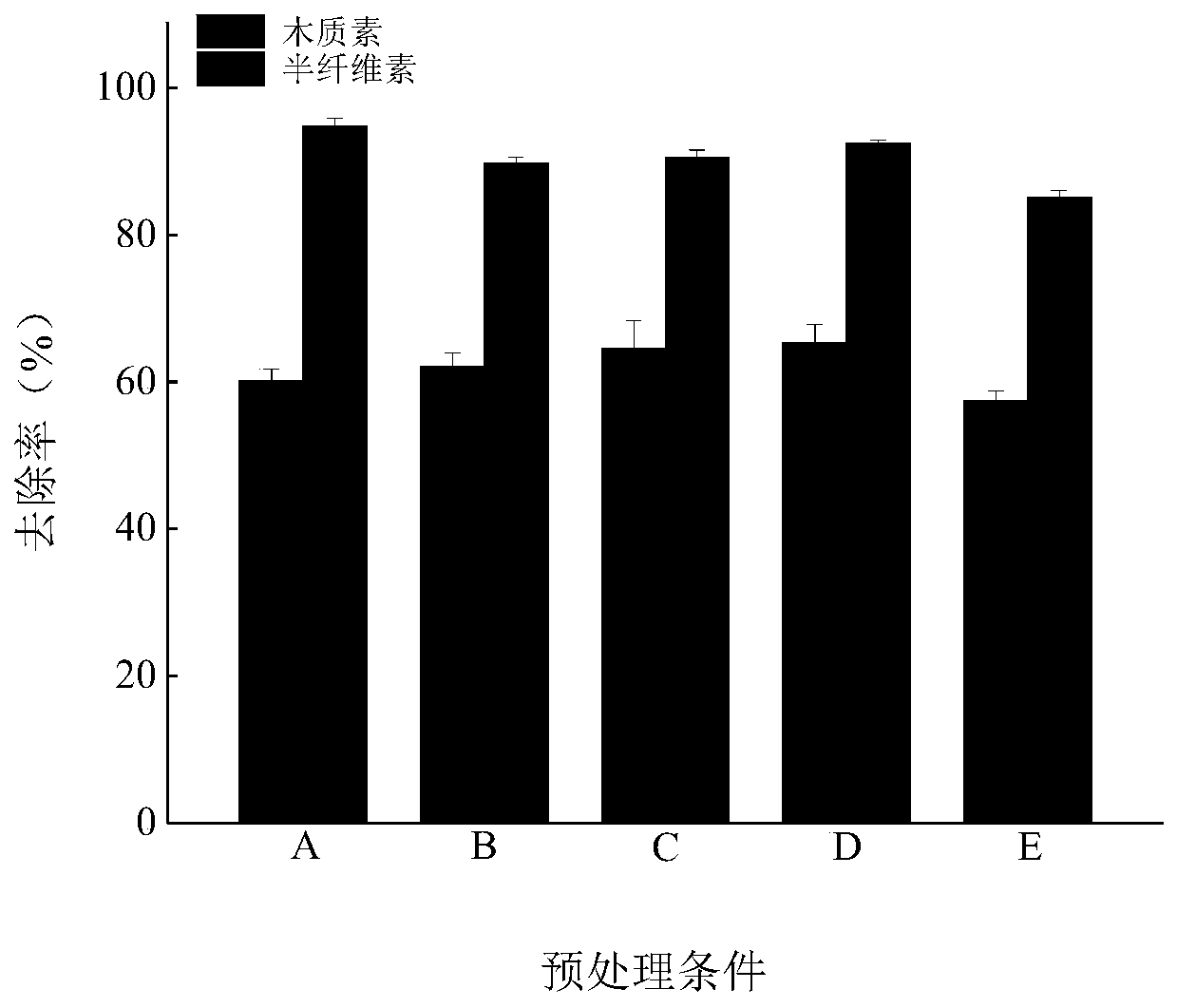

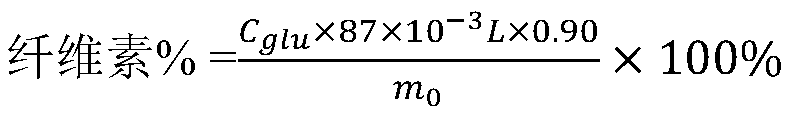

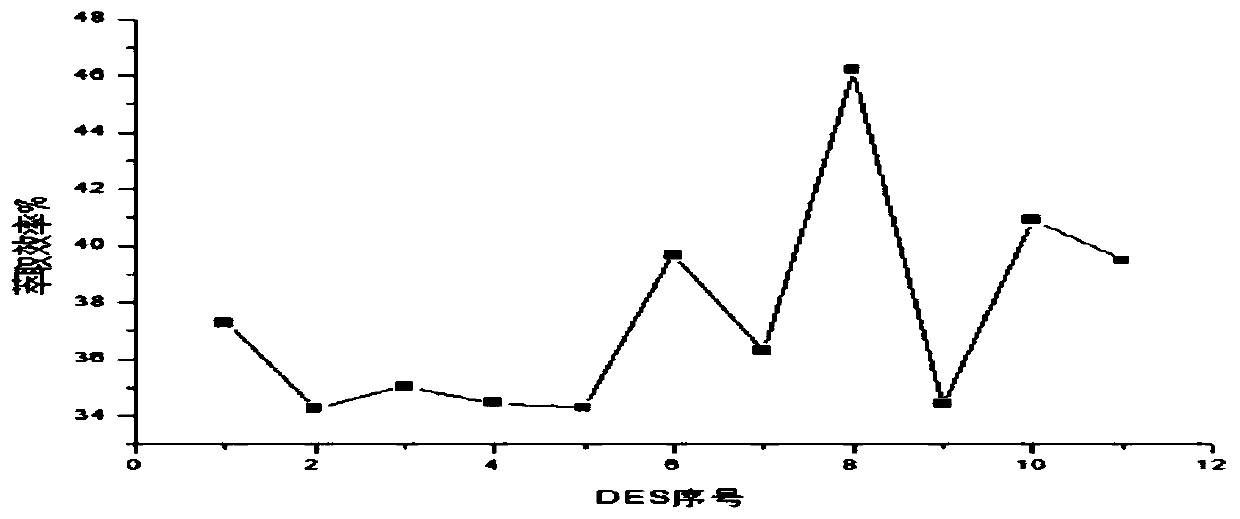

Method for dissociating corn stalks by utilizing ultrasonic microwave enhanced deep eutectic solvent

ActiveCN111321618ATo achieve the purpose of environmental protectionMeet the requirements of sustainable development of green chemistryPulping with organic compoundsOXALIC ACID DIHYDRATEGlycerol

The invention discloses a method for dissociating corn stalks by utilizing an ultrasonic microwave enhanced deep eutectic solvent, and belongs to the technical field of corn stalk component separation. The method comprises the following steps: synthesizing a deep eutectic solvent serving as a solvent by taking choline chloride, oxalic acid and glycerol as raw materials, mixing the deep eutectic solvent with corn stalks according to a certain proportion, putting the mixture into a multi-frequency combined ultrasonic emitter, processing the mixture in the ultrasonic emitter for a period of time,taking out the mixture, putting the mixture into a microwave digestion instrument to carry out digestion; after the reaction is finished, regenerating the corn stalks in the system, and measuring thecomponents. The constructed deep eutectic solvent is cheap, natural and pollution-free, and the selected ultrasonic microwave system not only has an outstanding effect, but also can realize the deconstruction of corn stalks under mild conditions. The method is a novel method for dissociating corn stalk components.

Owner:JIANGSU UNIV

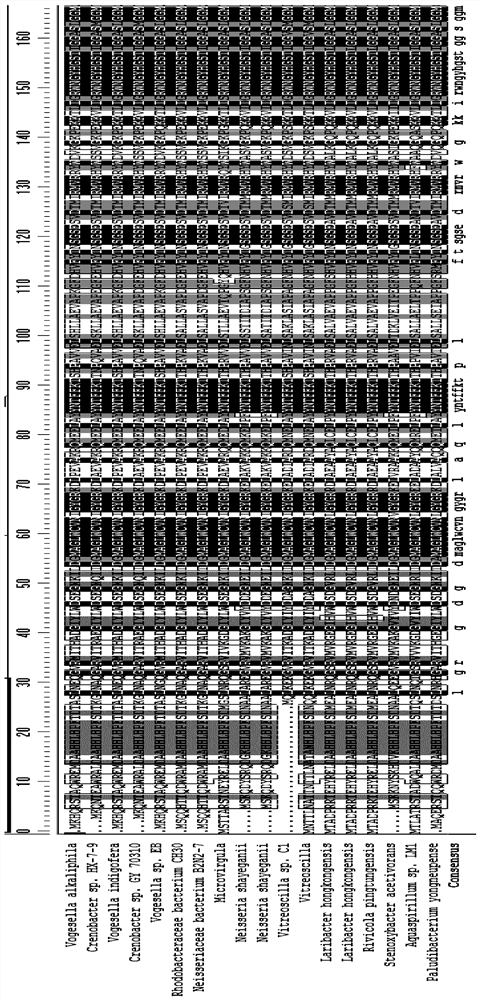

Transaminase mutant and application thereof

ActiveCN112980810AHigh activityHigh selectivityTransferasesFermentationChemical synthesisChemical compound

Owner:ASYMCHEM LAB TIANJIN +1

Preparation method of PVC heat stabilizer tin-doped lanthanum acetylacetonate

ActiveCN111807944AAchieving Green ChemistryImprove thermal stabilityPreparation of aldehyde/ketone chelatesUltrasonic assistedPhysical chemistry

The invention discloses a preparation method of a PVC heat stabilizer tin-doped lanthanum acetylacetonate. The preparation method comprises the following steps: (1) preparing a reaction solution, (2)preparing a sodium hydroxide solution, (3) feeding acetylacetone, (4) carrying out a first-stage reaction process, (5) carrying out a second-stage reaction process, (6) carrying out reaction liquid pretreatment, and (7) carrying out ultrasonic-assisted cleaning and after the cleaning is finished, collecting precipitates, namely the PVC heat stabilizer tin-doped lanthanum acetylacetonate. Accordingto the prepared PVC heat stabilizer tin-doped lanthanum acetylacetonate, the adding amount of the tin-doped lanthanum acetylacetonate in PVC is 0.10%-0.15%, and the adding amount of the tin-doped lanthanum acetylacetonate is reduced by 25%-50% compared with that of a common heat stabilizer, by adding and using the heat stabilizer, rapid reduction of the heat stability of PVC can be remarkably inhibited, and meanwhile, the color change time of PVC is prolonged.

Owner:ANHUI UNIVERSITY

Preparation method of ultra-high molecular weight polyethylene/graphene antistatic composite material

The invention relates to a preparation method of an antistatic ultra-high molecular weight polyethylene (UHMWPE) / graphene composite material. The method comprises the following steps: putting UHMWPE and graphene powder in a high-speed stirrer to be stirred to obtain UHMWPE / graphene composite particles, wherein the graphene powder is added to the high-speed stirrer in 2-50 times and the materials are stirred for 10-30 seconds each time at a speed of 10000-30000r / min; preheating the UHMWPE / graphene composite particles at 180-240 DEG C for 5-10 minutes, and then carrying out hot pressing for 30 minutes under the conditions of the same temperature and 10MPa, thus obtaining the UHMWPE / graphene material. The method has the beneficial effects that solvents are not involved in the method; the required antistatic composite material is prepared through electrostatic adsorption and hot press molding; the prepared material has a three-dimensional net structure; the percolation value of the material is slightly higher than that of the material prepared by a solution method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Malodorous gas eliminating agent

The invention relates to a malodorous gas eliminating agent which uses at least one of zeolite powder and clay powder as a carrier and contains camphor, wherein the weight ratio range of the camphor to the carrier is 1:2-99; one or two of citric acid and ferrous sulfate can be additionally added as addition agents, the weight ratio range of the camphor to addition agents is 1:1-2, and the optimal weight ratio range of the camphor to the carrier is 1:7-19; the zeolite powder and the clay powder are obtained by screening fine powder obtained by grinding zeolite or active clay through a screen of 280-380 meshes preferably. The malodorous gas eliminating agent can eliminate malodorous odor after being sprayed into henhouses of a chicken farm or pig houses of a pig farm and can completely and cooperatively eliminate malodorous gas when being sprayed into a refuse dump. When feed materials are processed, the malodorous gas eliminating agent is capable of effectively eliminating odor, forming good quality for materials, also supplying a plurality of trace elements and increasing nutrient ingredients of feeds.

Owner:曲连文

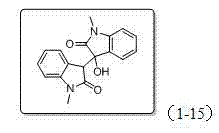

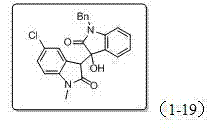

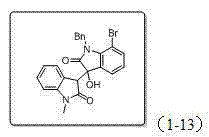

3,3'-disubstituted-3-hydroxy bis-indolinone derivative and preparation method and application thereof

InactiveCN102531995AReduce polarizationInhibit biological activityOrganic active ingredientsOrganic chemistryPtru catalystOrganosolv

The invention discloses a 3,3'-disubstituted-3-hydroxy bis-indolinone derivative and a preparation method and an application thereof. In the preparation method for the 3,3'-disubstituted-3-hydroxy bisindole ketone derivative disclosed by the invention, a one-step reaction is carried out on isatin and a diazo compound serving as raw materials by taking rhodium acetate as a catalyst and taking an organic solvent as a solvent, so that a product, i.e., the 3,3'-disubstituted-3-hydroxy bisindole ketone derivative is obtained. The preparation method disclosed by the invention has the advantages of high atom economy, high selectivity, high yield and the like, and is easy and safe for operating. The 3,3'-disubstituted-3-hydroxy bisindole ketone derivative prepared with the method is a precursor compound of a series of multi-indole ring-fused alkaloids.

Owner:EAST CHINA NORMAL UNIV

Method for detecting myrcene in soil by combining purging and trapping with GC-MS (Gas Chromatography-Mass Spectrometer)

ActiveCN114324657ALower requirementEasy to operateComponent separationAir quality improvementTrappingSediment

The invention discloses a method for detecting myrcene in soil by combining purging and trapping with GC-MS. The method comprises the following steps: firstly, collecting a soil or sediment sample, removing foreign matters, and adding 5.0 g of the sample into 5mL of ultrapure water; then placing the obtained sample in a purging and trapping sample injector, setting purging and trapping conditions to perform purging and trapping on the sample, purging myrcene in the sample out and entering a gas chromatograph-mass spectrometer, and setting chromatographic conditions of the gas chromatograph-mass spectrometer to analyze myrcene. According to the method, purging and trapping are combined with GC-MS, the detection efficiency is improved, the detection precision is greatly improved, the method is low in detection limit and good in repeatability, and myrcene in soil or sediment can be independently detected with high precision.

Owner:ZHEJIANG UNIV +1

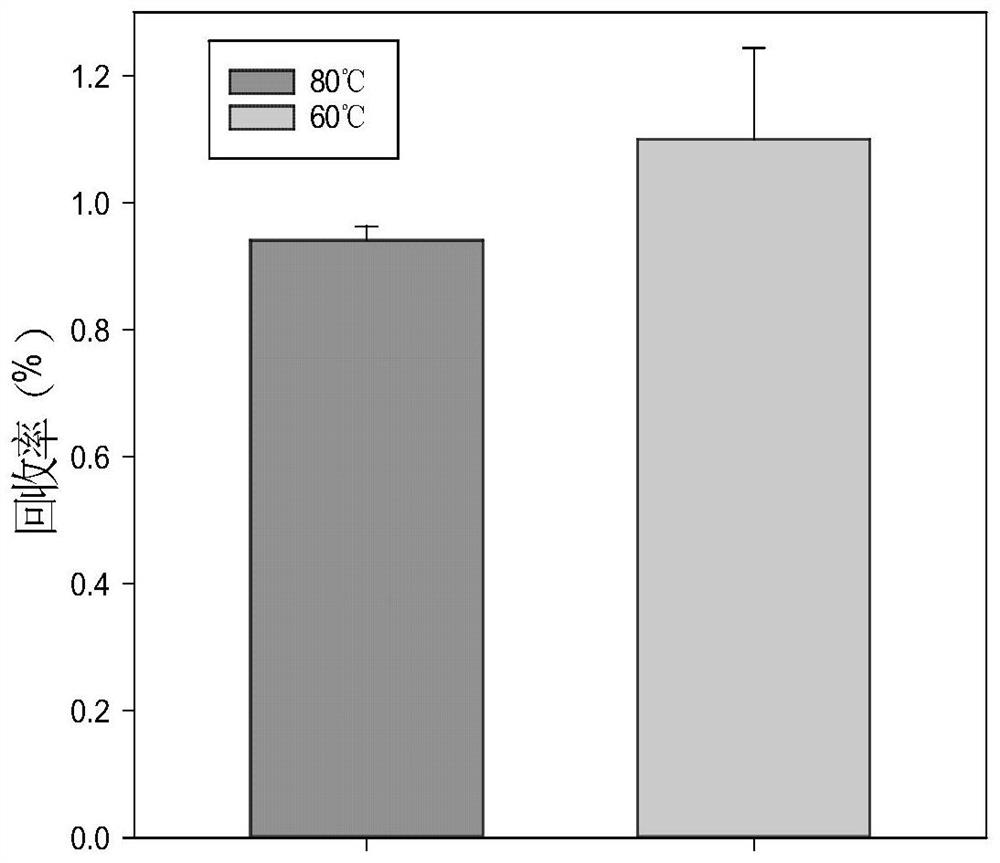

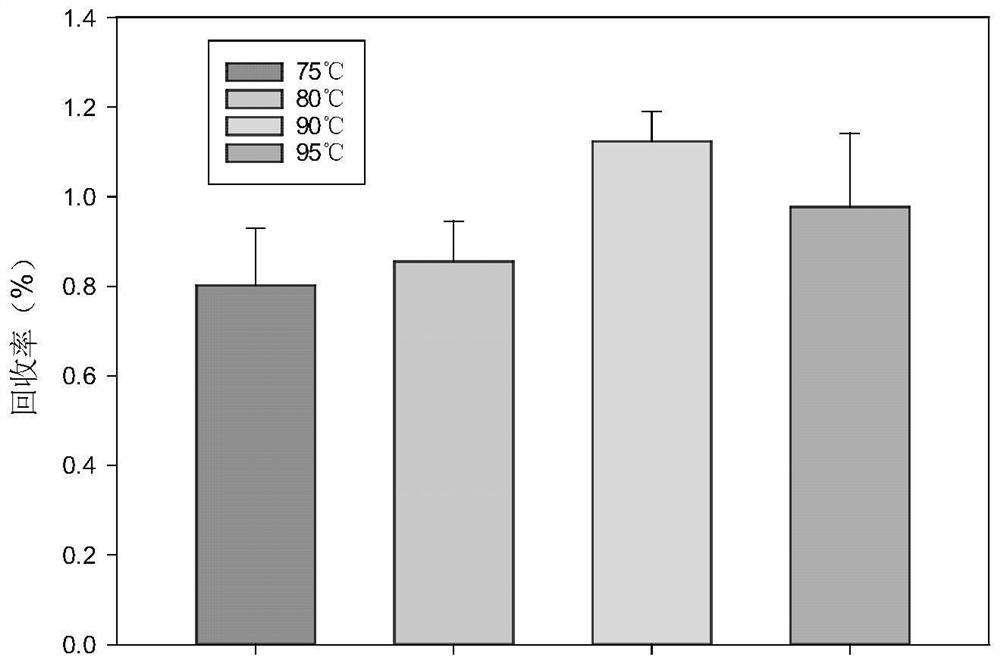

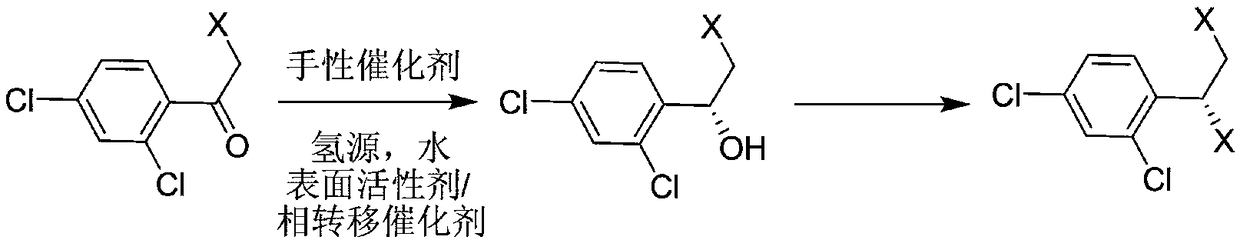

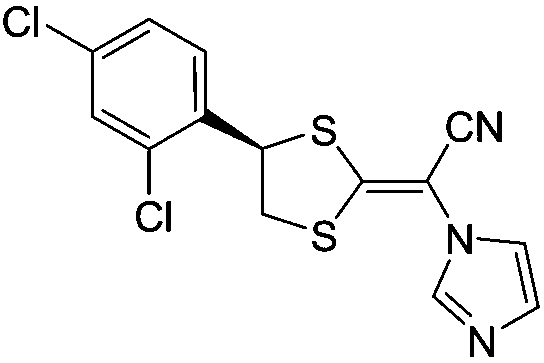

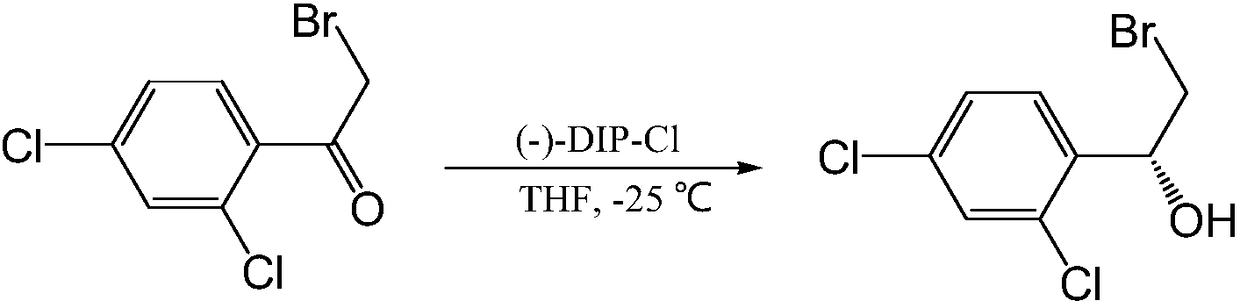

New synthesis method of luliconazole key chiral intermediate

InactiveCN108299156ALow costMild reaction conditionsOrganic compound preparationHydroxy compound preparationChemical synthesisBenzene

The invention discloses a new synthesis method of a luliconazole key chiral intermediate, belonging to the field of chemical synthesis. The method comprises the steps of firstly, preparing (R)-2-halogenated-1-(2,4-dichlorobenzyl)ethanol, and then carrying out halogenation on hydroxyl so as to obtain the synthesized luliconazole key chiral intermediate, i.e., (S) -2, 4-dichloro-1-(1,2-dihalogenatedethyl)benzene. According to the method, the preparation method of chiral alcohol is completed in a water phase, and an organic solvent does not need to be used, so that the harm of the organic solvent to the environment is reduced; a smaller amount of chiral catalyst is required by the method and can be recycled under the condition of extraction, so that the reaction cost is greatly lowered; furthermore, the method increases the yield of the final product (S)-2, 4-dichloro-1-(1,2-dihalogenated ethyl)benzene and is beneficial to industrial application.

Owner:ASTATECH CHENGDU BIOPHARM CORP

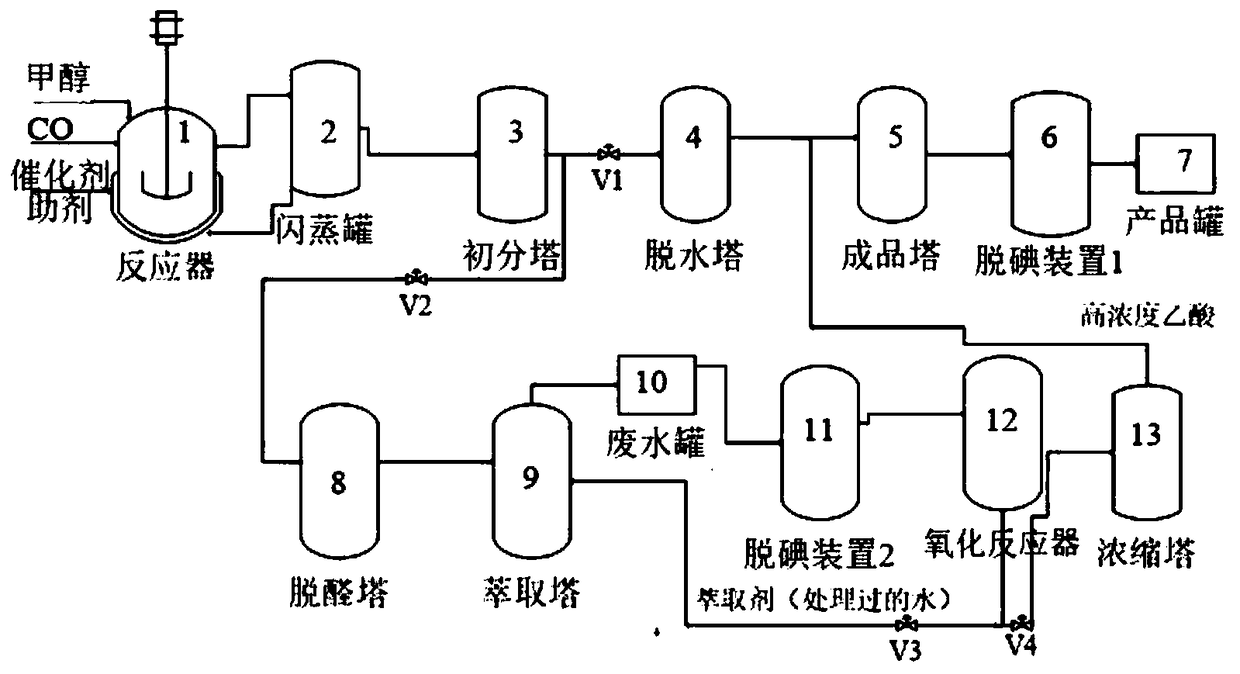

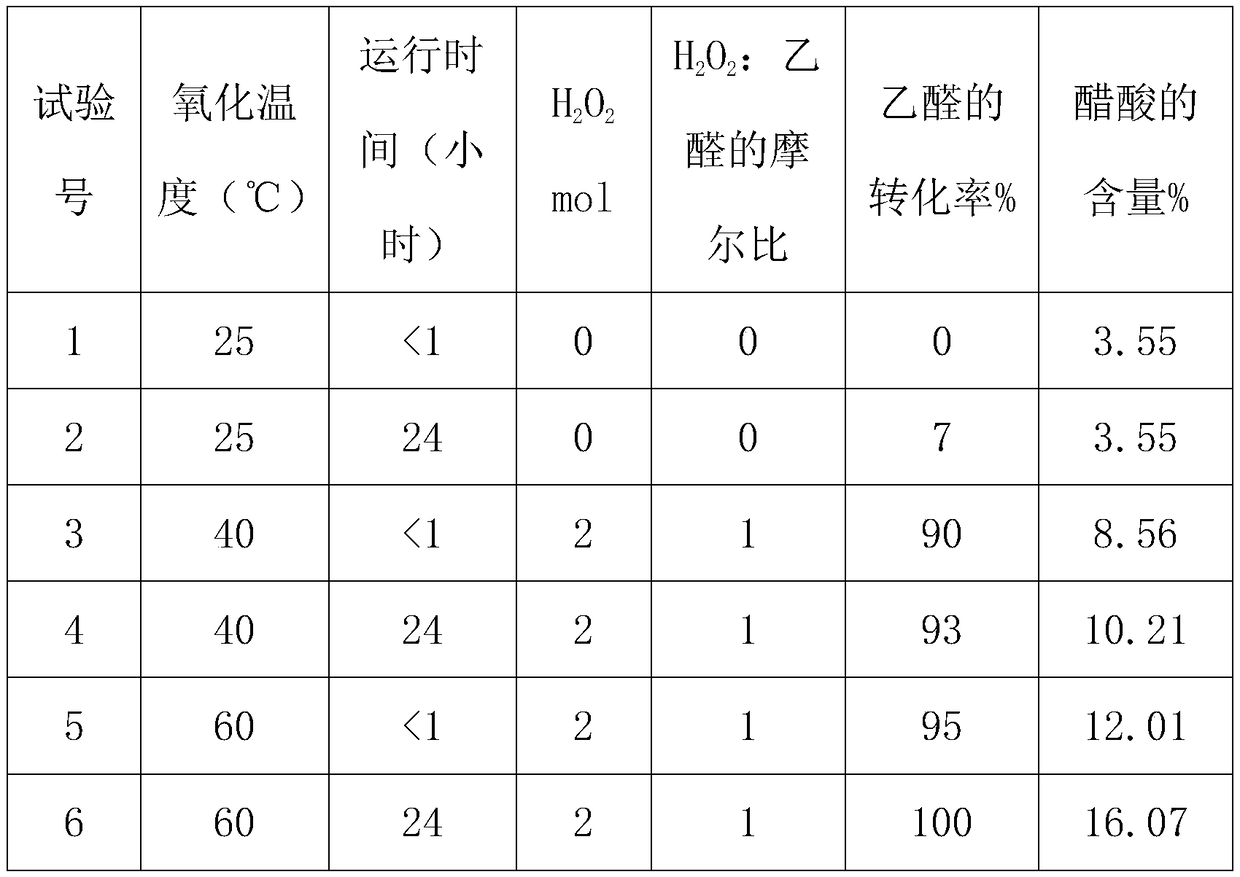

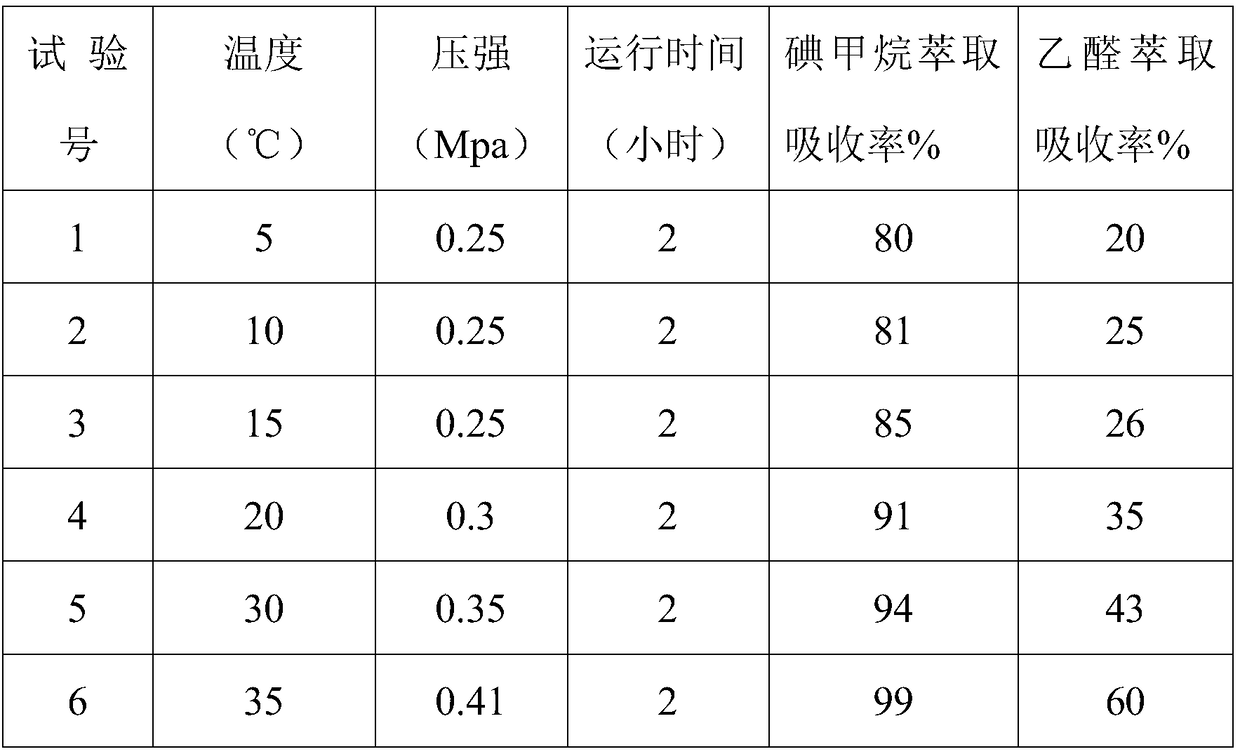

Technology for synthesizing acetic acid

InactiveCN109232223AAvoid pollutionAchieving Green ChemistryOrganic compound preparationChemical recyclingAcetic acid earAceric acid

The invention provides a technology for synthesizing acetic acid. A production technology mainly comprises the following step: enabling CO and methanol to generate the acetic acid in a reaction kettleunder the conditions that the pressure is 2.3 to 3.5Mpa and the temperature is 180 to 200 DEG C and under the actions of a rhodium catalyst, an iodomethane accelerant and a lithium iodide stabilizingagent; meanwhile, uniformly recycling an iodine-containing substance in a production process; after oxidizing the iodine-containing substance to obtain the acetic acid, recycling, wherein the recycled catalyst and extraction agent can be repeatedly utilized. A whole process technology is advanced and has the advantages of sufficient energy utilization, less energy source consumption, low production cost, high production efficiency and less investment equipment; a zero-emission environment-friendly technology is realized.

Owner:JIANGSU SOPO CHEM +1

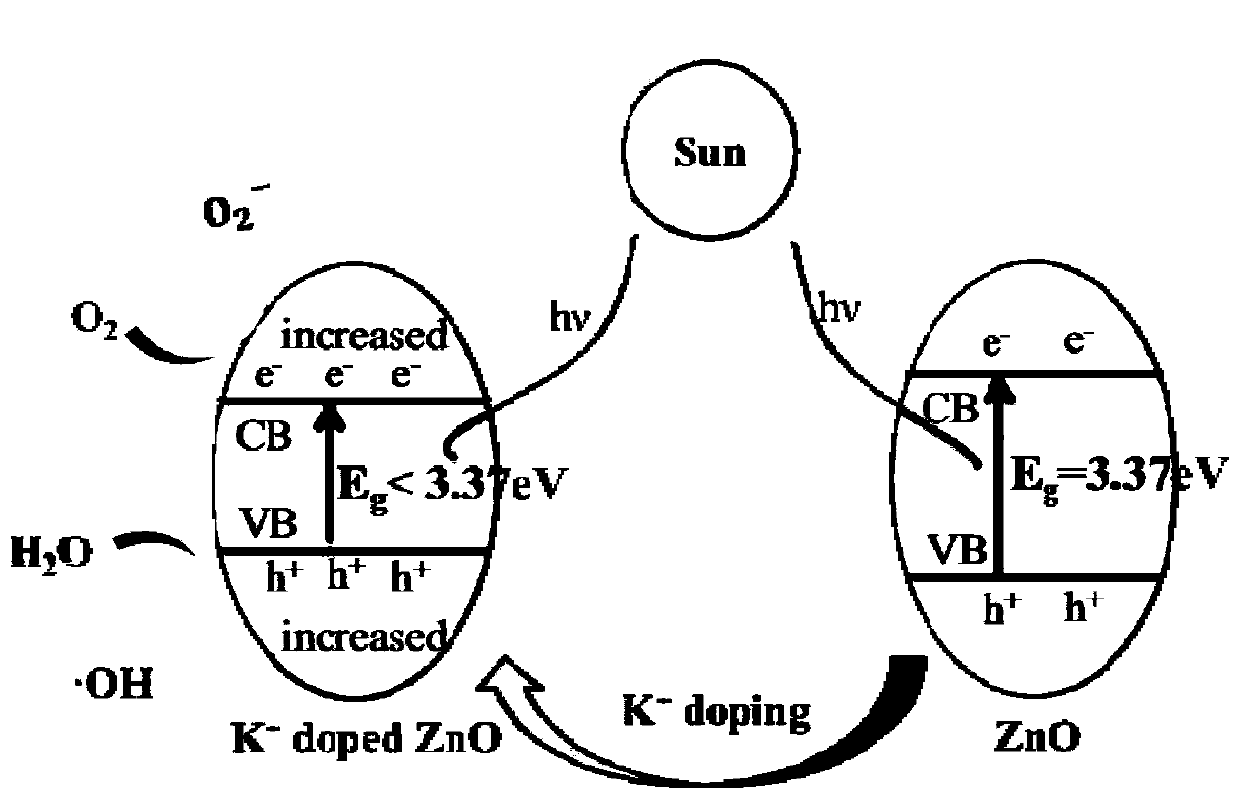

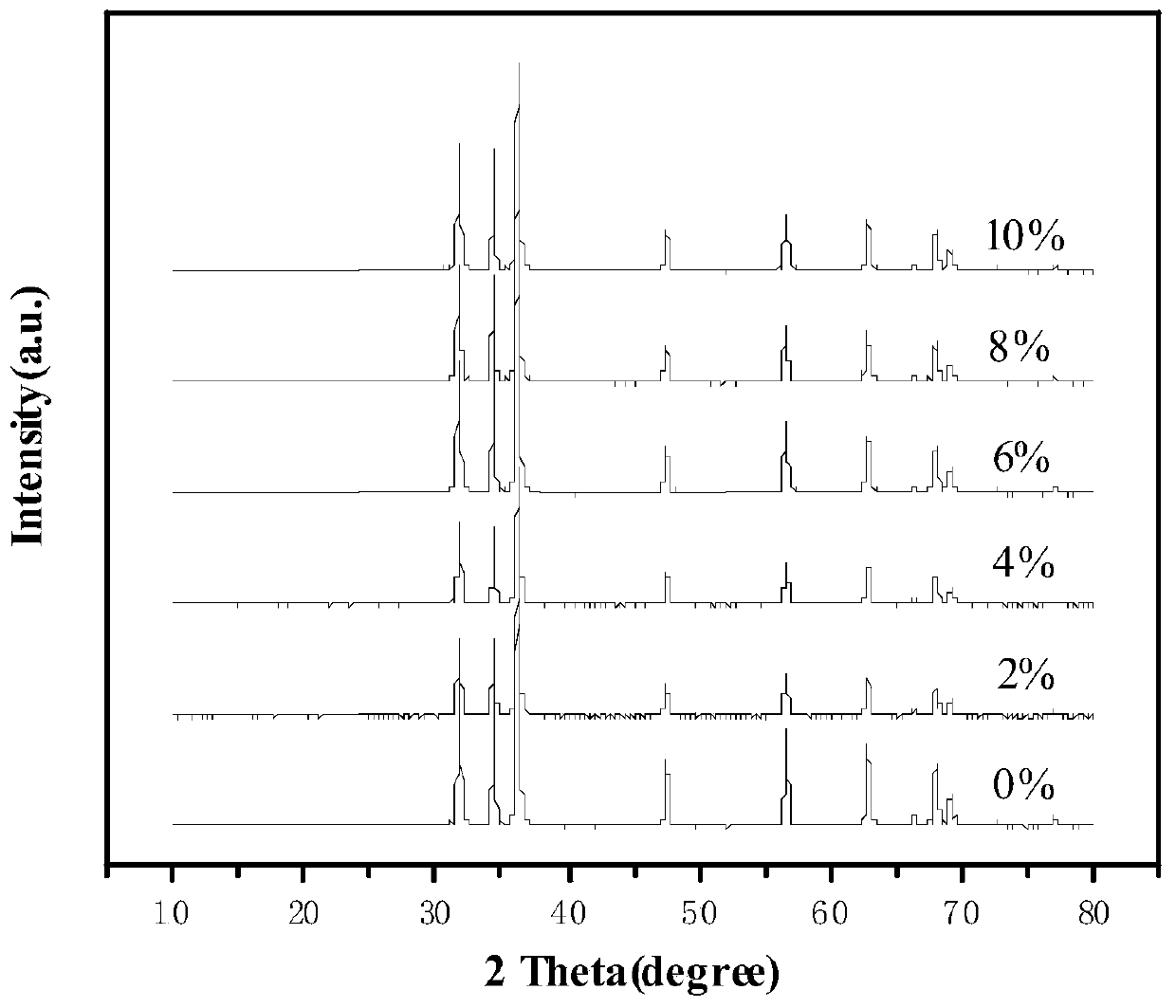

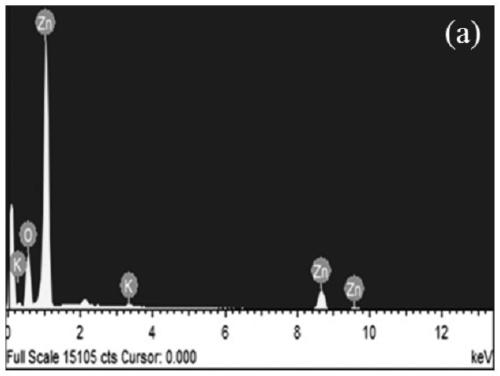

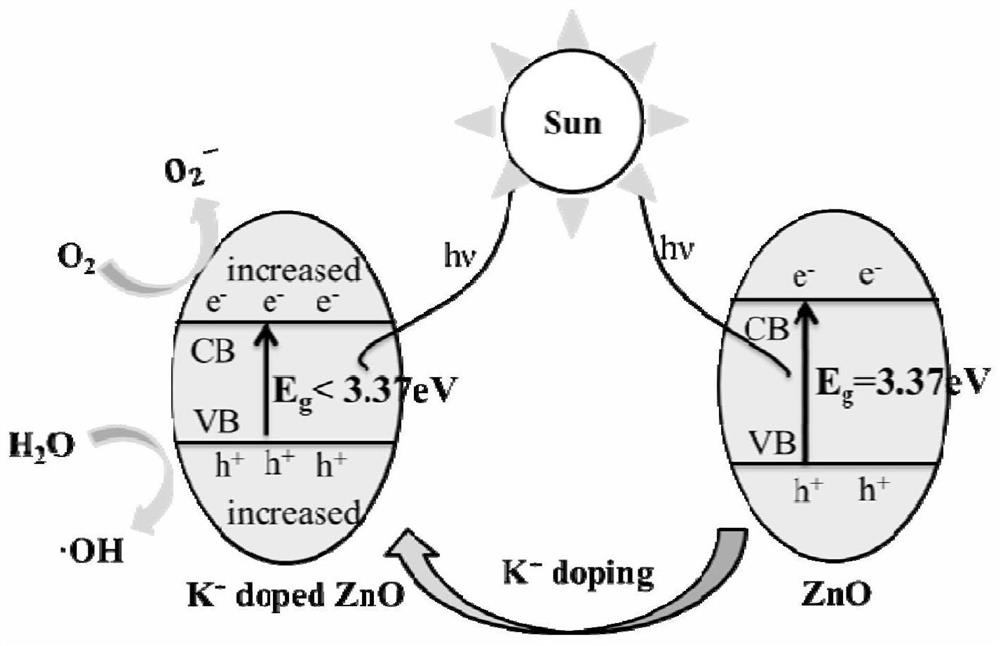

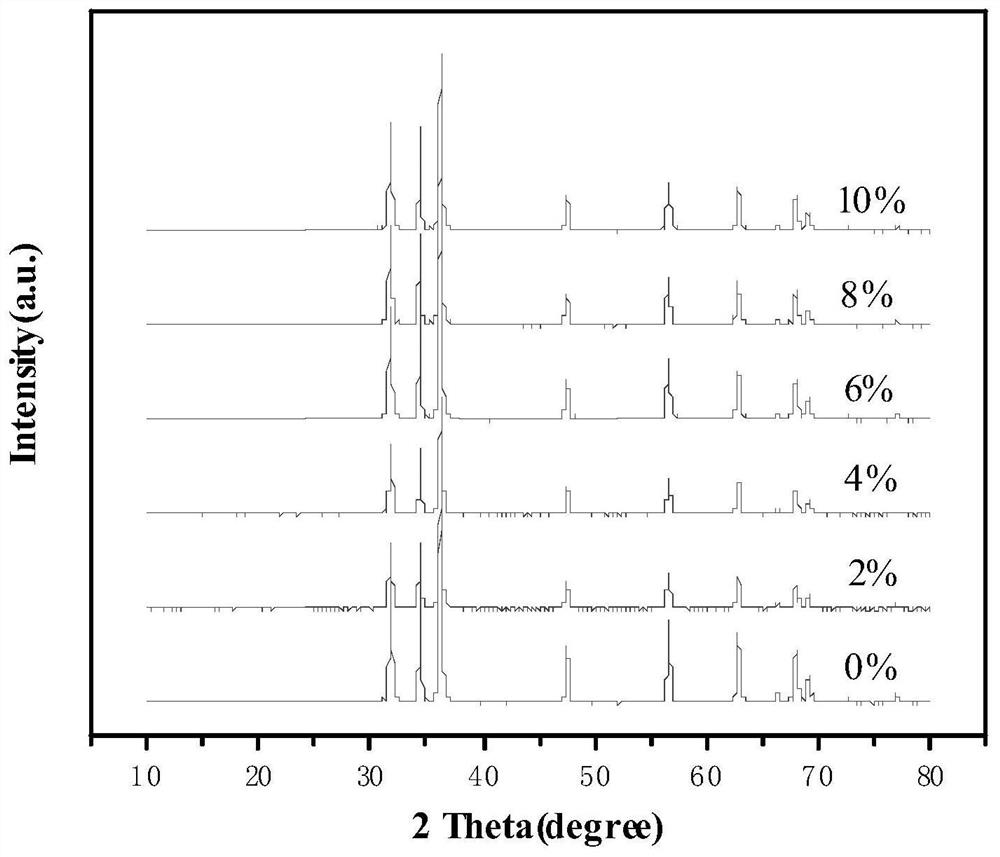

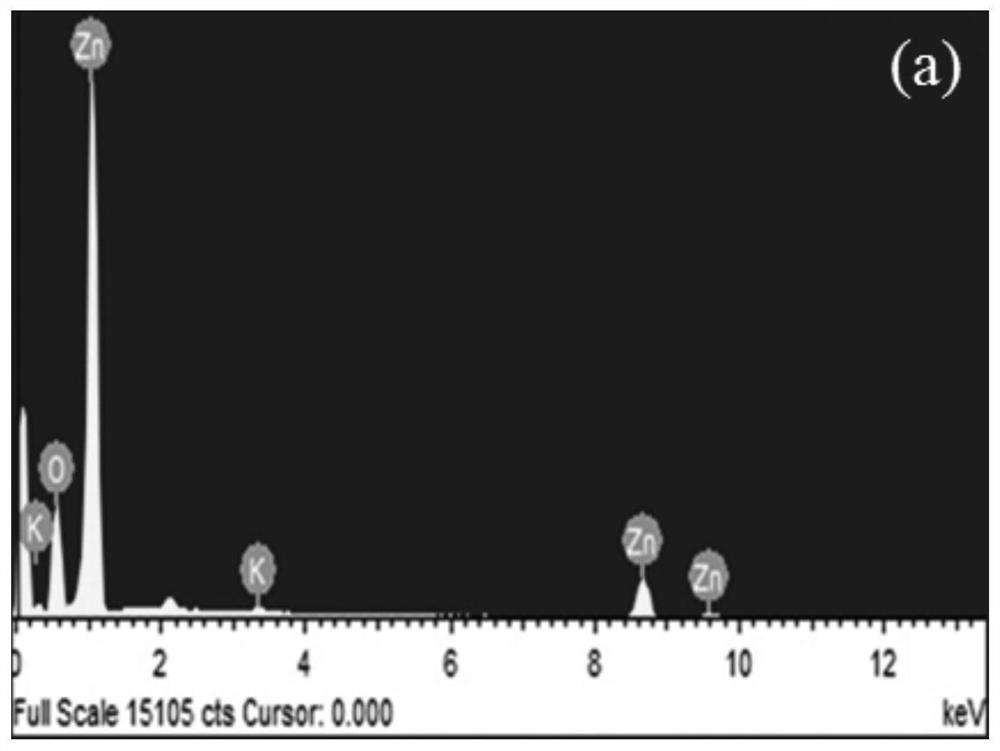

K-ion doped ZnO photocatalytic material, and preparation method and application thereof

ActiveCN110124657AEfficient separationReduce recombination rateGas treatmentOrganic compound preparationPotassiumElectronic band structure

The invention discloses a K-ion doped ZnO photocatalytic material, and a preparation method and an application thereof. The preparation method comprises the following steps: dissolving zinc salt intoan organic solvent, pouring potassium salt or potassium base with a certain molar ratio into a zinc salt solution under stirring, and continuing stirring until the potassium salt or potassium base isdissolved; placing an obtained mixed solution into an oven, and carrying out drying so as to obtain a precursor; and subjecting the precursor to high-temperature calcination so as to obtain K-ZnO. TheK-ion doped ZnO photocatalytic material prepared by using the method provided by the invention has the following advantages: the defect of low response of ZnO to visible light is improved; through the change of a band structure, the separation rate of electron holes is improved, and the recombination rate of the electron holes is reduced, so the photocatalytic activity can be effectively improved; the method has low cost, is simple and has simple operation; and the K-ion doped ZnO photocatalytic material can be utilized to degrade organic pollutants under the irradiation of the visible light.

Owner:LIAONING UNIVERSITY

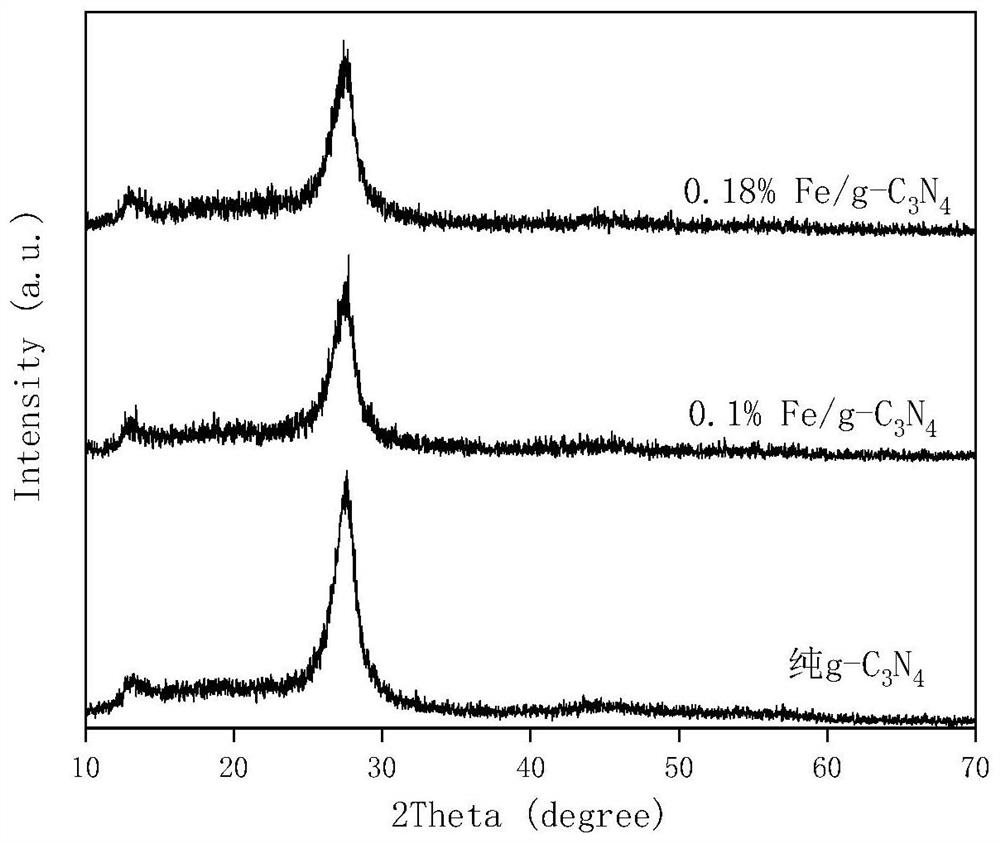

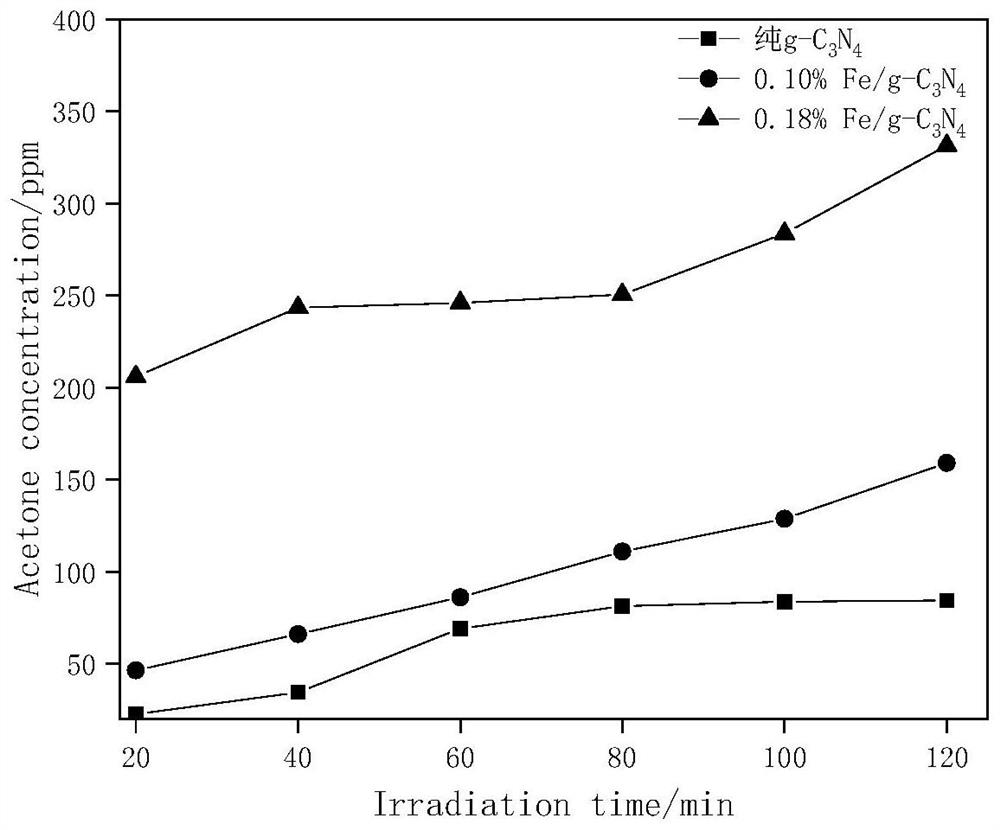

High-activity g-C3N4 photocatalytic material as well as preparation method and application thereof

PendingCN113019418AImprove photocatalytic activityRaw materials are cheap and easy to getGas treatmentDispersed particle separationPhoto catalysisNitrogen gas

The invention discloses a formaldehyde treated Fe ion doped g-C3N4 photocatalytic material as well as a preparation method and an application thereof. The preparation method comprises the following steps: a certain mass of iron salt is dissolved in deionized water, melamine is added into the solution, stirring is carried out, and ultrasonic treatment is carried out until the powder is uniformly mixed; the obtained precipitate is placed in a drying oven to be dried, the dried precipitate is placed in deionized water, water bath stirring is conducted till the solution is clear, a formaldehyde solution with a certain molar ratio is dropwise added, after water bath stirring is conducted for a certain time, the precipitate is placed in the drying oven to be dried, a precursor is obtained, the precursor is subjected to high-temperature calcination in a nitrogen environment, and formaldehyde-treated Fe-g-C3N4 is obtained. According to the formaldehyde-treated Fe ion-doped g-C3N4 photocatalytic material prepared by the method, the defect that g-C3N4 is low in response to natural light under visible light is overcome, the electron hole pair recombination rate is reduced, the photodegradation rate is increased, the photocatalytic activity can be effectively improved, and the method is low in cost, simple and easy to operate. Under natural light, organic pollutants can be degraded through illumination.

Owner:LIAONING UNIVERSITY

New technology for catalytically cracking light diesel oil from waste motor oil

InactiveCN101531948BEliminate pollutionReduce pollutionCatalytic crackingLubricant compositionDistillationOil water

The invention belongs to the diesel oil refining technology, especially a new technology for catalytically cracking light diesel fuel from waste motor oil. Currently, the drawbacks of the prior technology for refining the waste motor oil into diesel oil are that: the cetane number falls short of national standard and the chroma is deep and opaque, the recovery is low and the technology is complex. The new technology comprises the following steps: adding waste motor oil into a reaction kettle; adding a hone-made good catalyst accounting for 1 / 1000 of the weight of the waste motor oil; heating to 300-500 DEG C to make the waste motor oil catalytically crack, finally obtaining distillation product; putting the distillation product into a condenser, making the condensed liquid-sate light diesel oil and the tail gas through an oil-gas splitter, making the tail gas into a gas collector; split diesel oil flowing into a treatment tank, adding high efficiency treating agent with concentration of 5 / 10000 into the treatment tank, treating the diesel oil using a backflow spray head; finally layering and filtering the treated light diesel oil by an oil water splitter, namely the yellow transparent light diesel oil with flash point >55 DEG C is obtained, with recovery of higher 80%.

Owner:熊道陵 +2

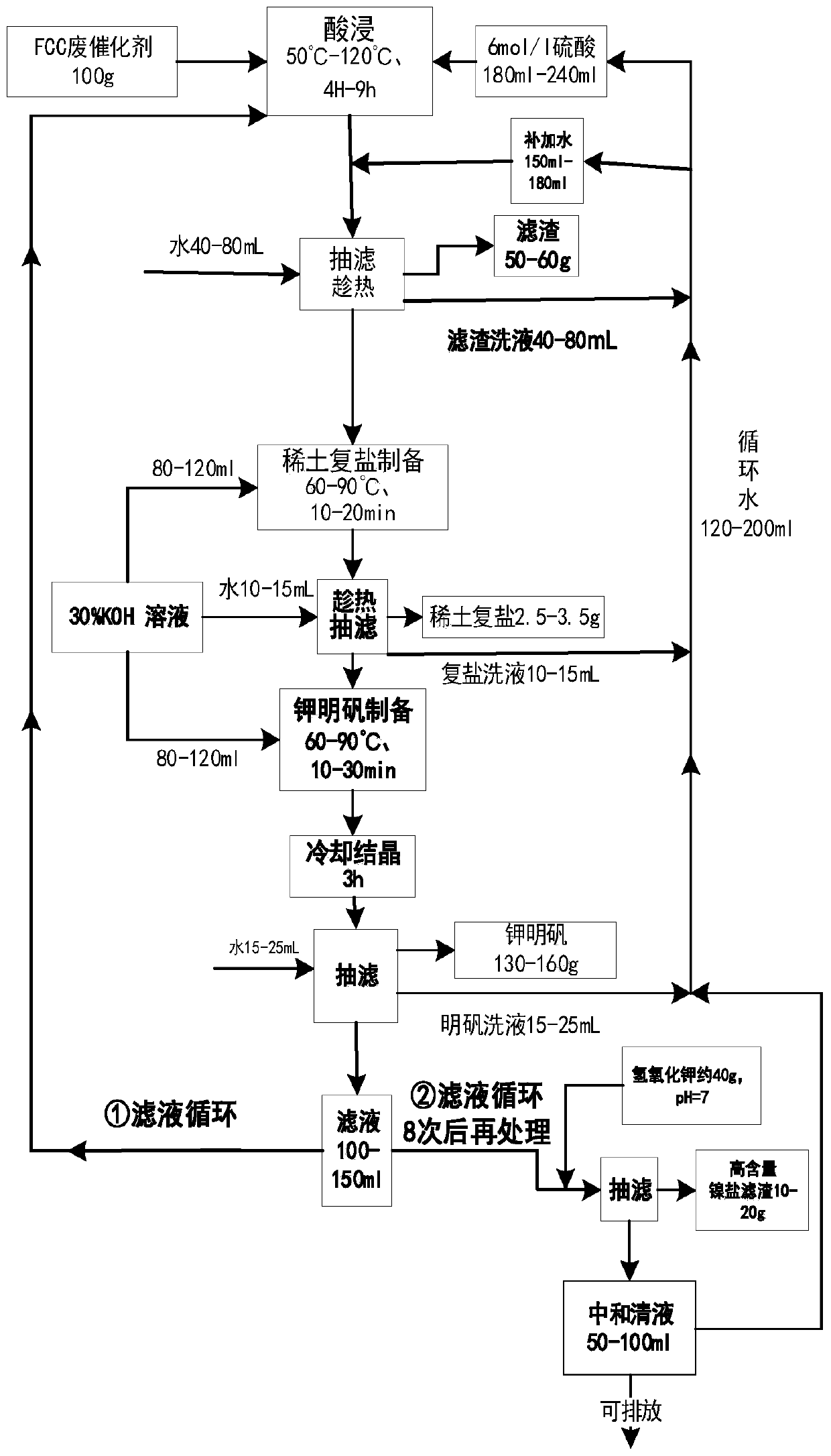

Technology for coproducing potassium alum and high-content lanthanum and cerium rare earth composite salt by using FCC waste catalyst

InactiveCN110563014AAchieve cycleEmission reductionTreatment involving filtrationMultistage water/sewage treatmentReduction treatmentRare earth

The invention discloses a technology for coproducing potassium alum and a high-content lanthanum and cerium rare earth composite salt by utilizing an FCC waste catalyst. The technology comprises the following steps: (1) carrying out drying and screening pretreatment on the waste catalyst; 2) leaching the waste catalyst with sulfuric acid; 3) preparing the lanthanum and cerium rare earth compositesalt by a potassium hydroxide method; 4) preparing the potassium alum; and 5) treating a circulating liquid. The technology can achieve the preparation of the potassium alum and the high-content lanthanum and cerium rare earth composite salt and realize harmless and reduction treatment of hazardous wastes by treating the FCC waste catalyst, so a reasonable and effective way is found for the harmless treatment and comprehensive utilization of the FCC waste catalyst.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

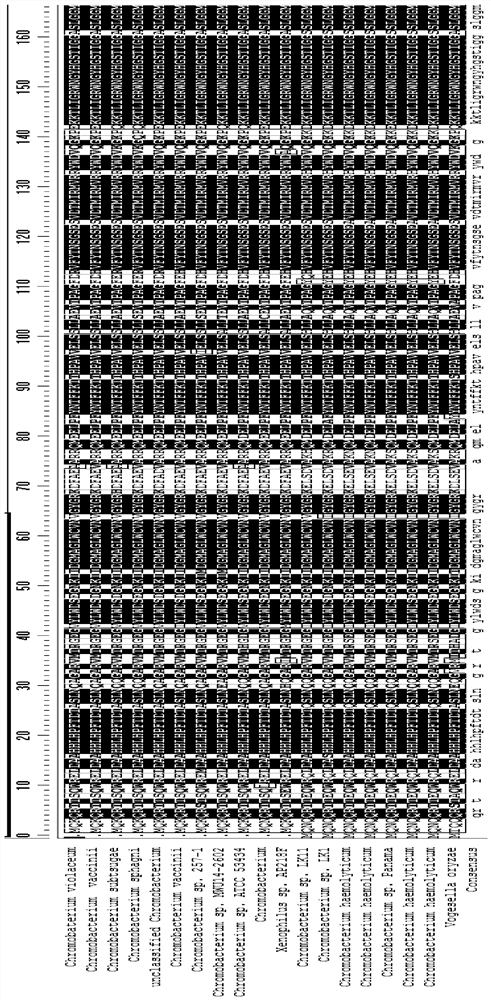

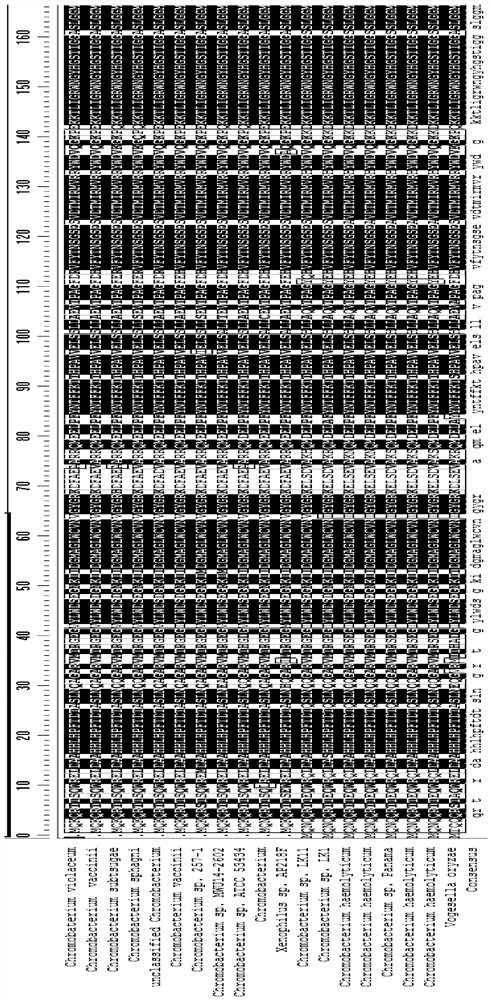

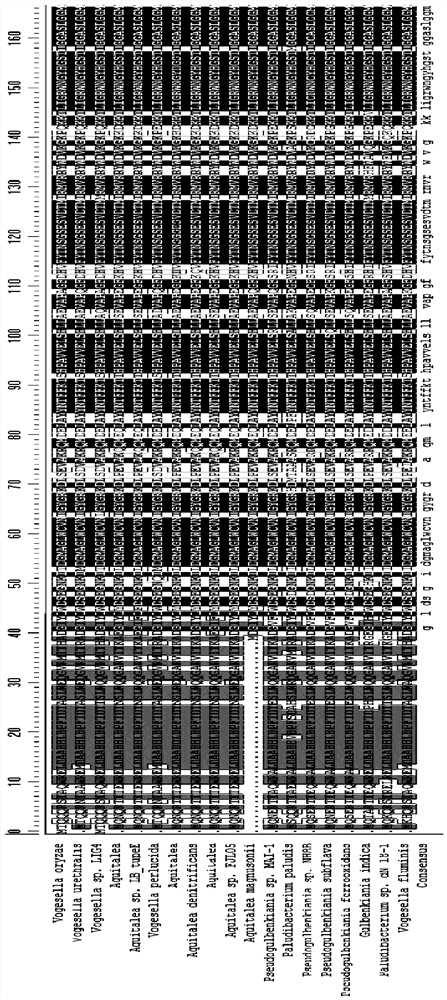

Transaminase mutant and application thereof

InactiveCN112501145AHigh activityHigh selectivityTransferasesGenetic engineeringChemical synthesisChemical compound

The invention provides a transaminase mutant and an application thereof. The transaminase mutant is obtained by mutation of one or more amino acids in SEQ ID NO: 2 or is a mutant which is obtained bymutation of conservative amino acids at the 54th-63rd site and the 84th-96th site by taking the sequence SEQ ID NO: 1 of wild type CvTA transaminase as a reference. The catalytic activity of the mutants is improved to different extents compared with that of wild transaminase, so that mutants are used for synthesizing chiral amine compounds, especially synthesizing chiral amine with large steric hindrance, the production efficiency is improved, and the industrial production cost is reduced. The biological enzyme is adopted for green chemical synthesis, thereby being beneficial to reducing industrial three wastes.

Owner:ASYMCHEM LAB TIANJIN

Method for synthesizing terephthalonitrile

ActiveCN112961075AHigh yieldEfficient use ofPhysical/chemical process catalystsPreparation by carboxylic acid amide dehydrationPtru catalystCatalytic oxidation

The invention provides a method for synthesizing terephthalonitrile. The method comprises the following steps: performing catalytic oxidation reaction on paraxylene serving as a raw material in the presence of a vanadium catalyst, and controlling the reaction of synthesizing an intermediate product to obtain the terephthalonitrile. The production of byproducts in the ammoxidation process can be effectively reduced in the reaction process, so that the yield of terephthalonitrile is greatly improved, the raw materials are effectively utilized, impurity products in the product are few, and the post-treatment process is simplified. And the method is beneficial to realization of green chemistry, and is suitable for large-scale production.

Owner:ANSHAN HIFICHEM CO LTD

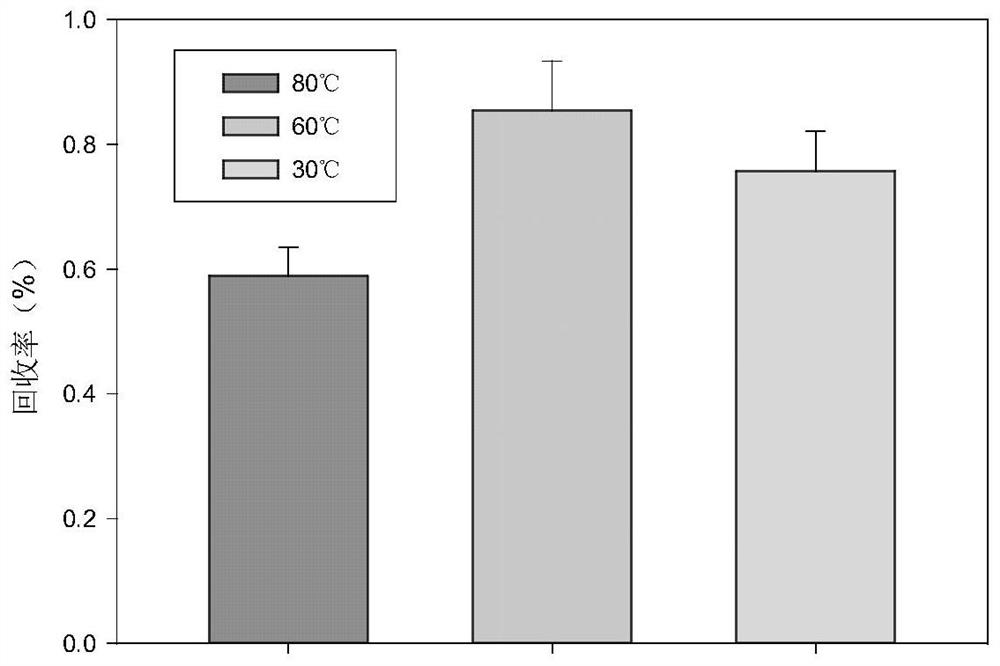

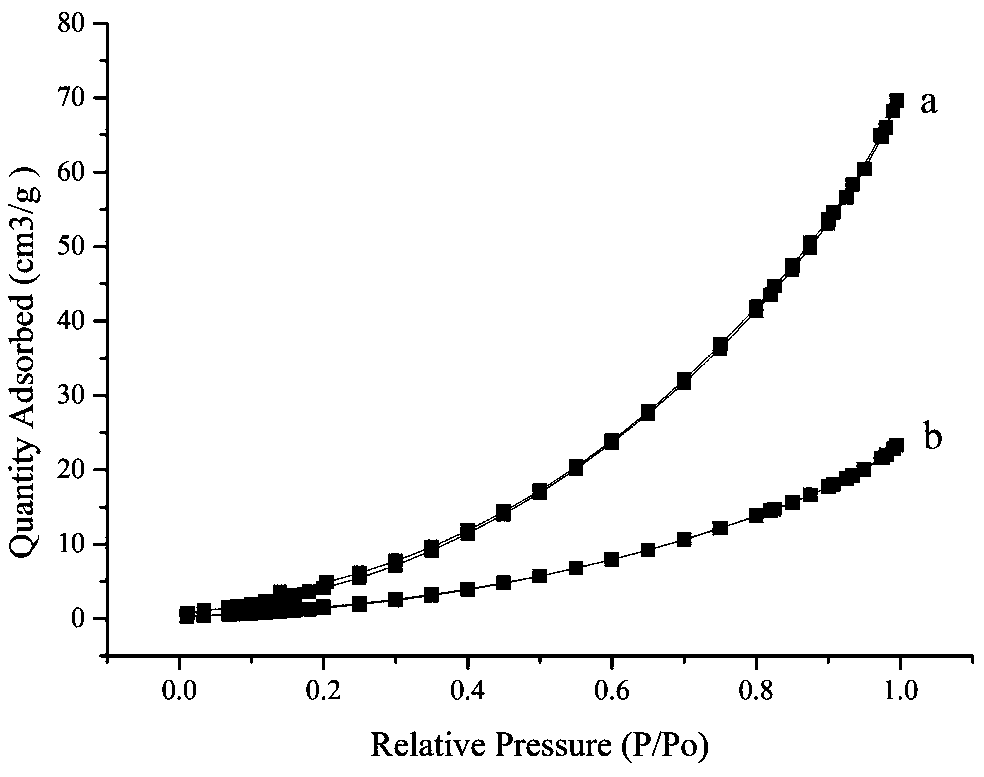

Polymer continuous bed and method for online ursolic acid enrichment and purification

ActiveCN110376321ALarge specific surface areaOptimized areaComponent separationCarbon nanotubeUrsolic acid

The invention provides a polymer continuous bed and method for online ursolic acid enrichment and purification. The polymer continuous bed of a whole porous material is prepared from multi-wall carbonnanotubes with double bonds after silylanization, styrene and ethylene glycol dimethacrylate by redox polymerization. The preparation method is simple, the polymer continuous bed for online ursolic acid enrichment and purification is high in specific surface area and excellent in porous structure, the active force between the polymer continuous bed and ursolic acid is increased, the ursolic acidcan be enriched online effectively, the adsorption quantity is large, the detection limit is low, the precision, sensitivity and accuracy of analysis and detection are improved, the recovery rate is high, operation steps as sample pretreatment are simplified, pretreatment time of samples is greatly reduced, and further the method is economic, practical and facilities green chemistry.

Owner:HEBEI UNIVERSITY

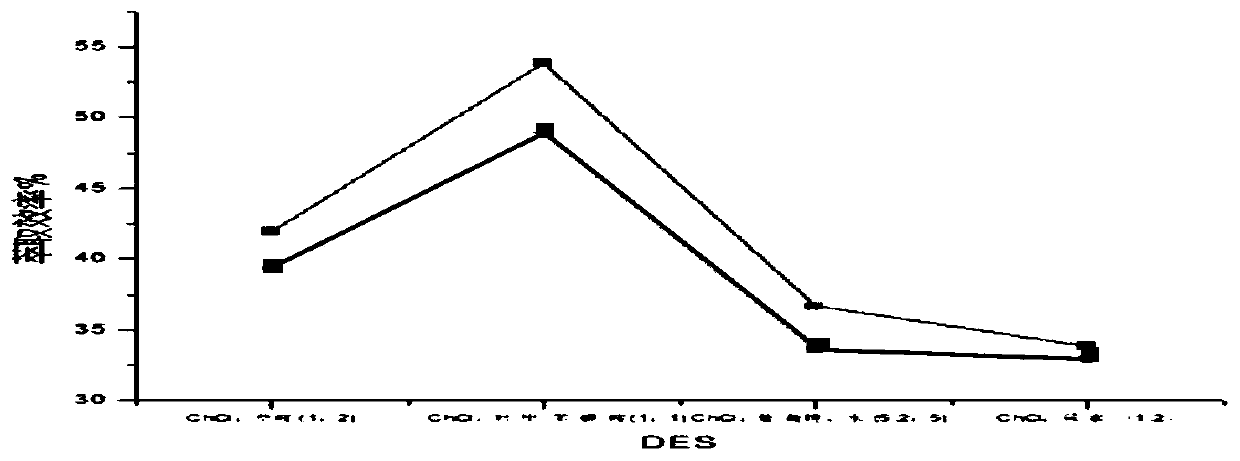

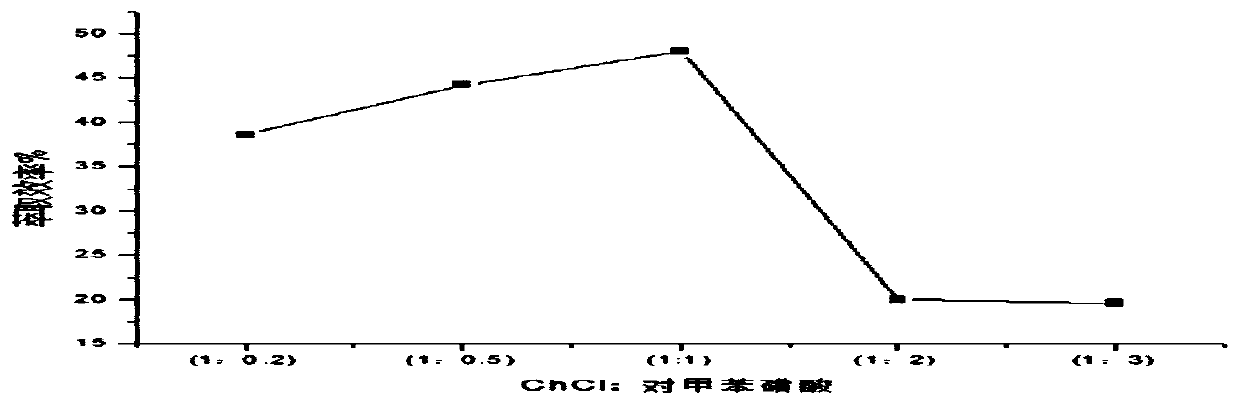

Method for separating alcohol in alcohol ester mixture by using deep eutectic solvent

InactiveCN110357764AImprove extraction efficiencyEasy to operateOrganic compound preparationCarboxylic acid esters preparationIsoamyl alcoholP-Toluenesulfonic acid

The invention discloses a method for separating alcohol in an alcohol ester mixture by using a deep eutectic solvent. The method comprises the following steps: step 1, mixing choline chloride and p-toluenesulfonic acid according to a molar ratio of 1: (0.5-1.5) to obtain the deep eutectic solvent; and step 2, mixing the obtained deep eutectic solvent and an isoamyl alcohol-isoamyl acetate mixtureaccording to a solid-liquid ratio of (2.5-4): 1, wherein the isoamyl alcohol-isoamyl acetate mixture has an alcohol-ester molar ratio of 1: (1.5-3.5), performing extraction, and taking out an upper-phase solution so as to separate isoamyl alcohol in the alcohol-ester mixture. According to the invention, the deep eutectic solvent obtained by mixing choline chloride and p-toluenesulfonic acid according to a certain ratio is used for extracting the isoamyl alcohol-isoamyl acetate mixture, and the solid-liquid ratio of the deep eutectic solvent to the alcohol ester mixture and the alcohol-ester ratio of the alcohol ester mixture are optimized, so extraction efficiency can be greatly improved, and optimal extraction efficiency can reach 57% or more; and the method is suitable for industrial production and can realize green chemistry.

Owner:BAODING UNIV

Method of synthesizing 1-methyl hydantoin

The present invention relates to a synthetic method of 1-methyl hydantoin, which belongs to synthetic method of compounds. The synthetic method includes following steps, adding 46.5g 30% aminomethane water solution, 106g 10% sodium carbonate water solution and 87.5g 20% 500ml 4-opening flasksodium monochloracetate water solution to react for 3 to 5hr at 50 to 70 DEG C; vaporizing to remove aminomethane and regulating pH value to 2; Heating to 100DEG C, dropping 91g 8% sodium cyanate water solution, agitating and reacting 30 minutes, adding 7.3g sodium cyanate solid to react 90 minutes, then cooling it to 5 DEG C, adding 25g concentrated sulfuric acid, heating to 100 DEG C and reflux reacting 2hr, generating crude product by vacuum distilling. The present invention is characterized in thatit implement green chemical because of avoiding using hypertoxic medicine of hydroxy acetonitrile and enhance the safety of operation, and its synthesis cost is low, entire syntheticroute is more simple, which is suitable for large scale industrial production.

Owner:王永生

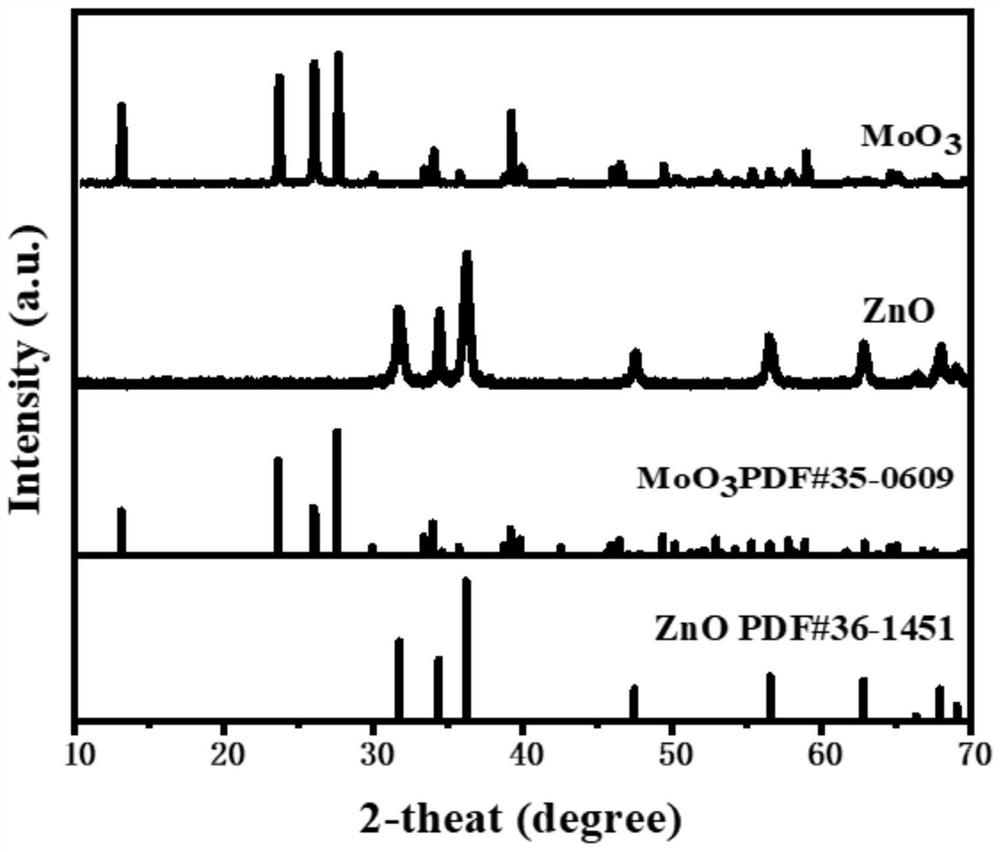

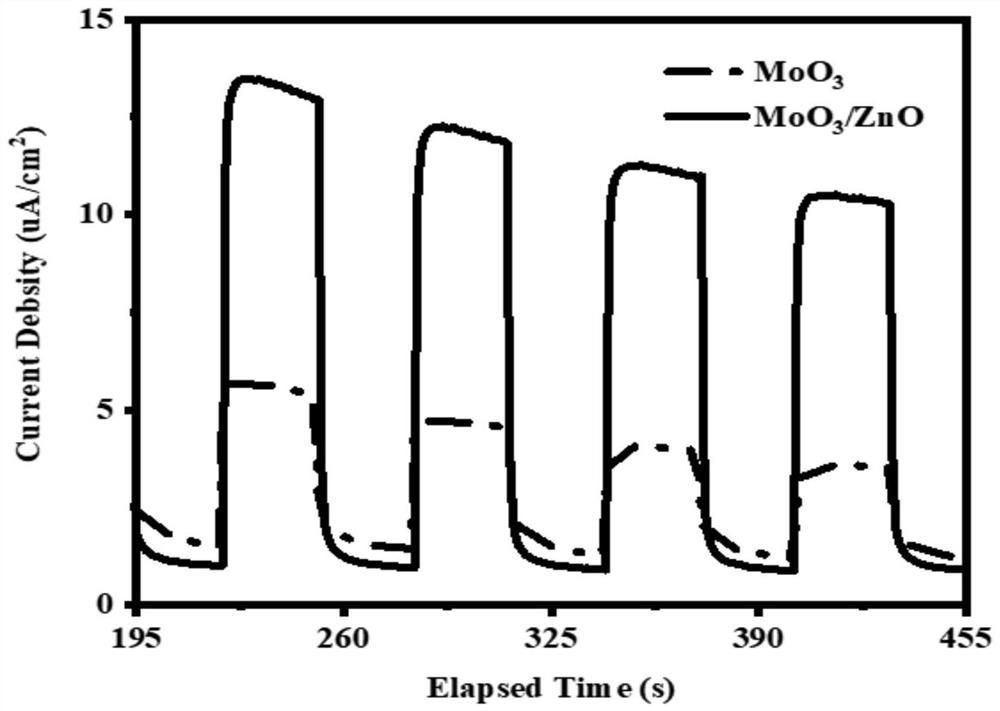

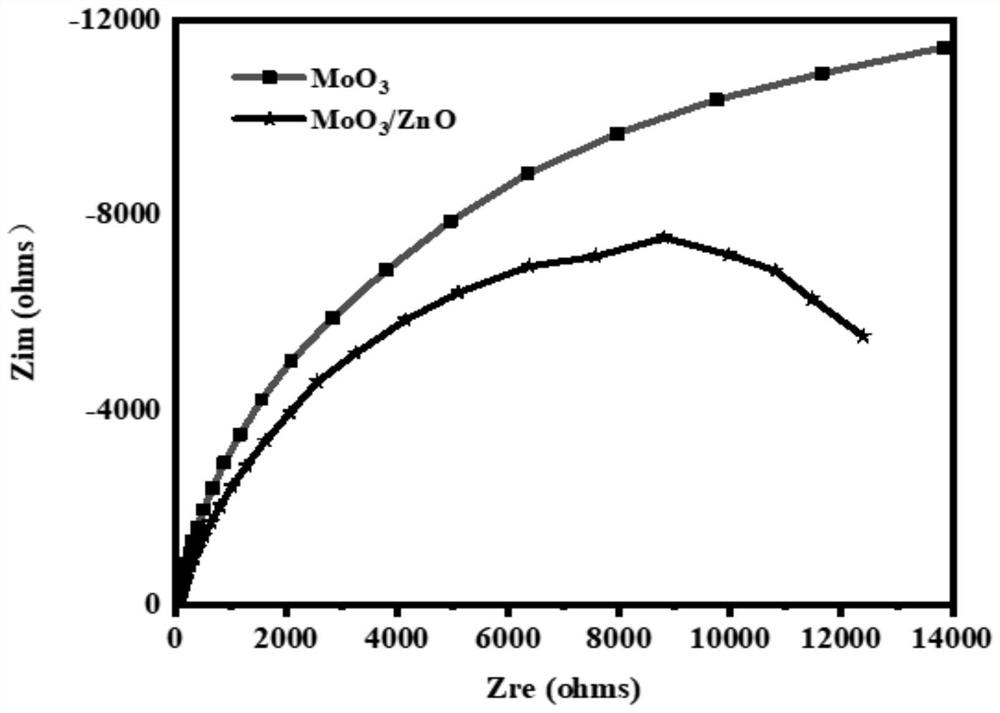

Preparation method and application of heterojunction MoO3/ZnO photoelectrode film

PendingCN114592212AReduce recombination rateImprove photoelectrochemical performanceEnergy inputElectrodesElectron transmissionThin membrane

The invention discloses a preparation method and application of a heterojunction MoO3 / ZnO photoelectrode film. The method comprises the following steps: putting cleaned conductive glass (FTO) into an acetone solution of MoO3, and obtaining a MoO3 film by adopting an electrophoretic deposition method. Putting ZnO into an acetone solution for ultrasonic dispersion, putting the obtained MoO3 thin film into the acetone solution of ZnO, and overlapping a layer of ZnO thin film on the MoO3 thin film by adopting an electrophoretic deposition method; and carrying out high-temperature annealing on the obtained product to obtain the MoO3 / ZnO heterojunction film. The MoO3 / ZnO photoelectrode film prepared by the invention is used for improving the photo-induced electron transmission capability of a MoO3 photoelectrode, so that the photoelectrochemical performance can be effectively improved, and the photocorrosion resistance of MoO3 is enhanced.

Owner:LIAONING UNIVERSITY

K ion doped zno photocatalytic material and its preparation method and application

ActiveCN110124657BEfficient separationReduce recombination rateGas treatmentOrganic compound preparationCalcinationPhotochemistry

Owner:LIAONING UNIVERSITY

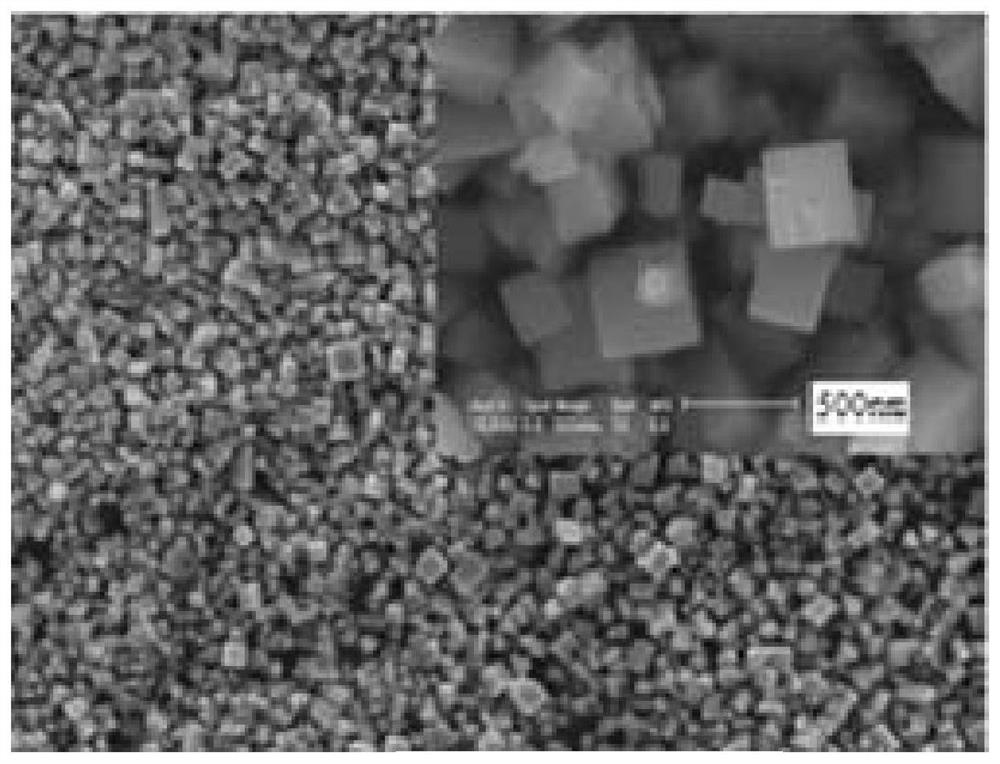

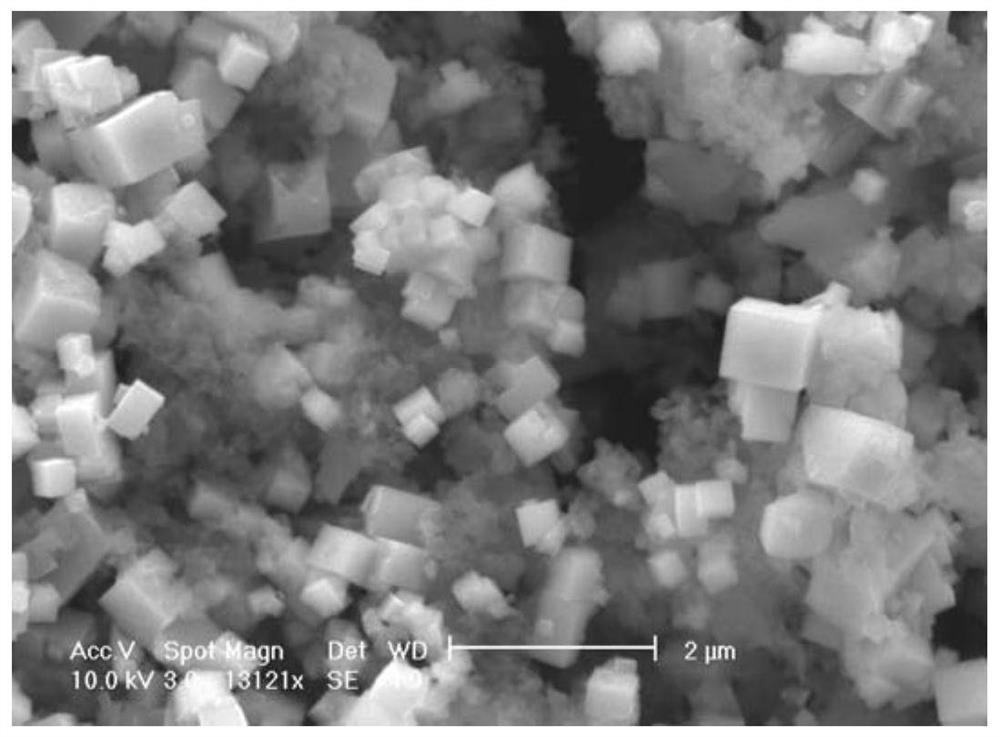

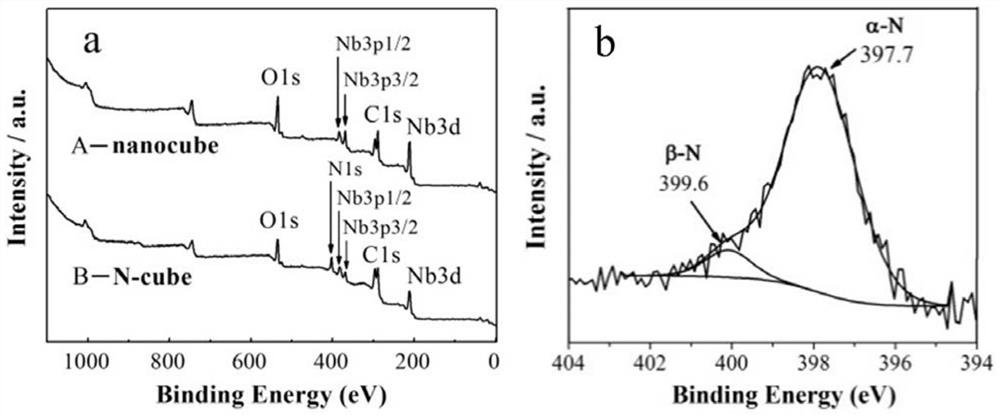

Nitrogen-doped potassium niobate nano photocatalyst and preparation method and application thereof

InactiveCN113856733ANo pollution in the processRaw materials are cheap and easy to getWater/sewage treatment by irradiationWater treatment compoundsNano catalystPtru catalyst

The invention discloses a nitrogen-doped potassium niobate nano photocatalyst and a preparation method and application thereof. The catalyst is prepared through the following steps: 1, weighing Nb2O5 and KOH and putting into a hydrothermal reaction kettle, then adding deionized water, stirring the mixture to be uniform, putting the reaction kettle into a drying oven for a reaction, after the reaction is completed, cooling the reaction kettle to the room temperature and taking out, centrifugally separating and washing white powder at the bottom until the white powder is neutral, and drying to obtain KNbO3 nano powder; and 2) weighing the KNbO3 nano-powder and urea, grinding, stirring and mixing uniformly, putting into a muffle furnace for reaction, and naturally cooling to room temperature after the reaction is finished to obtain the target product nitrogen-doped potassium niobate nano photocatalyst. The catalyst is a nano square block with flocculent attachments, has a side length of 150-450 nm, has visible light response, and can be used for photocatalytic degradation of organic pollutants, especially orange G, pentachlorobiphenyl and bisphenol A, under visible light.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com