Sulfur-doped graphite-phase carbon nitride nanosheet photocatalyst and preparation method and application thereof

A graphitic carbon nitride and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of low photocatalytic activity, large particle size, small specific surface area, etc., and achieves cheap and easy-to-obtain raw materials, reduced recombination rate, and simple and fast operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Pure g-C 3 N 4 (CNO) photocatalyst

[0030] (1) Preparation method

[0031] Put 3.76g of melamine directly into the crucible, and in a tube furnace, carry out calcination treatment at 550°C in a nitrogen atmosphere and keep it for 4h, with a heating rate of 5°C / min, to obtain pure g-C 3 N 4 (CNO) photocatalyst.

[0032] (2) Detection

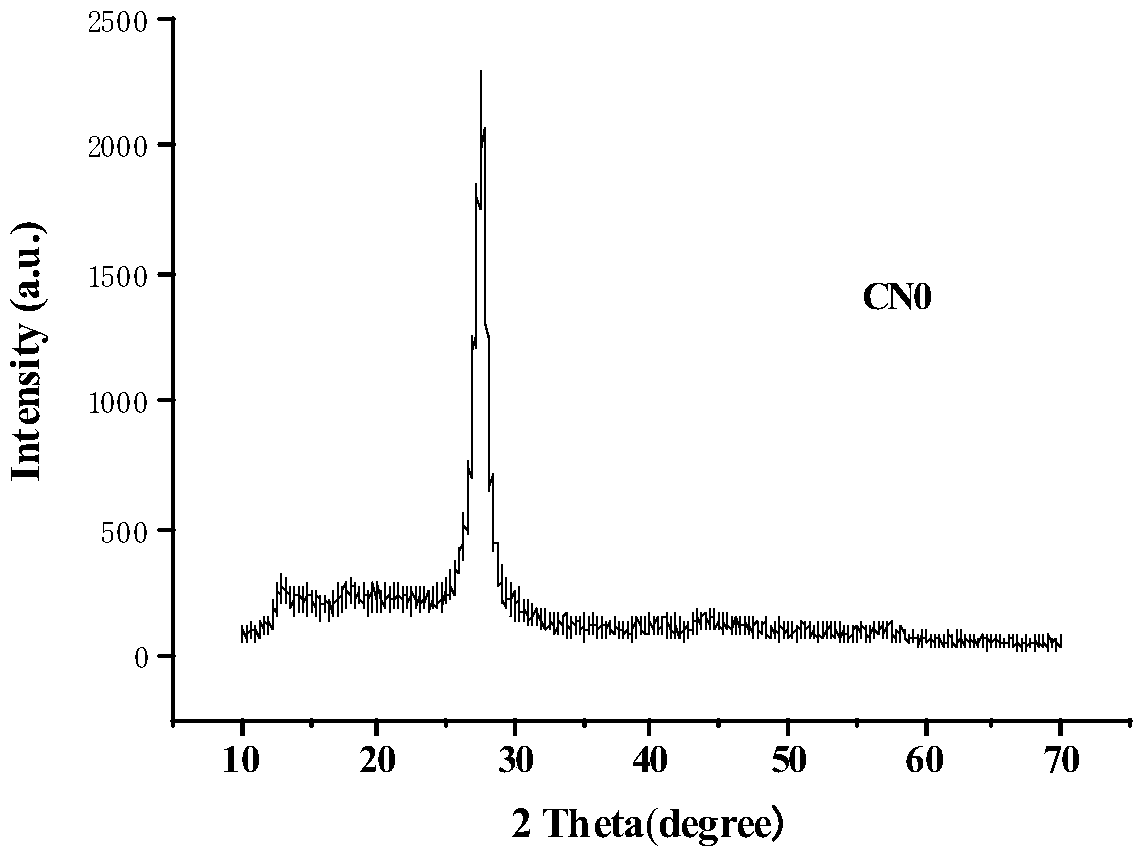

[0033] figure 1 For the XRD test pattern of the CNO prepared in embodiment 1, by figure 1 It can be seen that the sample has two diffraction peaks at 13° and 27°. It can be calculated from the formula that the grain size of the sample is about 15.2nm.

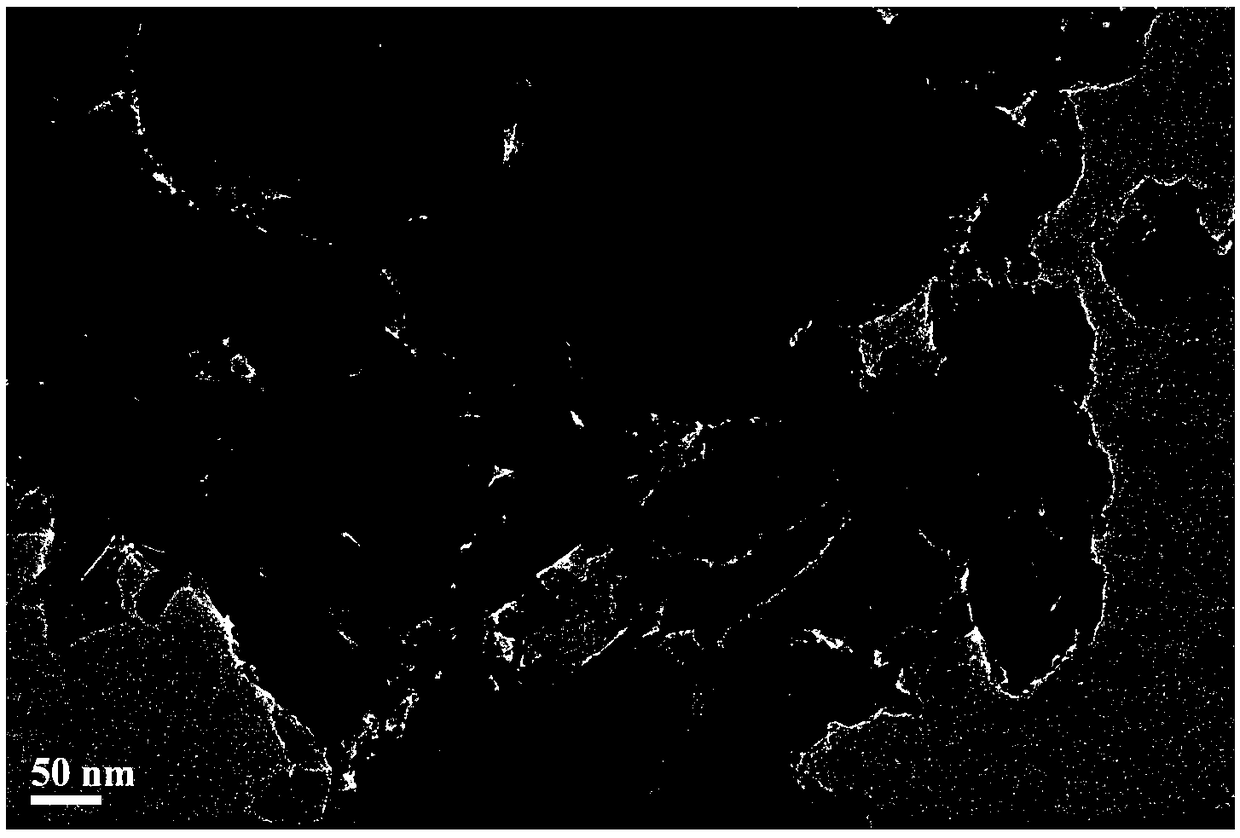

[0034] figure 2 For the TEM figure of the CNO prepared in embodiment 1, by figure 2 It can be seen that pure graphitic carbon nitride contains a very small amount of pores and can be approximately considered as a non-porous material.

Embodiment 2

[0035] Example 2 Sulfur-doped graphite phase carbon nitride nanosheet photocatalyst

[0036] (1) Preparation method

[0037] 1) Put 2.52g of melamine into a crucible, in a tube furnace, under the protection of nitrogen, raise the temperature to 450°C at a rate of 5°C / min, perform calcination and keep it for 4h, and cool naturally to obtain precursor A (solid);

[0038] 2) Grind 4.57g of thiourea, dissolve it in 100ml of deionized water and stir, add 2g of oxalic acid, stir well, put the resulting mixture into an oven and heat and dry at 80°C to obtain precursor B;

[0039] 3) Then put 2g of precursor A and 2g of precursor B into a mortar and grind them, put them in an alumina crucible after grinding, and put the crucible in a muffle furnace heated to 550°C in advance under a nitrogen environment. Calcined for 3h, naturally cooled to obtain the target product sulfur-doped graphite phase carbon nitride g-C 3 N 4 Nanosheet photocatalyst (CN1).

[0040] (2) Detection

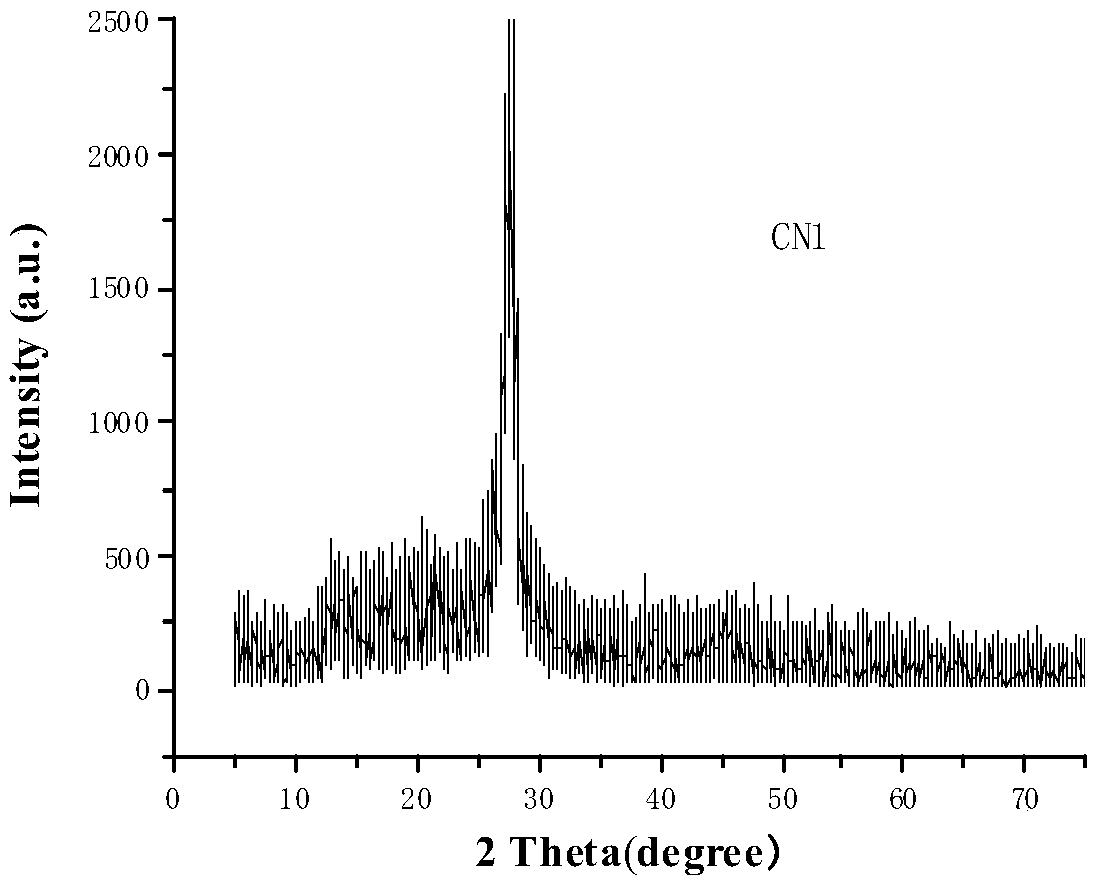

[0041...

Embodiment 3

[0044] Example 3 application

[0045] The photocatalyst prepared in Example 1-2 was subjected to photocatalyst material performance test.

[0046] The test process is as follows: use a 300W xenon lamp as the light source, adjust the photocurrent to 20A, adjust the center of the light intensity to irradiate the sample surface, fix the position, and place the CN0 and CN1 prepared in Example 1-2 respectively at 4cm 2 In the glass tank, put the glass tank containing the photocatalyst into a 224ml reactor containing an atmospheric pressure air, and finally inject 5ul isopropanol liquid into the reactor, start timing after 20 minutes of light, and take samples every 20 minutes One needle, test, record the peak area of isopropanol, the result is as follows Figure 5 Shown is the rate of degrading isopropanol per minute calculated after recording 6 times (lighting for two hours). The result is as Figure 5 .

[0047] Depend on Figure 5 It can be seen that the prepared sulfur-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com