Method for separating alcohol in alcohol ester mixture by using deep eutectic solvent

A low eutectic solvent and mixture technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of limited separation methods, low isoamyl alcohol content, affecting the purity of isoamyl acetate, etc., To achieve the effect of improving extraction efficiency, environmental friendliness and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

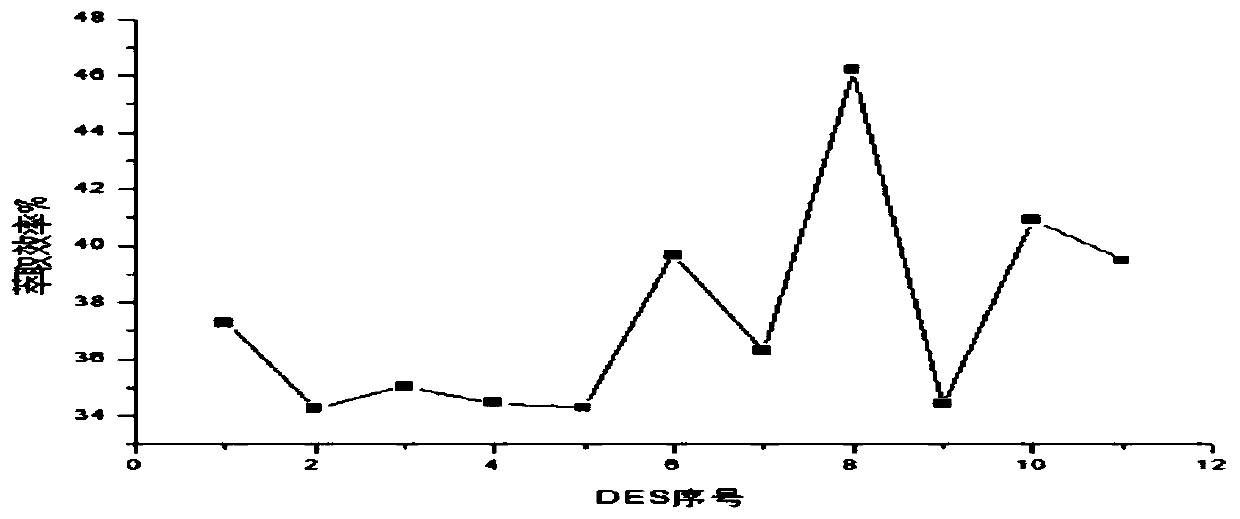

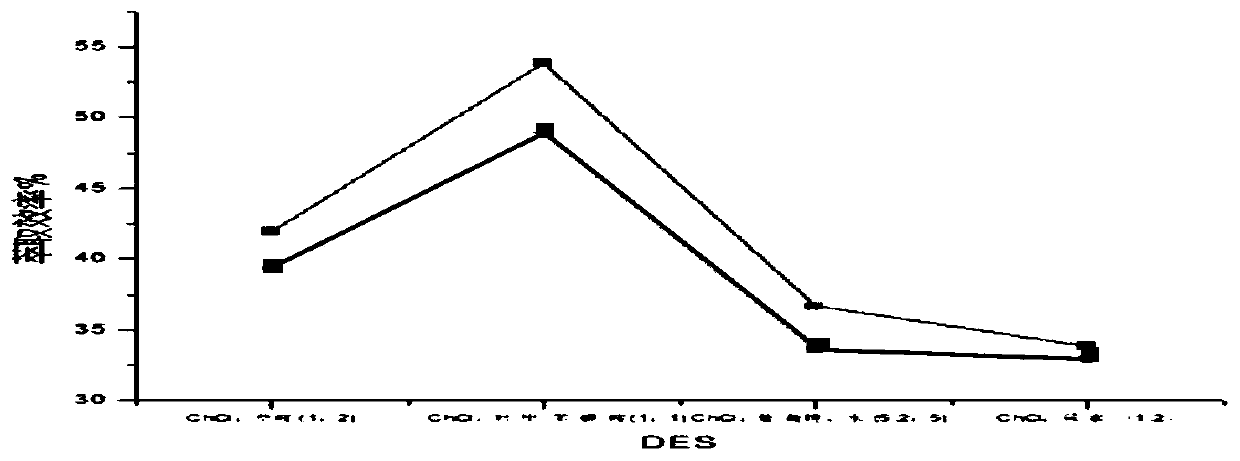

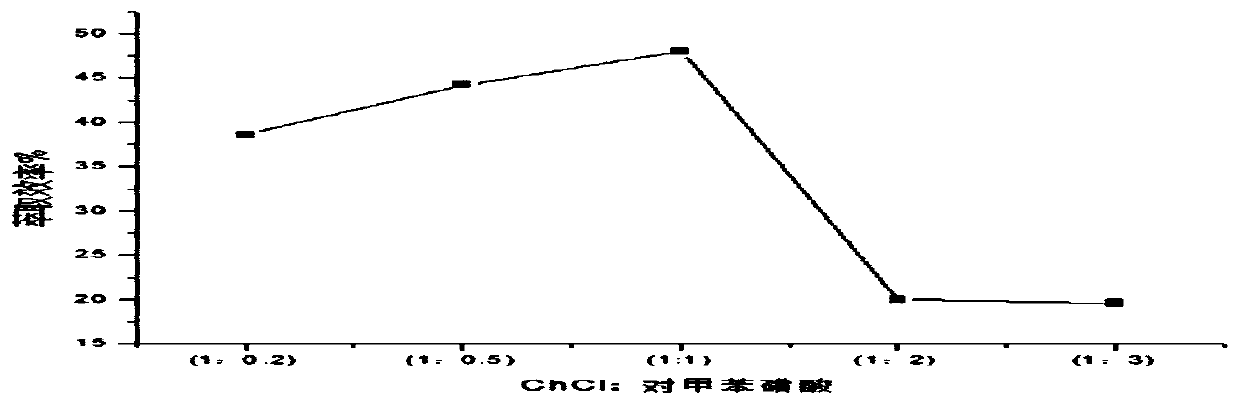

[0043] The experiment uses gas chromatography to detect the extraction and separation results of isoamyl alcohol in the organic mixture of isoamyl alcohol and isoamyl acetate by the deep eutectic solvent, and find the best experimental conditions. The result shows that, using the method of magnetic heating and stirring, choline chloride and p-toluenesulfonic acid 1:1 deep eutectic solvent extraction alcohol ester mol ratio is the organic mixture of 1:3, the alcohol ester organic matter and deep eutectic solvent The best extraction efficiency is obtained when the ratio of solid to liquid is 1:3.5.

[0044] 2.1 Instruments and reagents

[0045] 2.1.1 Experimental reagents

[0046] Choline chloride, urea, citric acid, oxalic acid, acrylamide, acetamide, p-toluenesulfonic acid, glucose, sucrose, sorbitol (analytical grade, Tianjin North Tianyi Chemical Reagent Factory); glycerol, ethylene glycol, Cyclohexane (analytically pure, Tianjin Damao Chemical Reagent Factory); isoamyl al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com