Preparation method of ultra-high molecular weight polyethylene/graphene antistatic composite material

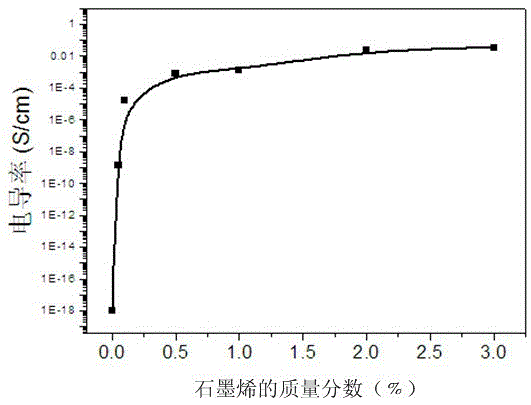

An ultra-high molecular weight and graphene composite technology is applied in the field of ultra-high molecular weight polyethylene/graphene antistatic composite materials and their preparation, which can solve problems such as environmental pollution and complex preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

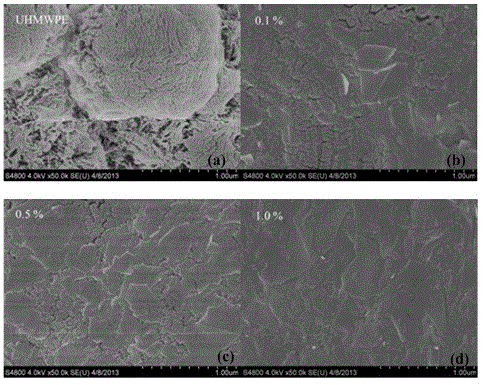

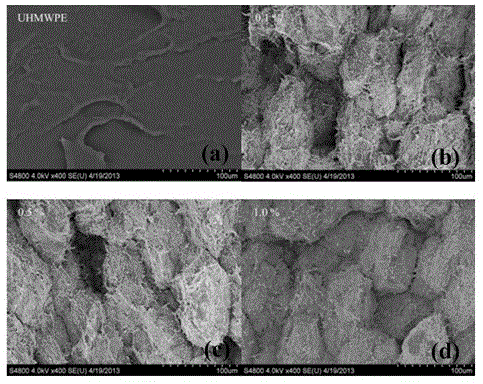

[0020] (1) Preparation of UHMWPE charged particles: UHMWPE was dried in a vacuum oven at 100°C for 24 hours, so that the moisture content in the UHMWPE raw material was lower than 0.01%. Put 10g of UHMWPE and 10mg of graphene in a high-speed mixer and stir to obtain ultra-high molecular weight polyethylene / graphene composite particles; among them, graphene was added to the high-speed mixer in 3 times, each time stirring at a speed of 10000r / min for 10s at a high speed.

[0021] (2) High-temperature compression molding: preheat the ultra-high molecular weight polyethylene / graphene composite particles prepared in step (1) at 200°C for 5 minutes; then hot-press at 200°C and 10MPa for 30 minutes; finally cool to At room temperature, the target product was prepared.

Embodiment 2

[0023] Others are the same as in Example 1, the added graphene content is 50 mg, and the number of times of high-speed stirring is 5 times.

Embodiment 3

[0025] Others are the same as in Example 1, the added graphene content is 100 mg, the number of high-speed stirring is 10 times, and 10 mg graphene is added each time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com