Preparation method and application of TiO2/g-C3N4 photoanode nanocomposite

A nano-composite material, g-c3n4 technology, applied in the field of photoelectrochemistry, can solve the problems of complex operation process, difficult to prepare large-scale, etc., and achieve the effects of simple operation, good optical properties, and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: TiO 2 / g -C 3 N 4 Photoanode nanocomposites

[0030] Preparation:

[0031] Mix 0.45g of melamine and 2ml of tetrabutyl titanate in 40ml of ethanol, stir to disperse the mixture evenly, put it into a 100ml hydrothermal kettle, the temperature of the hydrothermal is 180°C, and the time is 24h. After the hydrothermal is completed, centrifuge Filter, put the powder into a muffle furnace for annealing at 550°C for 4 hours, cool to room temperature, and grind to obtain TiO 2 / g -C 3 N 4 Photoanode nanocomposites.

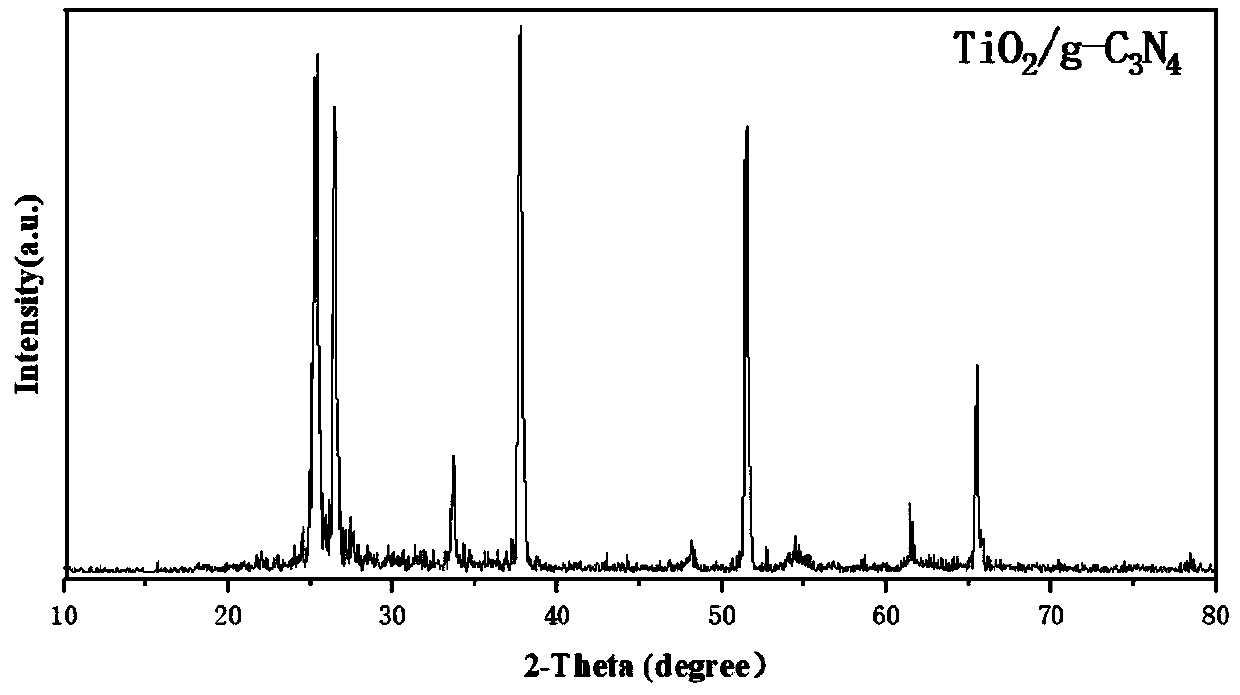

[0032] Will get TiO 2 / g -C 3 N 4 Powder carries out XRD test, the result is as follows figure 1 shown by figure 1 Visible, TiO 2 / g -C 3 N 4 Has good crystallinity.

Embodiment 2

[0033] Example 2: TiO 2 / g -C 3 N 4 Photoelectrode thin film (TiO 2 / g -C 3 N 4 -1min)

[0034] Preparation:

[0035] 1) Take 10mg I 2 Place in 25ml of acetone aqueous solution (the volume ratio of water and acetone is 1:25), seal and sonicate for 30min until the solution is evenly dispersed, and the mixture containing I 2 of acetone solution.

[0036] 2) get the TiO prepared by 0.6g embodiment 1 2 / g -C 3 N 4 Powder dispersed in containing I 2 In the acetone aqueous solution, sealed and sonicated for 120min, the electrophoretic deposition suspension was obtained.

[0037] 3) Place two pieces of conductive glass facing each other and immerse them in the electrophoretic deposition suspension parallel to each other, and apply a DC voltage of 25V between the two electrodes, and deposit for 1 min.

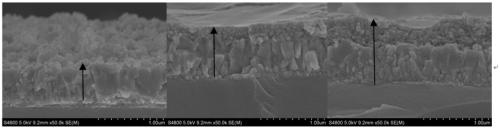

[0038] 4) Cut off the current, take the conductive glass (FTO) out of the suspension, dry it at room temperature, and bake it in a muffle furnace at 450°C for 90min to obt...

Embodiment 3

[0039] Example 3: TiO 2 / g -C 3 N 4 Photoelectrode thin film (TiO 2 / g -C 3 N 4 -3min)

[0040] The preparation method is the same as in Example 2, only changing the deposition time of step 3) to be 3min to obtain TiO 2 / g -C 3 N 4 Photoelectrode film, marked as TiO 2 / g -C 3 N 4 -3min.

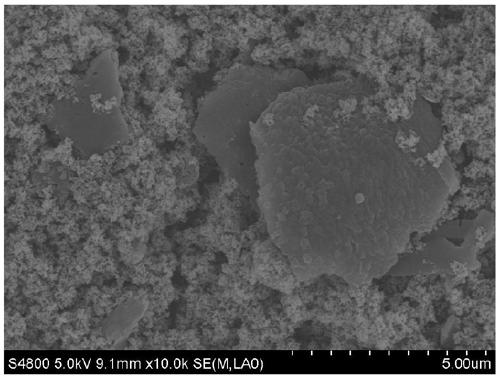

[0041] TiO 2 / g -C 3 N 4 -3min sample for SEM test, the result is as follows figure 2 As shown, in the figure it can be observed that TiO 2 and g-C 3 N 4 shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com