Method for producing an anti-reflective coating for optical and thermoelectrical devices

An anti-reflection coating and coating technology, applied in chemical instruments and methods, coatings, optics, etc., can solve the problem that coatings are not suitable for outdoor use, achieve good photochemical properties, optimize light transmission, and improve system efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation of anti-reflective coating and deposition on glass substrates.

[0044] First, a sol was prepared by mixing 2.147 μl of TEOS (tetraethylorthosilicate), 639 μl of MeTES (triethoxymethylsilane), 2637 μl of absolute ethanol, 462 μl of deionized water, and 114 μl of 60% nitric acid solution. The sol was mixed under continuous stirring and the sol was hydrolyzed at 65° C. for 3 hours in a thermostatic bath at 300 rpm. To 5 ml of the hydrolyzed sol was added 436 mg of castor oil and 10 ml of Brij 56 (non-ionic surfactant) dissolved in ethanol (11.2% m / m); they were mixed vigorously and hydrolyzed for a further 3 hours at 65° C. in a 300 rpm water bath. Then cool at room temperature for a few minutes.

[0045] Deposition is then continued to form the antireflective film by the previously obtained sol-gel spraying technique. Cleaning of the glass substrate was performed first for deposition with ethanol. A 1:2 dilution of the hydrolyzed and tempered...

Embodiment 2

[0048] Example 2: Measurement of the transmittance of the coated substrate obtained in Example 1.

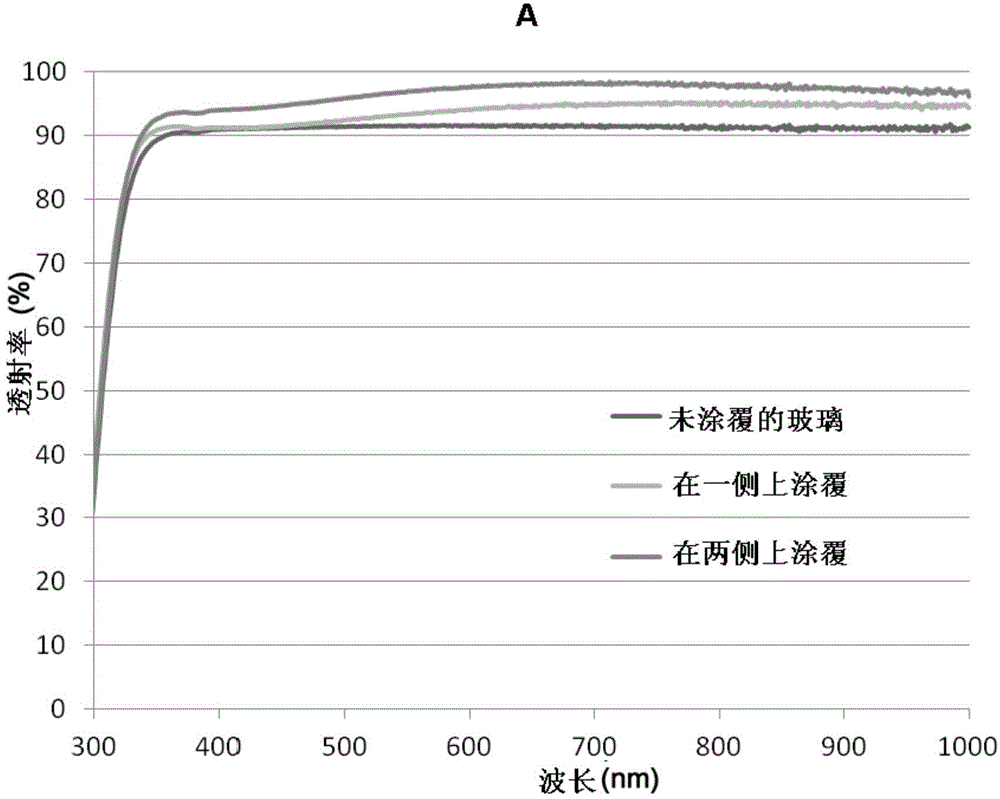

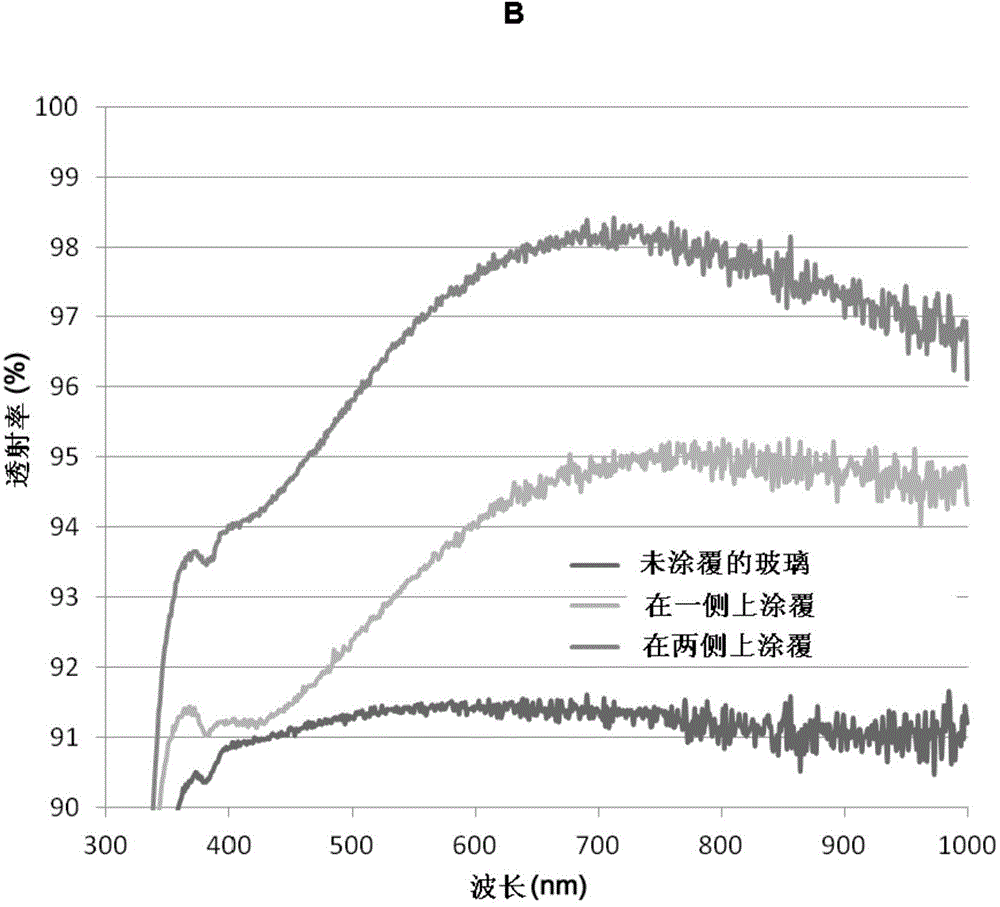

[0049] Subsequently, the transmittance according to the wavelength of the coated substrate obtained in Example 1 was measured by using a Cary50 ultraviolet spectrophotometer. Substrates coated on both sides were also measured. The data obtained are shown in figure 1 middle. As mentioned above, the transmission increased from 91.4% (at 600 nm) to 94% when the coating was implemented on one side, or to 97.6% when implemented on both sides.

Embodiment 3

[0050] Example 3: Photochemical stability test of the coated substrate obtained in Example 1.

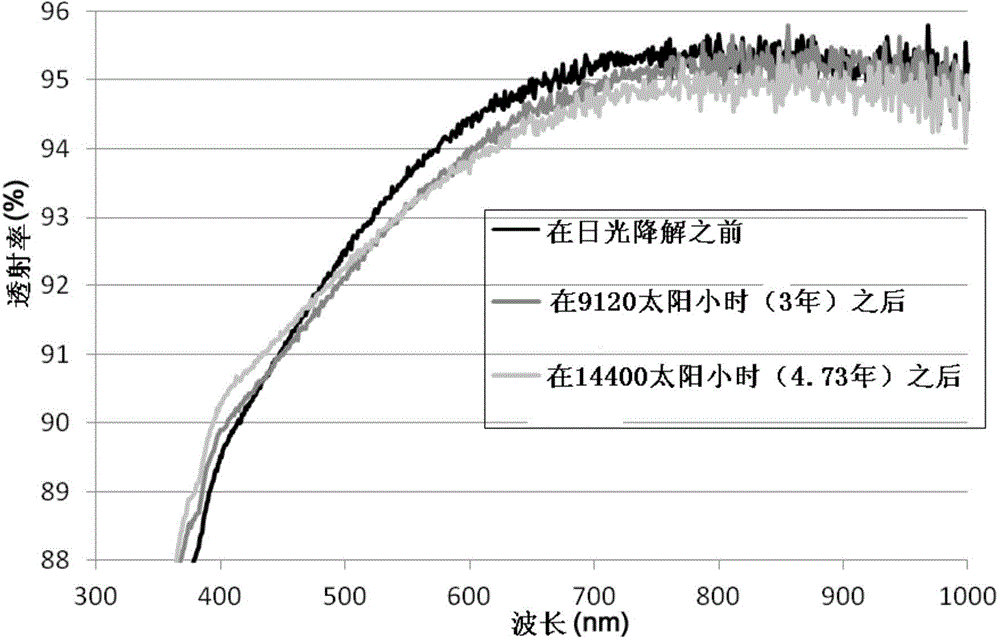

[0051] To test the photochemical stability of the coated substrates, a solar simulator was used, which reproduces the spectrum of sunlight and focuses the light to speed up the measurement. The coated glass substrate obtained in Example 1 was exposed to radiation at a temperature of 120° C. for 45 days to receive a concentrated radiation source corresponding to “10×sun”, which corresponds to 600 days of solar irradiation or at 1 14,400 hours of direct sunlight exposure under a single sun. figure 2 It is shown how the percent transmittance is almost unchanged despite being exposed for more than 14400 hours (the absolute transmittance of the coated substrates dropped by an average of 0.55% relative to the initial value).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com