Polymer continuous bed and method for online ursolic acid enrichment and purification

A technology of ursolic acid and polymers, which is applied in the field of separation material preparation, can solve the problems of cumbersome operation steps, increased adsorption capacity, large amount of solvent, etc., and achieve the effect of simplifying operation steps, reducing pretreatment time, and realizing green chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 0.2 g of hydroxylated multi-walled carbon nanotubes and 0.2 g of γ-methacryloxypropyltrimethoxysilane in 30 mL of 95% ethanol, heat at 60 °C for 6 h, and centrifuge to obtain silanized Double bonded multi-walled carbon nanotubes.

[0042] Precisely weigh 0.03g of benzoyl peroxide and 3.0mg of silanized multi-walled carbon nanotubes with double bonds into a centrifuge tube, add 0.35mL of styrene, 0.48mL of ethylene glycol dimethacrylate , 0.70mL n-butanol and 0.40mL isopropanol, vortex and sonicate for 30 minutes to disperse the solids in the mixture until the mixture is uniform, add N,N-dimethylaniline, mix quickly, put it into the chromatographic column tube, 30 After reacting in a water bath at ℃ for 3.0 h, a continuous bed of functionalized carbon nanotube polymer is obtained.

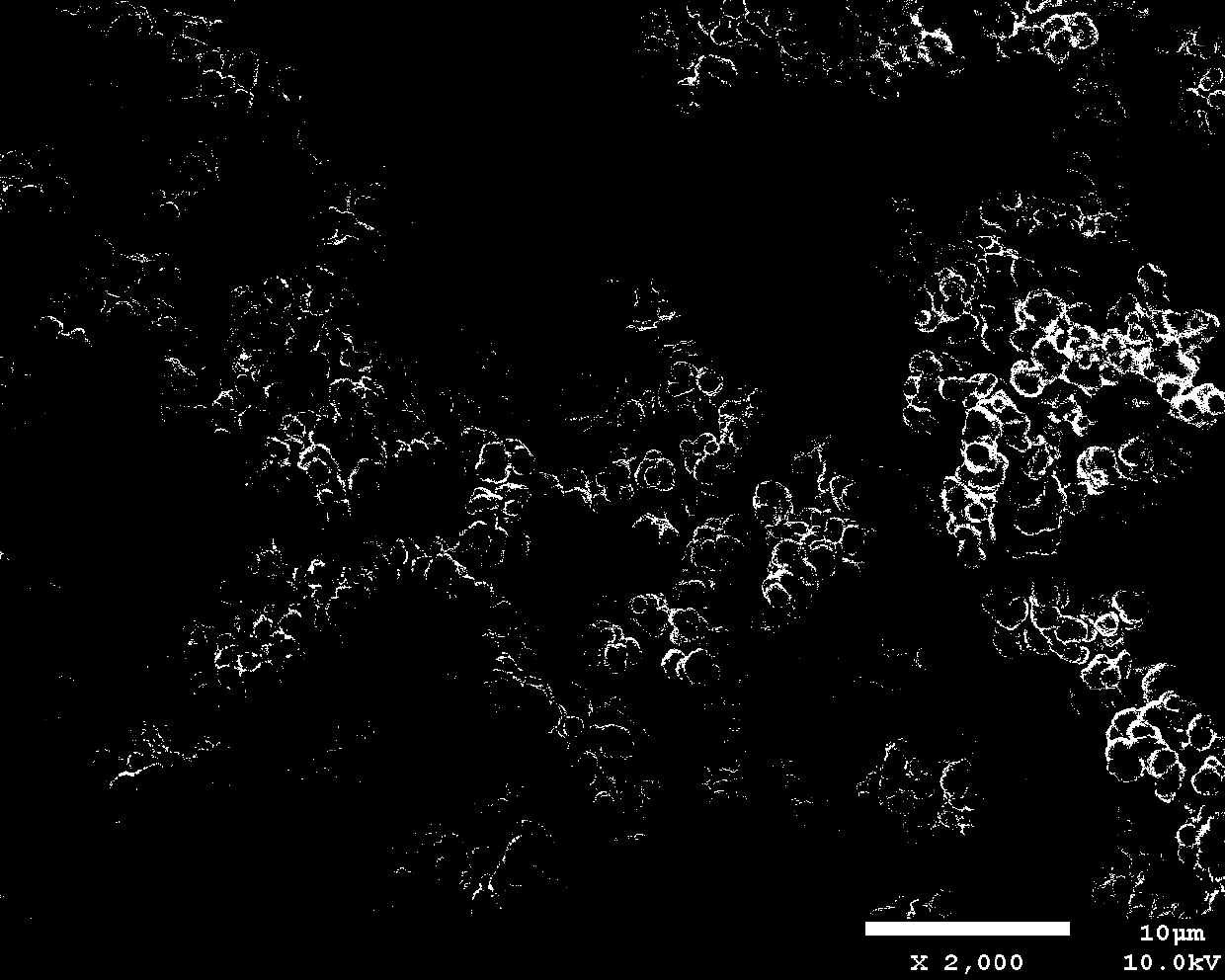

[0043] Adopt scanning electron microscope to observe the microscopic shape of the continuous bed that above-mentioned preparation obtains, the obtained result is as follows figure 1 ...

Embodiment 2

[0045] Under the same conditions as in Example 1, put 0.03g of benzoyl peroxide into a centrifuge tube, add 0.35mL of styrene, 0.48mL of ethylene glycol dimethacrylate, 0.70mL of n-butanol, and 0.40mL of isopropanol , use vortex to dissolve the solid in the mixture, disperse by ultrasonication for 30min until the mixture is uniform, add N,N-dimethylaniline, mix quickly, put it into the chromatographic column tube, and react in a 30℃ water bath for 3.0h, That is, a continuous bed of polymer without adding carbon nanotubes is obtained.

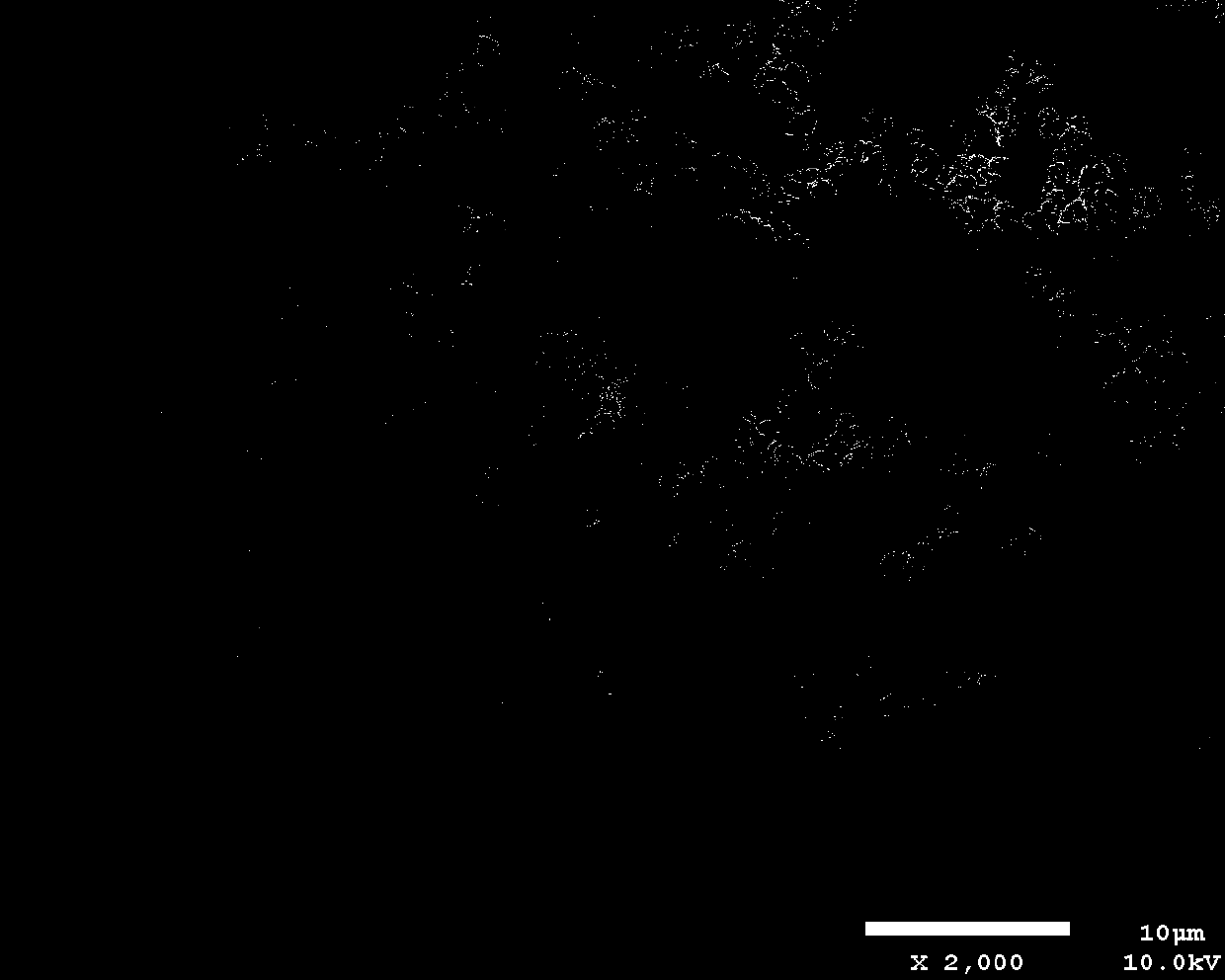

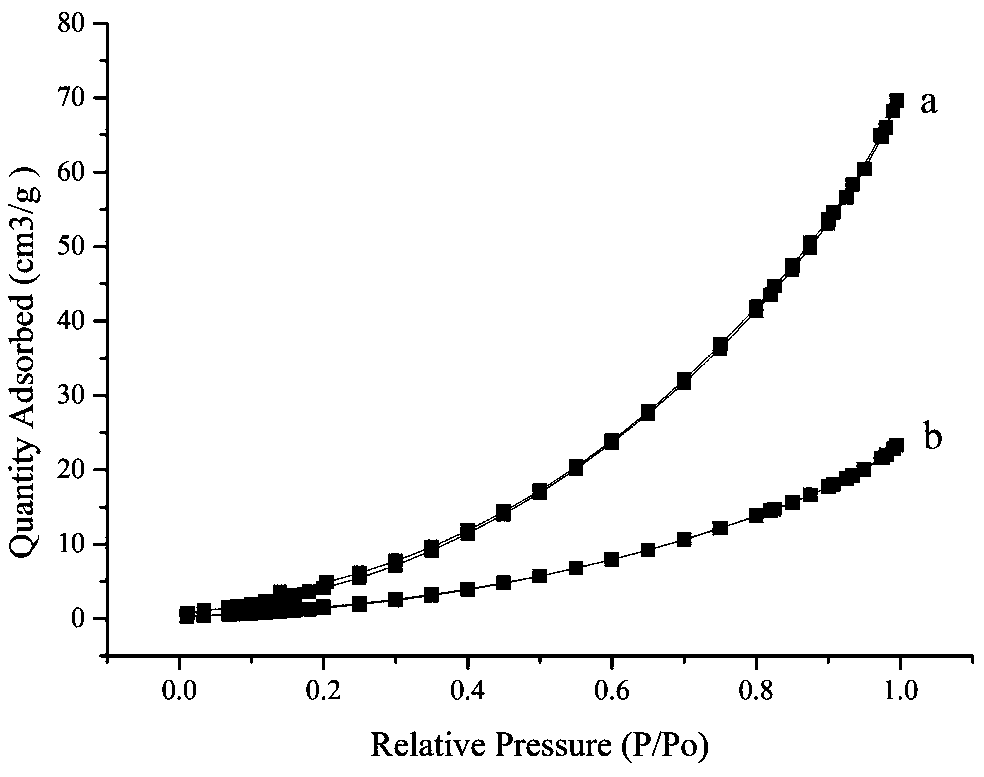

[0046] Observing the microscopic morphology of the continuous bed prepared above with a scanning electron microscope, the obtained results are as follows figure 2 . The nitrogen adsorption-desorption isotherm of this continuous bed is measured with a specific surface area measuring instrument as image 3 As shown, its specific surface area is 12.7505 m 2 / g.

Embodiment 3

[0048] Under the same conditions as in Example 1, put 0.03g benzoyl peroxide and 3.0mg silanized multi-walled carbon nanotubes with double bonds into a centrifuge tube, add 0.35mL styrene, 0.36mL ethylene glycol di Methacrylate, 0.70mL n-butanol, 0.40mL isopropanol, vortex and ultrasonic 30min to disperse the solid in the mixture until the mixture is uniform, add N,N-dimethylaniline, mix quickly, put In the chromatographic column tube, after 3.0 hours of constant temperature reaction in a water bath at 30°C, a continuous polymer bed is obtained. Observing the microscopic morphology of the continuous bed prepared above with a scanning electron microscope, the obtained results are as follows Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com