High-activity g-C3N4 photocatalytic material as well as preparation method and application thereof

A photocatalytic material, g-c3n4 technology, applied in the field of photocatalysis, can solve the problems of fast charge recombination, small specific surface area, and low efficiency, and achieve the effects of easy migration, cheap and easy-to-obtain raw materials, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The Fe-doped g-C of embodiment 1 formaldehyde treatment 3 N 4 photocatalytic material

[0023] The preparation method is as follows:

[0024] 1) Add 0.017gFe(NO 3 ) 3 9H 2 O was added to a beaker containing 40ml of deionized water, then 3g of melamine was added, stirred for 0.5h, ultrasonicated for 0.5h, and dried at 60°C for 10h;

[0025] 2) Grind the solid obtained in step 1), add 0.01mol melamine into a beaker of 100ml deionized water, stir while bathing in 80°C water, and when the solution is clear, add 40% formaldehyde solution dropwise (in molar ratio, formaldehyde: melamine =0.005:1), stirred in water bath for 2h;

[0026] 3) Put the mixed solution obtained in step 2) into an oven, and dry at 80°C for 20 hours;

[0027] 4) Grind the precursor obtained in step 3), and heat up to 550°C for 4 hours at a rate of 5°C / min in a nitrogen atmosphere to obtain formaldehyde-treated Fe-doped g-C 3 N 4 Photocatalytic material, sample marked as 0.18% Fe / g-C 3 N 4 . ...

Embodiment 2

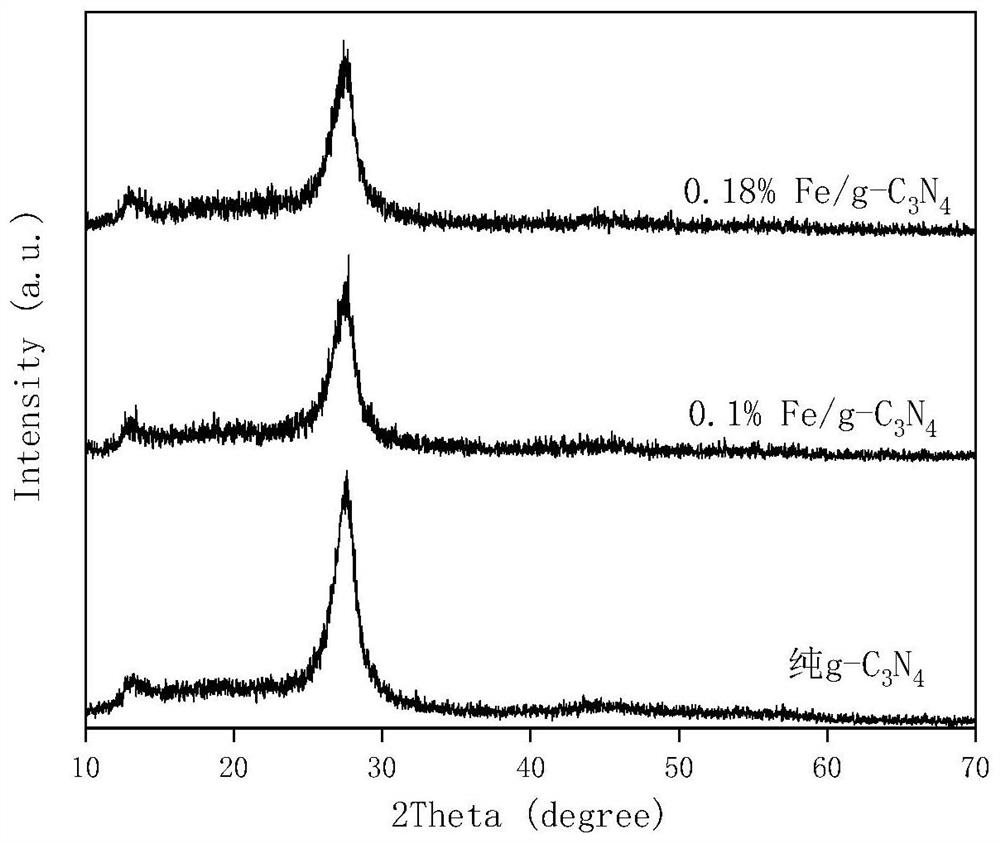

[0035] Example 2 detection

[0036] figure 1 For the sample 0.18% Fe / g-C 3 N 4 , sample 0.1% Fe / g-C 3 N 4 and pure g-C 3 N 4 The XRD test pattern, by figure 1 Visible, sample 0.18% Fe / g-C 3 N 4 , sample 0.1% Fe / g-C 3 N 4 There are two diffraction peaks at 13.1° and 27.3°, and pure g-C 3 N 4 The diffraction peaks are consistent. but with pure g-C 3 N 4 In comparison, with the increase of Fe doping amount, the XRD diffraction peak intensity decreases and the crystallinity of the sample becomes smaller.

Embodiment 3

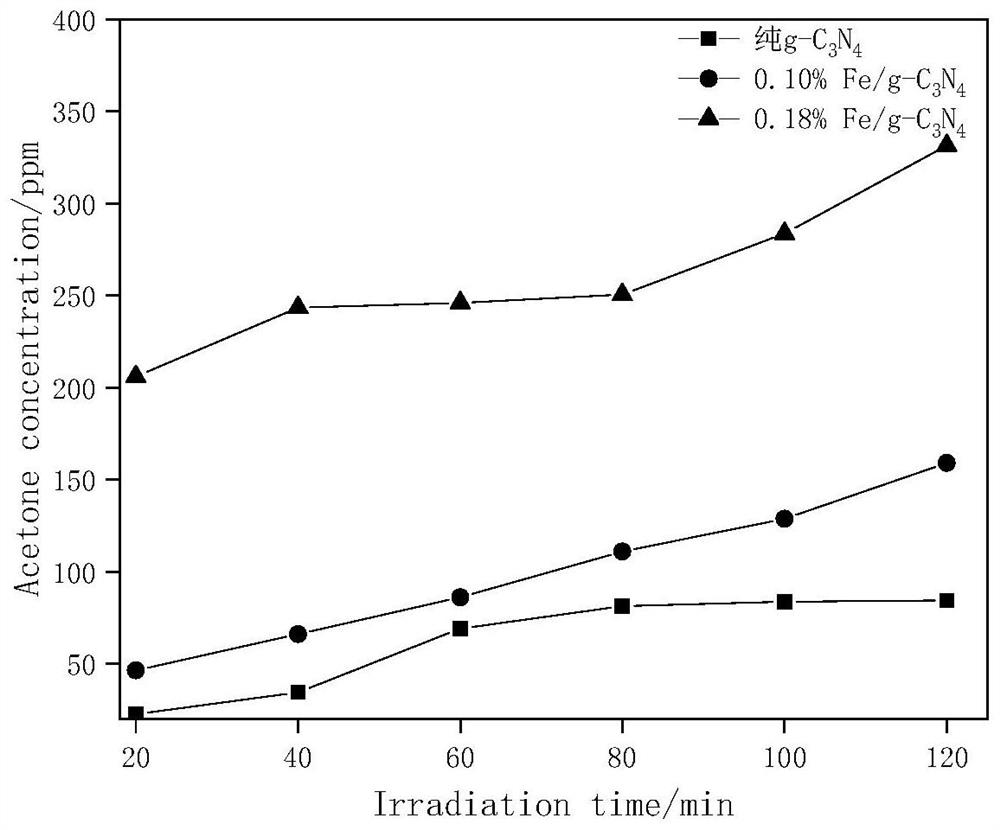

[0037] Example 3 application

[0038] (1) Effects of different catalysts on catalytic degradation of isopropanol under visible light

[0039] The test process is: use a 300W xenon lamp as the light source, adjust the photocurrent to the position of 20mA, adjust the light intensity center to irradiate the sample surface, fix the position, and place the 0.18% Fe / g-C prepared in Example 1 and Comparative Example 1-2 respectively 3 N 4 , 0.10% Fe / g-C3 N 4 and pure g-C 3 N 4 put in 4cm 2 In the glass tank, put the glass tanks loaded with photocatalyst into 325cm 3 In the reactor, inject 5ul of isopropanol liquid into the reactor at last, wait for 2h for the isopropanol to completely volatilize into gas, start timing after 20min of light, and take a sample every 20min for testing. Record the peak area that degrades isopropanol to generate acetone, and obtain the concentration change point line diagram that degrades isopropanol to generate acetone through calculation, as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com