Preparation method and application of heterojunction MoO3/ZnO photoelectrode film

A heterojunction and photoelectrode technology is applied in the field of photoelectrochemistry to achieve the effect of improving photoelectrochemical performance, improving transmission efficiency and high PEC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 A kind of heterojunction MoO 3 Preparation method of / ZnO photoelectrode thin film

[0026] (1) The preparation method is as follows

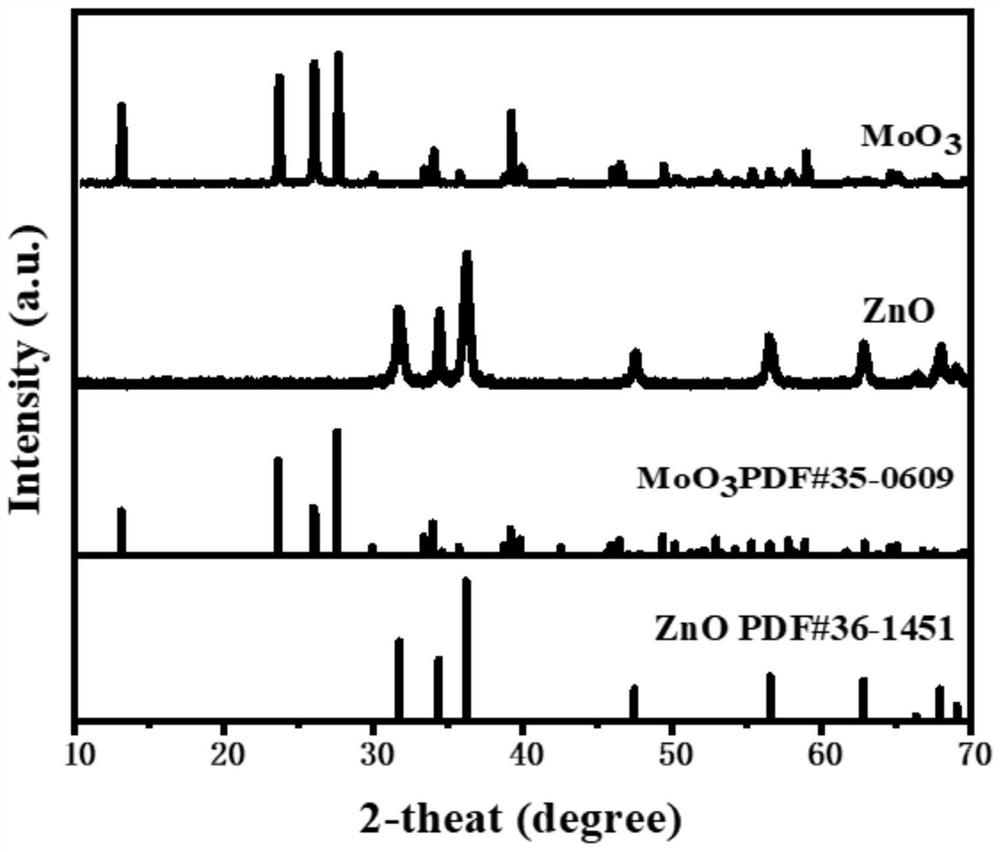

[0027] 1) Preparation of MoO by calcination 3 powder

[0028] 3g (NH 4 ) 6 Mo 7 O 24 Put it in a crucible, put it in a muffle furnace and calcine it in the air at 500°C for 4h to obtain MoO 3 powder.

[0029] 2) Preparation of ZnO powder by hydrothermal method

[0030] 0.24g Zn(C 2 H 3 O 2 ) 2 and 0.4g PVP were dissolved in 40mL DMF and 8mL distilled water, magnetically stirred for 20min, after mixing uniformly, slowly add 0.25M NaOH solution until the pH reached 10 and stop, after continuing magnetic stirring for 10min, transfer the obtained mixed solution to a high-pressure hydrothermal kettle , and then placed in an oven, heated at 140 °C for 90 min, the obtained product was centrifuged three times with acetone and ethanol respectively, and dried at 60 °C to obtain ZnO powder.

[0031] 3) Preparation of MoO 3 ...

Embodiment 2

[0038] Example 2 Heterojunction MoO 3 Application of / ZnO Photoelectrode Film

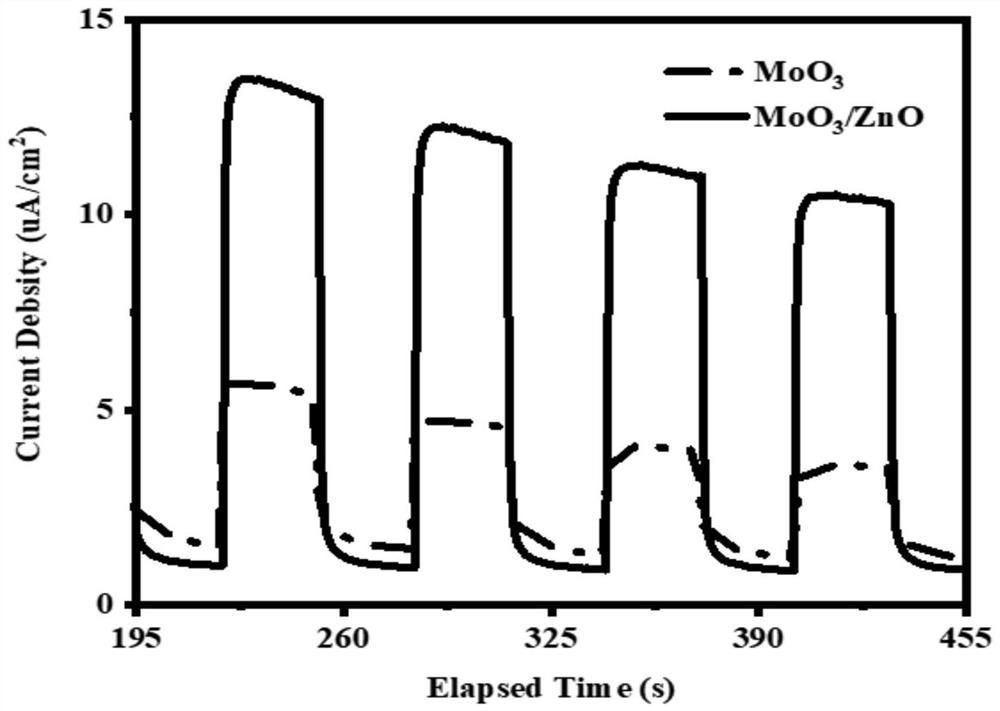

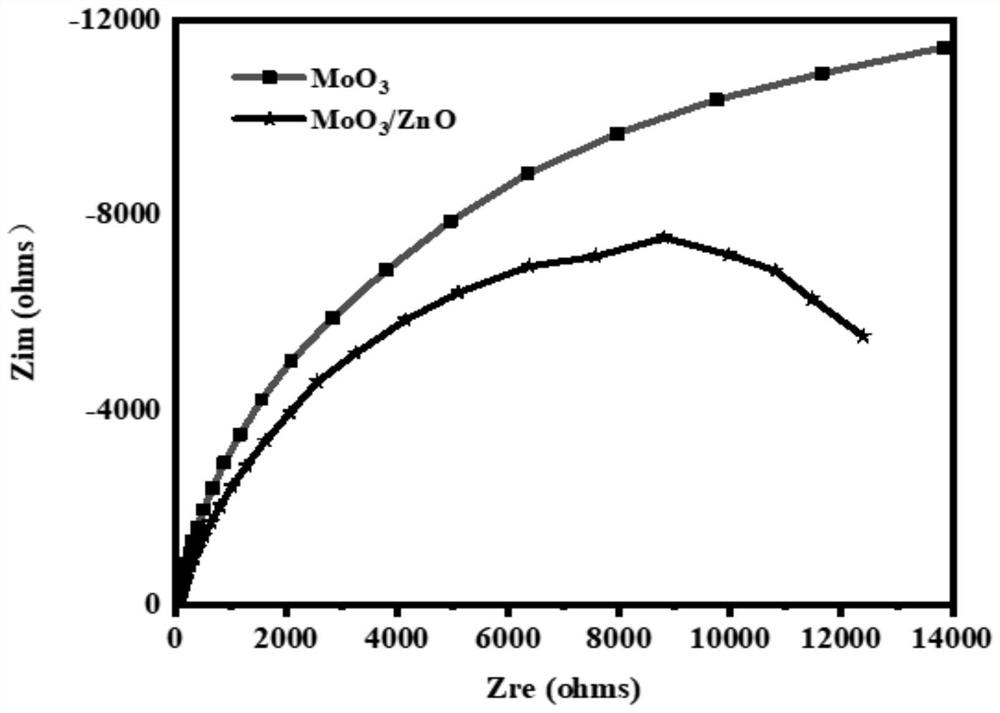

[0039] The pure MoO of Example 1 was 3 Thin Films and MoO 3 / ZnO photoelectrode films were tested for photoelectrochemical properties such as photocurrent and impedance.

[0040] All electrochemical experimental testing procedures were performed in an electrochemical workstation (Princeton Applied Research 2273) with a three-electrode system. The sample film is used as the working electrode, the platinum sheet is used as the counter electrode, the Ag / AgCl is used as the reference electrode, and the electrolyte is 0.1M NaSO 4 , the sample light irradiation area is 1cm 2 .

[0041] Photocurrent test: the light source is 300W xenon lamp, the bias voltage is 1.23Vvs.VRHE, the measured results are as follows figure 2 shown, the results show that the heterojunction MoO 3 The photocurrent of the / ZnO photoelectrode film is about 11.6 μA, and the MoO 3 The photocurrent of the photoelectrode film i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Photocurrent | aaaaa | aaaaa |

| Photocurrent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com