Preparation method of PVC heat stabilizer tin-doped lanthanum acetylacetonate

A technology of lanthanum acetylacetonate and heat stabilizer, which is applied in the preparation of aldehyde/ketone chelates, organic chemistry, etc., and can solve problems such as poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

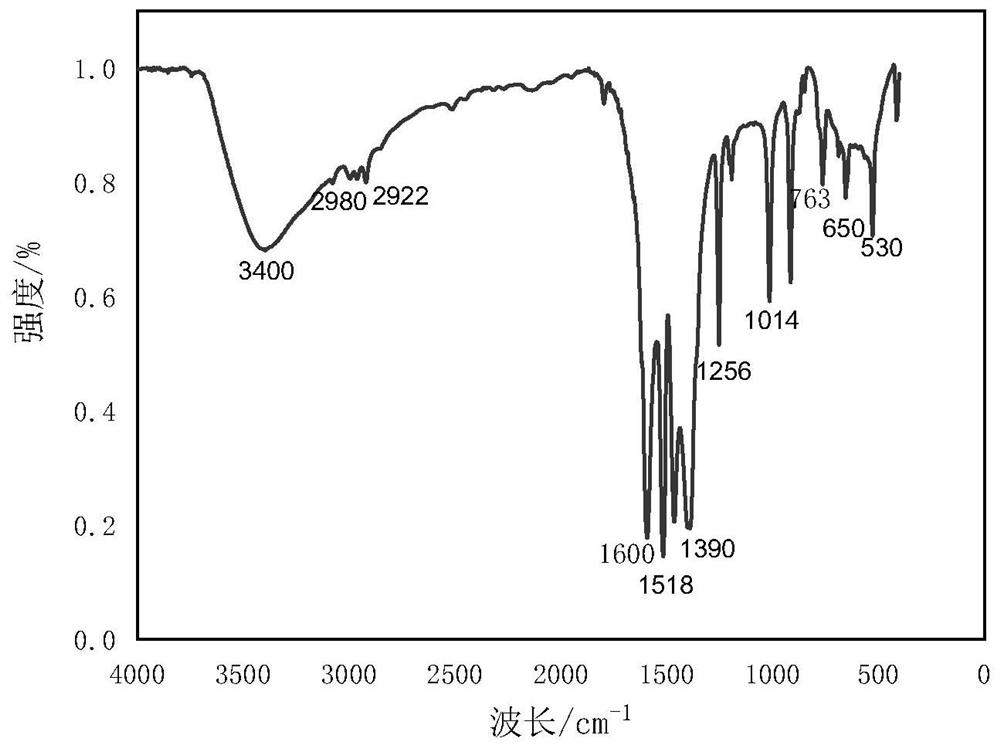

Embodiment 1

[0028] Embodiment 1: A kind of preparation method of PVC heat stabilizer tin-doped lanthanum acetylacetonate

[0029] A kind of preparation method of PVC thermal stabilizer tin-doped lanthanum acetylacetonate comprises the following steps:

[0030] Step 1: Weigh 2.9982 g SnCl 2 2H 2 O, 4.6951 g LaCl 3 ·6H 2 O, then mix lanthanum chloride hexahydrate with stannous chloride dihydrate to obtain metal salt mixture A; add metal salt mixture A to 40 ml of absolute ethanol, put it in a closed container, and then put it on a vortex shaker , using 750rmp for 4min to obtain reaction solution B;

[0031] Step 2: Put the reaction solution B into a transparent reaction container, stir at a stirring speed of 150r / min, and add acetylacetone into the transparent reaction container at a constant speed during the stirring process;

[0032] Step 3: Adjust the stirring speed to 425r / min, and keep the speed for reaction; meanwhile, add sodium hydroxide solution dropwise, adjust the pH value o...

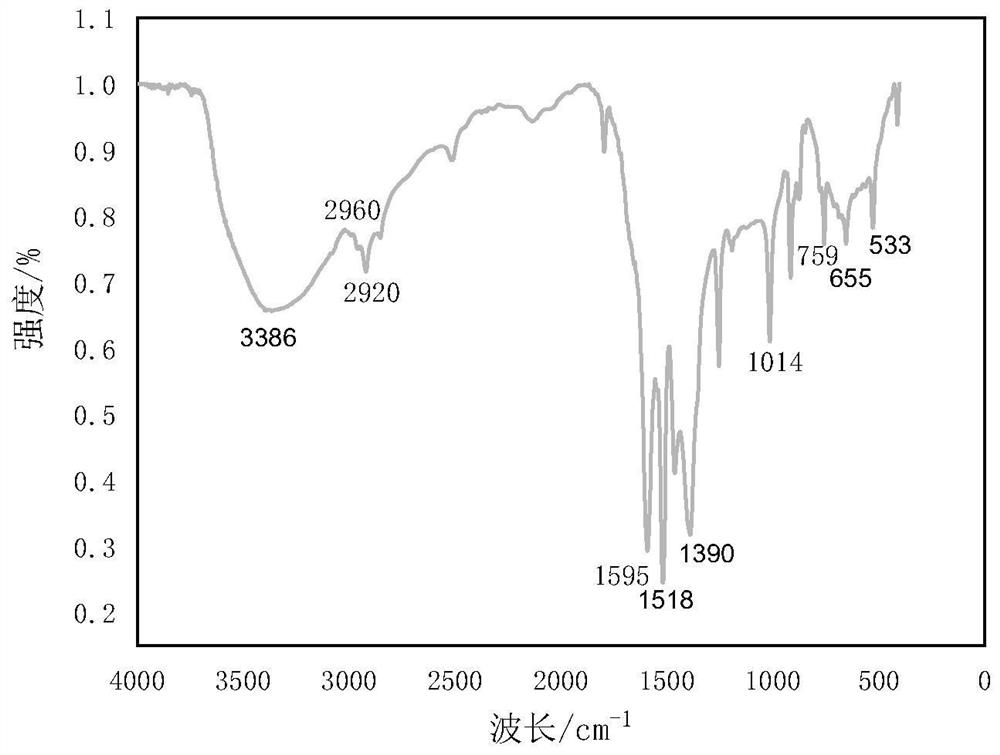

Embodiment 2

[0041] Embodiment 2: A kind of preparation method of PVC heat stabilizer tin-doped lanthanum acetylacetonate

[0042] A kind of preparation method of PVC thermal stabilizer tin-doped lanthanum acetylacetonate comprises the following steps:

[0043] Step 1: Mix lanthanum chloride hexahydrate and stannous chloride dihydrate at a molar ratio of 1:1 to obtain a metal salt mixture A; mix the metal salt mixture A with absolute ethanol at a mass ratio of 10:100, and put it in an airtight In the container, then on the vortex shaker, adopt 500rmp to process 3min, obtain reaction solution B;

[0044] Step 2: Put the reaction solution B into a transparent reaction container, stir at a stirring speed of 100r / min, and add acetylacetone into the transparent reaction container at a constant speed during the stirring process;

[0045] Step 3: Adjust the stirring speed to 400r / min, and keep the speed for reaction; meanwhile, add sodium hydroxide solution dropwise, adjust the pH value of the r...

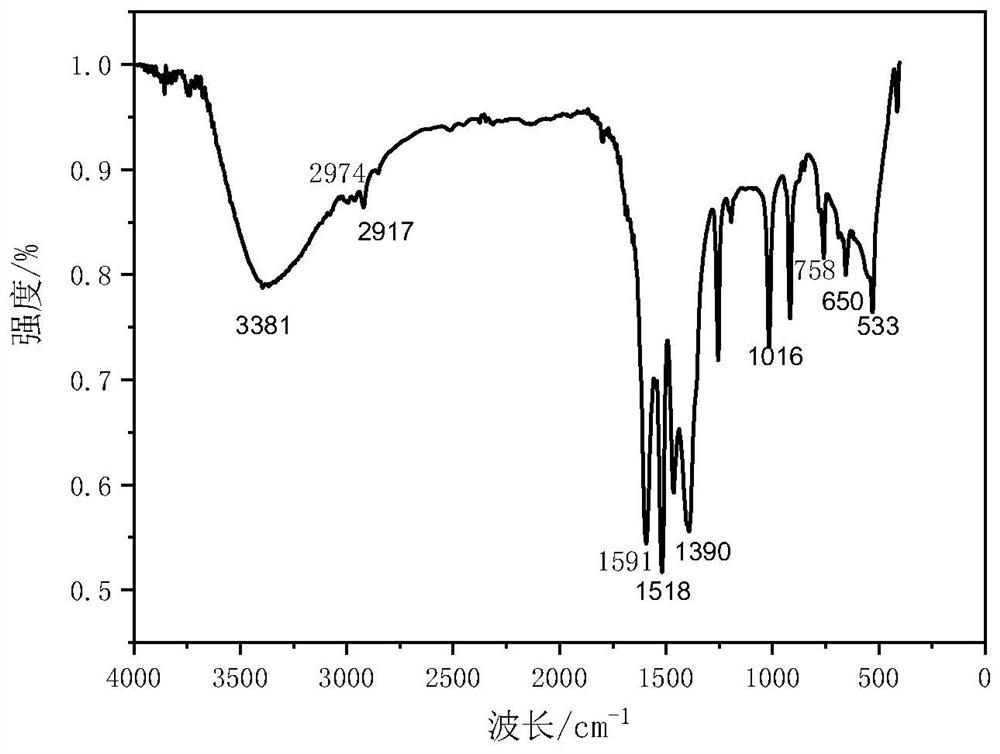

Embodiment 3

[0054] Embodiment 3: A kind of preparation method of PVC heat stabilizer tin-doped lanthanum acetylacetonate

[0055] A kind of preparation method of PVC thermal stabilizer tin-doped lanthanum acetylacetonate comprises the following steps:

[0056] Step 1: Mix lanthanum chloride hexahydrate and stannous chloride dihydrate at a molar ratio of 1:3 to obtain a metal salt mixture A; mix the metal salt mixture A with absolute ethanol at a mass ratio of 25:100, and put it in an airtight container, and then on a vortex shaker, using 1000rmp for 5min to obtain reaction solution B;

[0057] Step 2: Put the reaction solution B into a transparent reaction container, stir at a stirring speed of 200r / min, and add acetylacetone into the transparent reaction container at a constant speed during the stirring process;

[0058] Step 3: Adjust the stirring speed to 450r / min, and keep the speed for reaction; meanwhile, add sodium hydroxide solution dropwise, adjust the pH value of the reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com