Nitrogen-doped potassium niobate nano photocatalyst and preparation method and application thereof

A nano-photocatalyst, potassium nitrogen niobate technology, applied in the field of photocatalytic degradation of organic pollutants, can solve the problems such as few reports, achieve the effect of cost reduction, cheap and easy to obtain raw materials, simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1KNbO 3 Nanoparticles

[0027] (1) Preparation method

[0028] Weigh Nb 2 o 5 Put 0.53g in a 46mL hydrothermal reaction kettle, then weigh 12g KOH and put it into four reaction kettles, add 10mL deionized water, stir evenly, seal the reaction kettle, put it in an oven, and set the oven temperature rise program to 6°C / min Rise to 200°C and react at 200°C for 12 hours. After the reaction, close the oven and cool down to room temperature naturally. Take out the inner tank of the reaction kettle and centrifuge with deionized water to wash the white powder at the bottom until neutral, then bake at 80°C for 24 hours and take it out. Place in a sample bottle to get KNbO 3 .

[0029] (2) Detection

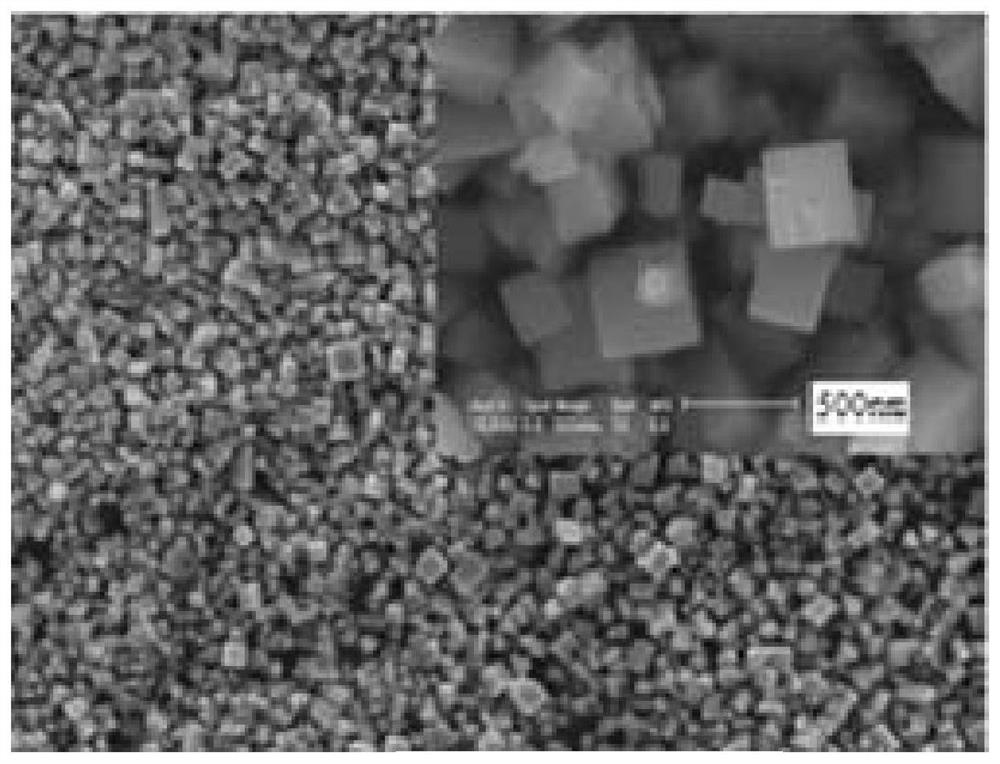

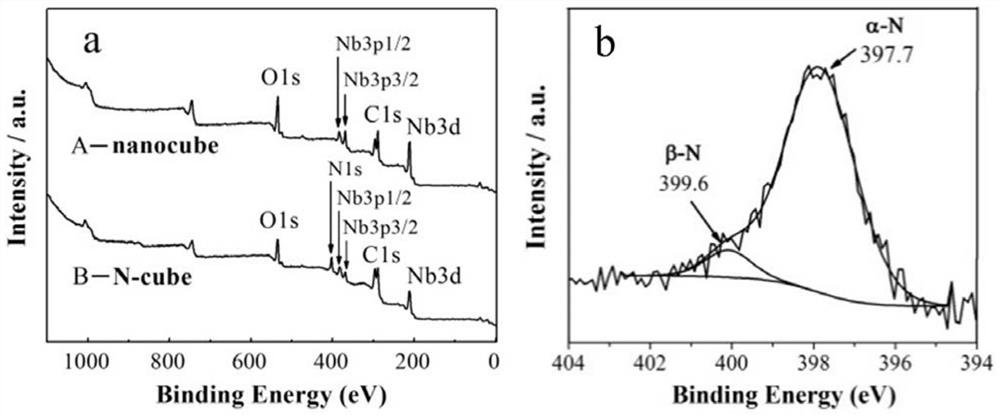

[0030] figure 1 Be the KNbO prepared under the hydrothermal condition of 30mol / L for the concentration of KOH in embodiment 1 3 The SEM image of figure 1 It can be seen that the shape of the sample is a nano-square with very sharp corners, and the statistical res...

Embodiment 2

[0031] Embodiment 2 Nitrogen-doped potassium niobate nanometer photocatalyst

[0032] (1) Preparation method

[0033] Weigh 0.3g of the white powder collected above and 1.0g of urea respectively, place them in a porcelain crucible, grind carefully with the bottom of a glass test tube, stir and mix evenly, cover the crucible lid, put them into a muffle furnace, and set the temperature of the muffle furnace to rise Program 20°C / min to rise to 425°C, and react at 425°C for 4 hours. After the reaction, close the muffle furnace, cool down to room temperature naturally, take out the sample and store it in a sample bottle to obtain the target nitrogen-doped potassium niobate photonanocatalyst.

[0034] (2) Detection

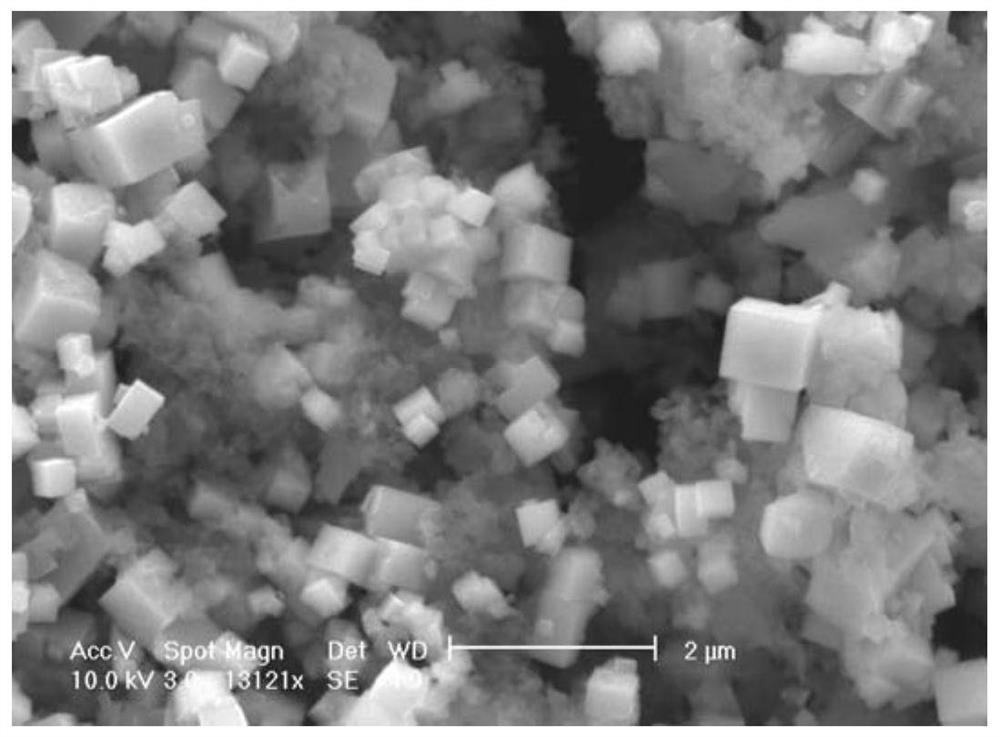

[0035] figure 2 It is the SEM photo of KNbO3 nano-squares doped with N in Example 2. The doping of N causes a certain change in the shape of the sample, mainly showing that there are many cotton-like substances on the surface of the nano-squares, but the size of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com