K-ion doped ZnO photocatalytic material, and preparation method and application thereof

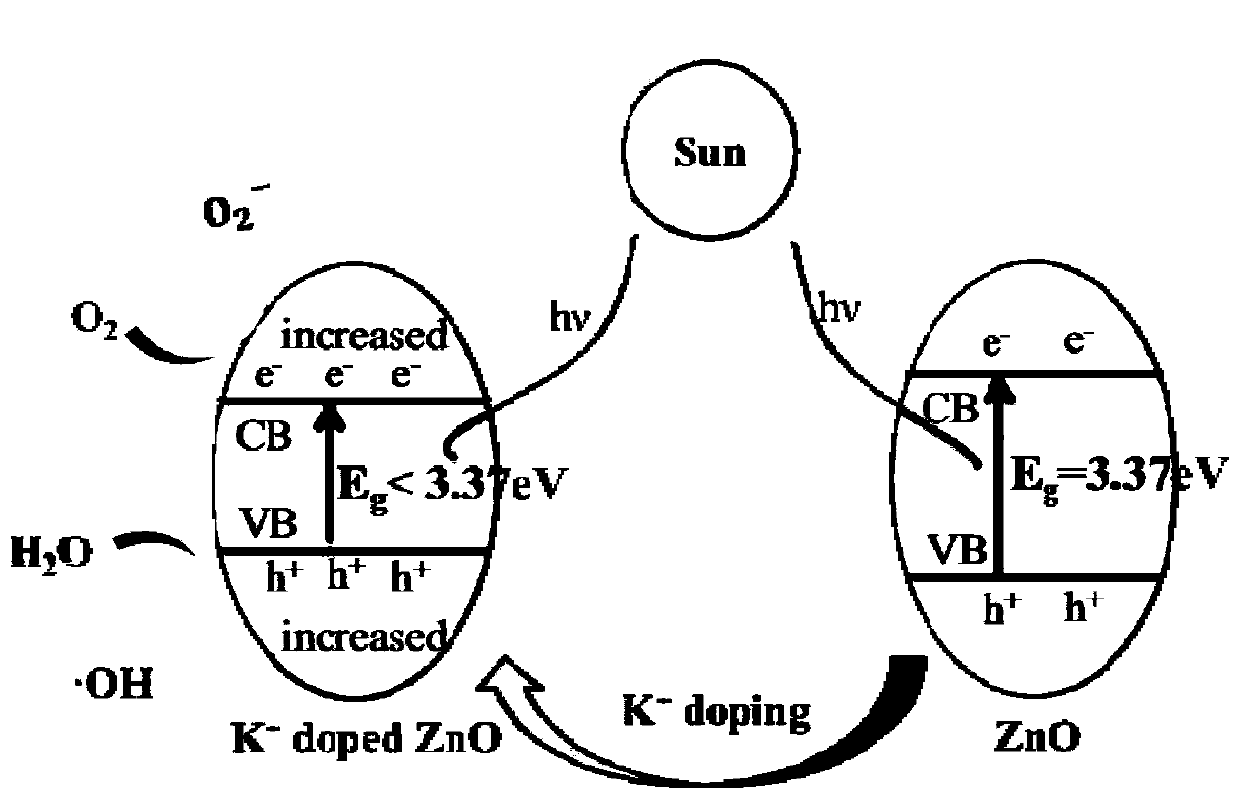

A photocatalytic material and ion doping technology are applied in the field of K ion-doped ZnO photocatalytic material and its preparation, which can solve the problems of low fast recombination quantum yield and poor response of photocatalytic reaction to visible light, etc., so as to promote photocatalysis. The effect of improving photocatalytic activity and improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

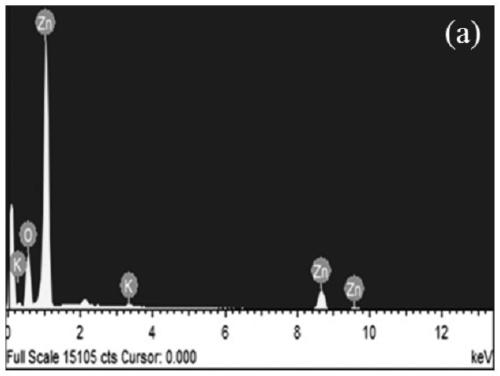

[0028] (1) K ion doped ZnO photocatalytic material

[0029] The preparation method is as follows:

[0030] 1) Pour 0.44g (2mmol) of zinc acetate into a beaker filled with 20ml of methanol solution, stir for 15min to fully dissolve;

[0031] 2) Grinding potassium hydroxide into powder. 2.24mg (0.04mmol) potassium hydroxide (K + The molar mass of Zn 2+ 2% of molar weight) is poured in the zinc acetate solution in stirring, continues to stir until potassium hydroxide dissolves;

[0032] 3) Put the mixed solution obtained in step 2) in an oven, dry at 80°C, and cool naturally to obtain the precursor;

[0033] 4) Grinding the precursor obtained in step 3), and then heating up to 450° C. for 2 h at a rate of 5° C. / min for high-temperature calcination to obtain the K ion-doped ZnO photocatalytic material K-ZnO.

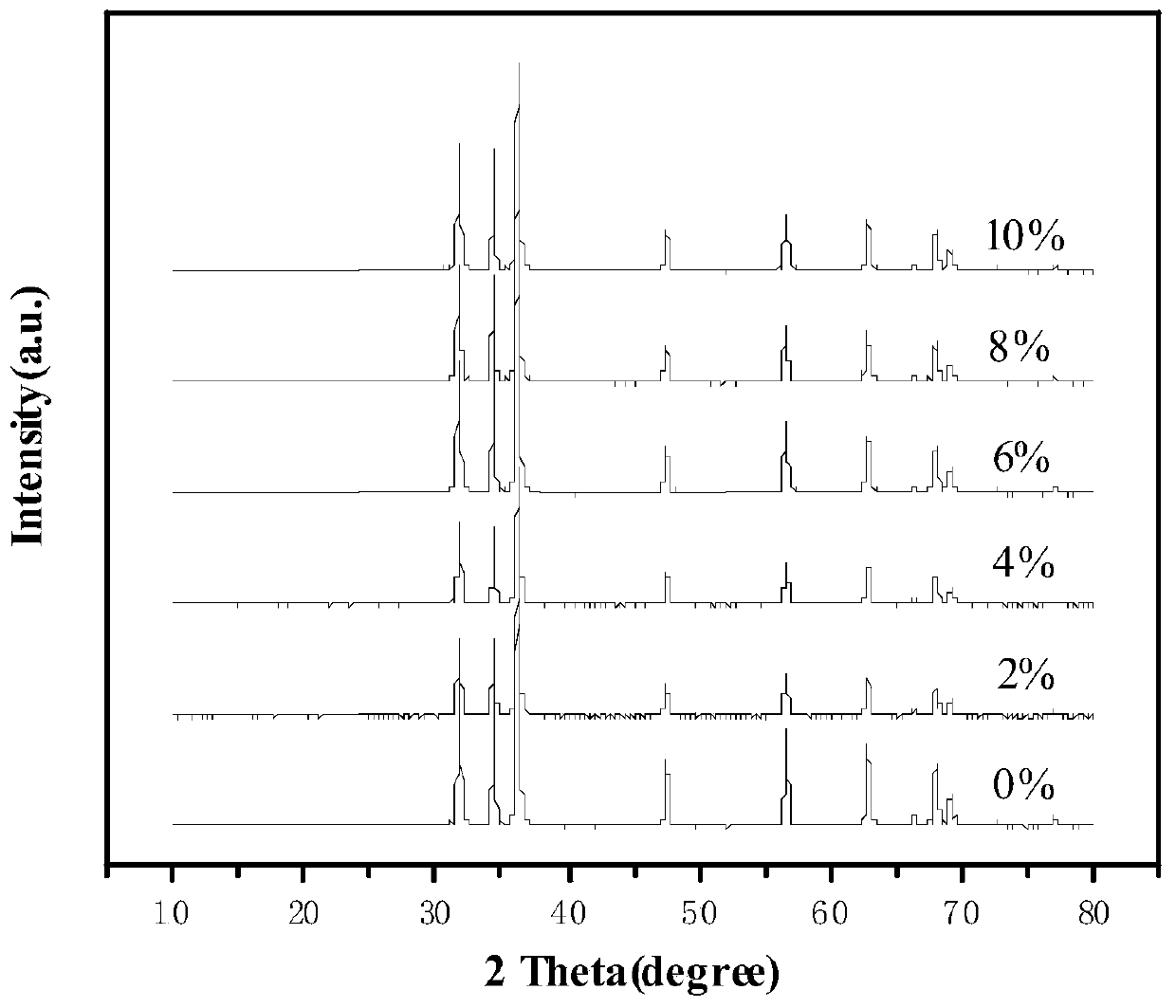

[0034] 5) Prepare K in the same way as step 1) to step 4) + The molar mass of Zn 2+ 4%, 6%, 8%, 10% of the molar amount of K ions doped ZnO photocatalytic material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com