Technology for synthesizing acetic acid

An acetic acid and process technology, applied in the technical field of synthesizing acetic acid, can solve problems such as the discharge of aldehyde-containing toxic substances, limited water solubility of aldehydes, etc., and achieve the effects of avoiding pollution, realizing recycling, and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

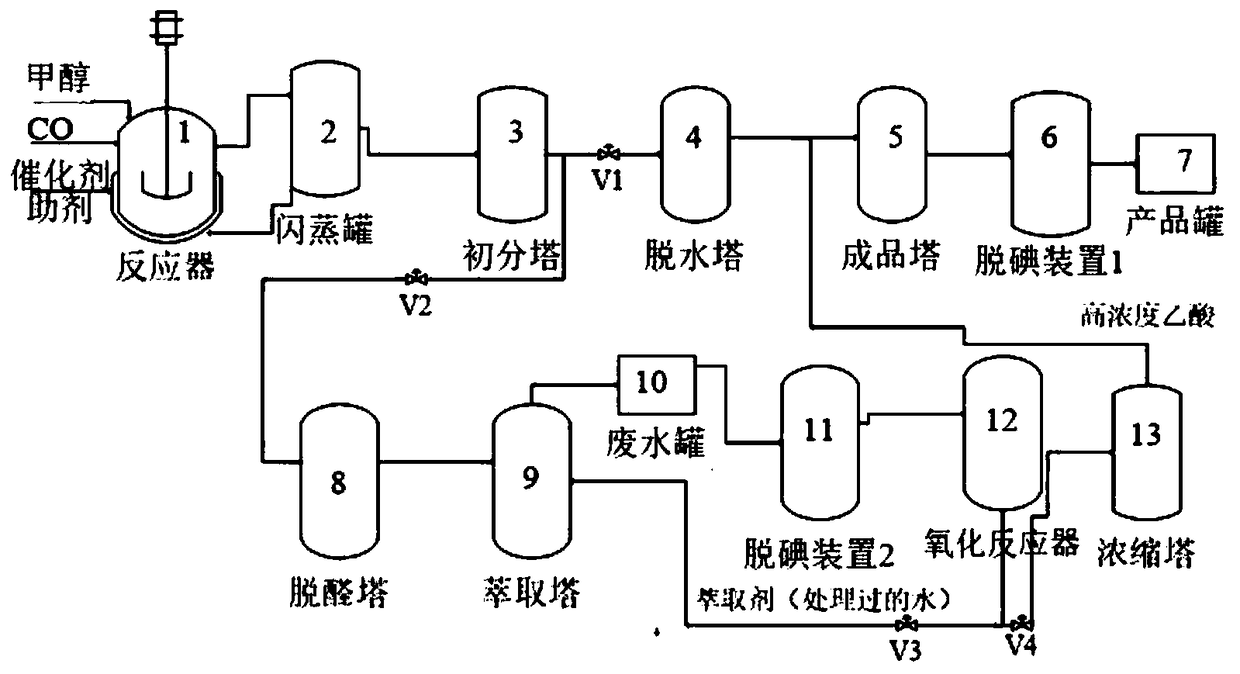

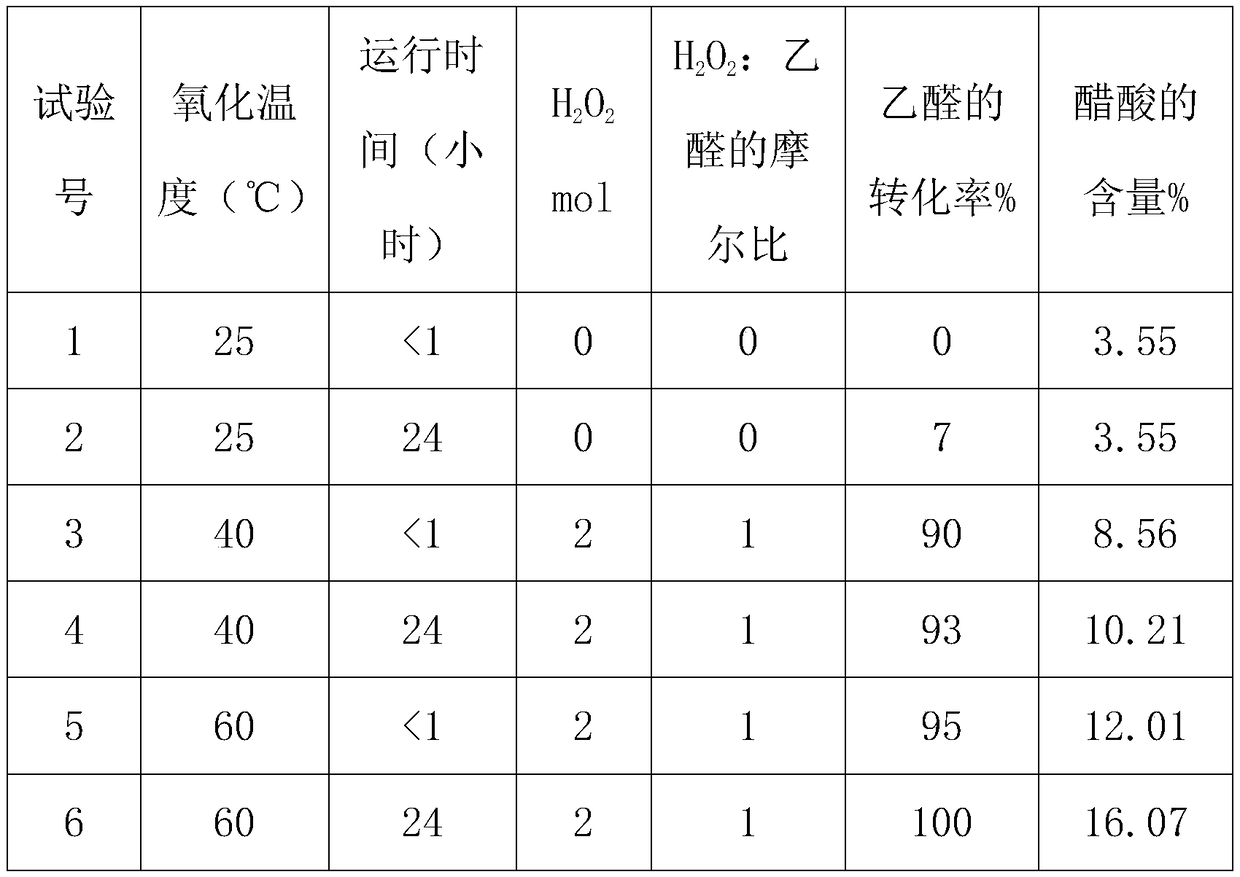

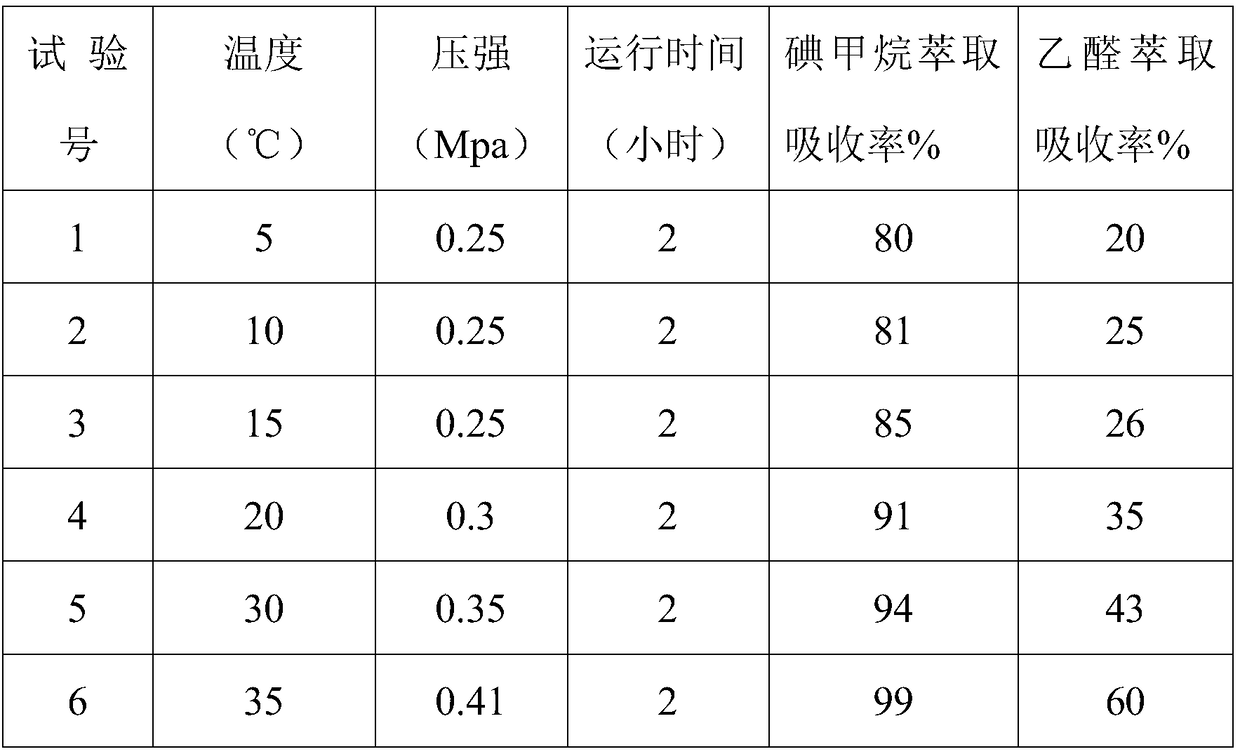

[0024] according to figure 1 Shown, the present embodiment proposes a kind of technique of synthesizing acetic acid, under the pressure of 2.3 ~ 3.5Mpa and the temperature of 180 ℃ ~ 200 ℃, methanol and CO in the rhodium catalyst, methyl iodide promoter and lithium iodide stabilizer Under the action, CO and methanol generate acetic acid in the reactor. The acetic acid and reaction liquid generated in the reaction kettle are reduced in temperature and pressure in the flash tank to a temperature of 135-150°C and a pressure of 0.05-0.2Mpa, and form a gas-liquid two-phase after flash evaporation. The liquid containing the rhodium catalyst is pumped back to the reaction kettle through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com