Cr2O3 thermal catalyst with oxygen defect, and preparation method and application of Cr2O3 thermal catalyst

A catalyst, oxygen deficiency technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. It is not high enough to achieve the effect of improving thermal catalytic activity, simple operation and cheap raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 has the dichromium trioxide thermal catalyst of oxygen defect

[0023] (1) Preparation method

[0024] Put 2g of chromium nitrate nonahydrate into a crucible, and in an inert gas environment or an air environment, carry out calcination in a muffle furnace at 500°C with a heating rate of 5°C / min, keep it for 2 hours, cool naturally, and grind to obtain the product: Chromium trioxide thermal catalyst with oxygen deficiency, the product is denoted as A500.

[0025] (2) Detection

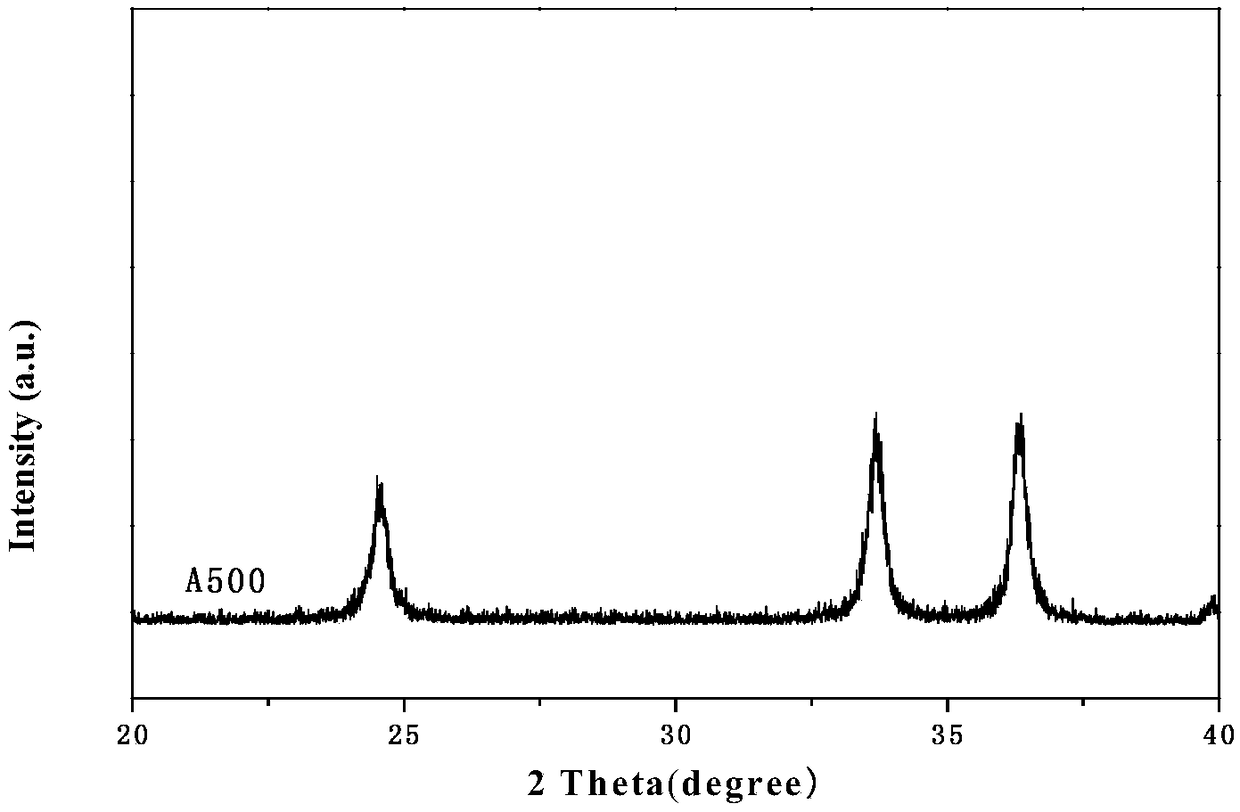

[0026] figure 1 For the A500XRD figure that embodiment 1 prepares, by figure 1 It can be seen that the sample has three diffraction peaks at 24.5°, 33.7° and 36.3°, which are characteristic peaks of dichromium oxide, which proves that the prepared sample is dichromium oxide.

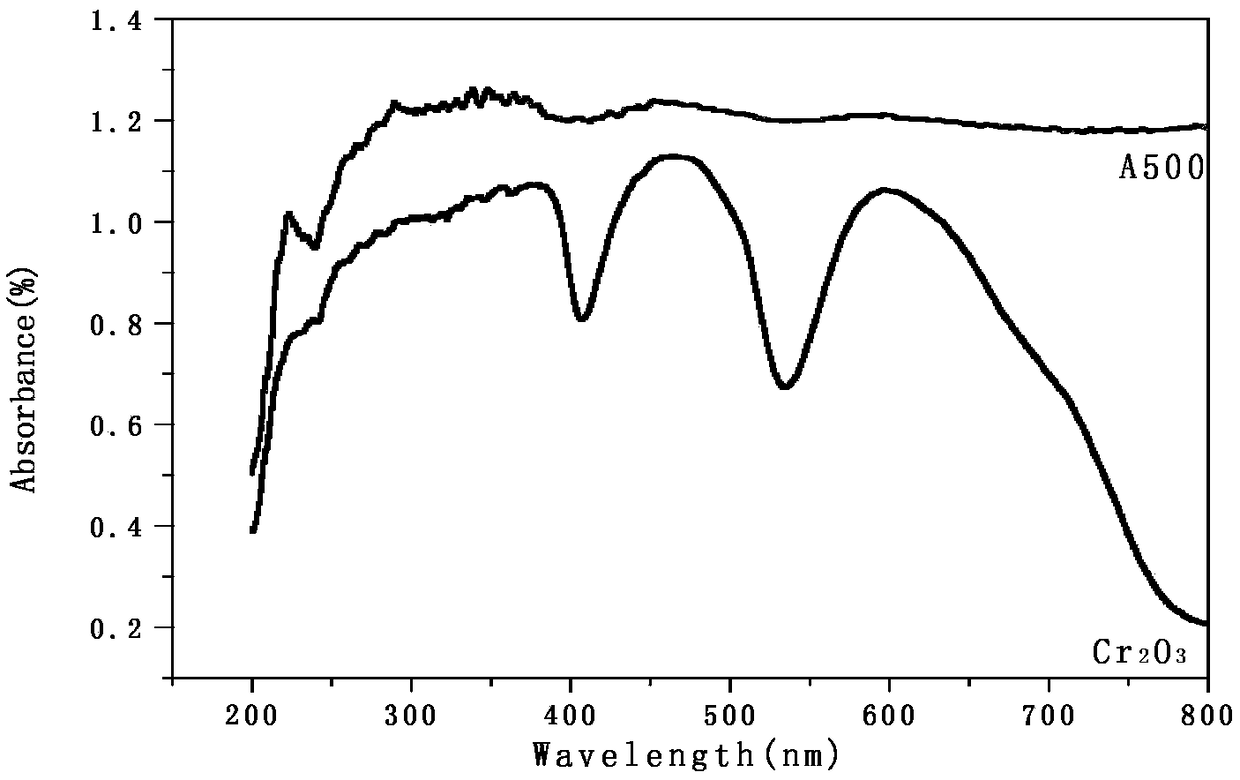

[0027] figure 2 For the UV-vis figure of the A500 prepared in embodiment 1, by figure 1 Visible, Cr 2 o 3 Four absorption bands are exhibited at 239, 373, 464 and 596nm, the prepared A500 thermal catal...

Embodiment 2

[0028] Embodiment 2 has the dichromium trioxide thermal catalyst of oxygen defect

[0029] (1) Preparation method

[0030] Put 2g of chromium nitrate nonahydrate into a crucible, and calcine in a muffle furnace at 900°C in an inert gas environment or an air environment, with a heating rate of 5°C / min, keep it for 2 hours, cool naturally, and grind to obtain the product: Chromium trioxide thermal catalyst with oxygen deficiency, the product is recorded as A900.

[0031] (2) Detection

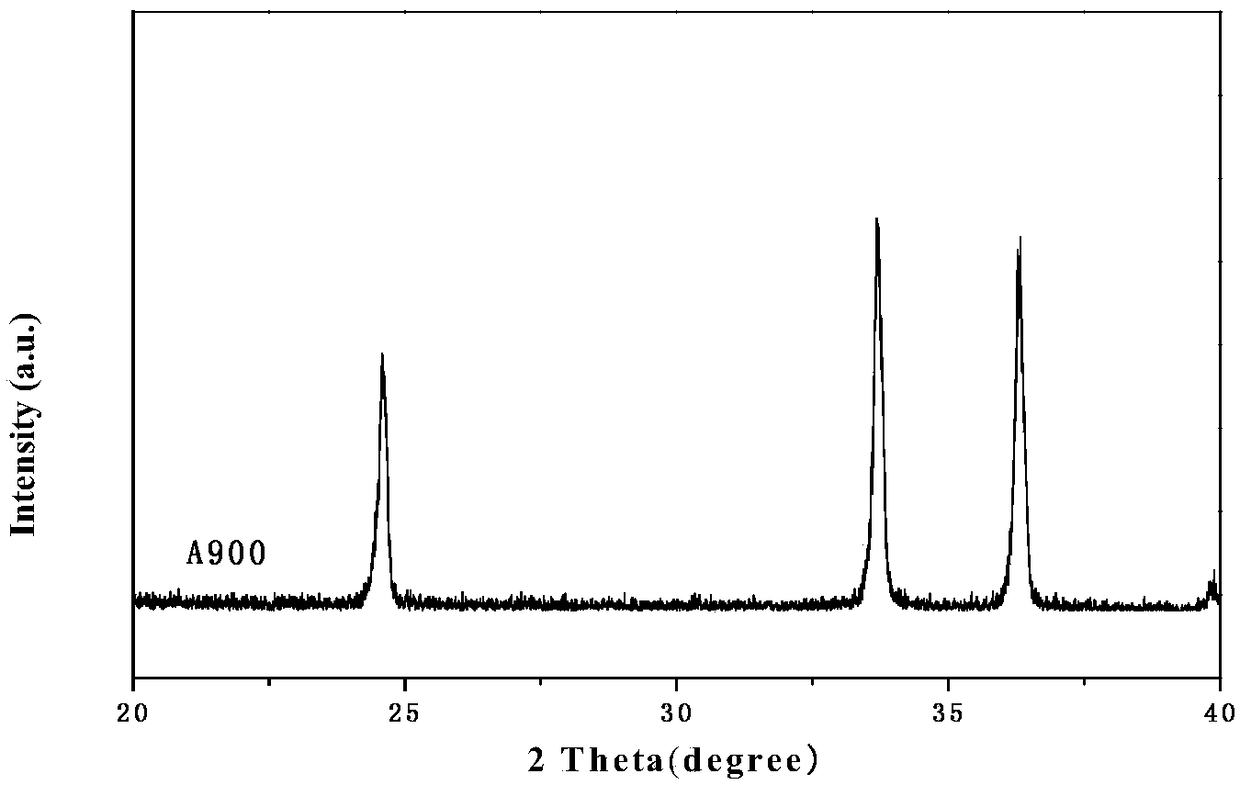

[0032] image 3 For the A900XRD pattern prepared in embodiment 2, by image 3 It can be seen that the sample has three diffraction peaks at 24.5°, 33.7° and 36.3°, which are characteristic peaks of dichromium oxide, which proves that the prepared sample is dichromium oxide. Compared with the A500XRD pattern prepared in Example 1, the peak intensity is obviously enhanced, indicating that as the temperature increases, the crystallinity of the sample is also better.

[0033] Figure 4 For the ...

Embodiment 3

[0035] Example 3 application

[0036] Cr with oxygen deficiency 2 o 3 Oxygen vacancies in thermal catalysts can effectively adsorb pollutants and undergo oxidation reactions, thereby degrading pollutants.

[0037] Depend on Figure 5 It can be seen that at the same temperature, the prepared oxygen-deficient chromium oxides A500 and A900 are degraded isopropanol per minute rate activity graph, and it can be seen that the catalytic activity of the prepared oxygen-deficient A500 thermal catalyst is higher than the sample activity of A900 The A500 sample is about 110 times faster than the A900 sample in degrading isopropanol, because the A500 sample has more oxygen defects than the A900 sample, which can adsorb pollutants and is more prone to oxidation reactions, so the degradation rate of isopropanol is higher. high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com