Technology for coproducing potassium alum and high-content lanthanum and cerium rare earth composite salt by using FCC waste catalyst

A technology of rare earth compound salt and waste catalyst, which is applied in the direction of rare earth metal compounds, aluminum compounds, aluminum sulfur compounds, etc., can solve the problems of secondary hazardous waste liquid and waste solid pollution, and achieve the promotion of recycling and reuse, saving water resources, Eliminate the effect of new waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

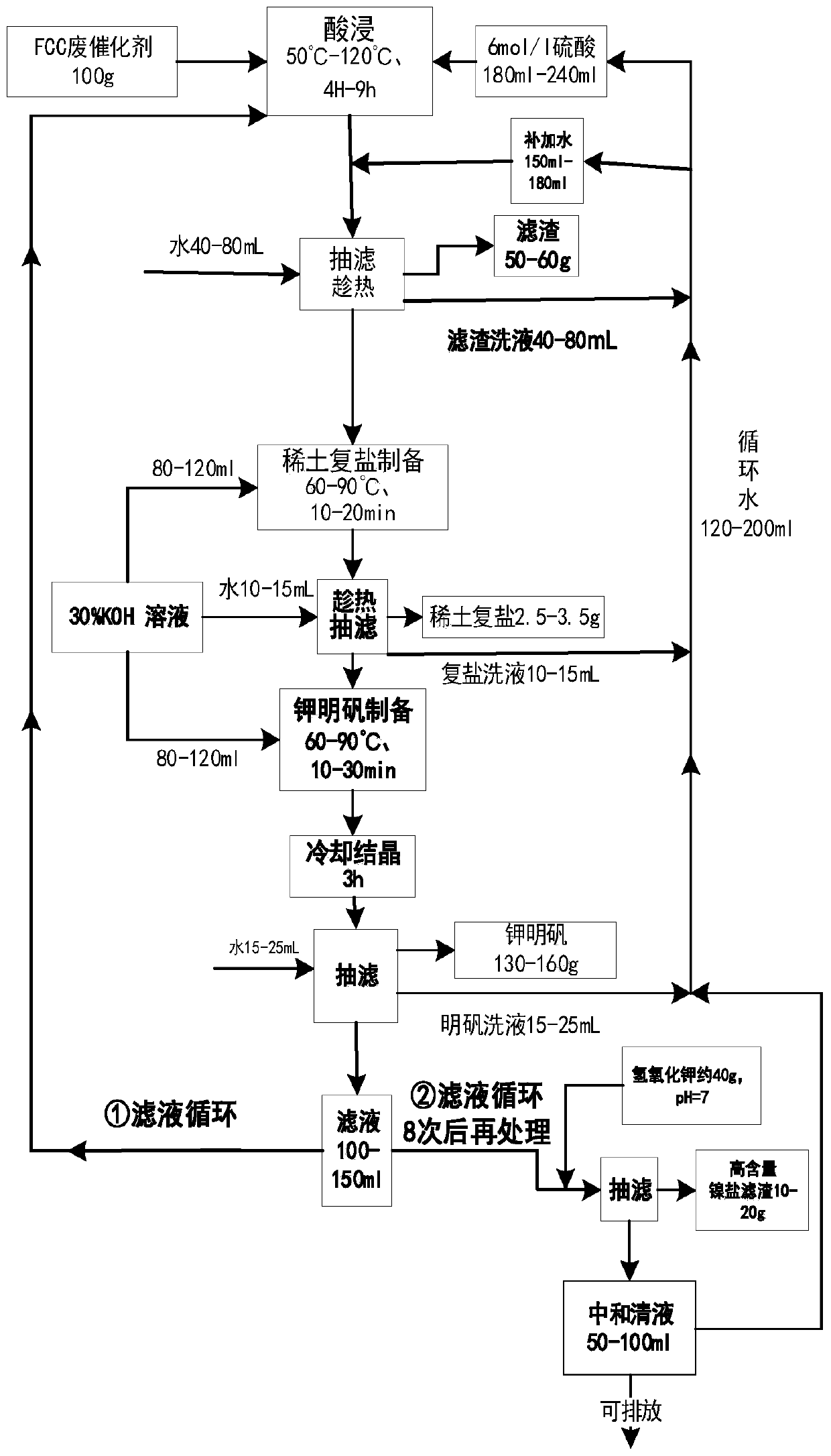

Method used

Image

Examples

Embodiment 1

[0031] The technique of utilizing FCC waste catalyst to jointly prepare potassium alum and high-content lanthanum, cerium rare earth compound salt comprises the following steps:

[0032] 1. Pretreatment: Take a petrochemical company’s FCC waste catalyst (containing Al: 19.26%, Ni: 0.96%, La: 0.41%, Ce: 0.32%, Fe: 0.31%) and heat it in an oven for 2 hours at 200°C , after drying the water, take out the spent catalyst and cool it to room temperature, sieve with a 300-600 mesh sieve to remove large grains of stones, and obtain a fine powder spent catalyst.

[0033] 2. Leaching: Accurately weigh 100g of the spent FCC catalyst in step 1, measure 230ml of 6mol / 1 sulfuric acid solution into a 500ml three-neck flask, and fix it on a constant temperature water bath, connect an electric stirrer, start heating and stirring, When the set temperature reaches 90°C, add the prepared spent catalyst and continue to stir until 5 minutes before the set time, add 162ml of water (to facilitate fil...

Embodiment 2

[0039] The technique of utilizing FCC waste catalyst to jointly prepare potassium alum and high-content lanthanum, cerium rare earth compound salt comprises the following steps:

[0040] 1. Pretreatment: Take a petrochemical company’s FCC waste catalyst (containing Al: 19.26%, Ni: 0.96%, La: 0.41%, Ce: 0.32%, Fe: 0.31%) and heat it in an oven for 2 hours at 200°C , after drying the water, take out the spent catalyst and cool it to room temperature, sieve with a sieve (300-600 mesh) to remove large particle stones, and obtain a fine powder spent catalyst.

[0041] 2. Leaching: Accurately weigh 100g of the spent FCC catalyst in step 1, measure 220ml of 6mol / l sulfuric acid solution into a 500ml three-neck flask, and fix it on a constant temperature water bath, connect an electric stirrer, and stir at a speed of 400r / min , start heating and stirring, when the set temperature reaches 100°C, add the prepared waste catalyst and continue to stir until 5 minutes before the set time, a...

Embodiment 3

[0046] Embodiment 3 utilizes the technology of FCC waste catalyst to jointly prepare potassium alum and high-content lanthanum, cerium rare earth compound salt and comprises the steps:

[0047] 1. Pretreatment: Take a petrochemical company’s FCC waste catalyst (containing Al: 19.26%, Ni: 0.96%, La: 0.41%, Ce: 0.32%, Fe: 0.31%) and heat it in an oven for 2 hours at 200°C , after drying the water, take out the spent catalyst and cool it to room temperature, sieve with a 300-600 mesh sieve to remove large grains of stones, and obtain a fine powder spent catalyst.

[0048] 2. Leaching: Accurately weigh 100g of the spent FCC catalyst in step 1, measure 210ml of 6mol / l sulfuric acid solution into a 500ml three-necked flask, and fix it on a constant temperature water bath, connect an electric stirrer, and stir at a speed of 400r / min , start heating and stirring, when the set temperature reaches 70°C, add the prepared waste catalyst and continue to stir until 5 minutes before the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com