ZnO/g-C3N4 composite photocatalyst as well as preparation method and application thereof

A technology of g-c3n4 and recombination light, which is applied in the direction of physical/chemical process catalysts, carbon-based compound preparation, chemical instruments and methods, etc., can solve problems such as poor response to visible light, achieve reduced recombination rate, simple and convenient operation, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

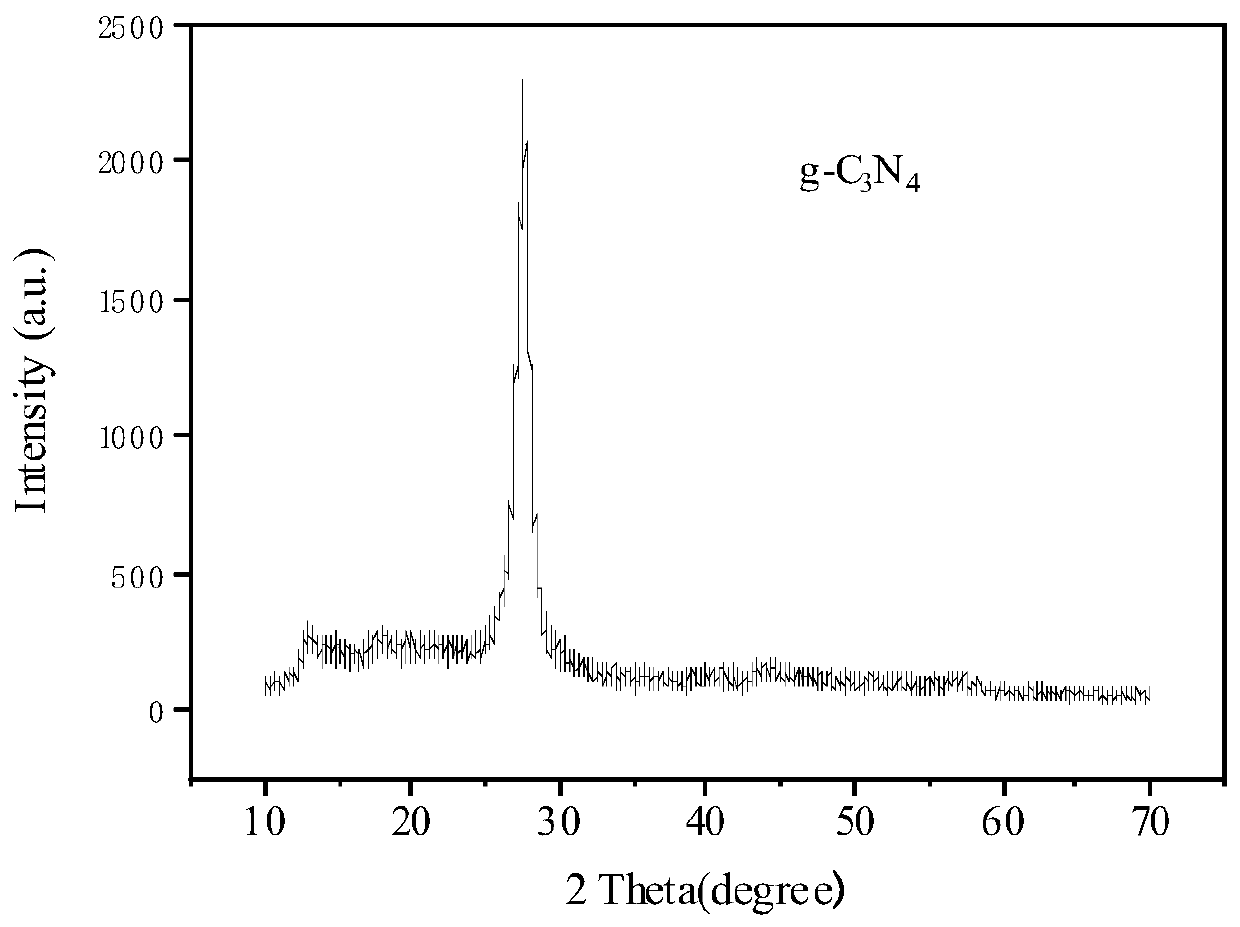

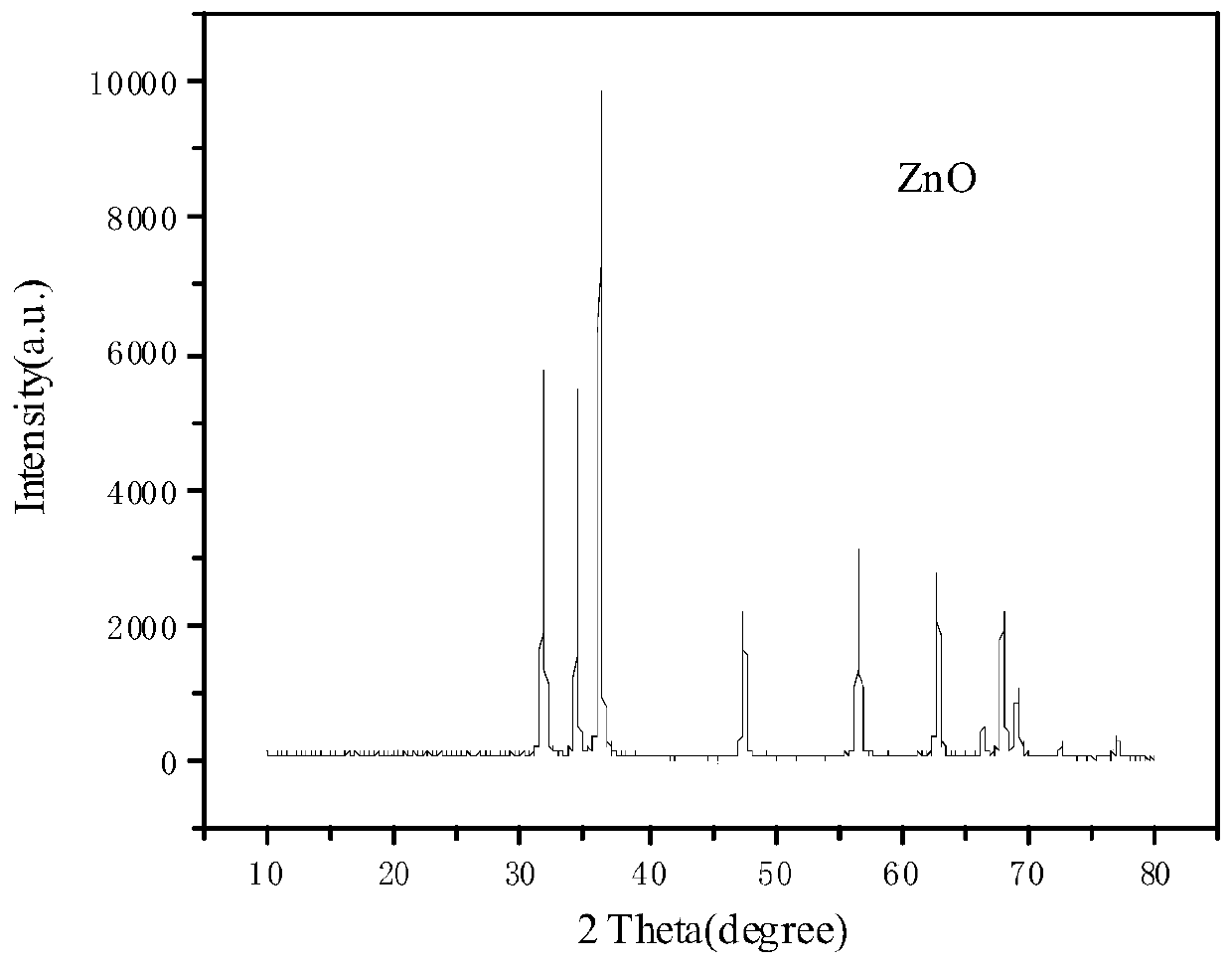

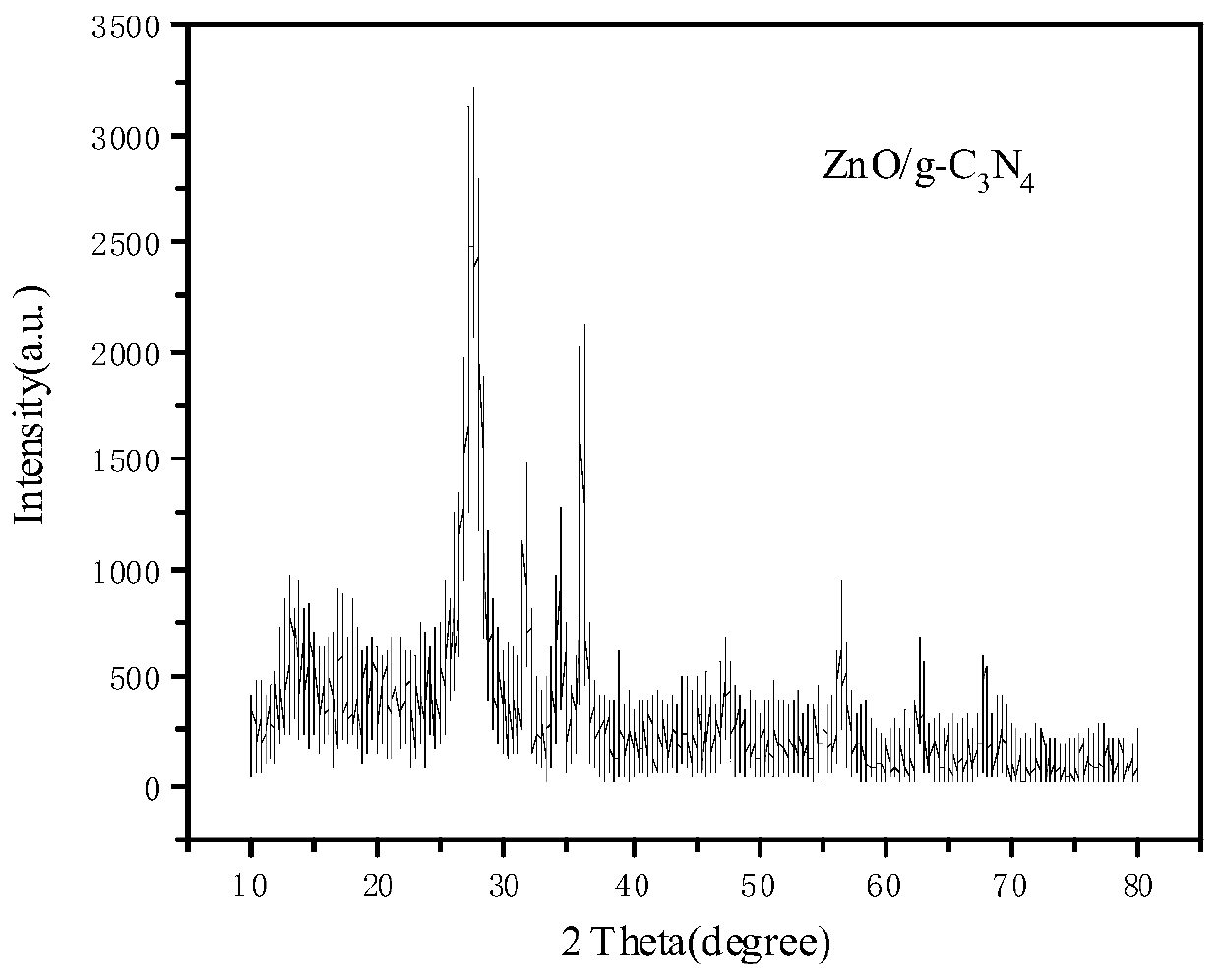

[0026] ZnO / g-C 3 N 4 composite photocatalyst

[0027] (1) The preparation method is as follows

[0028] 1) Pour 2.52g of melamine into a beaker filled with 100mL of deionized water. When the water temperature of the water bath is heated to 80°C, put the beaker into the water bath, heat and stir in the water bath until fully dissolved. Afterwards, the mixed solution was dried in an oven at 80° C., and then ground to obtain the recrystallization precursor A. Put the precursor A into the crucible, and in the tube furnace, under the protection of nitrogen, first heat up to 550°C at a heating rate of 5°C / min, then perform the first high-temperature calcination at 550°C, calcine for 4h, and cool to room temperature. Then, in the air environment, after heating up to 550°C at a heating rate of 5°C / min, a second high-temperature calcination was carried out at 550°C, calcined for 2 hours, and cooled naturally to obtain pure g-C 3 N 4 .

[0029] 2) Dissolve 0.44g of zinc acetate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com