Acetic acid cracking equipment for preparing ketene

A technology of acetic acid cracking and ketene, applied in the field of ketene, can solve the problems of high energy consumption in the ketene process, reduce the consumption of natural gas, etc., and achieve the effects of improving efficiency, reducing the amount of use, and increasing the initial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

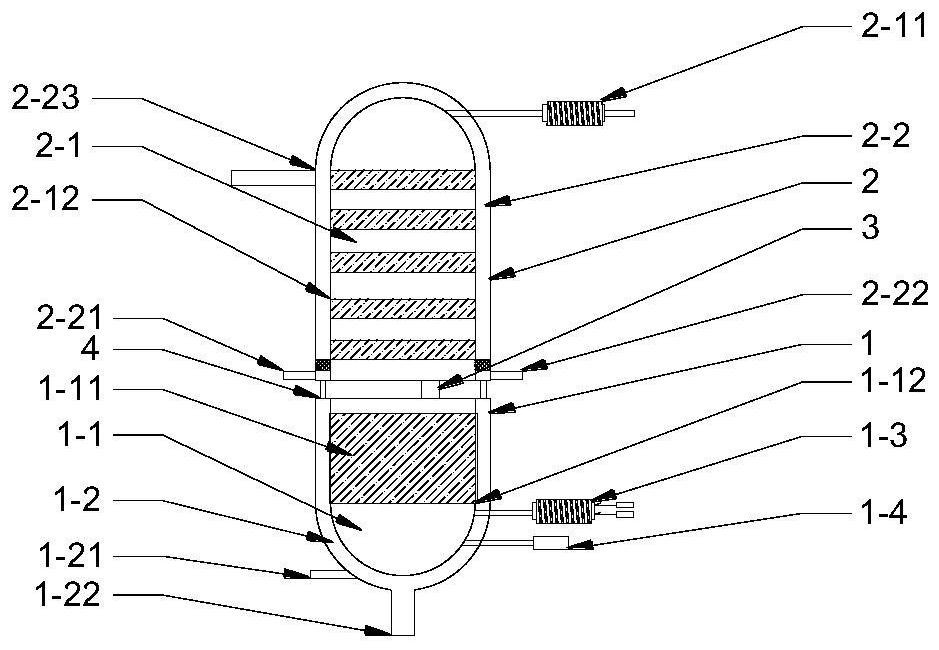

[0026] like figure 1 Shown: an acetic acid cracking device for preparing ketene, comprising: a preheating section 1 and a cracking section 2,

[0027] The preheating section 1 is composed of a preheating cavity 1-1 and a first heating jacket 1-2, and the first heating jacket 1-2 covers the outer surface of the preheating cavity 1-1. The bottom of the heating jacket 1-2 is connected with a natural gas inlet pipe 1-22, and an air inlet pipe 1-21 is arranged above the side of the natural gas inlet pipe 1-22, and the lower section of the preheating chamber 1-1 is connected with phosphoric acid for phosphoric acid. Quantitative metering pump 1-4 for triethyl ester and acetic acid evaporator 1-3 for acetic acid; acetic acid evaporator 1-3 is used to convert acetic acid vapor and water vapor into mixed steam, wherein water vapor accounts for 4% of the volume of acetic acid vapor %;

[0028] The cracking section 2 includes a cracking cavity 2-1 and a second heating jacket 2-2, and t...

Embodiment 2

[0041] An acetic acid cracking device for preparing ketene, comprising: a preheating section and a cracking section,

[0042] The preheating section consists of a preheating cavity and a first heating jacket, and the first heating jacket is covered on the outer surface of the preheating cavity, and a natural gas inlet pipe is connected to the bottom of the first heating jacket, and is located at the bottom of the first heating jacket. An air intake pipe is arranged above the side of the natural gas intake pipe, and the lower section of the preheating chamber is connected with a metering pump for quantifying triethyl phosphate and an acetic acid evaporator for acetic acid; the acetic acid evaporator is used to convert acetic acid vapor and water vapor into mixing Steam, of which water vapour accounts for 4% of the volume of acetic acid vapour;

[0043] The cracking section includes a cracking cavity and a second heating jacket, and the second heating jacket covers the surface o...

Embodiment 3

[0056] An acetic acid cracking device for preparing ketene, comprising: a preheating section 1 and a cracking section 2,

[0057] The preheating section 1 is composed of a preheating cavity 1-1 and a first heating jacket 1-2, and the first heating jacket 1-2 covers the outer surface of the preheating cavity 1-1. The bottom of the heating jacket 1-2 is connected with a natural gas inlet pipe 1-22, and an air inlet pipe 1-21 is arranged above the side of the natural gas inlet pipe 1-22, and the lower section of the preheating chamber 1-1 is connected with phosphoric acid for phosphoric acid. Quantitative metering pump 1-4 for triethyl ester and acetic acid evaporator 1-3 for acetic acid; acetic acid evaporator 1-3 is used to convert acetic acid vapor and water vapor into mixed steam, wherein water vapor accounts for 4% of the volume of acetic acid vapor %;

[0058] The cracking section 2 includes a cracking cavity 2-1 and a second heating jacket 2-2, and the second heating jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com