High-energy electron charging current testing system

A technology of high-energy electronics and charging current, applied in the direction of measuring current/voltage, measuring devices, measuring electrical variables, etc., can solve the problems of radiation damage sensitivity, semiconductor material performance deterioration, and unusability, etc., to achieve good radiation resistance, Simple structure, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

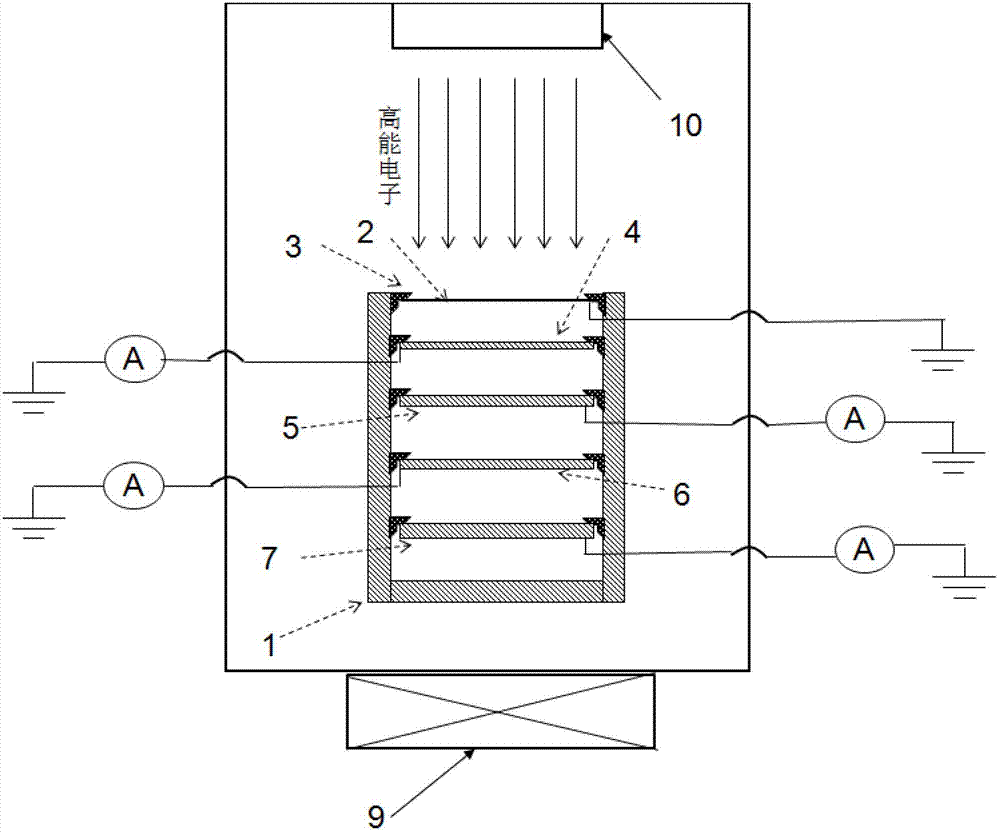

[0021] See attached figure 1 , a high-energy electron charging current testing system, which includes: a vacuum system 9, an electron accelerator 10 and an electron shielding device placed in the vacuum system 9, and an electrometer placed outside the vacuum system 9;

[0022] The electron accelerator 10 is placed directly against the upper end of the electron shielding device;

[0023] The electronic shielding device includes: metal shell 1, insulating ring 3, shielding layer 2, test pole A4, test pole B5, test pole C6 and test pole D7; the inside of the metal shell is composed of test pole A4, test pole B5, test pole C6 and The test pole D7 is layered sequentially from top to bottom. The top of the metal casing is sealed by the shielding layer 2. Insulation is provided at the connection between the metal casing and the shielding layer 2, test pole A4, test pole B5, test pole C6, and test pole D7. Ring 3; test pole A4, test pole B5, test pole C6 and test pole D7 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com