Electron-irradiation resisting shielding material and method for preparing same

A technology of electron radiation and shielding materials, applied in the fields of magnetic/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of high energy of bremsstrahlung radiation and limitation of shielding effect, and achieve reduced movement speed and good shielding effect , the effect of high shielding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

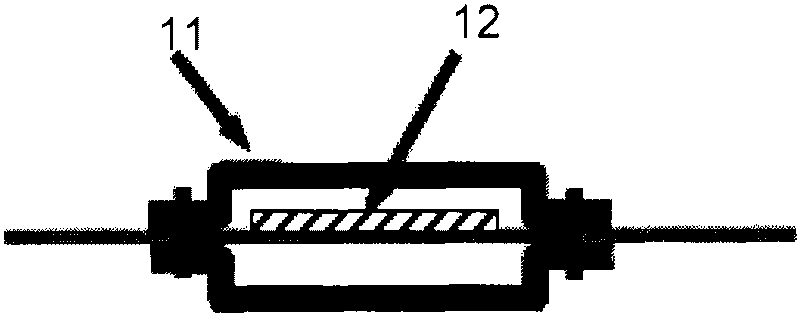

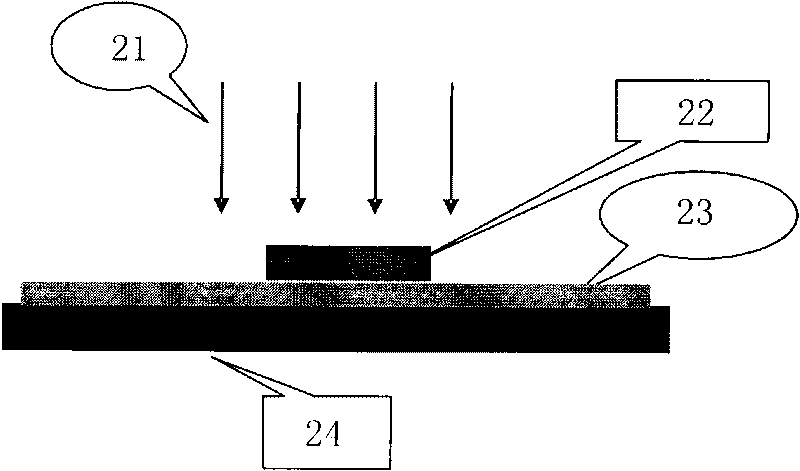

Image

Examples

Embodiment 1

[0039] According to 75vol.% AlN (average particle size of 3 microns), 25vol.% W (average particle size of 5 microns), and 3vol.% of the total volume of AlN and W CaF 2 Ingredients, the original powder adopts agate pot and zirconia balls, with absolute ethanol as the grinding medium, according to the ball-to-material ratio of 4:1, it is mixed on a high-energy planetary ball mill for 24 hours, and the speed is 125 rpm. After the mixed powder slurry was dried and sieved, the mixed powder was filled into a mold, subjected to 3MPa×5min unidirectional axial pressing, and then subjected to 200MPa×15min cold isostatic pressing to obtain Mo(W)-AlN Composite green body; placing the composite green body in ZrO 2Under a nitrogen atmosphere in a crucible, carry out hot-press sintering at 1800°C for 30MPa×30min to obtain a composite block material, and then process it into required standard samples according to different requirements.

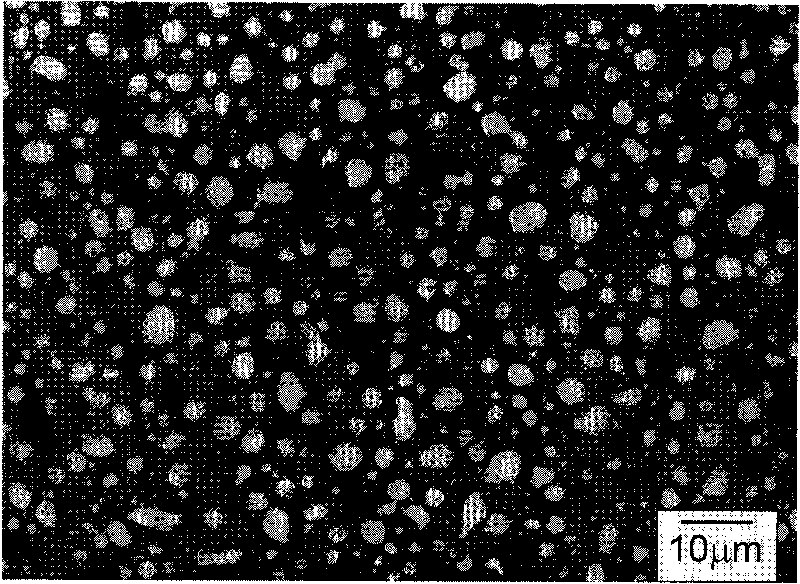

[0040] Use BRIGHT A100 digital metallographic microsc...

Embodiment 2

[0044] According to 85vol.% AlN (average particle size of 5 microns), 15vol.% W (average particle size of 20 microns), and 8vol.% of the total volume of AlN and W Y 2 o 3 Ingredients, the original powder adopts agate pot and zirconia balls, with absolute ethanol as the grinding medium, according to the ball-to-material ratio of 4:1, it is mixed on a high-energy planetary ball mill for 24 hours, and the speed is 125 rpm. After the mixed powder slurry was dried and sieved, the mixed powder was filled into a mold, subjected to 5MPa×1min unidirectional axial pressing, and then subjected to 200MPa×15min cold isostatic pressing to obtain Mo(W)-AlN Composite green body: place the composite green body in an AlN crucible for sintering under a nitrogen atmosphere at 1550°C at 30MPa×30min to obtain a composite block material, and then process it into the required standard sample.

Embodiment 3

[0046] According to 65vol.% AlN (average particle size of 0.1 micron), 35vol.% Mo (average particle size of 1 micron), and 5vol.% of the total volume of AlN and Mo CaF 2 Ingredients, the original powder adopts agate pot and zirconia balls, with absolute ethanol as the grinding medium, according to the ball-to-material ratio of 4:1, it is mixed on a high-energy planetary ball mill for 24 hours, and the speed is 125 rpm. After the mixed powder slurry was dried and sieved, the mixed powder was filled into a mold, subjected to 5MPa×2min unidirectional axial pressing, and then subjected to 200MPa×15min cold isostatic pressing to obtain Mo(W)-AlN Composite green body: the composite green body is placed in an AlN crucible for sintering under a nitrogen atmosphere at 1650°C for 3 hours under normal pressure to obtain a composite block material, and then processed into the required standard sample.

[0047] The anti-electron radiation shielding composite material prepared in Examples 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com