Processing method for improving enzymolysis efficiency of animal protein by utilizing high energy electron beam irradiation technology

A technology of high-energy electron beams and protein enzymes, which is applied in the fields of high-energy electron radiation processing and deep processing of livestock and poultry meat, can solve problems that do not involve enzymatic hydrolysis efficiency, and achieve the effects of accelerating efficiency and speed, increasing the speed of enzymatic hydrolysis, and increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

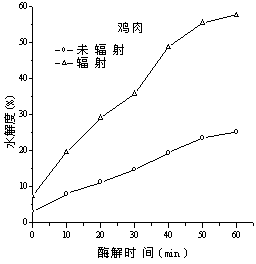

[0018] Embodiment 1: The method that high-energy electron radiation improves chicken enzymatic hydrolysis rate

[0019] According to the processing method of high-energy electron radiation technology to improve the efficiency of enzymatic hydrolysis in the manual, thaw the frozen chicken breast in running tap water, wash after thawing, remove foreign matter, and grind it through a meat grinder with a screen aperture of 6mm; grind it; Put the minced chicken breasts into PE bags, lay them flat on metal trays, keep the thickness basically uniform, and the maximum thickness does not exceed 6.0 cm, put the metal trays with chicken breasts on the conveyor chain of the high-energy electron radiator The radiation treatment is prepared on the top. The technical parameters of the radiation treatment are that the output energy of the electron beam is 10MeV, the distance between the high-energy electron beam scanner and the product is 520mm, the scanning frequency is 300pps, and the scanni...

Embodiment 2

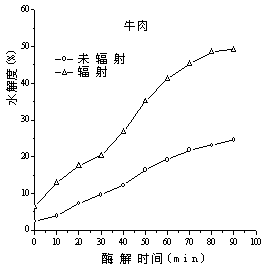

[0020]Embodiment 2: the method that high-energy electron radiation improves beef enzymatic hydrolysis rate

[0021] According to the processing method of high-energy electron radiation technology to improve the efficiency of enzymatic hydrolysis in the manual, the frozen beef (beef brisket) is thawed in running tap water, cleaned after thawing, and foreign matter, tendons and tendons, etc. are removed, and the hole diameter of the mesh plate is 6mm. ground meat in a special meat grinder; put the ground beef into a PE bag and lay it flat on a metal tray to keep its thickness basically uniform, and the maximum thickness shall not exceed 6.0 cm. Place the metal tray containing the beef on the The radiation treatment is prepared on the transmission chain of the high-energy electron irradiator. The technical parameters of the radiation treatment are that the output energy of the electron beam is 10MeV, the distance between the high-energy electron beam scanner and the product is 520...

Embodiment 3

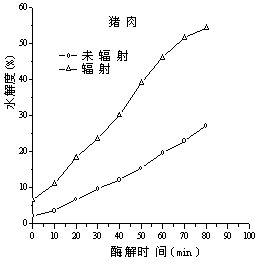

[0022] Embodiment 3: the method that high-energy electron radiation improves pork enzymatic hydrolysis rate

[0023] According to the processing method of high-energy electron radiation technology to improve the efficiency of enzymatic hydrolysis in the manual, thaw frozen pork (pig hind legs) in running tap water, wash after thawing, and remove foreign matter, and use a meat grinder with a sieve aperture of 6mm. Grinding treatment; put the minced pork into PE bags, spread it flat on metal trays, keep its thickness basically uniform, and the maximum thickness does not exceed 6.0 cm, and place the metal trays containing pork on a high-energy electron radiator Radiation treatment is prepared on the conveyor chain. The technical parameters of radiation treatment are that the output energy of the electron beam is 10MeV, the distance between the high-energy electron beam scanner and the product is 520mm, the scanning frequency is 380pps, and the scanning width is 500 mm. The radiati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com