Patents

Literature

75results about How to "Organizational structure is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

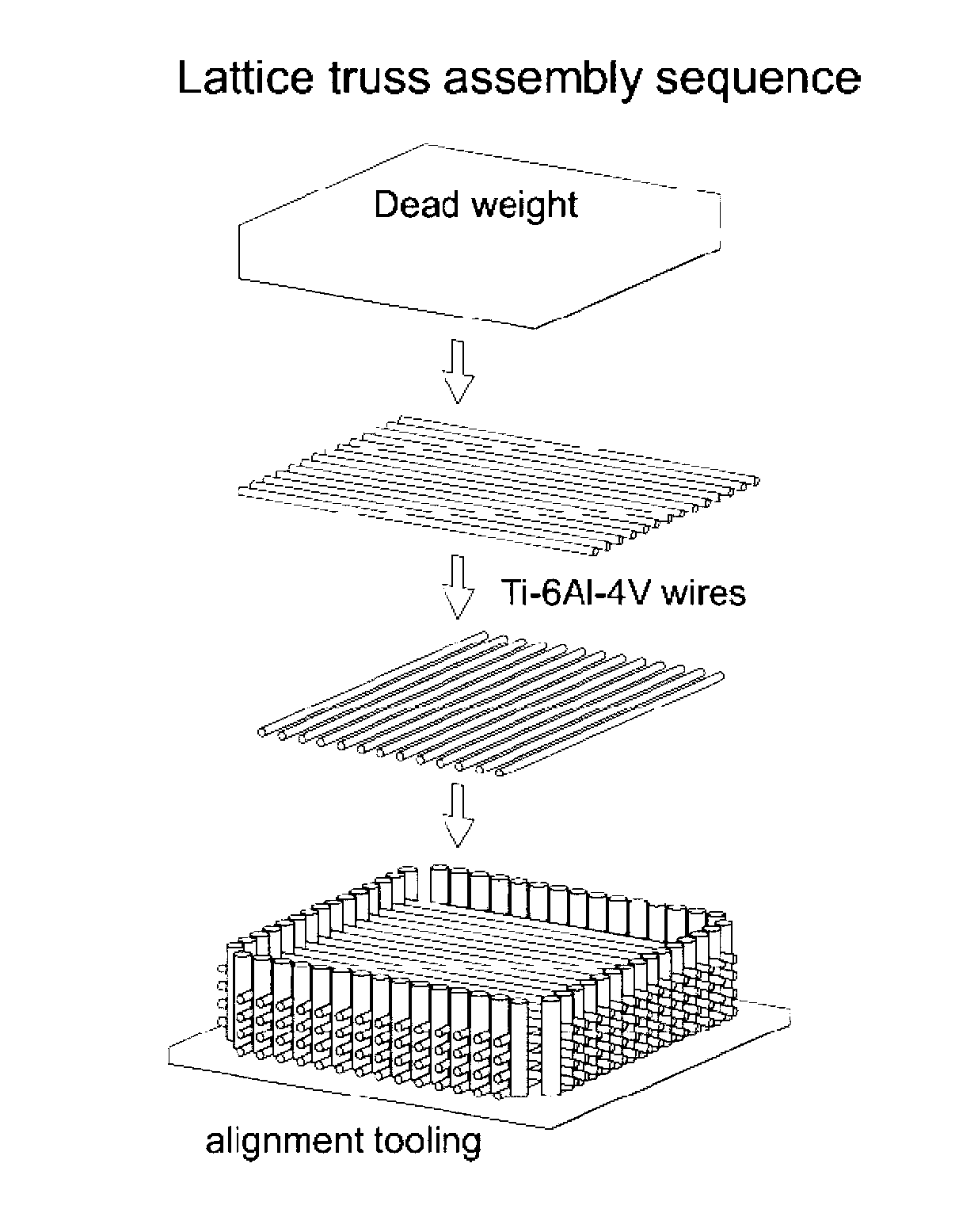

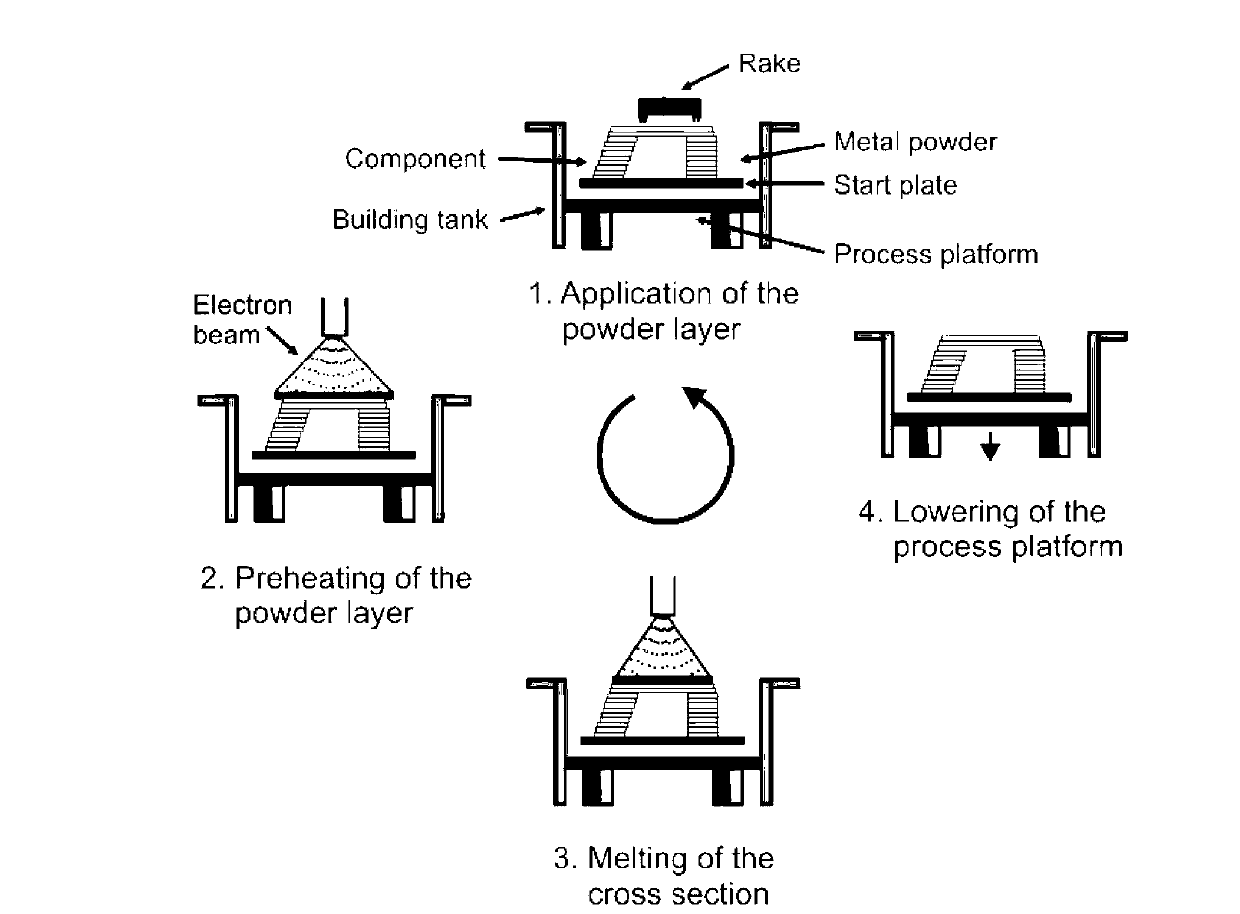

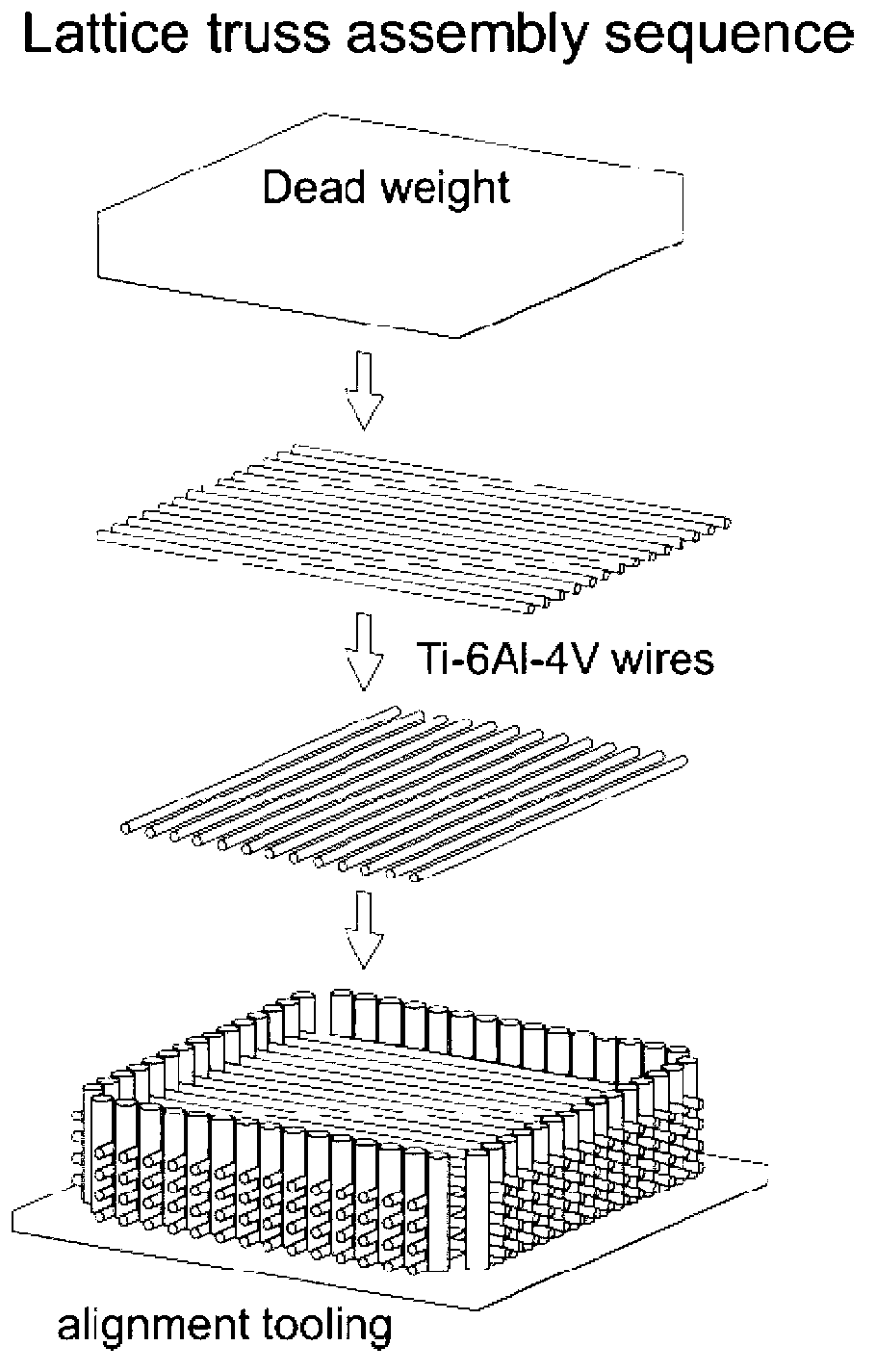

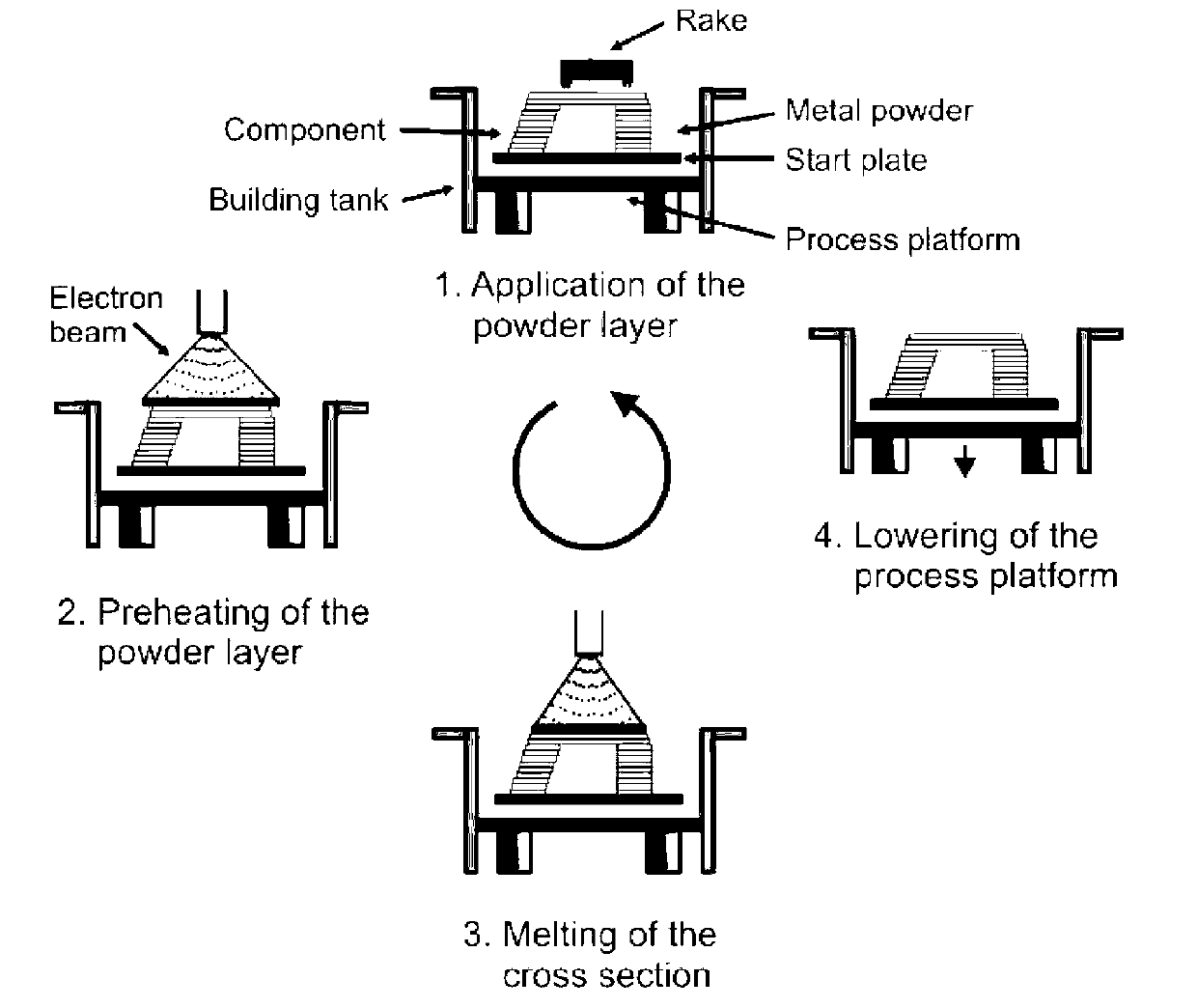

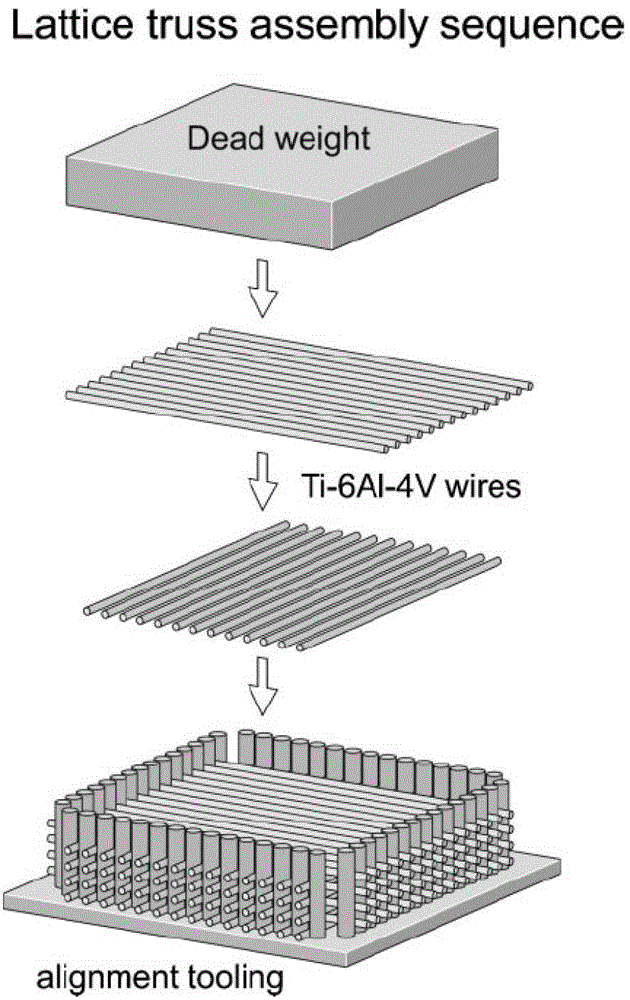

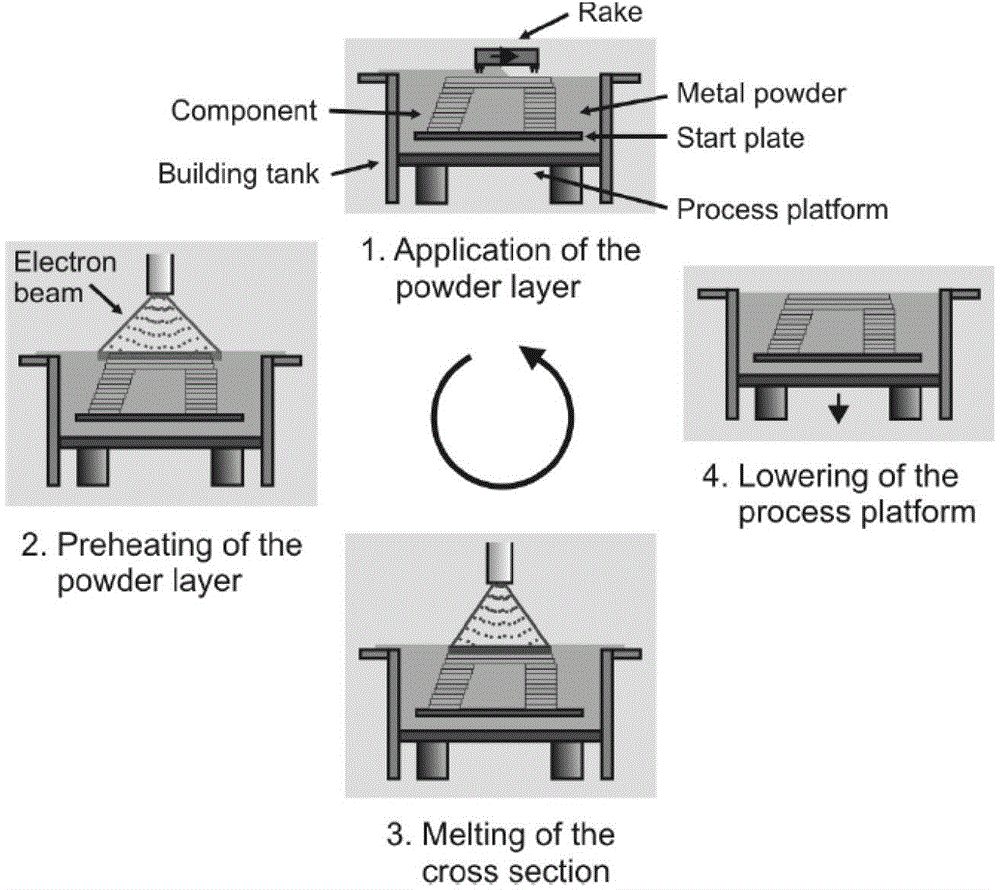

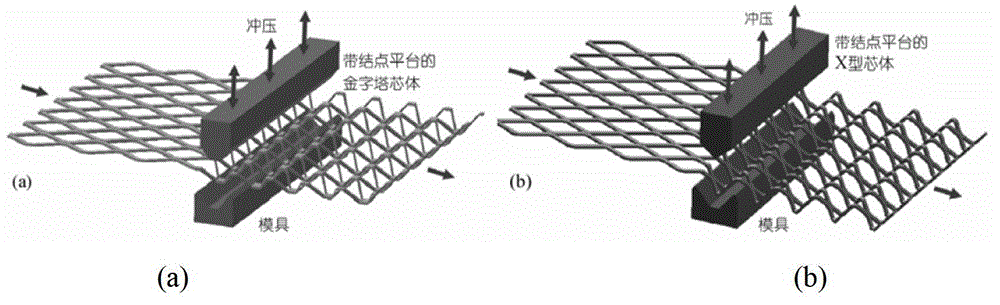

Preparation method of titanium alloy three-dimensional lattice sandwich structure

ActiveCN102990300AImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusUltimate tensile strengthTitanium alloy

The invention belongs to a titanium alloy structure forming technology, and in particular relates to a preparation method of a titanium alloy three-dimensional lattice sandwich structure. According to the invention, a titanium alloy three-dimensional lattice sandwich member is prepared by adopting a superplastic forming method, and the method of preparing the titanium alloy three-dimensional lattice sandwich structure by adopting a superplastic forming / diffusion connection process is proposed for the first time, therefore on one hand, the shape of a formed part, in particular to the titanium alloy three-dimensional lattice structure with a complex shape, can be accurately controlled, and on the other hand, the technical problem that a titanium alloy three-dimensional lattice sandwich layer is difficult to form is solved. The structure which is prepared by superplastic forming / diffusion connection has higher bonding strength because the three-dimensional lattice sandwich layer and upper and lower panels are bonded together by a diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

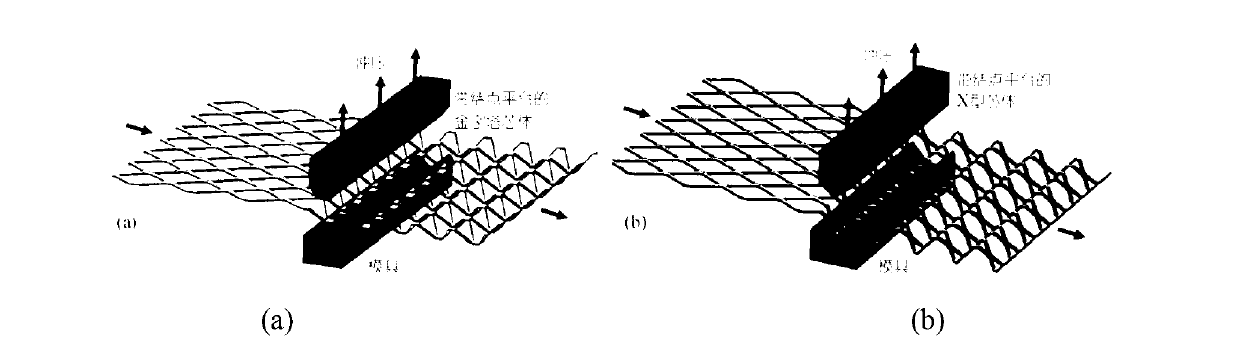

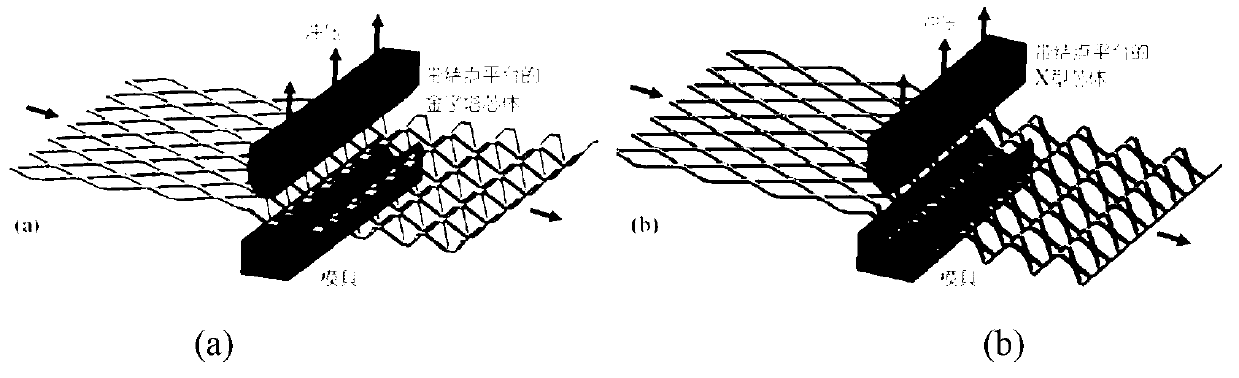

Preparation method for X-type titanium alloy three-dimensional lattice sandwich structure

ActiveCN102990299AImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusMetallurgyUltimate tensile strength

The invention belongs to the titanium alloy structure forming technology and relates to a method for preparing an X-type titanium alloy three-dimensional lattice sandwich structure by superplastic forming / diffusion connection. An X-type titanium alloy three-dimensional lattice sandwich member is prepared by adopting the superplastic forming method; and the X-type titanium alloy three-dimensional lattice sandwich structure is prepared by adopting the superplastic forming / diffusion connection process for the first time, so that on one hand, formed parts, especially the X-type titanium alloy three-dimensional lattice sandwich structures with complex shapes can be accurately controlled in shape, and the technical difficult problem of low possibility of formation of an X-type titanium alloy three-dimensional lattice sandwich is solved at the same time. The structure prepared by adopting the superplastic forming / diffusion connection process is higher in bonding strength as the three-dimensional lattice sandwich is connected with upper and lower panels through the diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Manufacturing method for fine copper-silver alloy wires

ActiveCN104353696AComposition is stableOrganizational structure is stableSingle bars/rods/wires/strips conductorsWire breakageMaterials science

The invention discloses a manufacturing method for fine copper-silver alloy wires. The method comprises steps as follows: (1) smelting and continuous casting of copper-silver alloy blanks; (2) drawing of copper-silver alloy rods; (3) intermediate heat treatment of copper-silver alloy wires; (4) drawing of the copper-silver alloy wires after intermediate heat treatment into copper-silver alloy wires with diameters in a range of 0.1-0.25 mm by an intermediate wire drawing machine. With the adoption of the manufacturing method for the fine copper-silver alloy wires, components and organization structures of raw copper-silver alloy materials can be stabilized, the texture and the performance of silver are stabilized through control on the distribution form of the silver in the copper-silver alloy wires through heat treatment during wire drawing, wire breakage due to local stress concentration caused by unstable components and organization structures during wire machining is avoided, and manufacturing of the fine copper-silver alloy wires is guaranteed.

Owner:HENAN YOUK ELECTRONICS MATERIALS +2

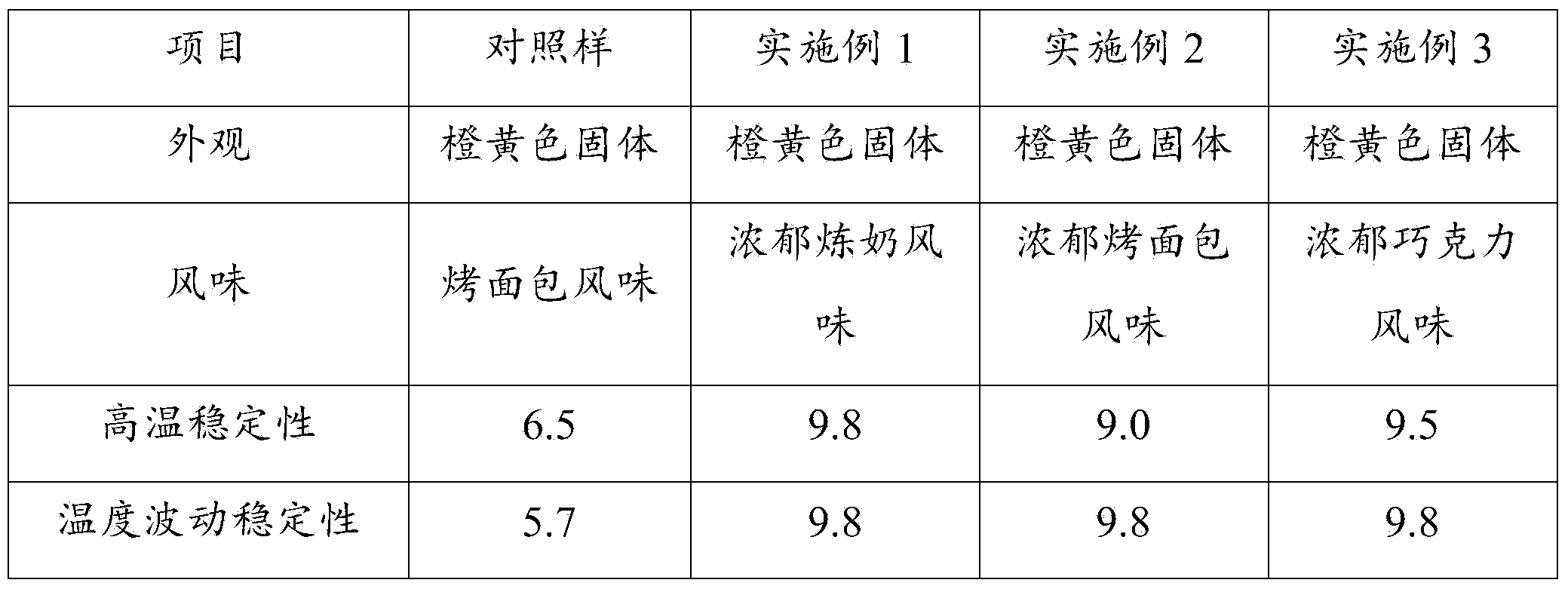

Sweet cream and its preparation method

ActiveCN103815050AImprove fatty acid profileImprove stabilityEdible oils/fats production/working-upGlycerolOil phase

The invention discloses sweet cream and its preparation method, and the sweet cream is prepared from the following raw materials by weight: 30.0-60.0% of base oil, 8.0-15.0% of a sweetening agent, 0.1-0.5% of a thickening agent, 5.0-15.0% of a filler, 0.5-2.0% of glycerol, 0.1-0.5% of an aqueous phase emulsifier, 0.2-0.5% of an oil phase emulsion, 0.1-0.3% of an edible essence, 0.0005-0.0015% of beta carotene and the balance of water. The sweet cream has good high temperature stability, may not precipitate by 30min of high temperature cooking at 100 DEG C, may not sugar by 7 cycles of repeated temperature fluctuations with each cycle comprising 12h of placing at 5 DEG C and 12h of placing at 20 DEG C, and has a stable organizational structure.

Owner:广州市雅禾生物科技有限公司

Preparation method of ITO tubular target material

ActiveCN107244911AIncrease profitMeet application requirementsDischarging arrangementVacuum evaporation coatingHigh densitySlurry

The invention discloses a preparation method of an ITO tubular target material. The preparation method comprises: using ITO nanometer powder as a raw material, dewatering and molding a prepared ITO slurry by using a rotation mold and an ultrasonic wave vibration device to obtain an ITO target material billet, carrying out degreasing treatment on the billet at a low temperature, and sintering the degreased billet under a certain sintering condition to obtain the ITO tubular target material. According to the present invention, with the preparation method, the automated production is easily performed so as to reduce the labor intensity and the labor cost; and the prepared ITO rotating target material product has characteristics of uniform and stable structure, high density and good market prospect, and can meet the application requirements of downstream enterprises.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for graphene-enhanced copper-niobium multi-core composite wire

ActiveCN106448799AHigh strengthImprove ductilityConductive materialMetal/alloy conductorsReduction treatmentAlcohol

The invention provides a preparation method for a graphene-enhanced copper-niobium multi-core composite wire. The preparation method comprises the following steps: firstly, uniformly mixing graphene powder, niobium powder and copper powder to obtain mixed powder; secondly, adding a tackifier and the mixed powder into alcohol ketone mixed solution, stirring uniformly, drying to obtain a powder material, and then performing thermal reduction treatment on the powder material to obtain graphene-enhanced copper-niobium composite powder; thirdly, filling a pipe with graphene-coated copper-niobium composite powder to obtain a piped composite body; fourthly, drawing to obtain a single-core composite wire; fifthly, performing primary compounding moulding to prepare a 19-core composite wire; sixthly, performing secondary compounding moulding to prepare a 192-core composite wire; seventhly, performing tertiary compounding moulding to obtain the graphene-enhanced copper-niobium multi-core composite wire. The wire prepared by the preparation method has the characteristics of high strength, high extensibility, high conductivity and the like of the graphene, and the obstacle that the performance of a Cu / Nb material prepared by a conventional process cannot be further improved is overcome.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

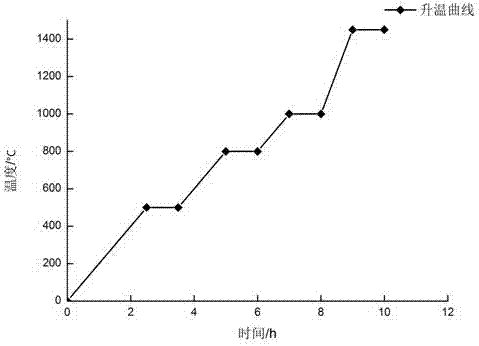

Preparation method of (Mn, Co)3O4 spinel coating

ActiveCN103103592AUniform and dense structureImprove performanceElectrolytic inorganic material coatingAlcoholCeramic coating

The invention relates to a preparation method of a (Mn, Co)3O4 spinel coating, and belongs to the technical fields of preparation and property of a ceramic coating. The preparation method comprises the steps of: mixing by taking (Mn, Co)3O4 powder as a material and taking absolute ethyl alcohol as a solvent, wherein the percent content of mass fraction of the (Mn, Co)3O4 powder is 1-15%; carrying out ultrasonic agitation to obtain (Mn, Co)3O4 powder suspension liquid; then depositing a (Mn, Co)3O4 coating on the surface of a metal substrate under the effect of 200-700V of constant voltage or pulse voltage; and drying and then carrying out high temperature thermal treatment to obtain the (Mn, Co)3O4 spinel coating. The method disclosed by the invention has the advantages of simple technological operation, low cost, good formed coating structure compactness and the like.

Owner:昆明理工大学设计研究院有限公司

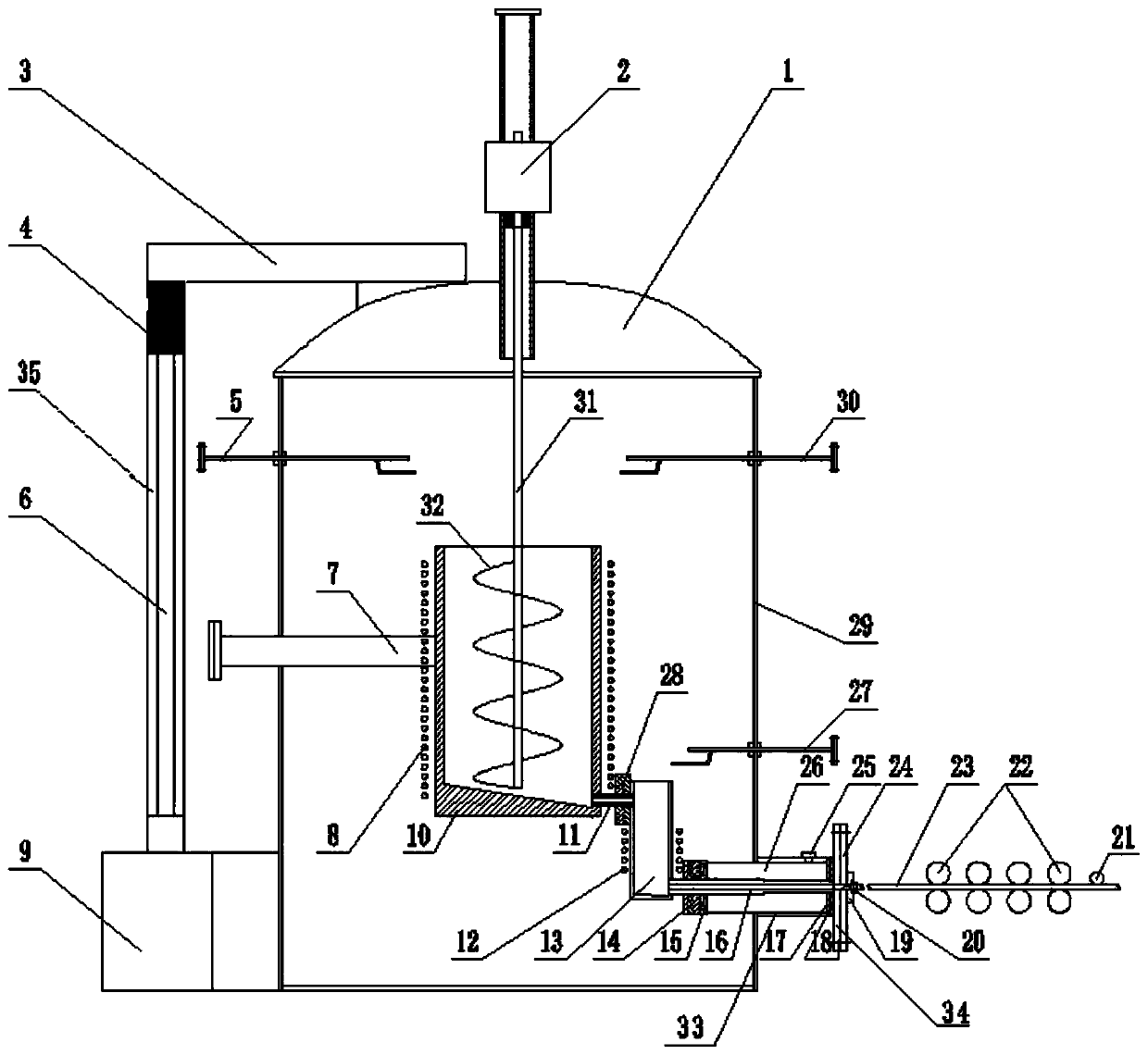

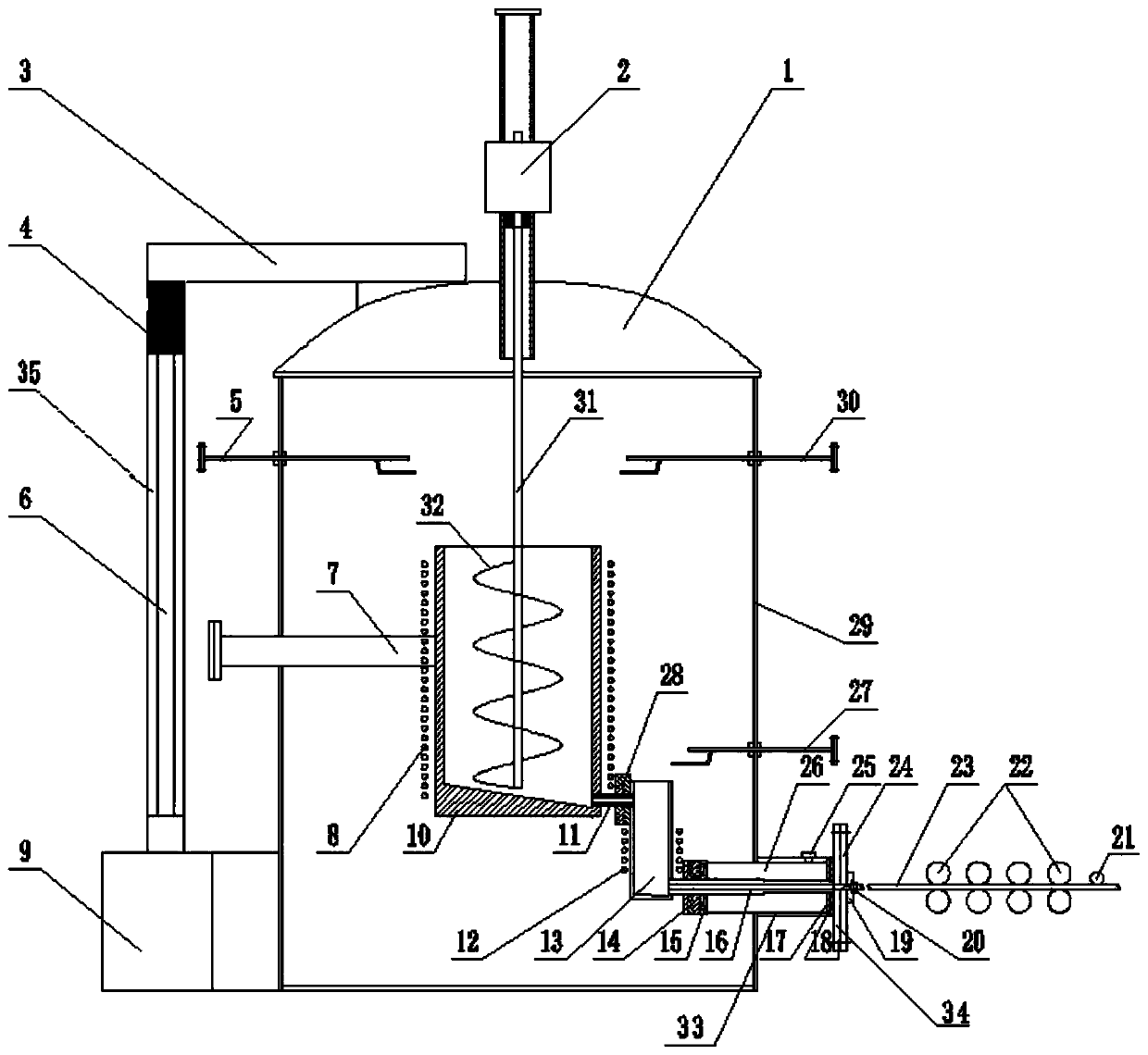

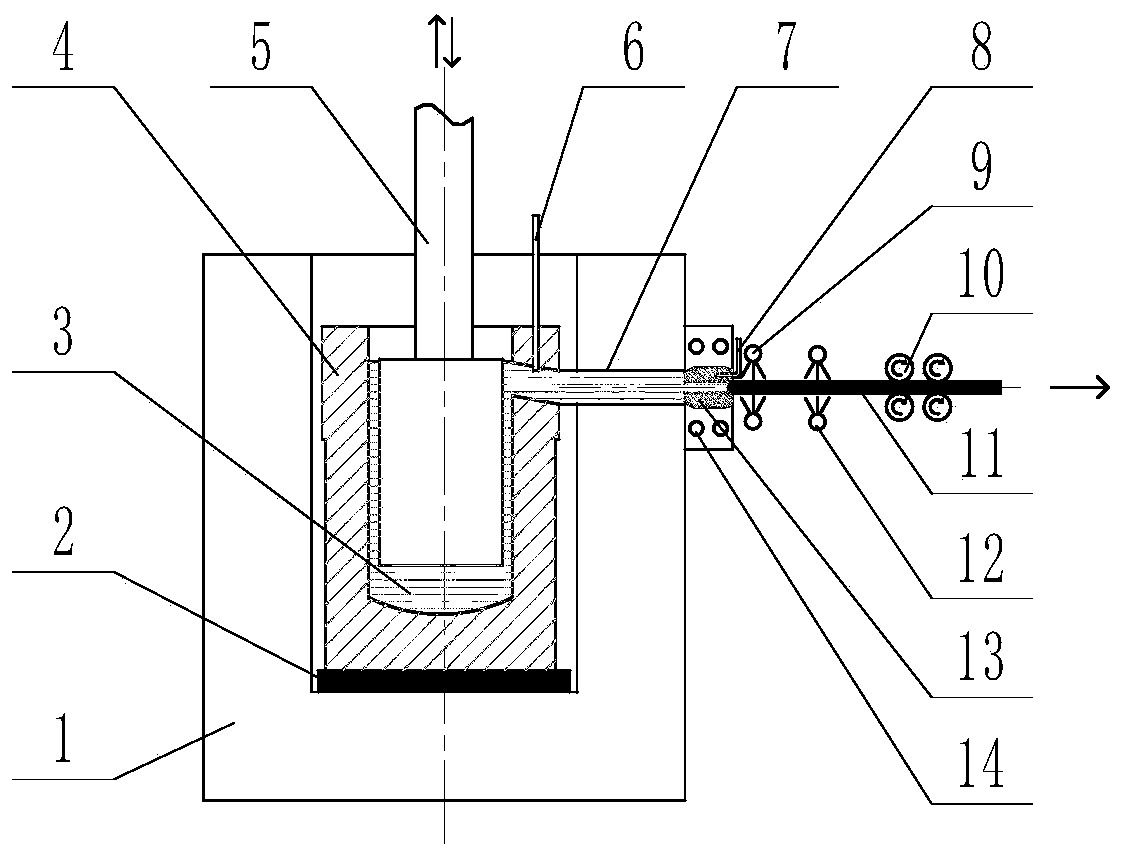

Horizontal guide type copper alloy wire rod vacuum continuous casting machine

The invention belongs to an alloy wire rod casting device, and particularly discloses a horizontal guide type copper alloy wire rod vacuum continuous casting machine. The machine comprises an vacuum device, a smelting device, a crystallizer device, a cooling device and a traction device. The smelting device is located in the vacuum device, the smelting device comprises a main crucible and an auxiliary crucible, the auxiliary crucible is located at the tail end of the main crucible; the crystallizer device is connected with the smelting device, the cooling device is used for cooling the crystallizer device; and the traction device is positioned at the tail end of the crystallizer device and is used for carrying out traction continuous casting on the alloy in the crystallizer. According to the vacuum continuous casting machine, vacuum melting is adopted, so that the alloy elements are prevented from being oxidized, and the continuous casting alloy range of the vacuum continuous casting machine is greatly increased. The double-crucible system of the main crucible and the auxiliary crucible ensures that the alloy is accurately added, the influence of the liquid disturbance of the maincrucible on the continuous casting stability is eliminated through double-crucible smelting, and the multicomponent alloy material which is uniform in component and stable in structure is obtained.

Owner:ZHEJIANG TONY ELECTRONICS CO LTD

High-strength, high-electrical-conductivity and high-heat-conductivity copper-silver series alloy wire material and preparation method thereof

The invention relates to a high-strength, high-electrical-conductivity and high-heat-conductivity copper-silver series alloy wire material and a preparation method thereof and belongs to the technicalfield of metal material preparation. The preparation method for the high-strength, high-electrical-conductivity and high-heat-conductivity copper-silver series alloy wire material comprises the following steps of (1), batching and smelting; (2), hot type horizontal continuous casting, specifically, a melt adopts the hot type horizontal continuous casting to obtain a blank material, a crystallizerof the hot type horizontal continuous casting is a hot type crystallizer, the temperature of the melt inside the hot type crystallizer is maintained above the melting point of the copper-silver series alloy wire material, and a cooling method of the hot type horizontal continuous casting is twice cooling and is water cooling; and (3), combined thermomechanical treatment, specifically, solid solution treatment, drawing plastic deformation treatment and aging heat treatment are performed on the blank material in sequence, and the high-strength, high-electrical-conductivity and high-heat-conductivity copper-silver series alloy wire material is obtained. By means of the preparation method for the high-strength, high-electrical-conductivity and high-heat-conductivity copper-silver series alloywire material, improvement of casting-state structures is facilitated, the electrical conductivity, the heat conductivity and the tensile strength of copper-silver alloy are improved, and continuousproduction can be realized.

Owner:HENAN UNIV OF SCI & TECH

Re-containing seamless Cr-Mo-V type alloy steel pipe and production method thereof

InactiveCN103215494AOrganizational structure is stableHigh durabilityFurnace typesRigid pipesChemical compositionEconomic benefits

The invention relates to a Re-containing seamless Cr-Mo-V type alloy steel pipe and a production method thereof. The Re-containing seamless Cr-Mo-V type alloy steel pipe is characterized in that the material of the steel pipe comprises the following chemical components by weight percent: 0.08-0.15% of C, 0.19-0.36% of Si, 0.40-0.70% of Mn, 0.95-1.20% of Cr, 0.15-0.30% of V, 0.25-0.35% of Mo, 0.03-0.06% of Re, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.015% of N, less than or equal to 0.003% of O and the balance of Fe and inevitable impurities. The process of normalization and tempering is adopted for the steel pipe having the wall thickness of less than 30 mm in thermal treatment in the production method; the heating temperature of normalization is in the range of 980-1020 DEG C, and heat preservation time is 2.0 min / mm, but not less than 30 minutes; the temperature of tempering is in the range of 730-750 DEG C and heat preservation time is not less than 1 hour; and then cooling is performed in static air. Quenching and tempering are adopted for the steel pipe with the wall thickness greater than or equal to 30 mm; the temperature of quenching is within the range of 950-990 DEG C, the temperature of tempering is in the range of 730-750 DEG C and heat preservation time is not less than 1 hour; and then cooling is performed in static air. The Re-containing seamless Cr-Mo-V type alloy steel pipe is simple in components, low in cost, high in production efficiency, good in economic benefit, and suitable for large-scale production, and has high popularization value.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Process for manufacturing cylinder head cover

InactiveCN106086539AReduce flowReduce frictional resistanceFoundry mouldsMetallic material coating processesManganeseAlloy

The invention relates to a process for manufacturing a cylinder head cover. The process includes the following steps of raw material preparation, mold preheating, paint spraying, core setting and mold assembling, smelting, pouring, cooling, cleaning and polishing, heat treatment, shot blasting and passivating treatment. According to the step of raw material preparation, a certain amount of copper, silicon, magnesium, manganese, nickel, titanium, zinc, chromium, lead, tin, ferrum and aluminum is weighed as required. According to the step of smelting, the raw materials in the first step are put into an electric furnace to be heated and smelted. According to the step of pouring, molten alloy in the fifth step is poured into a mold preheated in the second step. According to the step of cleaning and polishing, the method of sand blasting is adopted for cleaning the surfaces of castings. According to the step of heat treatment, parts obtained in the eighth step are subjected to quenching treatment and aging treatment. According to the step of shot blasting, the parts obtained in the ninth step are subjected to shot blasting. According to the step of passivating treatment, the parts obtained in the tenth step are put into a chromate solution for passivating. The process for manufacturing the cylinder head cover has the advantages of being reasonable in working procedure, capable of saving raw materials and reducing cost, easy to operate, stable in working, high in production efficiency, high in product percent of pass and good in forming quality.

Owner:娄土岭

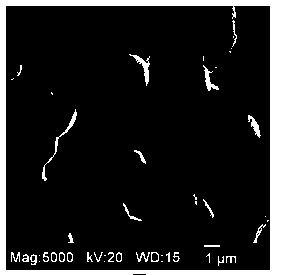

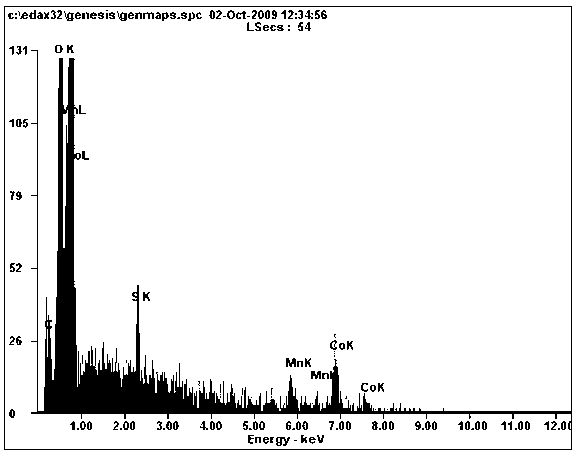

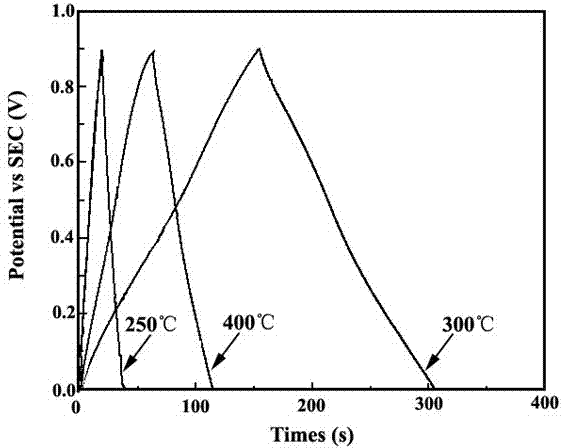

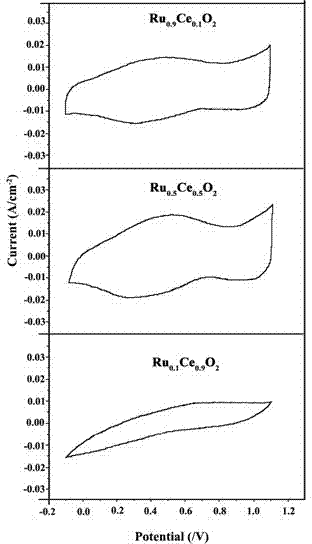

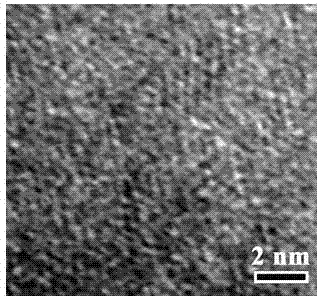

Active oxide material containing Ce and preparation method thereof

InactiveCN102500369AImprove electrocatalytic activityMulti-electrocatalytic activityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCatalyst activation/preparationSocial benefitsSource material

The invention discloses an active oxide material containing Ce and a preparation method thereof. The molar ratio of Ce and Ru of the active oxide material is from 3:7 to 7:3, CeCI3 and RuCI3 are used as source materials to be soluble in ethanol so as to be made into active slurry, and the active slurry is evaporated and solidified through heating and is oxidized and sintered to obtain the Ru-containing oxide active material with high Ce. Compared with pure RuO2 active materials and RuO2 active materials with 10% molar content of Ce, active area of the active oxide material is improved remarkably, and the active oxide material containing Ce has superior electro-catalysis activity. The active oxide material containing Ce is simple in preparation method, strong in operability, easy to obtain raw materials and low in cost, and has remarkable economic and social benefits.

Owner:FUZHOU UNIV

High-temperature-resistant coating for ships

InactiveCN105778684AImprove high temperature resistanceEasy to prepareFireproof paintsAnti-corrosive paintsFiberCellulose

The invention discloses a high-temperature-resistant coating for ships. The high-temperature-resistant coating for the ships is prepared from organic silicon resin, ethylcellulose, nano titania, nano aluminium oxide, fluorinated siloxane-acrylate emulsion, silicon carbide, propylene glycol, fluorinated ethylene propylene, polyetheretherketone fibers, polyacrylamide, water, ethanol, a dispersing agent, an antifoaming agent, a leveling agent, a plasticizing agent, a thickening agent and a coupling agent. The high-temperature-resistant coating is excellent in high temperature resistance and resistant to a high temperature ranging from 600 DEG C to 700 DEG C; under a high temperature condition, the coating is structurally stable, less prone to phase-change degradation and generation of detrimental phases, excellent in combination with a substrate and free of cracking and keeps perfectly. In addition, the coating has a superior anti-corrosion function and keeps almost unchanged hardness and adhesion and excellent performances after being soaked in salt mist and salt brine with the salinity being 4% for 25d at 50 DEG C, thereby being applicable to high-temperature protection of the ships.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

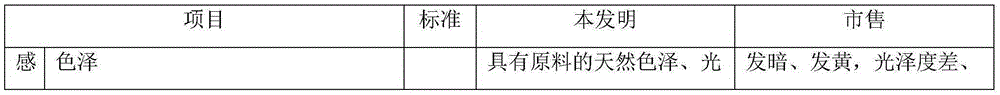

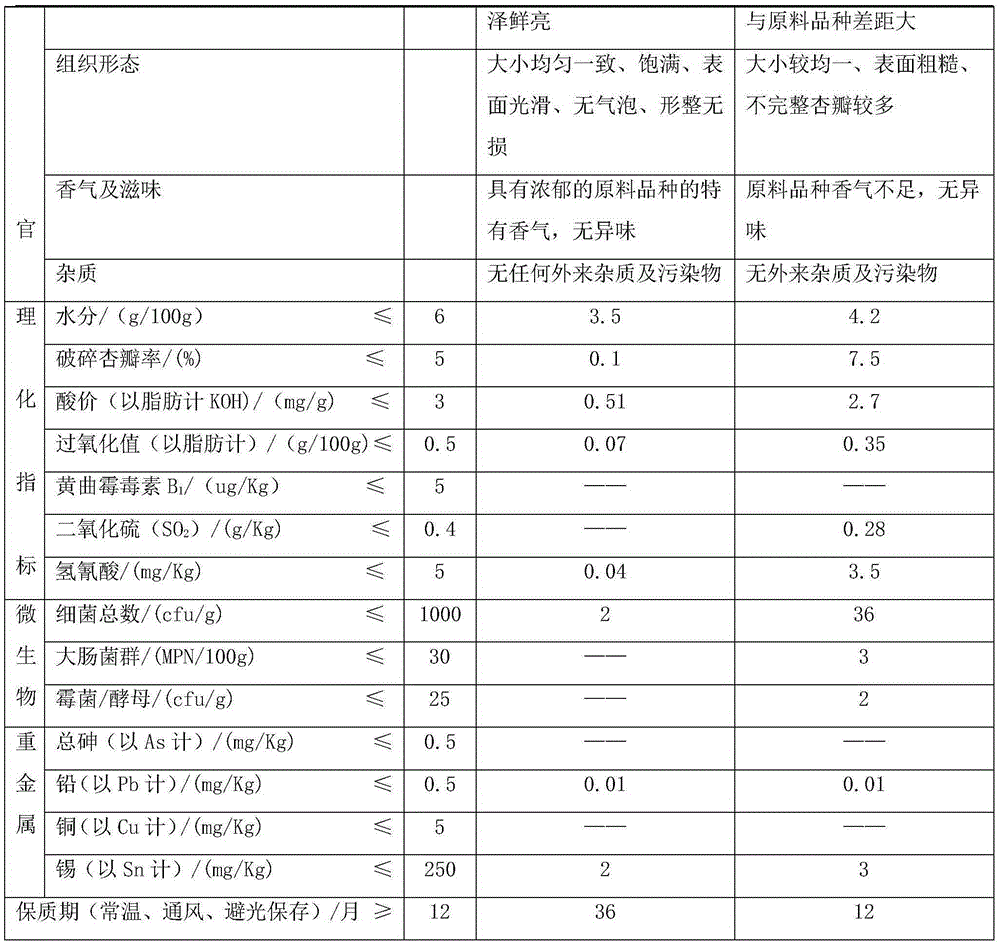

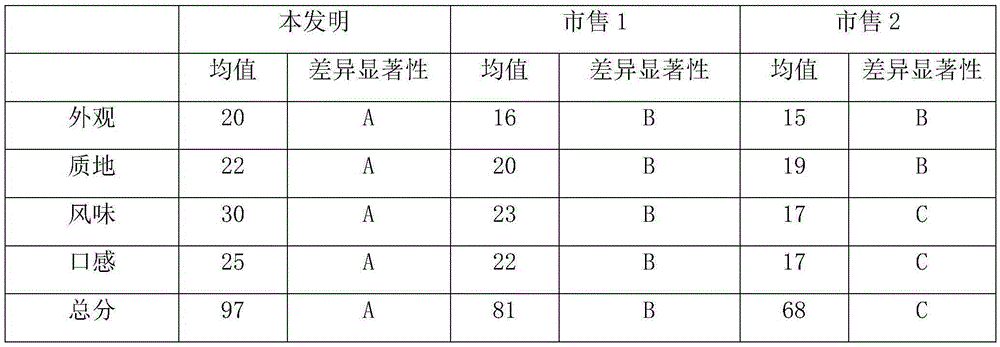

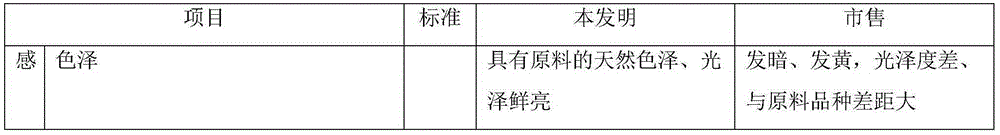

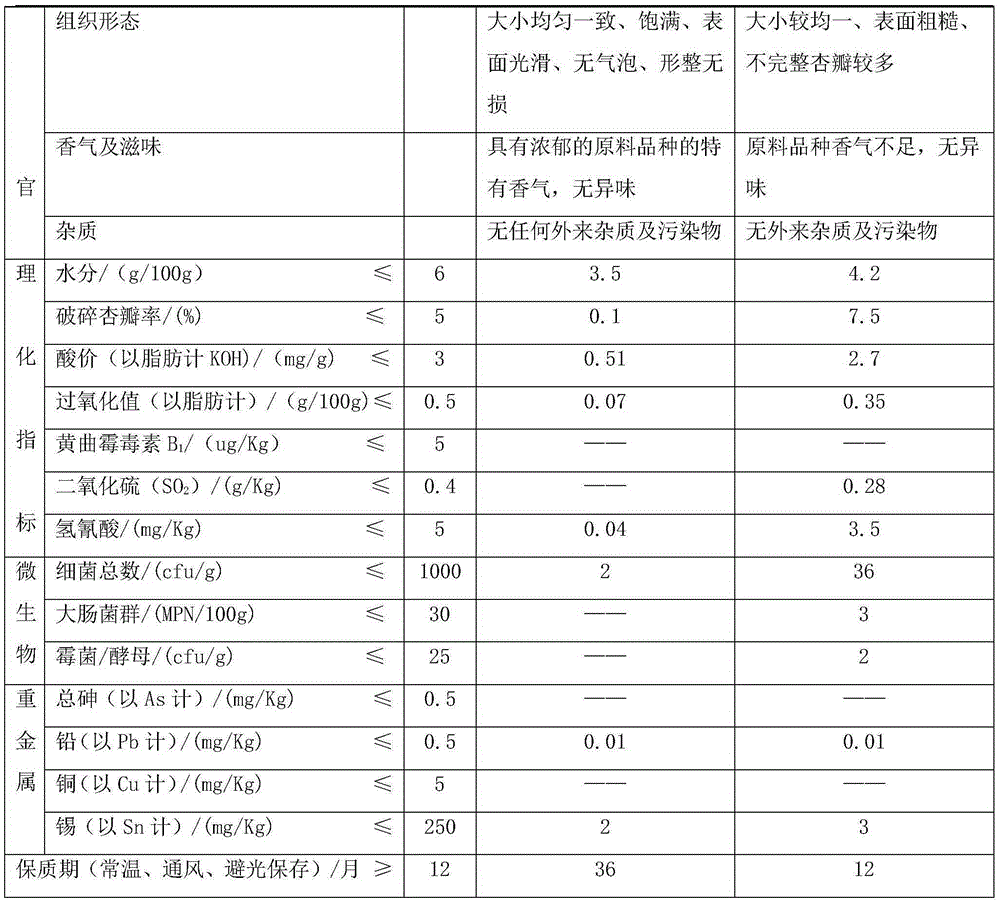

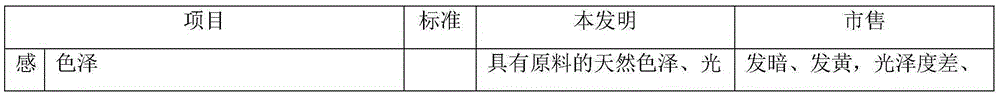

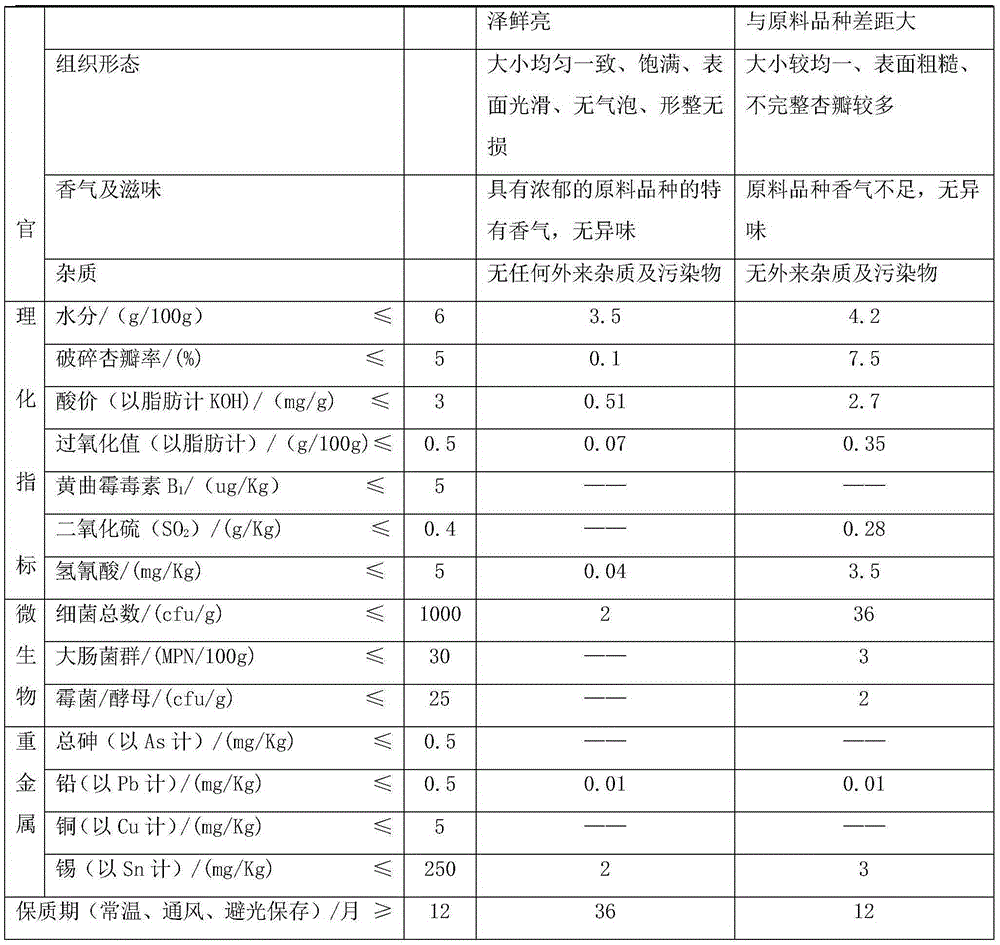

Low-yanide semen armeniacae amarum and preparation method thereof

InactiveCN105310044AReduce processing breakage rateImprove food safetyFood freezingNatural extract food ingredientsFlavorCyanide

The invention discloses low-yanide semen armeniacae amarum and a preparation method thereof and belongs to the technical field of primary processing of semen armeniacae amarum. The preparation method comprises the following steps: semen armeniacae amarum is adopted as the raw material and subjected to peeling, debittering and detoxification to obtain almond carpel; the almond carpel is subjected to microwave drying to obtain dry almond carpel; semen armeniacae amarum skin is collected, frozen and crushed, and the crushed semen armeniacae amarum skin is uniformly mixed with a debittering liquid; the mixture is subjected to enzymolysis and twice distillation to obtain a semen armeniacae amarum skin extract; the semen armeniacae amarum skin extract is decolored and then mixed with the dry almond carpel at a certain proportion; the obtained mixture is stir-fried to obtain the semen armeniacae amarum which has the natural flavor of semen armeniacae amarum, is smooth and tidy, high in debittering ratio (98.5-99.8 percent), remarkable in detoxification effect (the cyanide residual quantity is 0.04-0.06 mg / kg) and long in guarantee period (24-36 months). The preparation method is simple in process, short in period, high in efficiency and energy-saving, can realize mass production, achieves the purpose of zero emission of toxic substances in the technical field of primary processing of semen armeniacae amarum, is environmental-friendly and explores a novel shortcut for deep processing of semen armeniacae amarum.

Owner:邵素英

Low temperature-resistant steel pipe material and preparation method thereof

InactiveCN103741055AImprove low temperature impact toughnessOrganizational structure is stableChemical compositionEconomic benefits

The invention discloses a low temperature-resistant steel pipe material and a preparation method thereof. The low temperature-resistant steel pipe material comprises the following chemical components in percentage by weight: 0.05-0.15% of C, 0.1-0.3% of Si, 2.2-2.8% of Ni, 1.5-2.0% of Cr, 0.8-1.2% of Mn, 0.3-0.6% of Al, 0.2-0.4% of Mo, 0.1-0.2% of Nb, 0.05-0.15% of Ti, 0.03-0.05% of Nd, 0.02-0.04% of Er, 0.004-0.008% of N, 0.002-0.005% of V, not more than 0.01% of S, not more than 0.02% of P and the balance of Fe. The steel pipe material disclosed by the invention has great low-temperature impact toughness, can be used for a long time in an extreme low temperature area at the temperature of below -196 DEG C, has the advantages of stable organizational structure, high strength, great corrosion resistance and good welding property and formability and can expand the range of applications; furthermore, the production process has the advantages of simplicity and easiness in operation, low cost and good economic benefits, and is suitable for large-scale industrial production.

Owner:安徽鼎德智能科技有限公司

Process for producing meshed double-faced spraying and painting advertisement cloth

InactiveCN102660837AUniform meshOrganizational structure is stableFibre typesWarp knittingPolyesterEpoxy

The invention relates to a process for producing meshed double-faced spraying and painting advertisement cloth. The process comprises the following steps of: weaving polyester yarns by using a three-guide bar warp knitting machine in a knitting mode of threading 19 yarns with one vacant stitch, performing slurry immersing treatment on slurry, and sizing, cutting edges, and rolling to manufacture the meshed double-faced spraying and painting advertisement cloth, wherein the slurry consists of the following components in percentage by weight: 8 to 12 percent of epoxy resin curing agent, 1 to 2 percent of benzoxazole fluorescent whitening agent, 0.1 to 0.2 percent of silicone oil emulsion defoamer, 1.5 to 3 percent of parahydroxybenzoate ester, 1.5 to 2.5 percent of rutile nano titanium dioxide, 0.03 percent of pigment and the balance of water. The meshed double-faced spraying and painting advertisement cloth has the advantages of high strength, firm tissue structure, high ink absorption performance, no deflection of grids, environment friendliness and the like, and has the characteristic that a display effect of double-faced patterns is good after the advertisement cloth is subjected to single-faced spraying and painting.

Owner:浙江华生科技股份有限公司

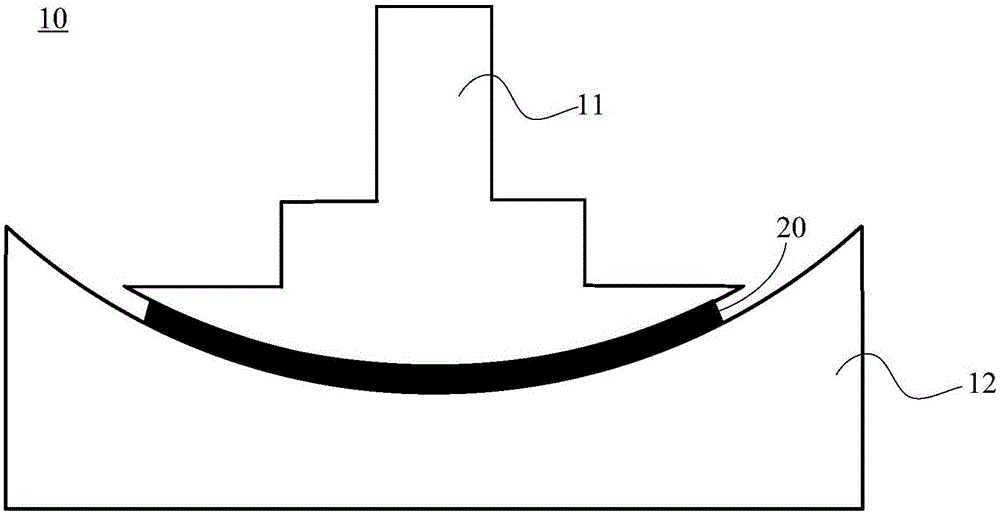

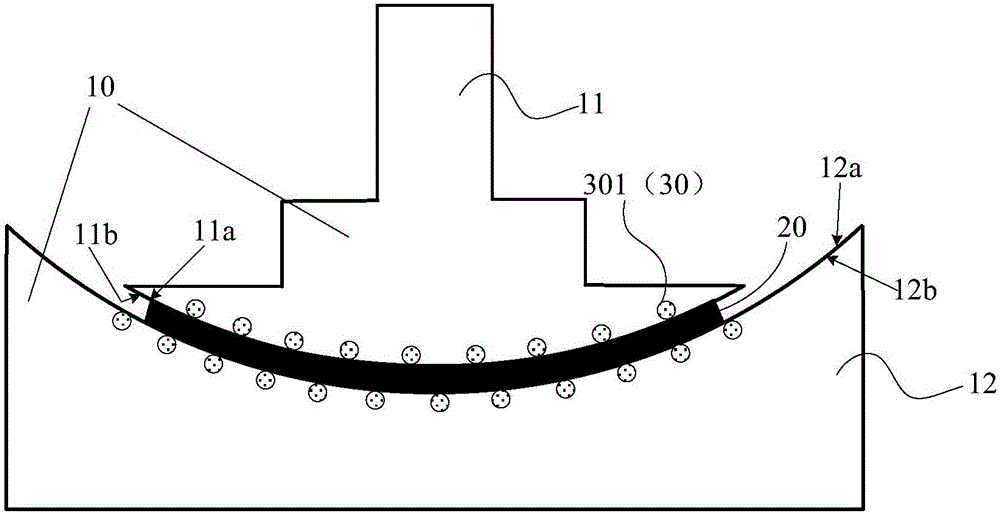

Mold

InactiveCN106825250AOrganizational structure is stableInternal Residual Stress ReliefShaping toolsRoom temperatureMaterials science

The embodiment of the invention provides a mold and relates to the technical field of display. The mold can be used for forming a part to be formed, which is not easy to deform at a room temperature, and the resilience amount is small. The mold comprises an upper mold and a lower mold, which are arranged oppositely; after the molds are assembled, a surface, facing the lower mold, of the upper mold is in contact with a surface, facing the upper mold, of the lower mold; a heating part is arranged on the upper mold and / or the lower mold and is used for heating the part to be formed and forming the part to be formed.

Owner:BOE TECH GRP CO LTD +1

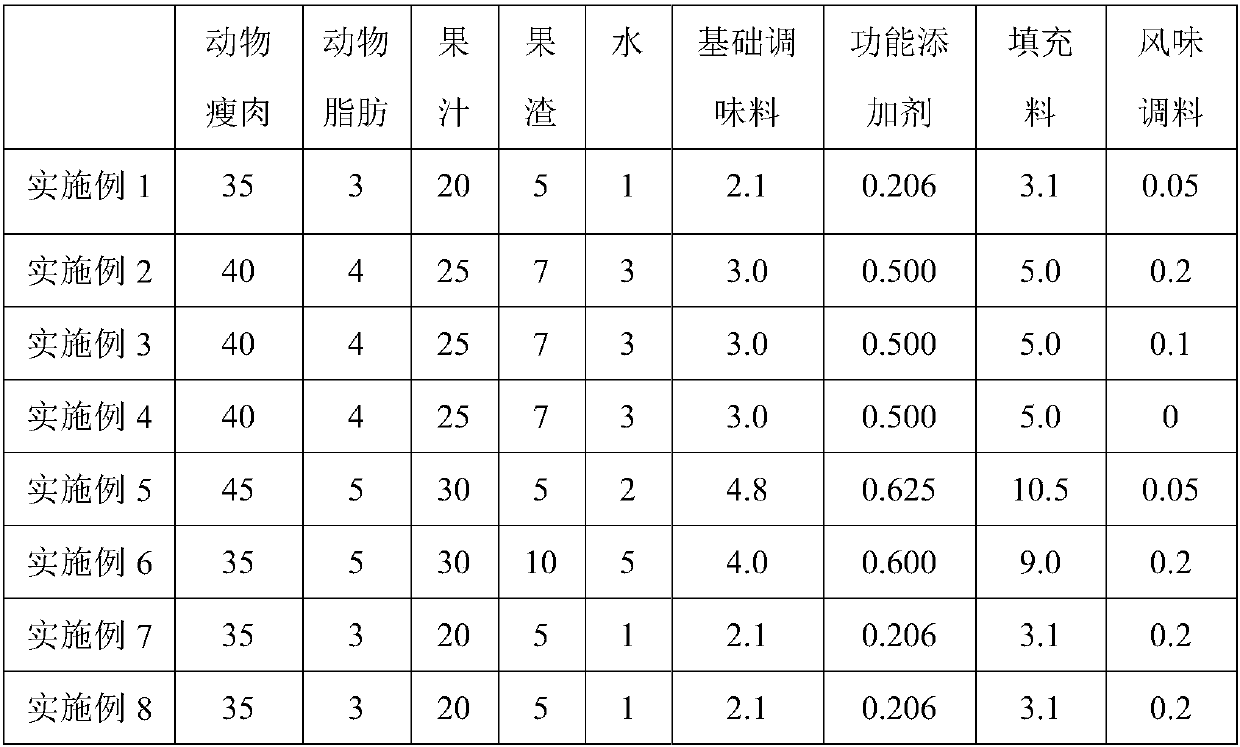

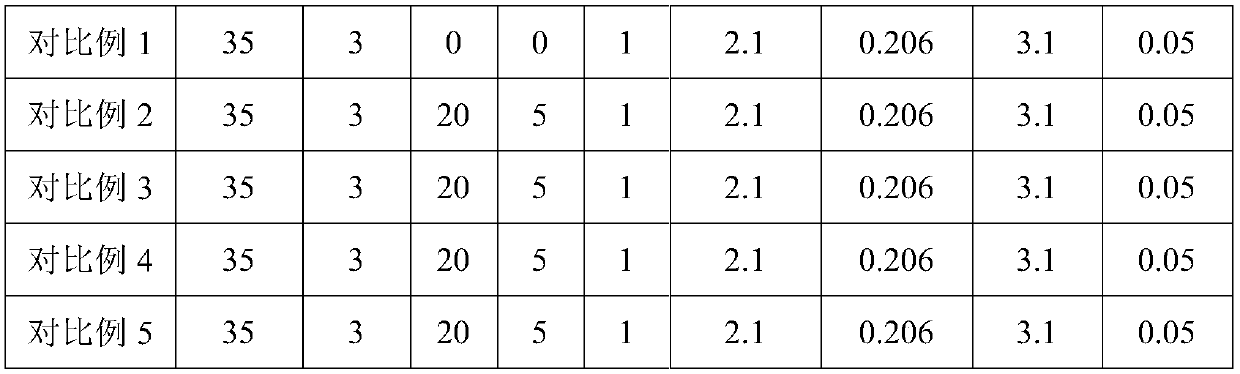

Fruit composite type meat sausages and making method thereof

The invention discloses fruit composite type meat sausages and a making method thereof. The fruit composite type meat sausages are made from animal lean meat, animal fat, fruit juice, fruit residues,water, basic seasoning, a functional additive and a filling. The autologous characteristics of all food material components are combined, further precise optimization and adjustment are performed, andthe making method of the fruit composite type meat sausages is provided, so that the original flavor and original nutrition of raw materials and fruits of the product namely the fruit composite typemeat sausages can be reserved to the maximum extent, and the obtained fruit composite type meat sausages are excellent in color, fragrance and taste and balanced in nutrition. The made meat sausages are natural flesh red in color; sections are obvious in meat texture and good in elasticity, and meat granules and fruit residues are uniformly distributed; the fruit composite type meat sausages are good in meat feeling and chewy; besides, the fruit composite type meat sausages are moderate in sweetness, and have special fragrance of the fruits; different edible spices and flavored seasonings areadded, so that requirements of crowds having different taste and appetence can be comprehensively met; and besides, the fruit composite type meat sausages are convenient to eat and convenient to carryand store, and have high popularization value.

Owner:湖南唐人神肉制品有限公司

High-magnesium limestone calcining method and lime produced by same

The invention belongs to the technical field of metallurgy, and particularly relates to a high-magnesium limestone calcining method and lime produced by the same. The high-magnesium limestone calcination method comprises the following steps: (1) preheating crushed and screened high-magnesium limestone, (2) carrying out water spraying and air cooling treatment on the preheated high-magnesium limestone, so that the temperature of the high-magnesium limestone is rapidly reduced to 100 DEG C or below, and (3) calcining the high-magnesium limestone pretreated in the step (2) to obtain lime. According to the method for calcining the high-magnesium limestone, the preheated high-magnesium limestone is subjected to cold water spraying and air cooling quenching temperature treatment, so that the organization structure of the limestone can be stabilized, the strength of the limestone is enhanced, and the situation that the kiln condition is deteriorated due to the fact that powder is generated inthe calcining process is avoided.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

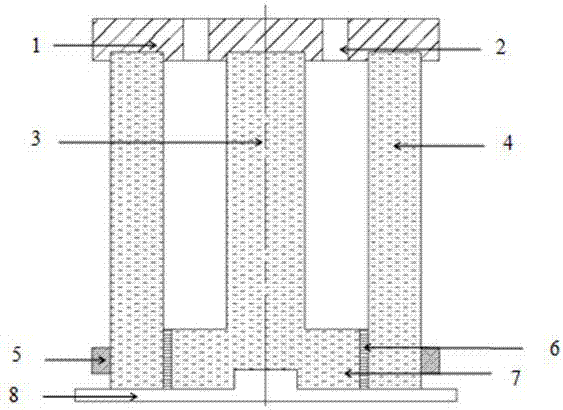

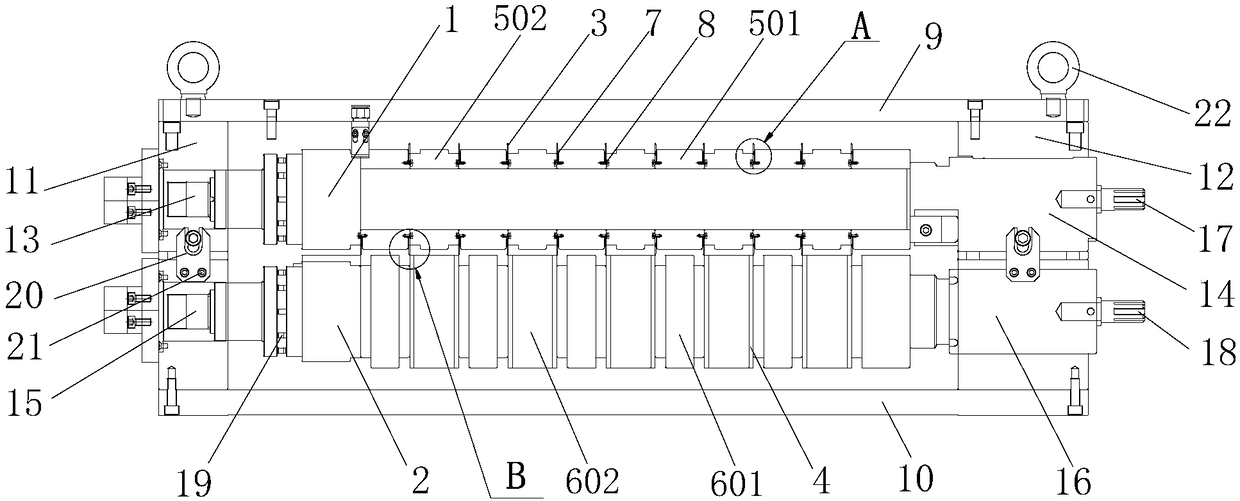

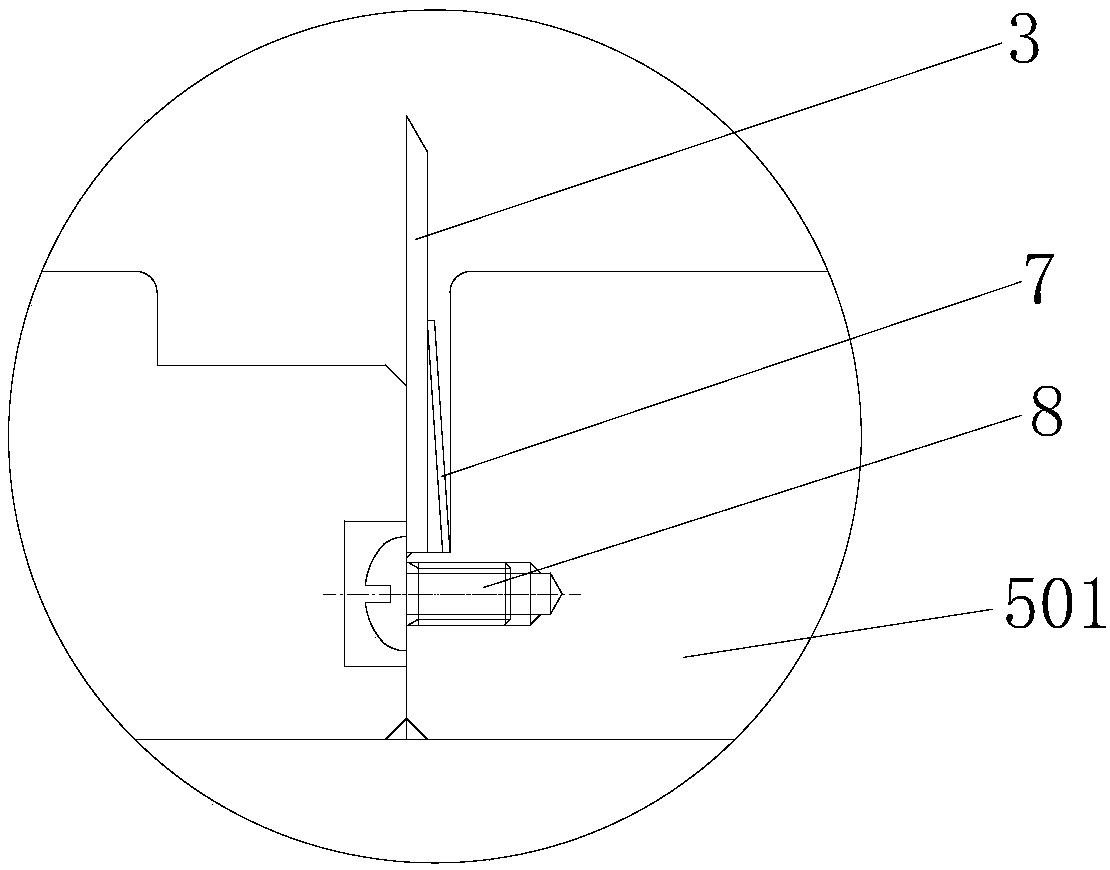

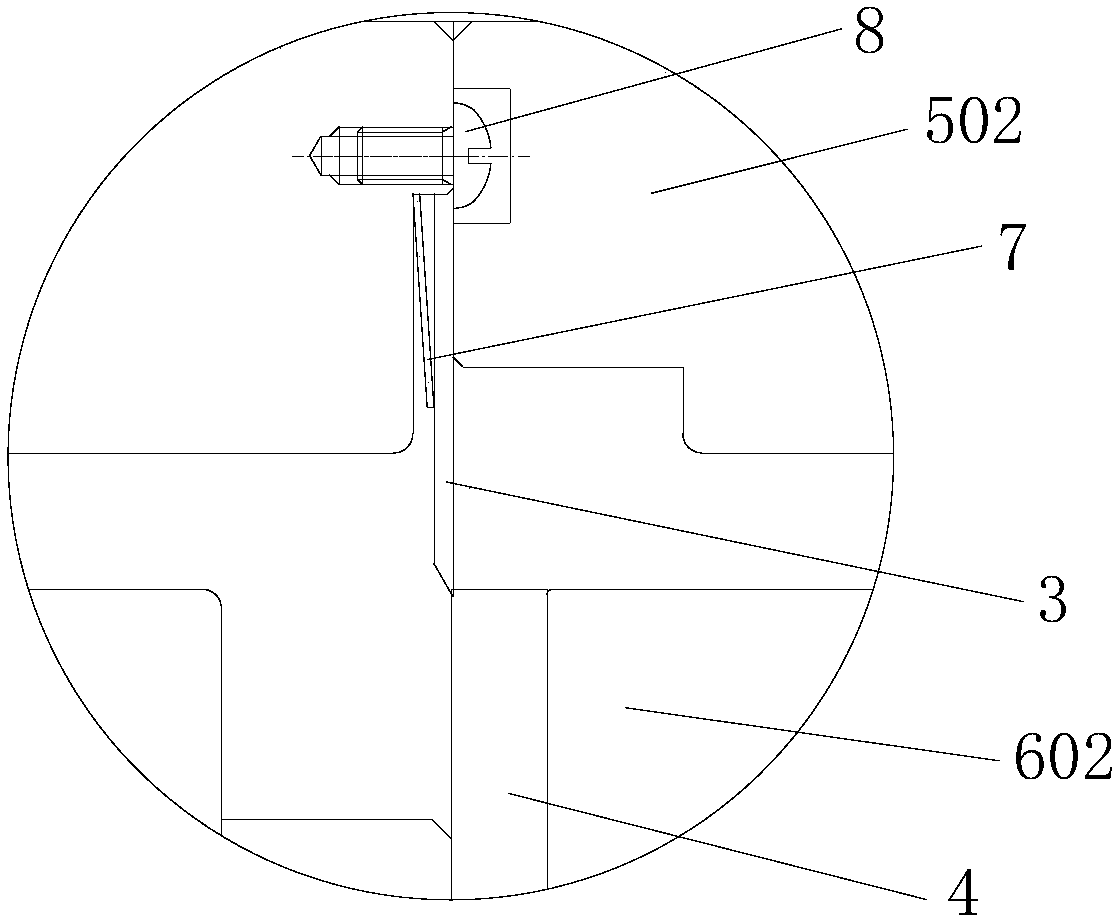

Electrode slice slitting device

InactiveCN108405962ARealize the goal of slitting operationHigh precisionShearing machinesMaintainance and safety accessoriesEngineeringKnife holder

The invention discloses an electrode slice slitting device. The slitting device comprises a frame, a first slitting mechanism, a second slitting mechanism, a connecting mechanism and an oil coating mechanism; multiple first cutters of the first slitting mechanism are arranged on a first cutter frame at intervals; first clamping sleeves are arranged between every two adjacent first cutters; secondcutters of the second slitting mechanism are arranged on a second cutter frame at intervals; second clamping sleeves are arranged between every two adjacent second cutters; the connecting mechanism isused for fixedly connecting the first slitting mechanism with the second slitting mechanism, so that edges of the first cutters are bonded with edges of the second cutters; a felt of the oil coatingmechanism is connected with a switch through an oil pipe; the switch is used for controlling an oil content on the felt; and the felt can lubricate and clean the first cutters and the second cutters.The slitting device is stable and reliable in structure, high in slitting precision, excellent in product consistency and long in service life of the cutters.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

Sulfonated composite modified starch

The invention provides sulfonated composite modified starch. The sulfonated composite modified starch is mainly prepared from the following components in parts by weight: 100 parts of starch, 1-6 parts of sodium hydroxide, 1-10 parts of ammonium persulfate solution (1-10%), 1-10 parts of ammonium ferrous sulfate solution (1-10%), 1-10 parts of 1,3-propyl sultone and 1-23 parts of water. The sulfonated composite modified starch has the advantages that hydroxyls on a starch molecular chain are oxidized in a preparation process, and hydrophilic sulfonic acid groups are introduced; the productiontechnology is simple, conditions are mild, an organic solvent polluting the environment is not used, and the obtained sulfonated composite modified starch has high viscosity stability and strong permeability, can greatly improve adhesion property after gelatinization and has excellent temperature resistance and salt tolerance.

Owner:HUNAN ER KANG PHARMA

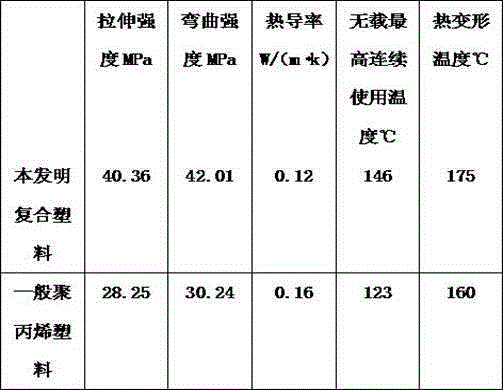

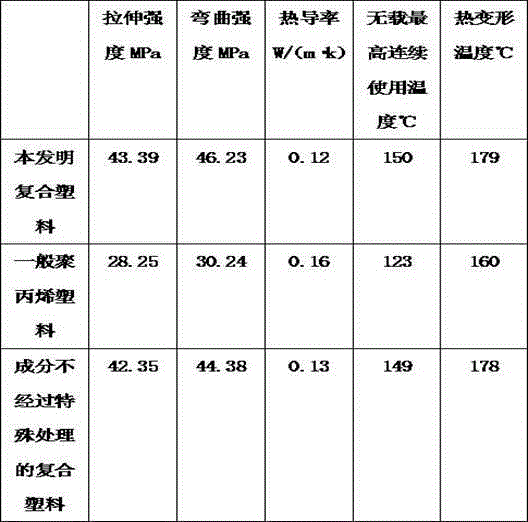

Modified compound plastic

InactiveCN105237874AImprove structural performanceGood weather resistancePolymer sciencePolypropylene

The invention discloses a modified compound plastic, which is made from components: polypropylene, thermoplastic styrene-butadiene rubbers, attapulgite, silicon powder, phenolic resins, bentonite, sodium acrylate, aluminium nitride, dispersants, plasticizers and heat stabilizers. The modified compound plastic is steady in quality and excellent in mechanical and physical chemical properties, and has excellent adaptive efficiency. The modified compound plastic can improve structure performance and enhances weather resistance by adding the treated attapulgite. The modified compound plastic enables plastic components to be more uniform by mixing and pretreating the phenolic resins and the aluminium nitride, and enables organization structures to be more firm. The modified compound plastic can enhance plastic texture by adding the treated silicon powder, and is not easy to soften. The polypropylene and the sodium acrylate are mixed to add into a twin-screw extruder firstly, can improve integration of the polypropylene and other components, improve structure quality, and prolong service life.

Owner:QUANJIAO XIANGRUI PLASTIC

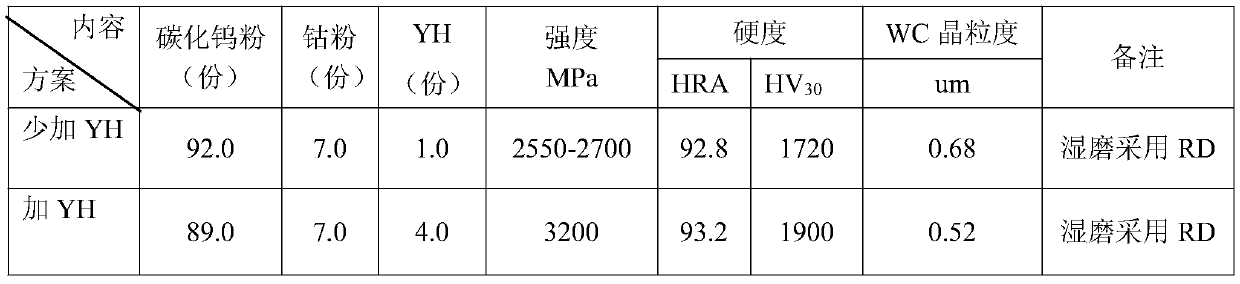

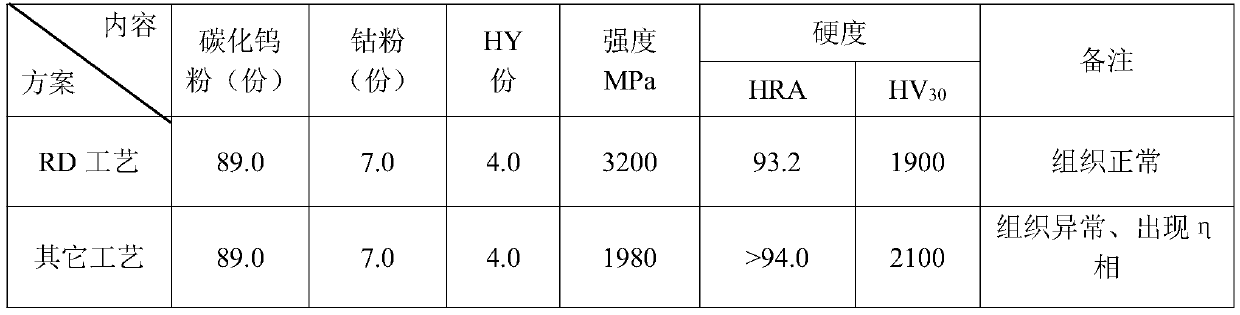

Microcrystalline GW10u hard alloy and preparation method thereof

InactiveCN111057929AAddressing disorganizationSolution to grain growthPtru catalystChemical composition

The invention discloses microcrystalline GW10u hard alloy. The microcrystalline GW10u hard alloy is prepared from the following raw materials in parts by mass: 89-93 parts of tungsten carbide powder,5-7 parts of cobalt powder and 2-4 parts of catalyst YH. According to the microcrystalline GW10u hard alloy, the superfine tungsten carbide powder and the cobalt powder are used as main raw materials,a trace grain inhibitor Y, a metal activator H and a combination of the trace grain inhibitor Y and the metal activator H are added, and the mixture is mixed under a unique wet grinding RD oxygen barrier medium, so that the defects of unstable performance caused by uneven structure, grain growth and unstable chemical composition of the mixture in the preparation process of the superfine hard alloy material are effectively overcome, and the GW10u hard alloy which has stable structure microcosmically and high strength and hardness macroscopically is prepared. The grade can be simultaneously suitable for machining K, N, S and H hard cutting metals, has a wide cutting range and completely covers the range specified by the existing national standard GB / T18376.1. In addition, the process is mature and simple, the product stability is good and the performance is excellent.

Owner:成都金钨硬质合金有限公司

Novel modified composite plastic

The invention discloses novel modified composite plastic which is prepared from polypropylene, thermoplastic styrene-butadiene rubber, a silicon powder and aluminum powder mixture, phenolic resin, a bentonite and kaolin mixture, sodium acrylate, bamboo powder, bauxite, aluminum nitride, a dispersing agent, a plasticizer and a heat stabilizer. The novel modified composite plastic is stable in mass and good in mechanical, physical and chemical property. By adding the silicon powder and aluminum powder mixture, the heat resistance of the composite plastic is greatly improved, and the structure is improved; by means of mixing pretreatment of the phenolic resin and the aluminum nitride, plastic ingredients are more uniform; by adding the bentonite and kaolin mixture, the weather resistance of the composite plastic is greatly improved, and the secondary processing performance is improved; during processing and preparation, the polypropylene and the sodium acrylate are mixed and added to a double-screw extruder at first, accordingly, the integration between the polypropylene and other ingredients can be improved, the structural quality of plastic is improved, and the service life of the plastic is prolonged.

Owner:QUANJIAO XIANGRUI PLASTIC

High-performance breaking device rear cylinder body and machining method thereof

ActiveCN107541660AImprove performanceOrganizational structure is stableFurnace typesHeat treatment furnacesEngineeringQuenching

The invention discloses a high-performance breaking device rear cylinder body and a machining method thereof, and belongs to the technical field of breaking cylinder body machining. The problem that an existing breaking device rear cylinder body is easy to damage due to cracking in the machining and using process is solved. A rear cylinder body workblank comprises components including, by weight percent, 0.20 to 0.29% of C, 0.20 to 0.30% of Si, 0.40 to 0.58% of Mn, 1.2 to 1.5% of Cr, not larger than 0.20% of Ni, 0.35 to 0.42% of Mo, not larger than 0.02% of P, not larger than 0.02% of S and the balance iron and inevitable impurities. The material is subject to forging, machining and forming and then is subject to heat treatment, in the heat treatment process, a protection medium is used isused for carrying out quenching protection on the interior of the rear cylinder body, the protection medium in the rear cylinder body can prevent the temperature of an inner cavity from being too high in the heating process, and during quenching, the phenomenon that the quenching media enter the cavity, and the interior hardening capacity is caused is avoided.

Owner:马鞍山平文锻造有限公司

Preparation method for X-type titanium alloy three-dimensional lattice sandwich structure

ActiveCN102990299BImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusUltimate tensile strengthTitanium alloy

The invention belongs to the titanium alloy structure forming technology and relates to a method for preparing an X-type titanium alloy three-dimensional lattice sandwich structure by superplastic forming / diffusion connection. An X-type titanium alloy three-dimensional lattice sandwich member is prepared by adopting the superplastic forming method; and the X-type titanium alloy three-dimensional lattice sandwich structure is prepared by adopting the superplastic forming / diffusion connection process for the first time, so that on one hand, formed parts, especially the X-type titanium alloy three-dimensional lattice sandwich structures with complex shapes can be accurately controlled in shape, and the technical difficult problem of low possibility of formation of an X-type titanium alloy three-dimensional lattice sandwich is solved at the same time. The structure prepared by adopting the superplastic forming / diffusion connection process is higher in bonding strength as the three-dimensional lattice sandwich is connected with upper and lower panels through the diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Bright bitter apricot seeds and preparation method thereof

InactiveCN105285867AReduce processing breakage rateImprove food safetyFood freezingNatural extract food ingredientsFlavorCyanide compound

The invention discloses bright bitter apricot seeds and a preparation method thereof, and belongs to the technical field of primary processing of bitter apricot seeds. The preparation method comprises the following steps of peeling, debitterizing and detoxifying the bitter apricot seeds serving as raw materials so as to obtain apricot seed cloves; then performing microwave drying so as to obtain dried apricot seed cloves; collecting bitter apricot seed peel, refrigerating the collected bitter apricot seed peel, crushing the refrigerated bitter apricot seed peel, uniformly mixing the crushed bitter apricot seed peel with debitterizing liquid, and performing enzymolysis and distillation twice so as to obtain an apricot seed peel extract; and then performing decoloration, mixing the apricot seed peel extract after the decoloration with the dried apricot seed cloves according to a certain proportion so as to obtain a mixture, and then stir-frying the mixture so as to obtain the bitter apricot seeds with natural flavor of the bitter apricot seeds, high smoothness and tidiness, high debitterizing rate (98.5-99.8%), significant detoxifying effects (the quantity of cyanide residues is 0.04-0.06mg / kg), long quality guarantee period (24-36 months) and low cost. The preparation method disclosed by the invention is simple in technology, short in cycle and high in efficiency, energy resources are saved, the large-scale production can be realized, zero discharge of toxic substances in the technical field of the primary processing of the bitter apricot seeds is realized, the preparation method is environment-friendly, and a new shortcut is explored for the deep processing of the bitter apricot seeds.

Owner:邵素英

Semen armeniacae amarum with long quality guarantee period and preparation method of semen armeniacae amarum

InactiveCN105285865AWith natural flavorsImprove the rate of relief from bitternessFood scienceCyanide compoundFlavor

The invention discloses semen armeniacae amarum with a long quality guarantee period and a preparation method of the semen armeniacae amarum, and belongs to the technical field of primary processing of semen armeniacae amarum. The preparation method comprises the following steps of using the semen armeniacae amarum as raw materials, and peeling, debitterizing and detoxifying the semen armeniacae amarum so as to obtain the embryo of semen armeniacae amarum; then performing microwave drying so as to obtain the dried embryo of semen armeniacae amarum; collecting the seedcoat of semen armeniacae amarum, refrigerating the collected seedcoat of semen armeniacae amarum, crushing the refrigerated seedcoat of semen armeniacae amarum, uniformly mixing the crushed seedcoat of semen armeniacae amarum and debitterizing liquid, and performing enzymolysis and two times of distillation so as to obtain an extract of the seedcoat of semen armeniacae amarum; and then performing decoloration, mixing the extract after the decoloration with the dried embryo of semen armeniacae amarum according to a certain proportion so as to obtain a mixture, and then stir-frying the mixture so as to obtain the semen armeniacae amarum with a natural flavor of the semen armeniacae amarum, high smoothness and tidiness, a high debitterizing rate (98.5-99.8%), significant detoxifying effects (the quantity of cyanide residues is 0.04-0.06mg / kg), a long quality guarantee period (24-36months) and a low cost. The preparation method disclosed by the invention is simple in technology, short in cycle, and high in efficiency, saves energy resources, can realize large-scale production, can realize zero discharge of toxic substances in the technical field of the primary processing of the semen armeniacae amarum, is environment-friendly, and provides a new shortcut for the deeply processing of the semen armeniacae amarum.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

Warp-knitted zebra curtain fabric and manufacture process thereof

InactiveCN110219094AIncreasing the thicknessHorizontal and vertical structure stabilityWarp knittingCurtainsHigh densityEngineering

The invention relates to warp-knitted zebra curtain fabric and a manufacture process thereof, in particular to transverse-type warp-knitted zebra curtain fabric and a manufacture process thereof. Thewarp-knitted zebra curtain fabric and the manufacture process thereof have the advantages that the process is simple, the knitting cost is low, the texture is stable, the curtain fabric is free of looseness and slip, knitted fabrics are ever-changing, and the curtain fabric has many patterns and styles and is attractive and practical. The manufacture process is characterized in that a (Tricot-typeor Raschel-type) warp knitting machine and an electronic translation mechanism are adopted; fine spinning yarns are used for forming chains and meshes, and thick spinning yarns are used for weft insertion and warp insertion; warp knitting of the chains is combined with weft insertion to basically form fabric with high density and thickness, namely shading fabric, and warp knitting of the meshes is combined with warp insertion to basically form light-transmitting fabric with low density and thickness. The shading fabric and light-transmitting fabric are arrayed alternately and segmentally during knitting to form the transverse-type warp-knitted zebra curtain fabric that can be freely switched between a shading mode and a light transmitting mode.

Owner:HAINING KEYUAN WARP

Method for improving dimensional stability of GT35 steel-bonded hard alloy

The invention provides a method for high dimensional stability obtaining of a GT35 steel-bonded hard alloy, and belongs to the field of metal-based composite material processing. The hard alloy is theGT35 steel-bonded hard alloy after forging, the hard alloy is heat-treated in the subsequent processing process, and the hard alloy with small and stable structure and small residual stress. According to the GT35 steel-bonded hard alloy obtained through an optimization technology, compared with conventional treatment methods, the surface residual stress of the hard alloy can be effectively lowered by 50-100 MPa, the hardness of the hard alloy is improved by 40-70 Hv, and as for storage for half a year or above at the room temperature, the dimensional change is less than 0.007%.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com