Novel modified composite plastic

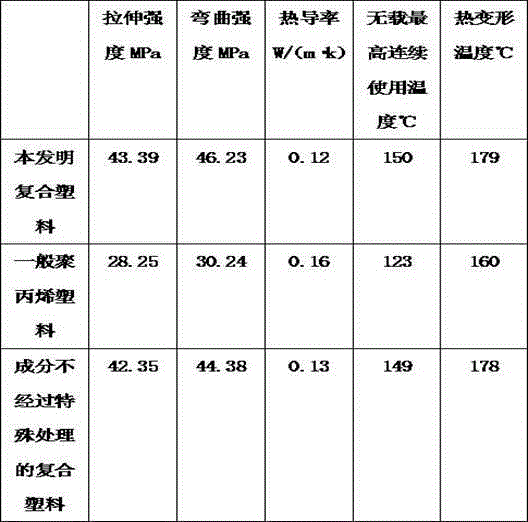

A composite plastic and modification technology, which is applied in the field of new modified composite plastics, can solve problems such as difficulty in containing liquid or semi-liquid packaging, insufficient strength, and easy overflow to the human body, etc., to improve secondary processing performance and improve structural quality and service life, the effect of a firm organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A new type of modified composite plastic, made of the following ingredients in parts by weight: 93 parts of polypropylene, 20 parts of thermoplastic styrene-butadiene rubber, 10 parts of a mixture of silicon powder and aluminum powder, 26 parts of phenolic resin, and 6 parts of a mixture of bentonite and kaolin , 4 parts of sodium acrylate, 6 parts of aluminum nitride, 4 parts of bauxite, 8 parts of bamboo powder, 1 part of dispersant, 0.5 part of plasticizer, and 0.2 part of heat stabilizer.

[0014] Further, the mixture of silicon powder and aluminum powder is aerobically calcined at 200°C and then mixed with a 4.5% phosphoric acid solution, treated at a constant temperature of 80-95°C for 1-1.5 hours, filtered, and dried; the silicon powder and Aluminum powder is mixed in a ratio of 3:1.

[0015] Further, the dispersant is sodium hexametaphosphate, the plasticizer is citrate, and the heat stabilizer is lead dibasic phosphite.

[0016] Further, the mixture of bentoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com