High-strength, high-electrical-conductivity and high-heat-conductivity copper-silver series alloy wire material and preparation method thereof

An alloy wire, high electrical conductivity technology, applied in the field of high strength, high electrical conductivity and high thermal conductivity copper-silver alloy wire and its preparation, can solve the problems of disordered grain orientation, reduced electrical conductivity, large difference in solid solubility, etc. Enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

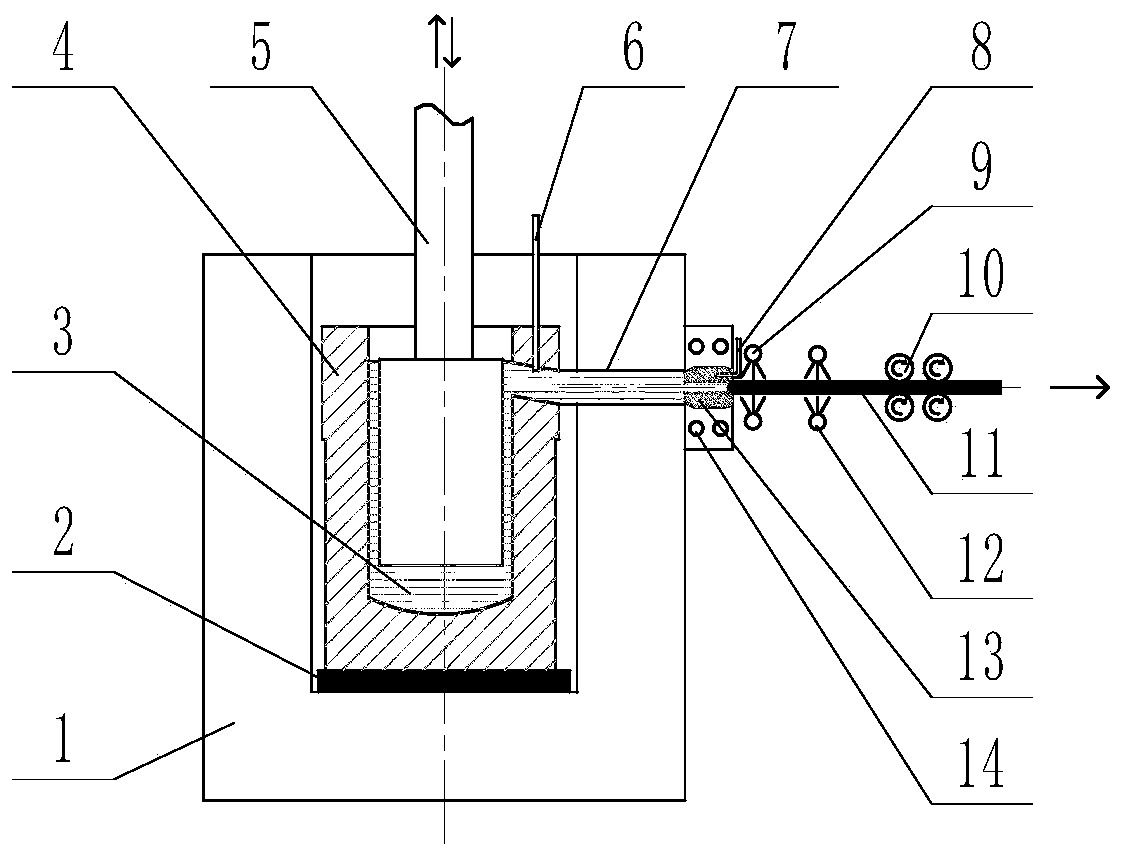

Image

Examples

Embodiment 1

[0036] The preparation method of the high-strength, high-conductivity and high-thermal-conductivity copper-silver alloy wire rod of this embodiment comprises the following steps:

[0037] (1) Batching and smelting: Select No. 1 electrolytic copper and high-purity silver particles as raw materials, and carry out batching according to the mass ratio of copper to silver in the copper-silver alloy wire rod as 96:4; the purity of No. 1 electrolytic copper is 99.95%, and the high-purity silver The purity of the particles is 99.99%; the prepared raw materials are put into a high-purity graphite crucible for heating and melting, and the melting temperature is controlled at 1100°C; the melting process is carried out in a thermal crystallizer horizontal continuous solidification device;

[0038] (2) Hot-type horizontal continuous casting: hot-type horizontal continuous casting is carried out in a hot-type crystallizer horizontal continuous solidification device, and the melt is heated an...

Embodiment 2

[0041] The preparation method of the high-strength, high-conductivity and high-thermal-conductivity copper-silver alloy wire rod of this embodiment comprises the following steps:

[0042] (1) Batching and smelting: use No. 1 electrolytic copper, high-purity silver particles and high-purity chromium particles as raw materials, and carry out batching according to the mass ratio of copper, silver and chromium in the copper-silver alloy wire rod as 96.5:2.0:1.5; among them, No. 1 The purity of electrolytic copper is 99.95%, the purity of high-purity silver particles is 99.99%, and the purity of high-purity chromium particles is 99.95%. Put the prepared raw materials into a high-purity graphite crucible for heating and melting, and the melting temperature is controlled at 1200°C; The process is carried out in a thermal crystallizer horizontal continuous solidification device;

[0043] (2) Hot-type horizontal continuous casting: hot-type horizontal continuous casting is carried out ...

Embodiment 3

[0046] The preparation method of the high-strength, high-conductivity and high-thermal-conductivity copper-silver alloy wire rod of this embodiment comprises the following steps:

[0047] (1) Ingredients and smelting: use No. 1 electrolytic copper, high-purity silver particles, high-purity chromium particles, zirconium particles and niobium particles as raw materials, and the mass ratio of copper to silver in copper-silver alloy wire is 99.86:0.1:0.02:0.01 : 0.01 for batching; wherein the purity of No. 1 electrolytic copper is 99.95%, the purity of high-purity silver particles is 99.99%, the purity of high-purity chromium particles is 99.95%, the purity of zirconium particles is 99.5%, and the purity of niobium particles is 99.95%; Put the prepared raw materials into a high-purity graphite crucible for heating and melting, and the melting temperature is controlled at 1300°C; the melting process is carried out in a thermal crystallizer horizontal continuous solidification device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com