Microcrystalline GW10u hard alloy and preparation method thereof

A cemented carbide and microcrystalline technology, applied in the field of cemented carbide, can solve problems such as poor wear resistance, increased strength, and decreased hardness, and achieve excellent performance, wide cutting range, and good product stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

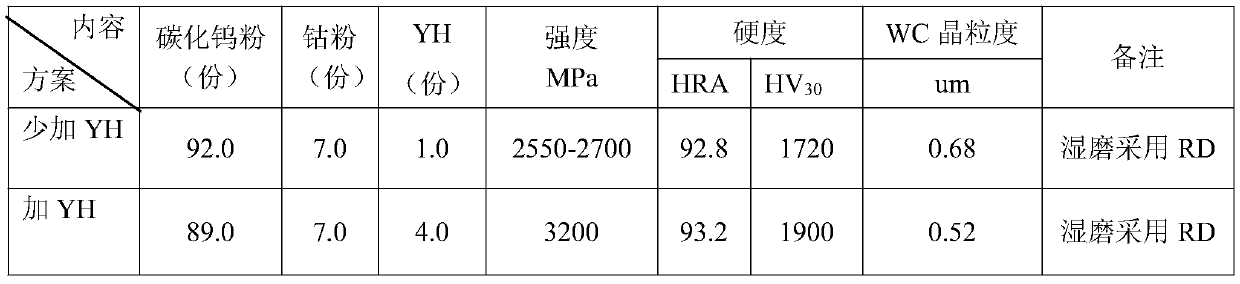

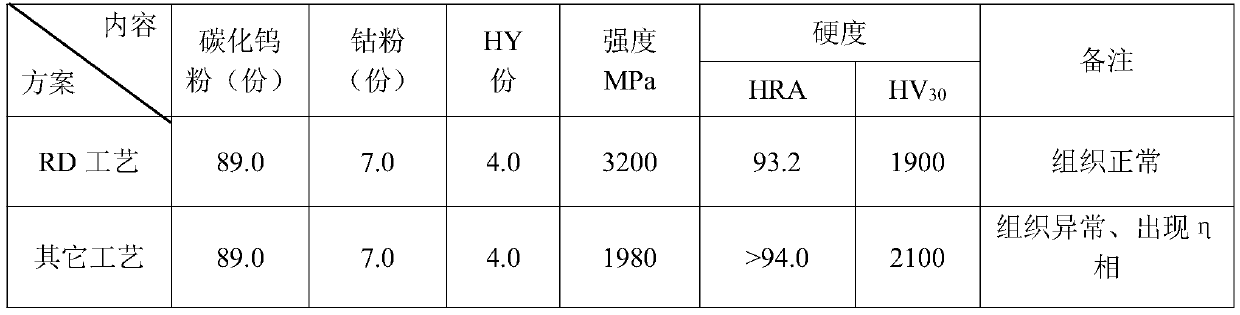

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the microcrystalline GW10u cemented carbide provided by the present embodiment comprises the following steps:

[0020] (1) Take 93.0 parts of tungsten carbide powder, 5.0 parts of cobalt powder and 2.0 parts of catalyst in mass parts, the particle diameter of the tungsten carbide powder is 0.63um, and the catalyst YH includes a mass percentage of 55:45 Agent Y (TaC, VC and Cr2C3; mass composition ratio: 2 / 3 / 2) and activator H (Re powder);

[0021] The above raw materials are fully mixed under the RD oxygen barrier medium, the RD oxygen barrier medium is anhydrous 120# gasoline solvent and SD molding agent, and the anhydrous 120# gasoline solvent accounts for 35% of the raw material quality, and the SD molding agent accounts for 35% of the raw material quality 25%;

[0022] (2) Put the mixed raw materials on a wet ball mill for ball milling for 60.0h to form a slurry;

[0023] (3) Let the slurry stand and settle for 2.5 hours, then put it into...

Embodiment 2

[0026] The preparation method of the microcrystalline GW10u cemented carbide provided by the present embodiment comprises the following steps:

[0027] (1) Take 91.0 parts of tungsten carbide powder, 6.0 parts of cobalt powder and 3.0 parts of catalyst YH in mass parts, the particle diameter of the tungsten carbide powder is 0.63um, and the catalyst YH includes 60:40 Inhibitor Y (TaC, VC and Cr2C3, mass composition ratio: 0 / 3 / 3) and activator H (Re powder);

[0028] The above raw materials are fully mixed under the RD oxygen barrier medium, the RD oxygen barrier medium is anhydrous 120# gasoline solvent and SD molding agent, and the anhydrous 120# gasoline solvent accounts for 40% of the raw material quality, and the SD molding agent accounts for 40% of the raw material quality 30%;

[0029] (2) Put the mixed raw materials on a wet ball mill for ball milling for 72 hours to form a slurry;

[0030] (3) Let the slurry stand and settle for 3 hours, then put it into a Z-type sti...

Embodiment 3

[0033] The preparation method of the microcrystalline GW10u cemented carbide provided by the present embodiment comprises the following steps:

[0034] (1) Get the tungsten carbide powder of 89.0 parts of mass parts, the cobalt powder of 7.0 parts and the catalyst YH of 4.0 parts, the particle diameter of described tungsten carbide powder and cobalt powder is 0.55um, and described catalyst YH comprises mass percent and is 50 :50 inhibitor Y (TaC, VC and Cr2C3, mass composition ratio: 3 / 3 / 1) and activator H (Re powder);

[0035] The above raw materials are fully mixed under the RD oxygen barrier medium, the RD oxygen barrier medium is anhydrous 120# gasoline solvent and SD molding agent, and the anhydrous 120# gasoline solvent accounts for 30% of the raw material quality, and the SD molding agent accounts for 30% of the raw material quality 20%;

[0036] (2) Put the mixed raw materials on a wet ball mill for ball milling for 72.0h to form a slurry;

[0037] (3) Let the slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com