Vacuum stirrer

A vacuum mixer and vacuum valve technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems affecting the mechanical strength and performance of plaster molds, low service life of plaster molds, and low production efficiency. Achieve the effects of reducing labor intensity of workers, balancing water absorption and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

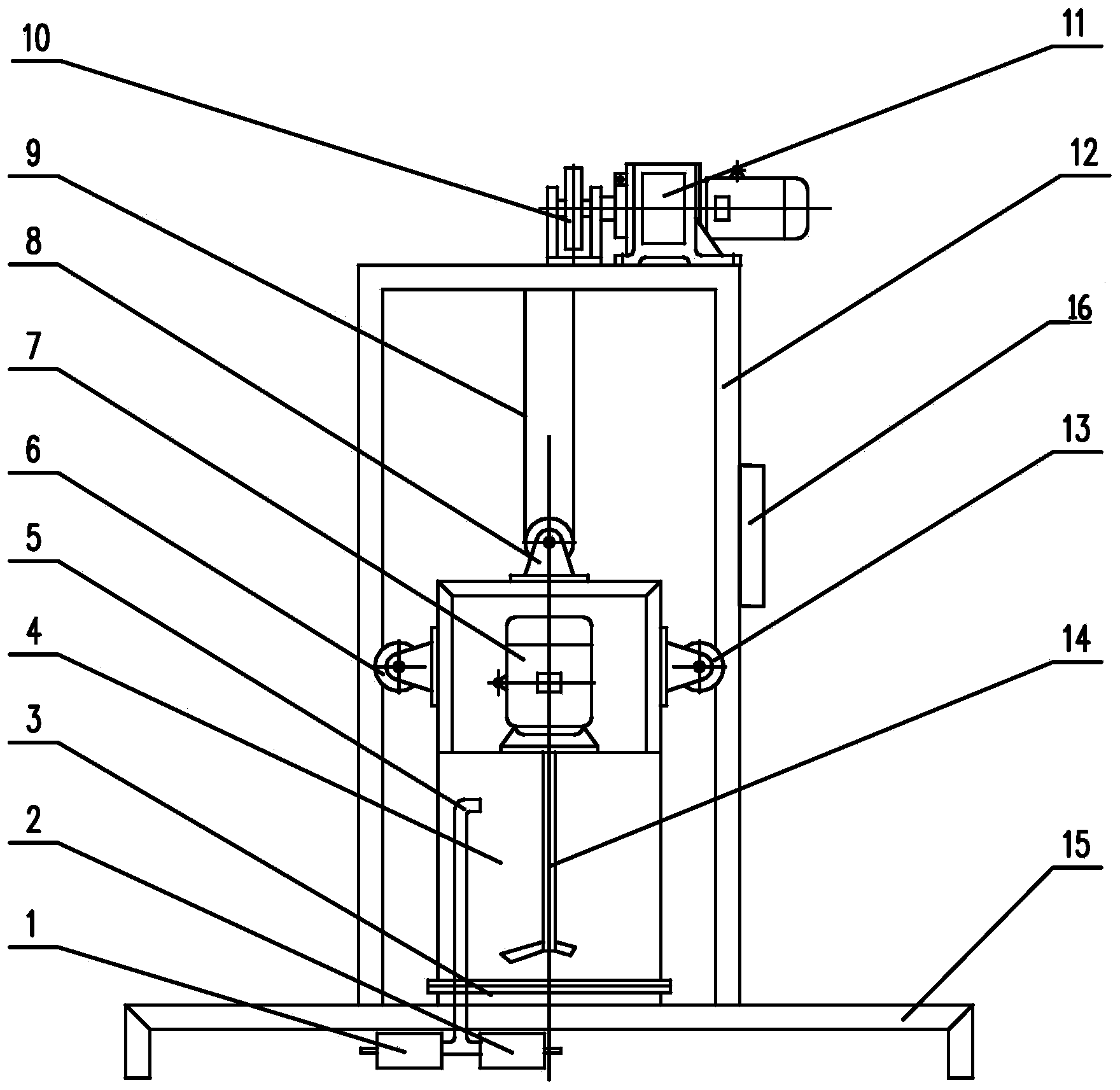

[0019] Such as figure 1 Shown, a kind of vacuum mixer comprises support 15, door-shaped support 12, lower bell jar 3, upper bell jar 4, roll wheel 10, roll wheel motor 11, air pipe 5, wherein, described door-shaped support 12 and described Described lower bell jar 4 is fixedly installed on the support 15, and described lower bell jar 4 is positioned at the internal space of door-shaped support 12, and in the two column inner sides of door-shaped support 12, each is provided with a vertical to base 15. Sliding guide groove (not shown in the figure); Described reel 10 is electrically connected with reel motor 11, and is all positioned on the crossbeam of gate-shaped support 12; Described upper bell jar 4 is positioned at described lower bell jar 3 above, And it is closed with the bell jar 3 by a sealing strip seal, and a stirring motor 7 is installed above the inside of the upper bell jar 4, and the stirring motor 7 is connected with a stirring shaft 14, and the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com