Vacuum agitating device for original-state titanium gypsum slag slurry

A technology of vacuum mixing and titanium gypsum, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of performance decline, cost reduction, long mixing time, etc., to improve mechanical performance and water resistance, vacuum The effect of improving the precision, widening the forming range and processing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

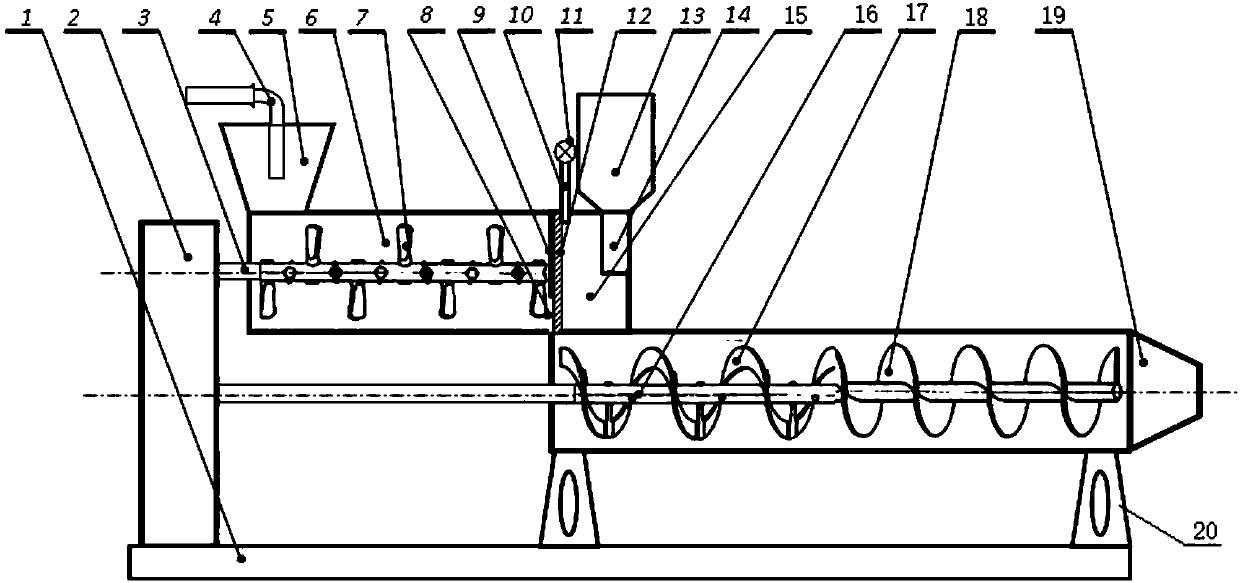

[0019] Such as figure 1 As shown, a vacuum stirring device for undisturbed titanium gypsum slurry is composed of five parts: a transmission part, a slurry powder mixing chamber, a vacuum chamber, an aggregate mixing chamber and a frame.

[0020] The transmission part is composed of a transmission motor and a reducer 2, and the two output shafts of the reducer 2 are respectively connected to the slurry powder mixing screw shaft 3 of the slurry powder mixing chamber and the aggregate mixing screw shaft 16 of the aggregate mixing room through a coupling; The powder mixing chamber and the aggregate mixing chamber are arranged in upper and lower layers, and the vacuum chamber is located between the two chambers, connecting the two chambers into a whole; the mixing part and the mud squeezing part in the aggregate mixing chamber are on the same level, and are The same aggregate stirring screw shaft 16; the transmission part, the slurry powder mixing chamber, the vacuum chamber, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com