Patents

Literature

42results about How to "Wide range of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

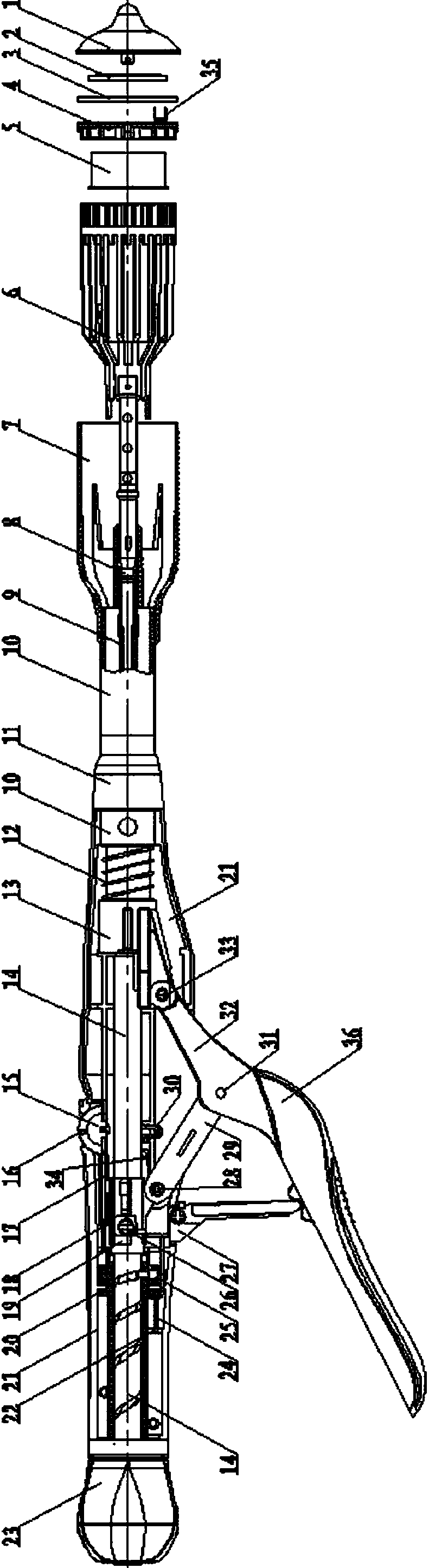

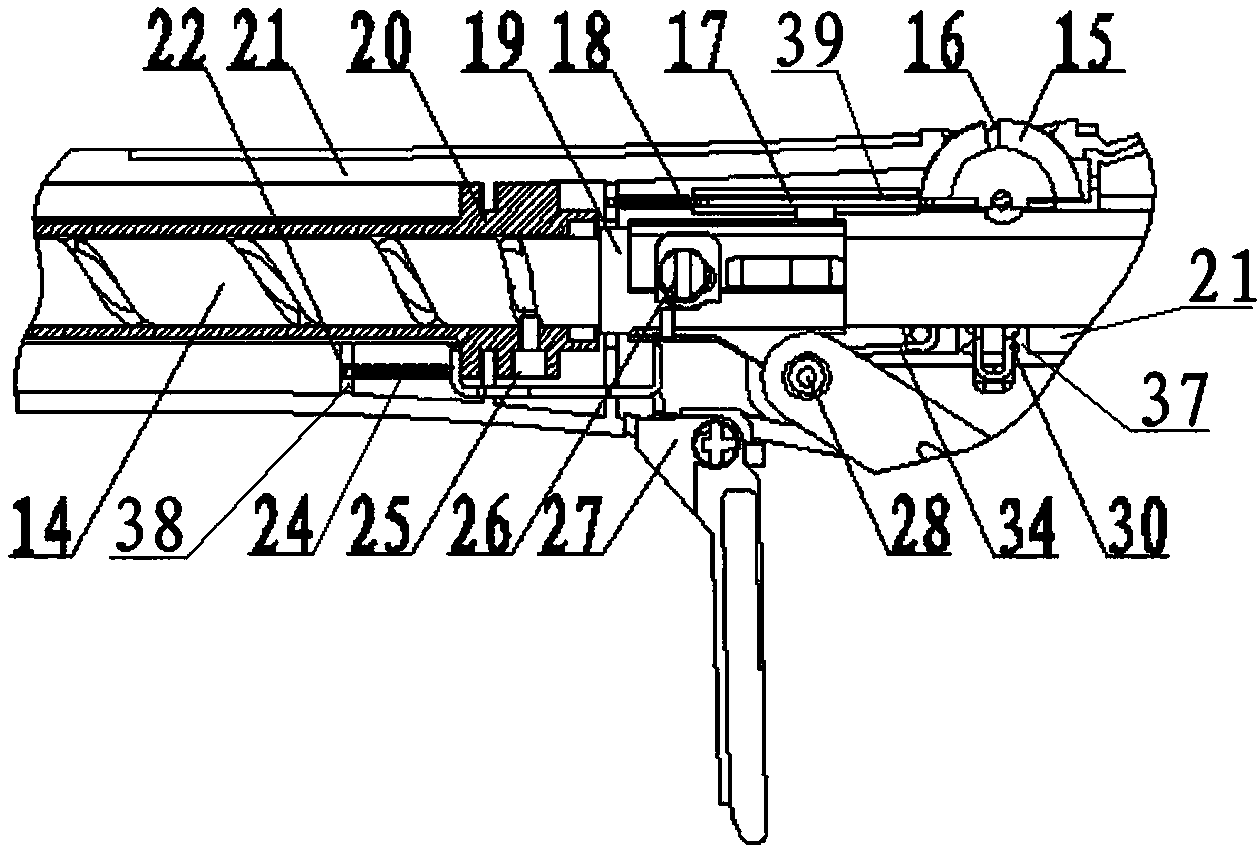

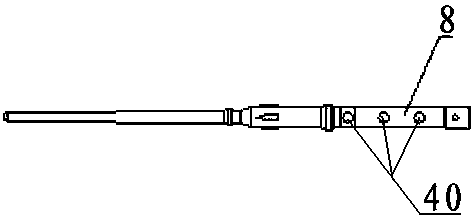

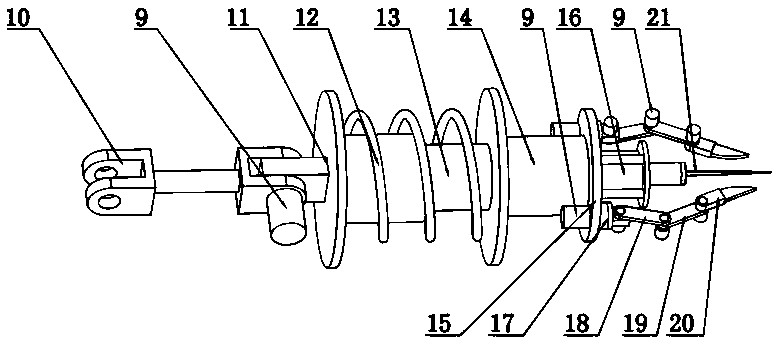

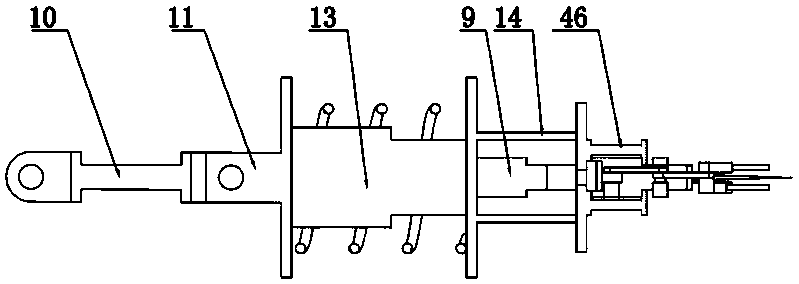

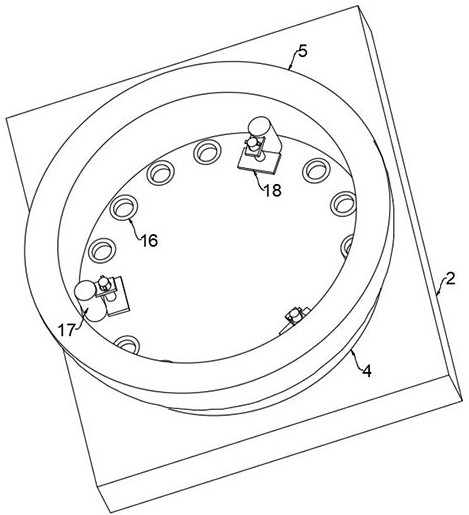

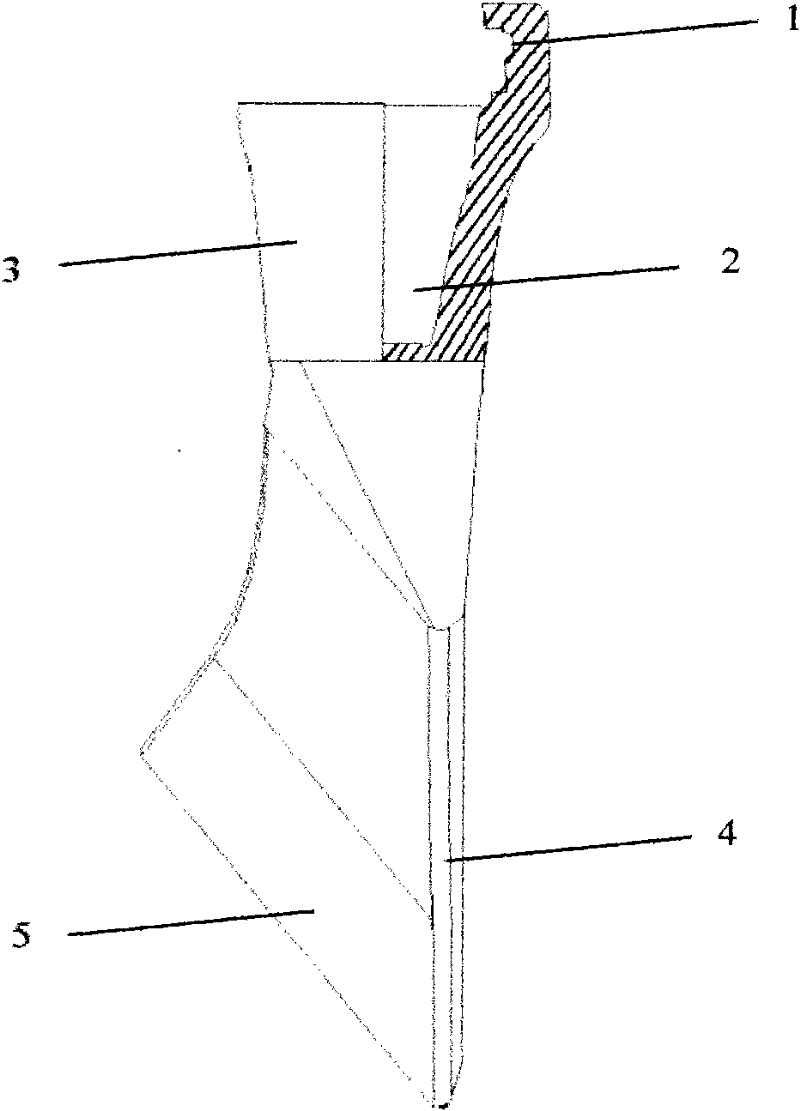

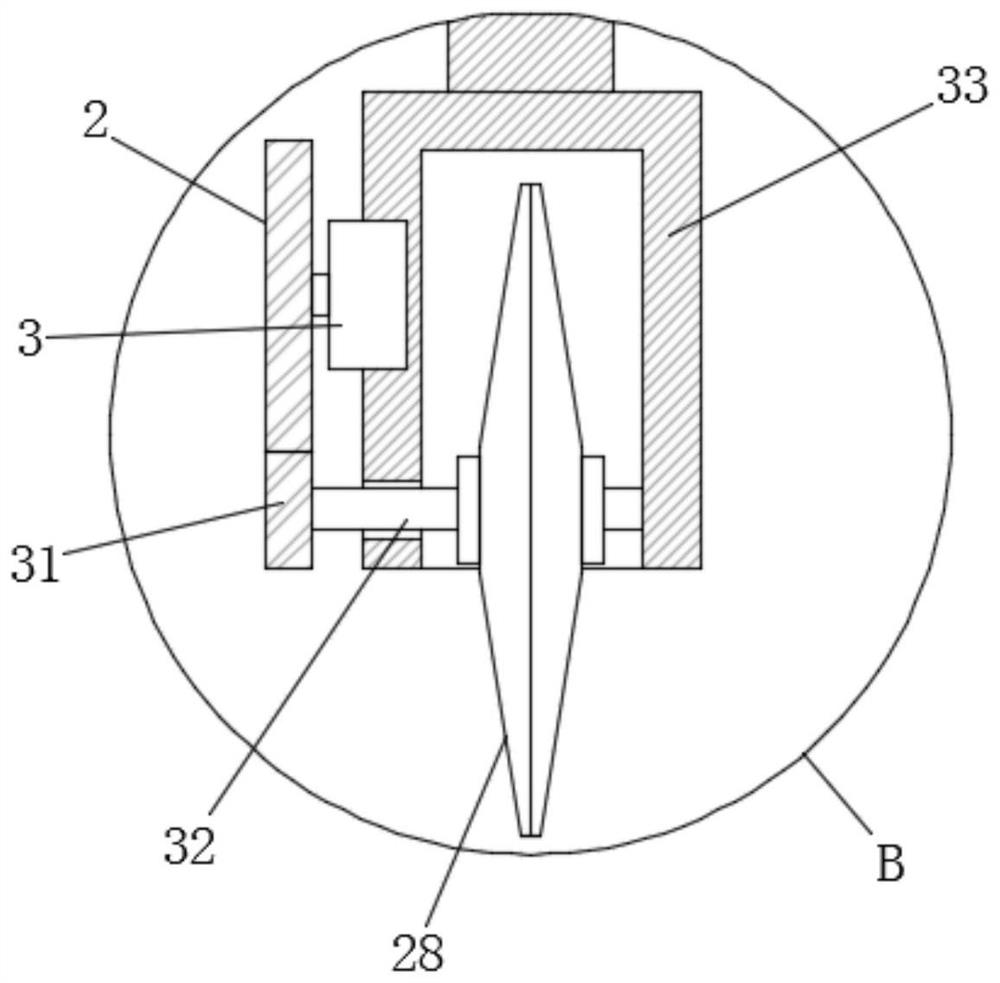

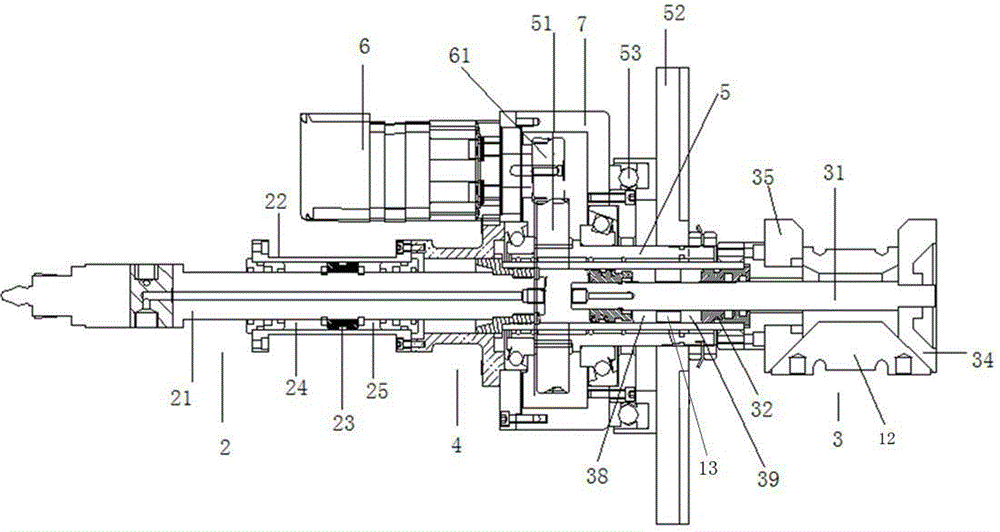

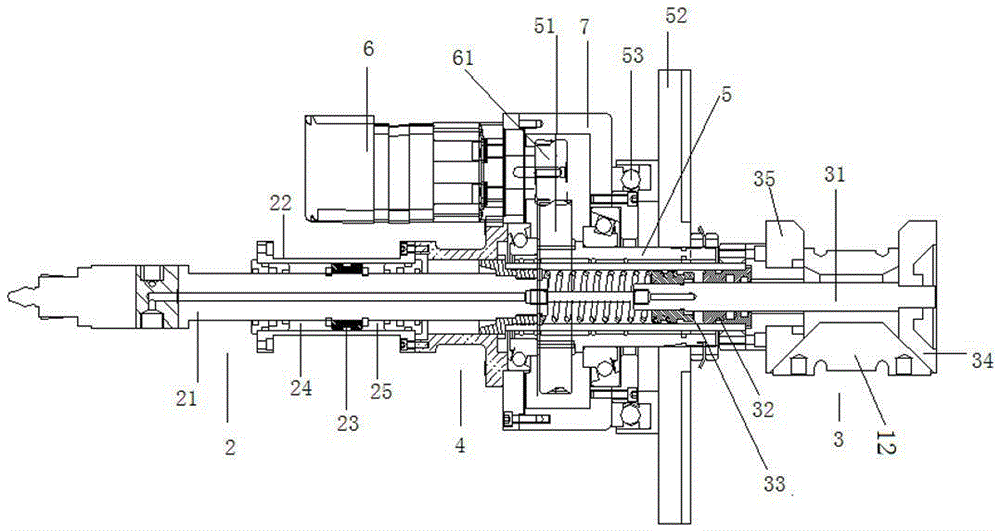

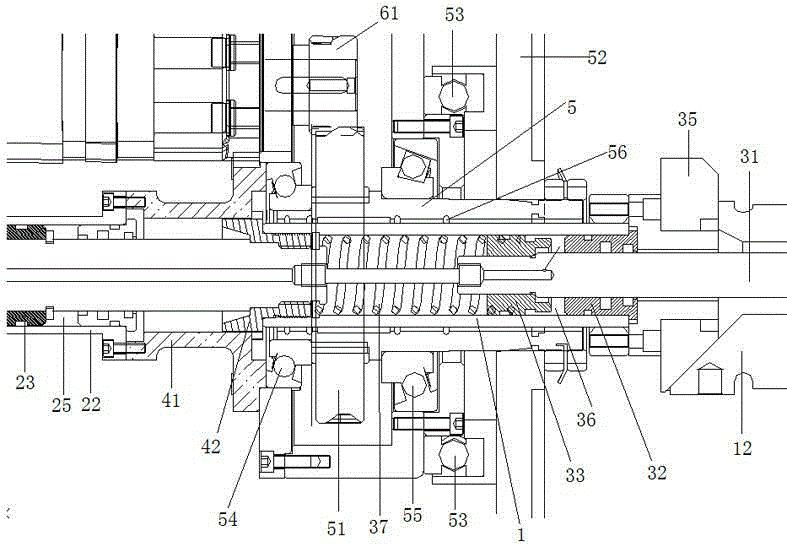

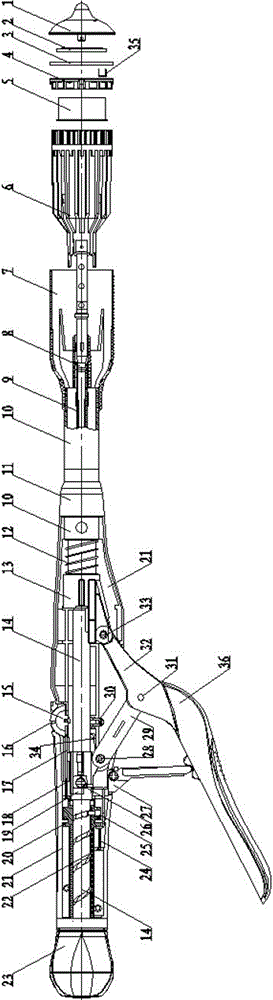

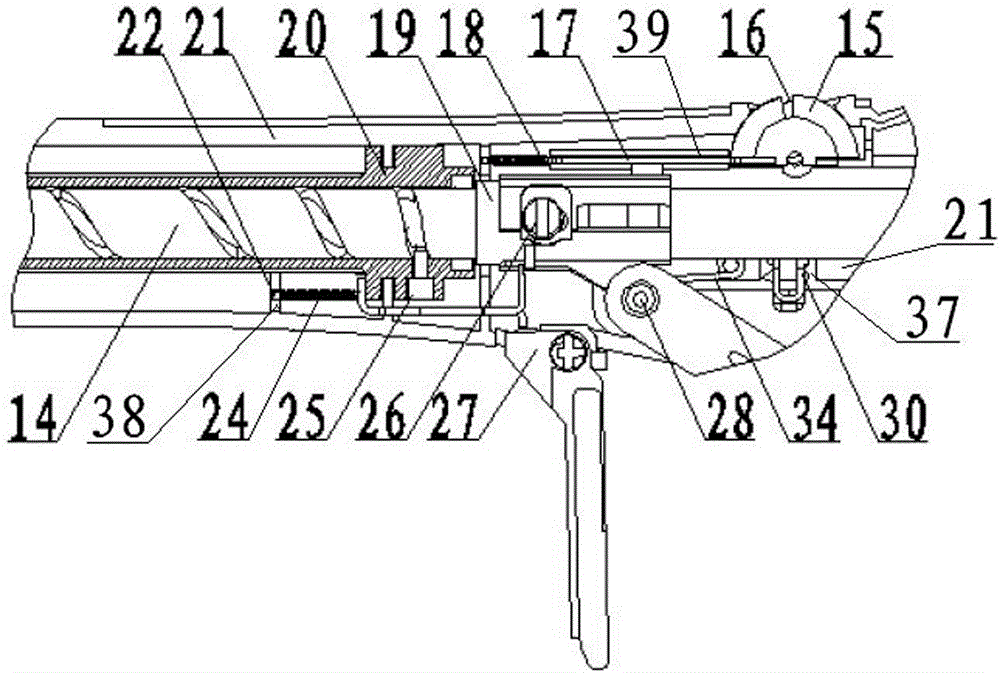

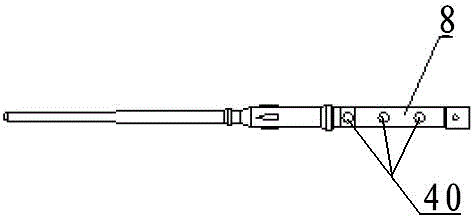

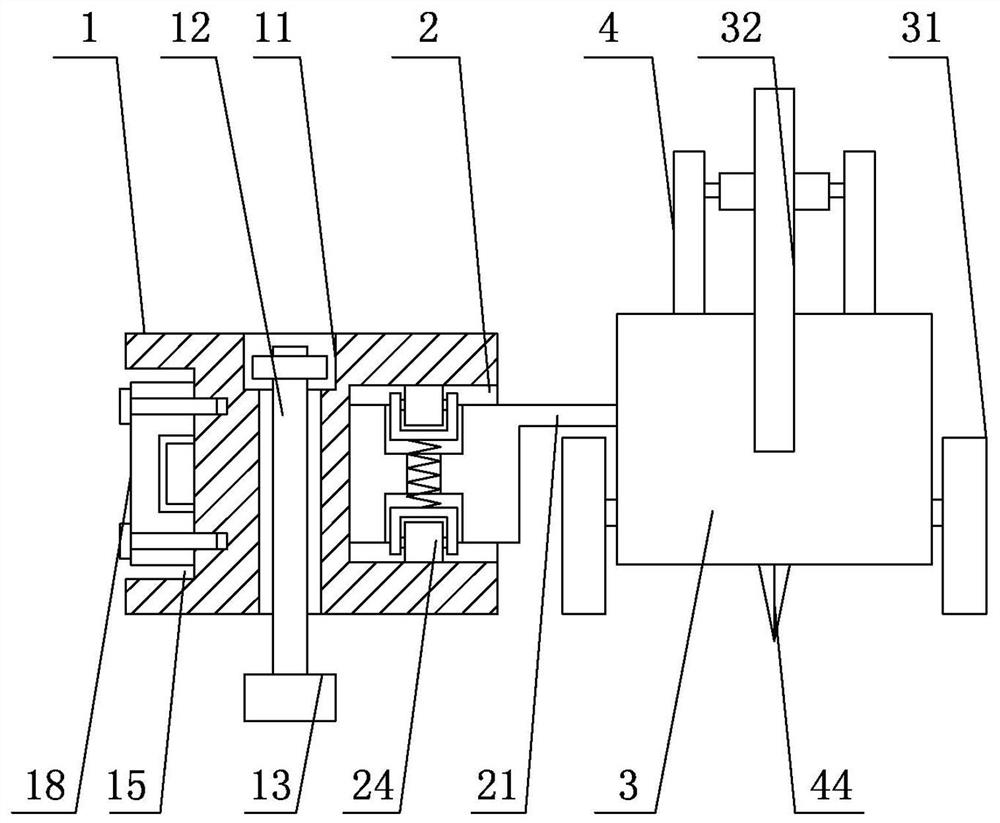

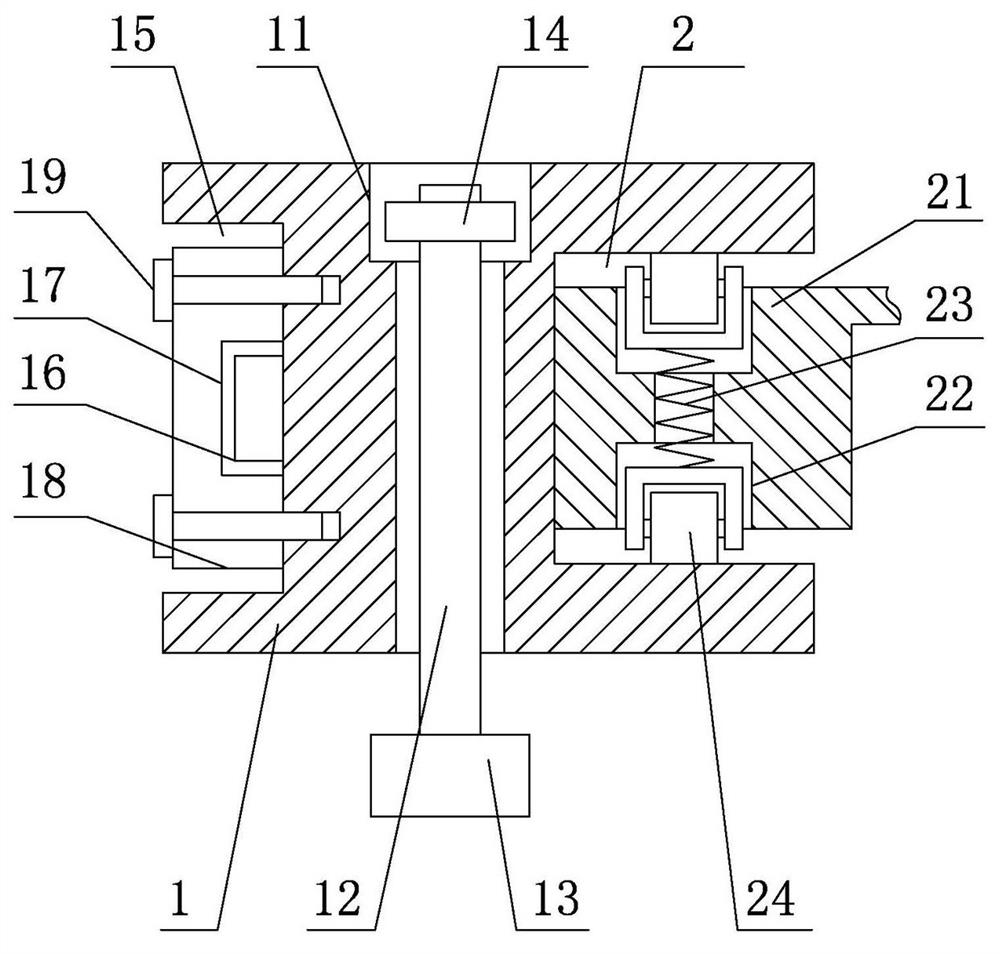

Disposable guide type anorectal hemorrhoid anastomat

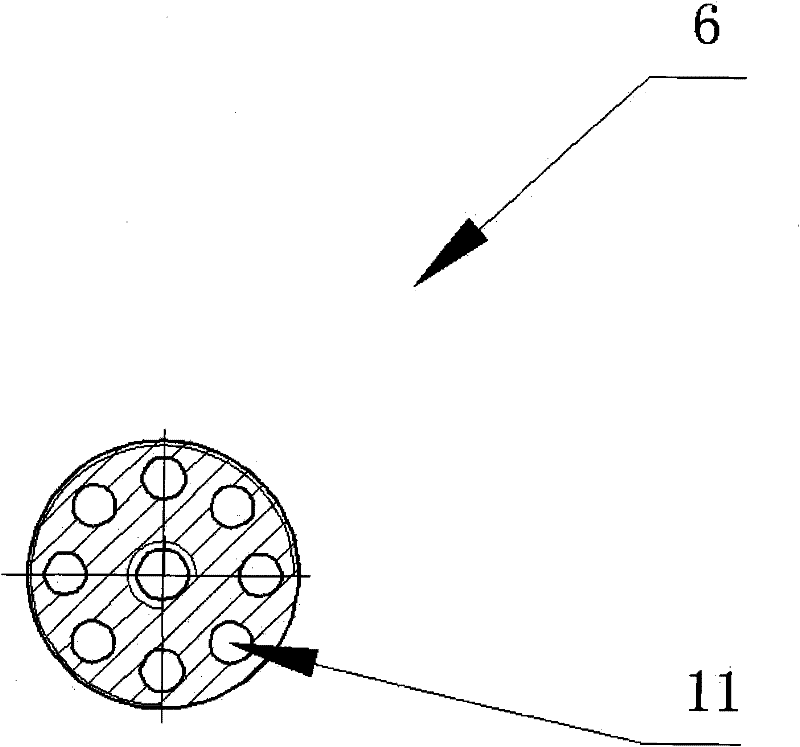

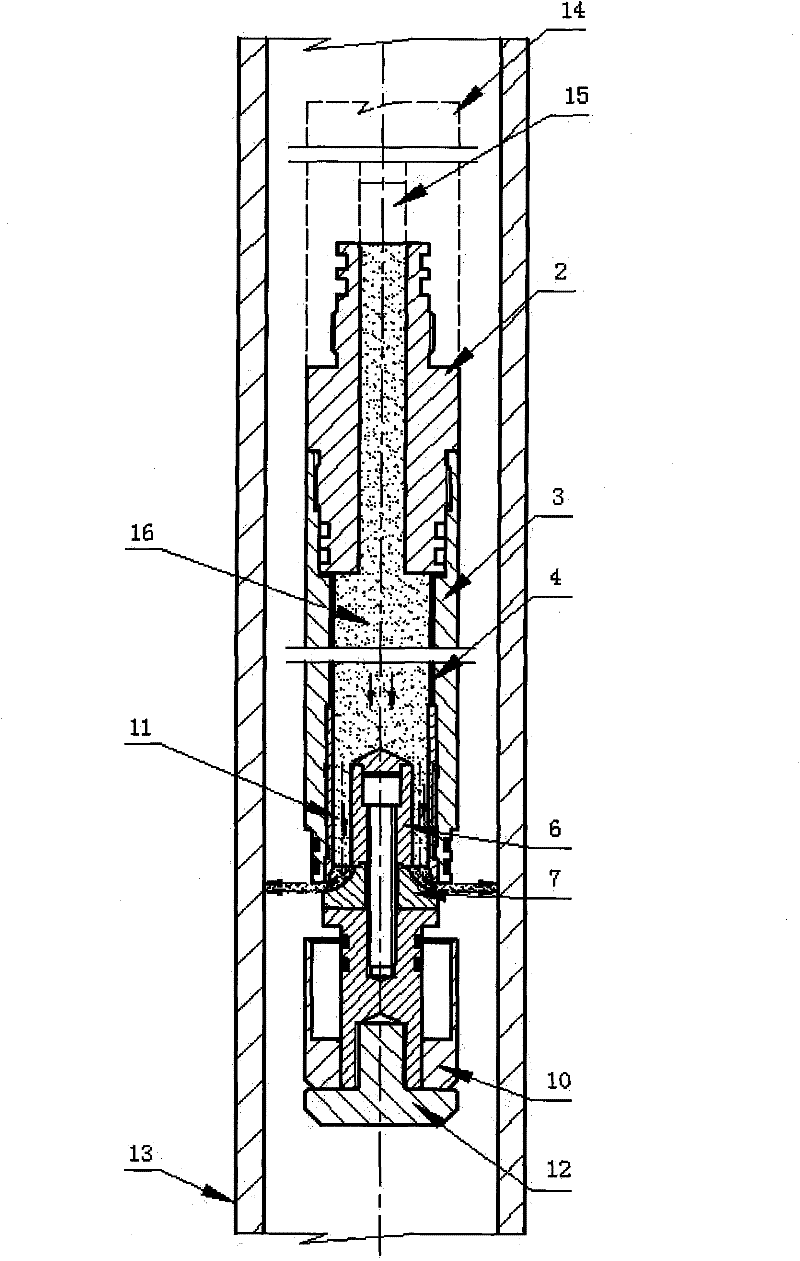

The invention relates to a disposable guide type anorectal hemorrhoid anastomat, which is suitable for being used as an anorectal hemorrhoid incising and sewing surgical instrument. The disposable guide type anorectal hemorrhoid anastomat comprises an abutting nail seat, a pad cutter ring, an abutting nail piece, a nail bin, an annular cutter, a needle pushing piece, a needle bin cover, a positioning shaft, a connecting pipe, an aluminum pipe, a locking ring, a reset spring, a push pipe, a screw, an indication shield, an indication block, an indication pull piece, a spring I, a bolt, an adjusting pipe, a fixing handle, an adjusting knob, an safety card, a spring II, a top post, a moving block, a safety block, a positioning pin I, a support rod, a sounding block, a positioning pin III, a movable handle, a positioning pin II, a torsion spring, a sewing needle and a movable handle shield; the left end of the movable handle is movably connected with the right end of the support rod of which the left end is movably connected with the fixing handle; the moving block is fixed on the screw; the adjusting pipe is matched with a threaded section at the left end of the screw by the top post; the adjusting knob is fixed at the left end of the adjusting pipe.; the sounding block is fixed in a sounding block mounting groove of the fixing handle, and the safety block is movably connected with the fixing handle.

Owner:WUXI SHENKANG MEDICAL INSTR EQUIP

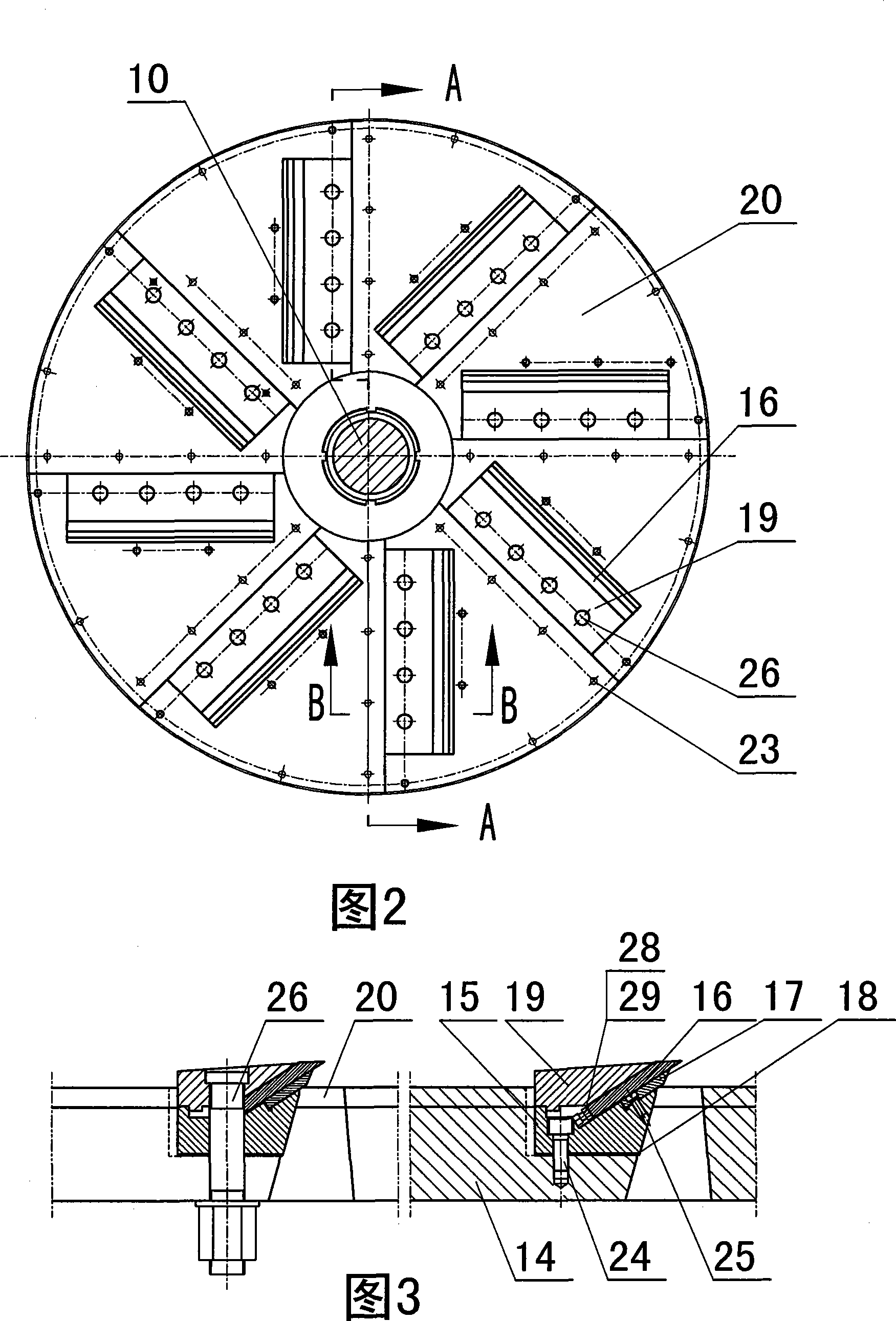

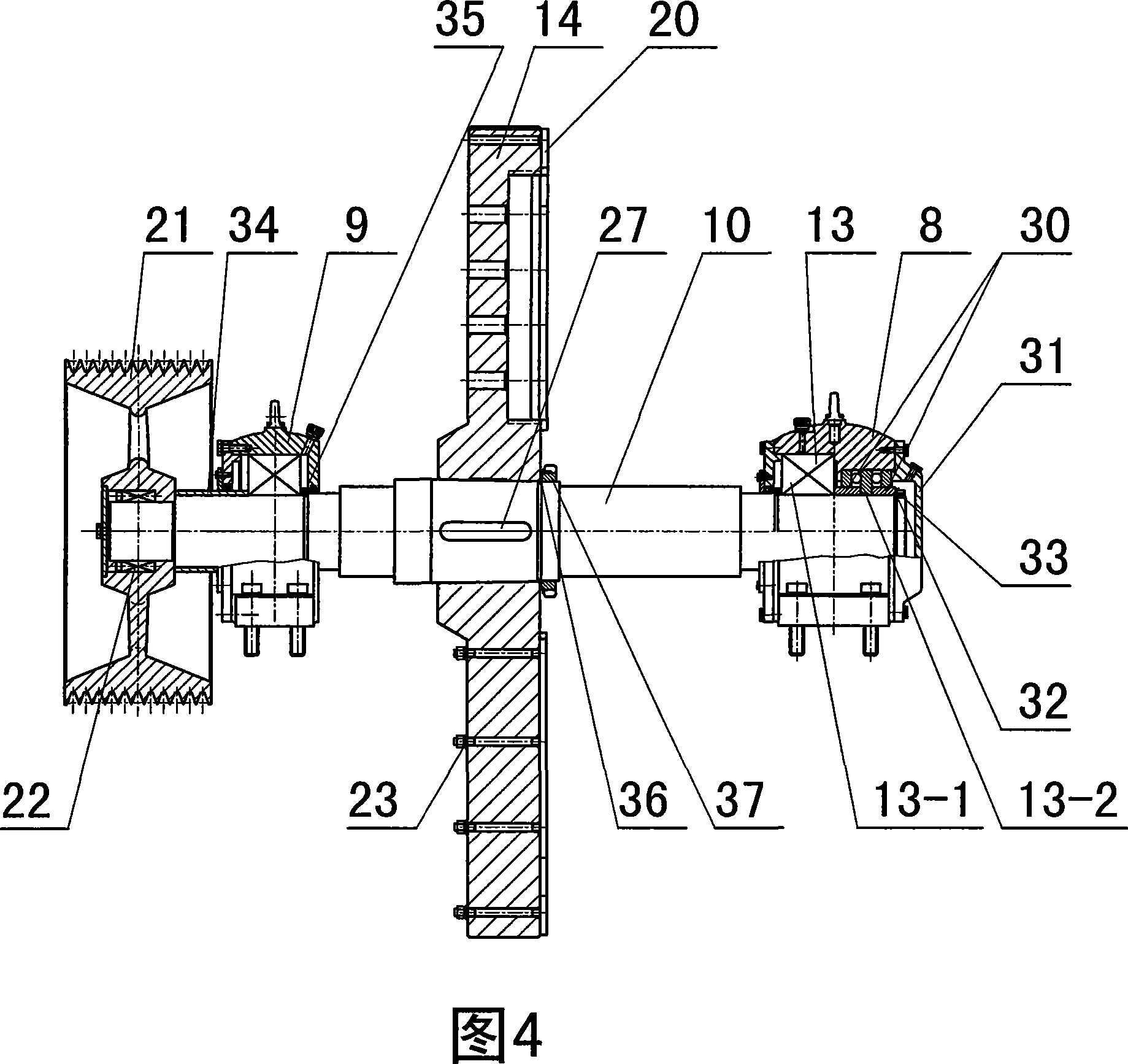

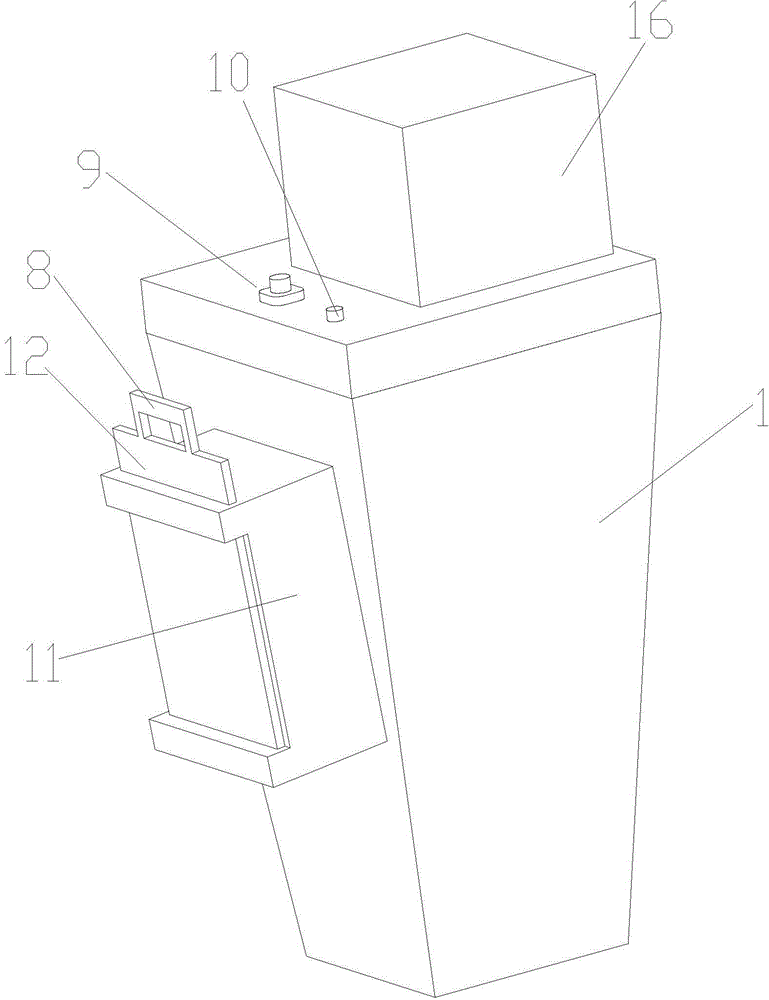

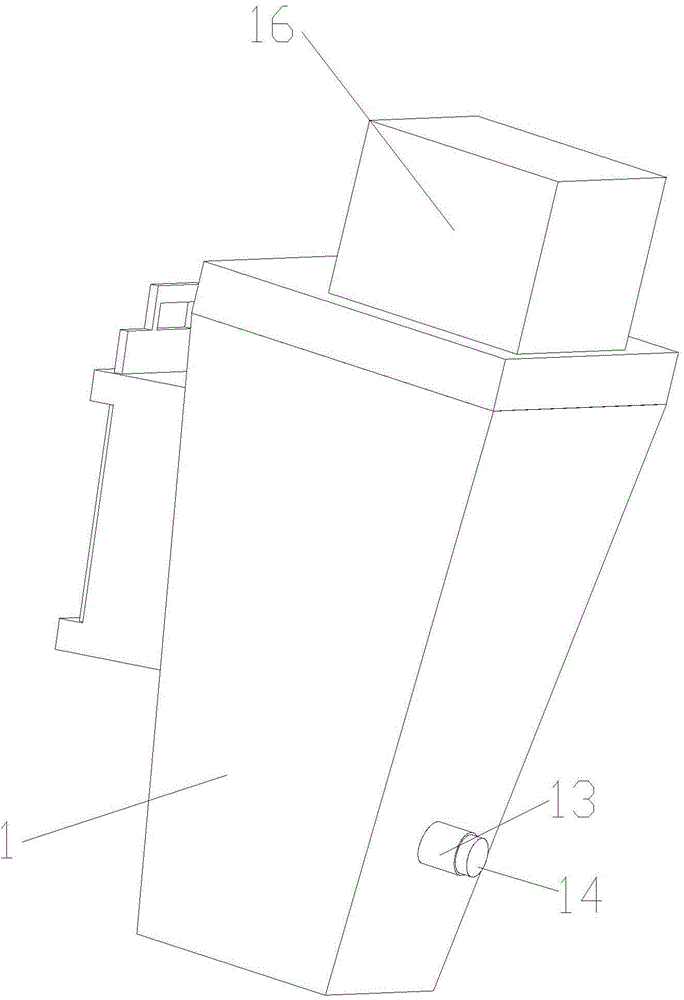

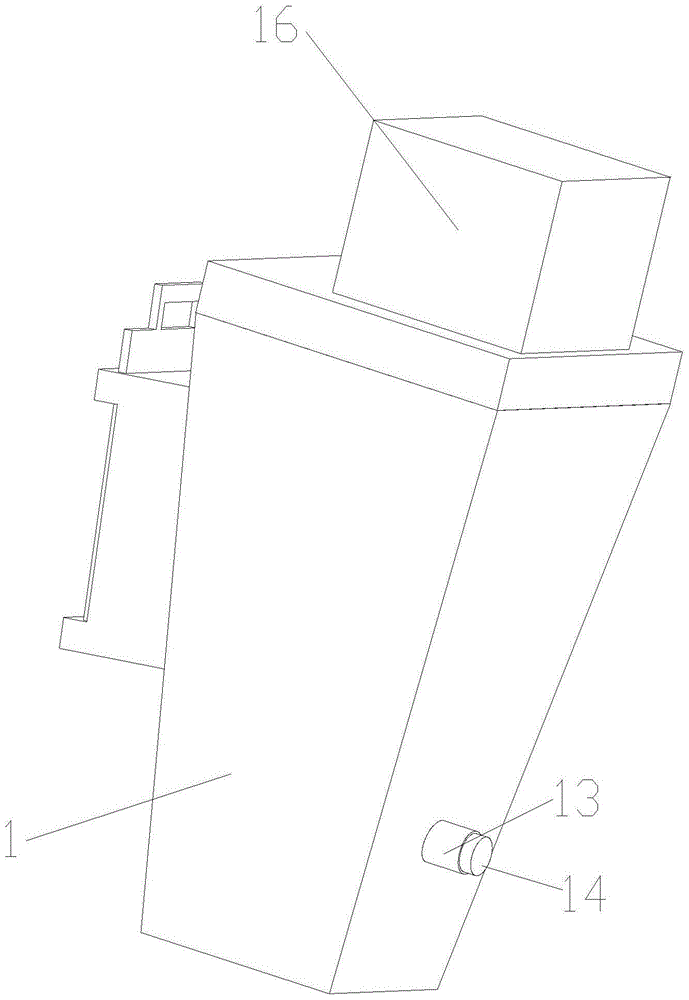

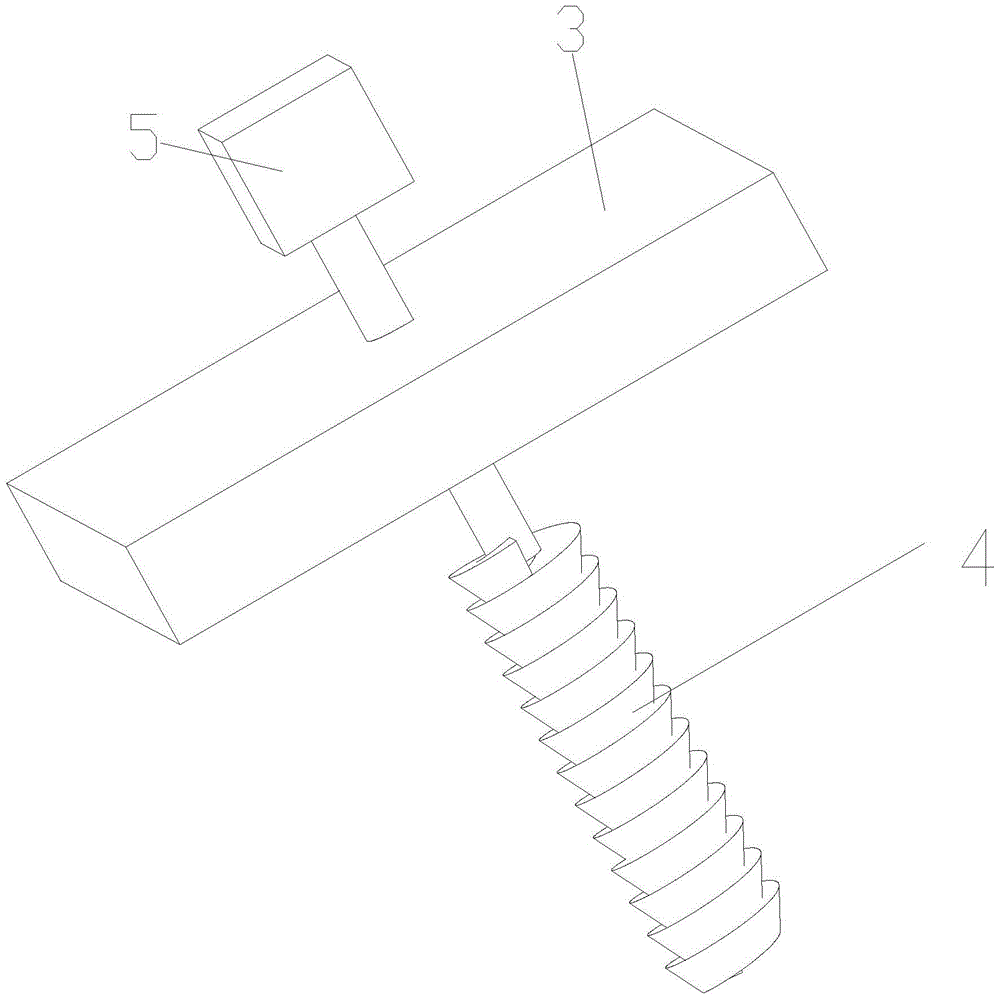

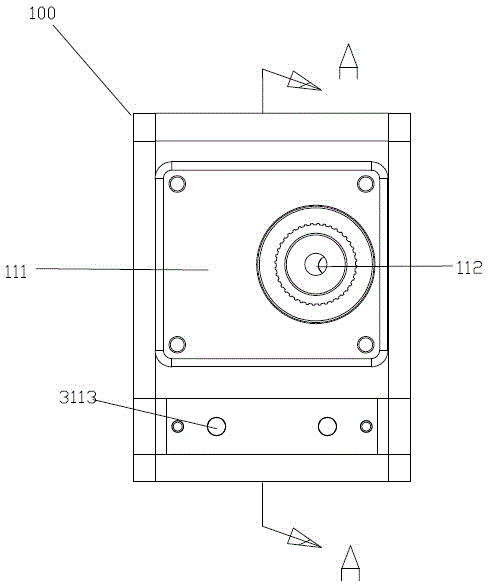

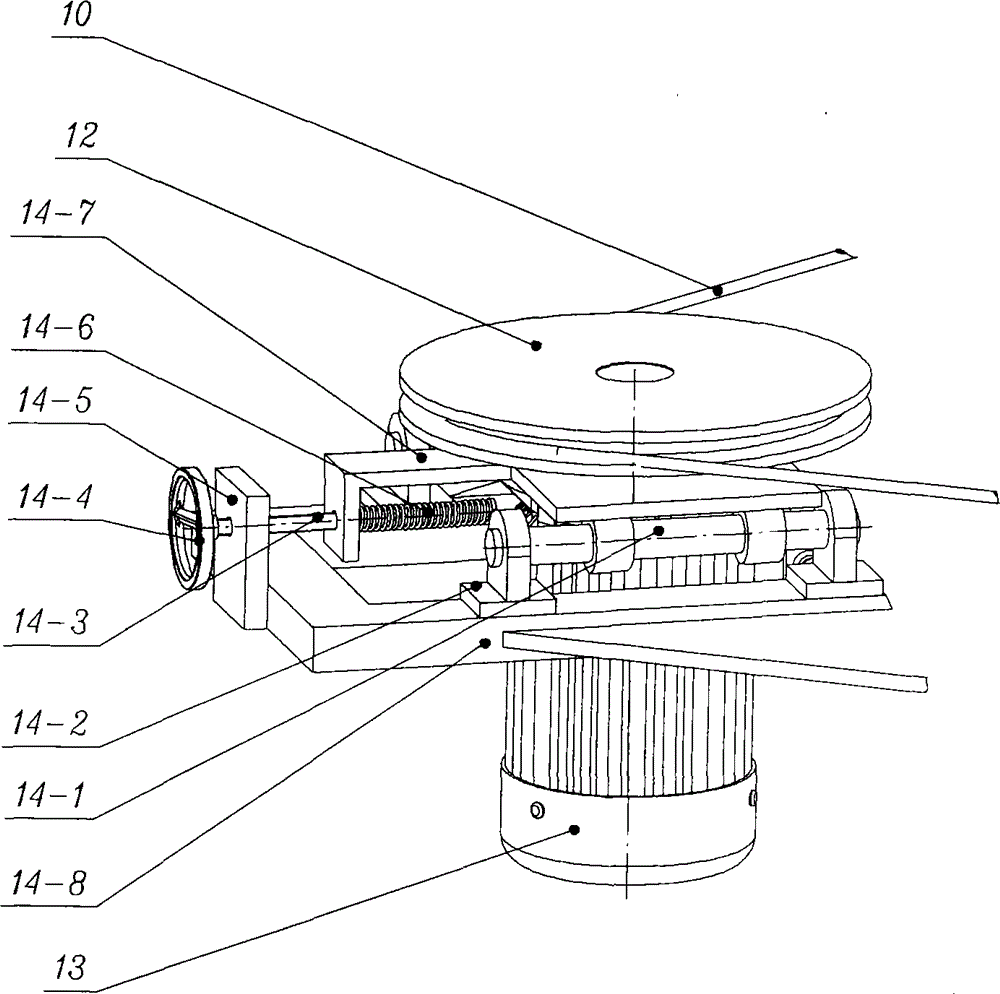

Disk chipper

InactiveCN101134332AOvercome the disadvantage of non-adjustableChange lengthVeneer manufactureEngineeringGasket

The present invention relates to chipping machine, and is especially one kind of disc type chipping machine, which includes one machine bed; one capstan housing on the machine bed; one feeding device on the capstan housing and with material inlet, bottom cutter, side cutter and discharge opening; one capstan device including spindle, capstan, flying cutter and cutter pushing block; and one driving device. The disc type chipping machine has the advantages of wide chipping range and capacity of chipping in different sizes.

Owner:江苏保龙机电制造有限公司

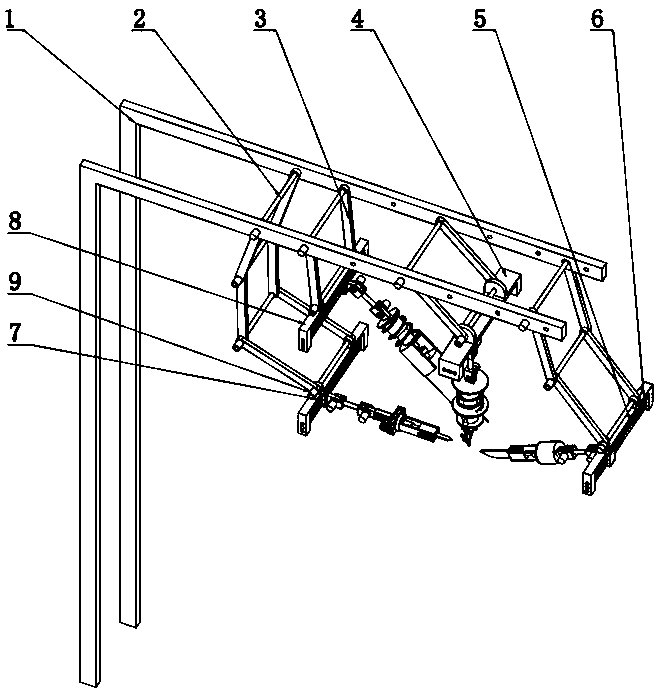

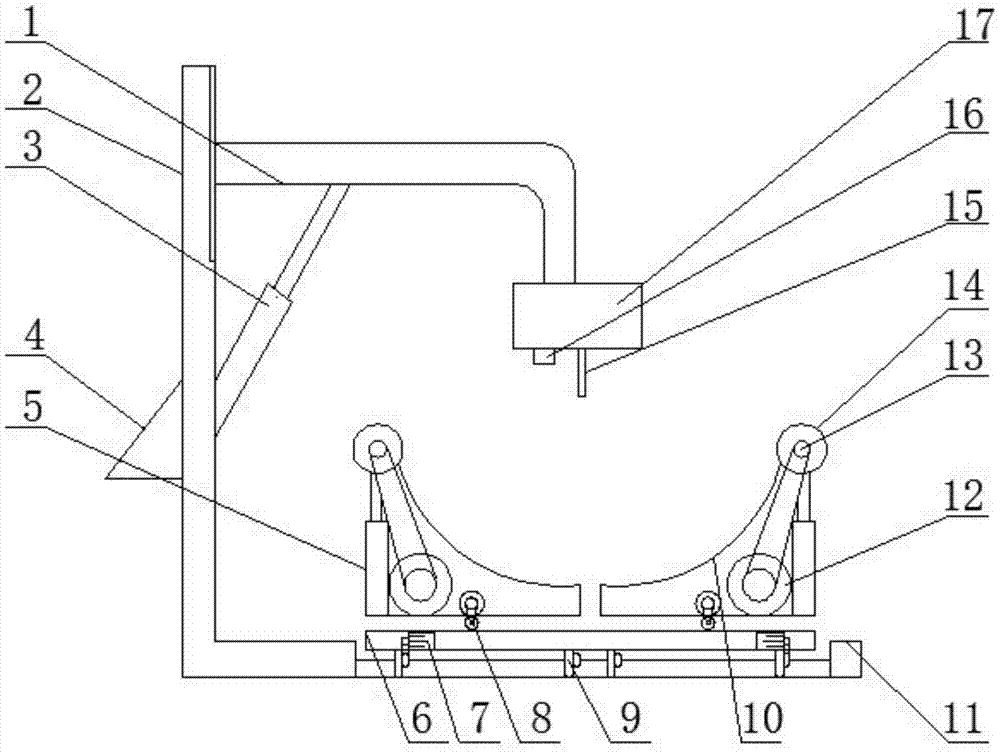

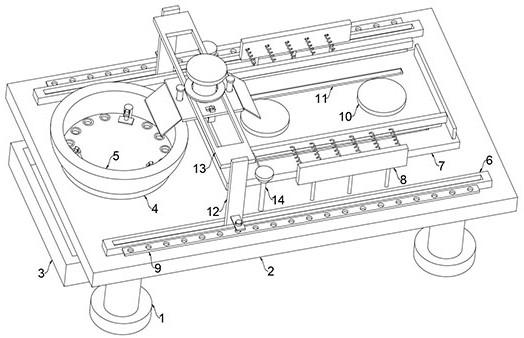

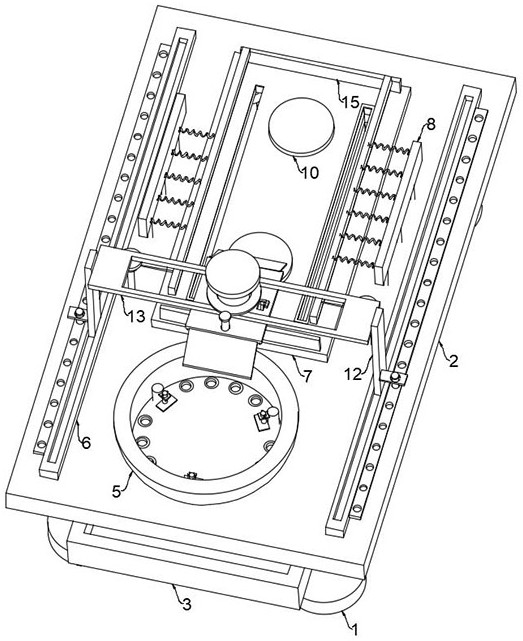

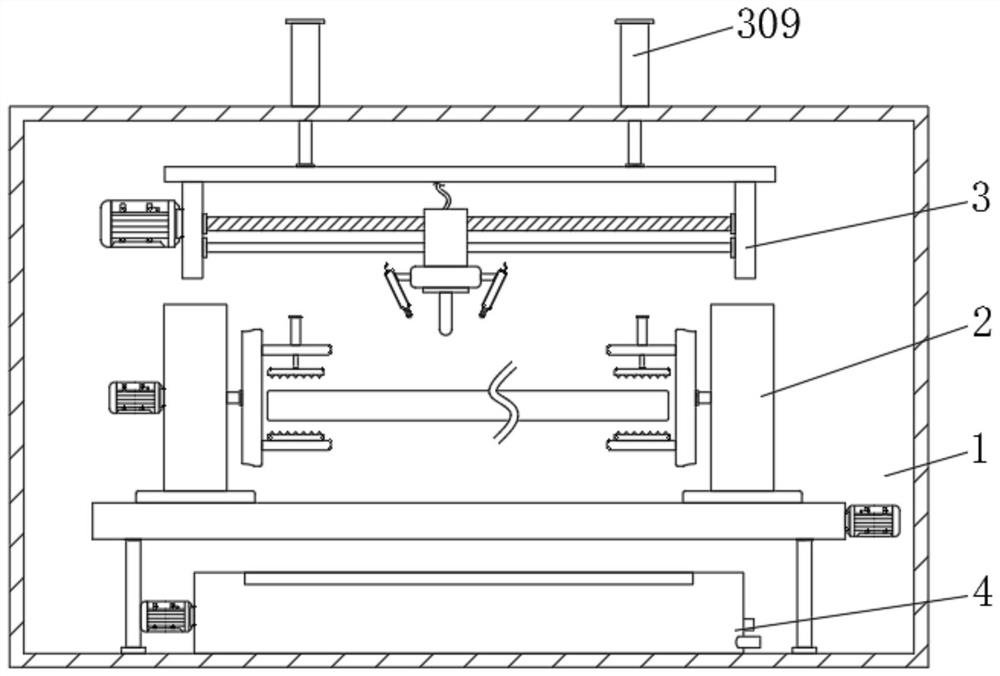

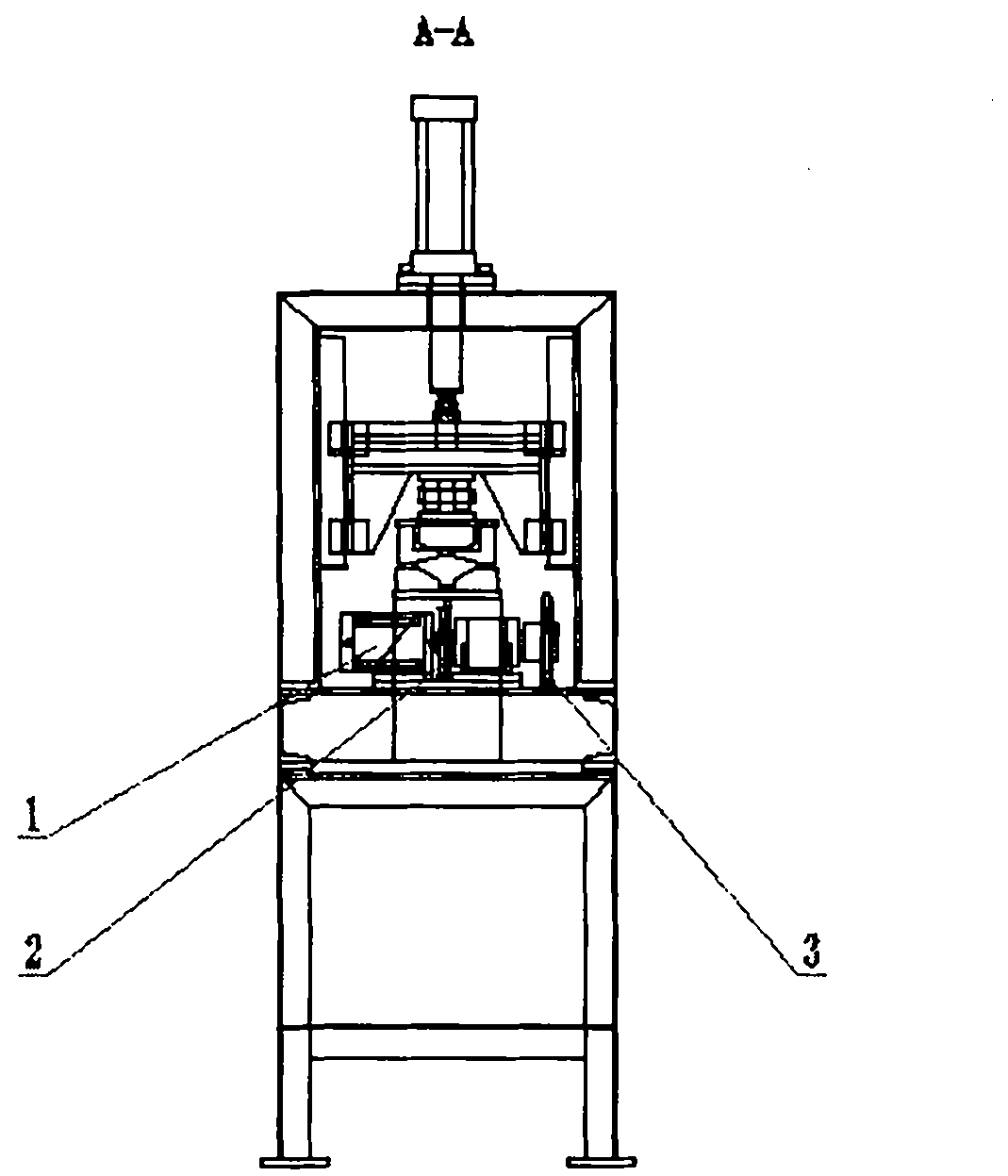

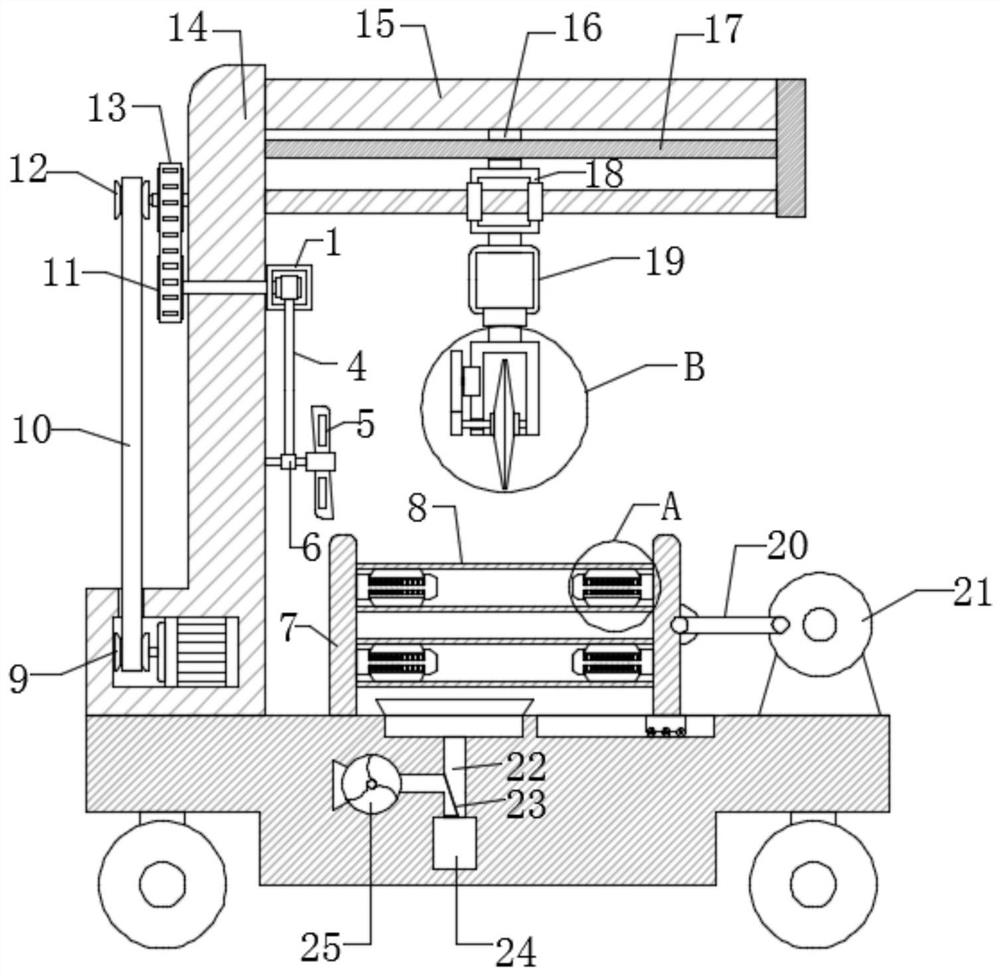

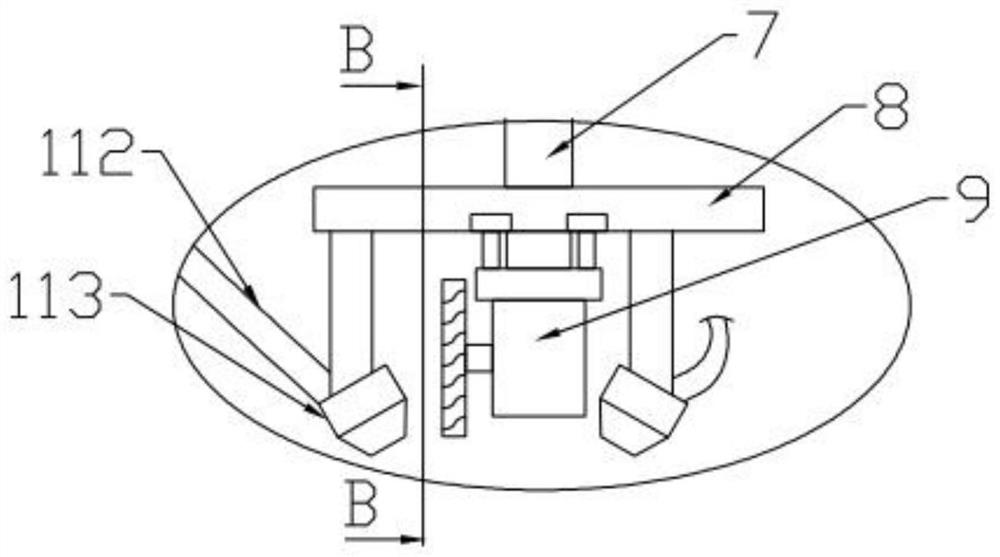

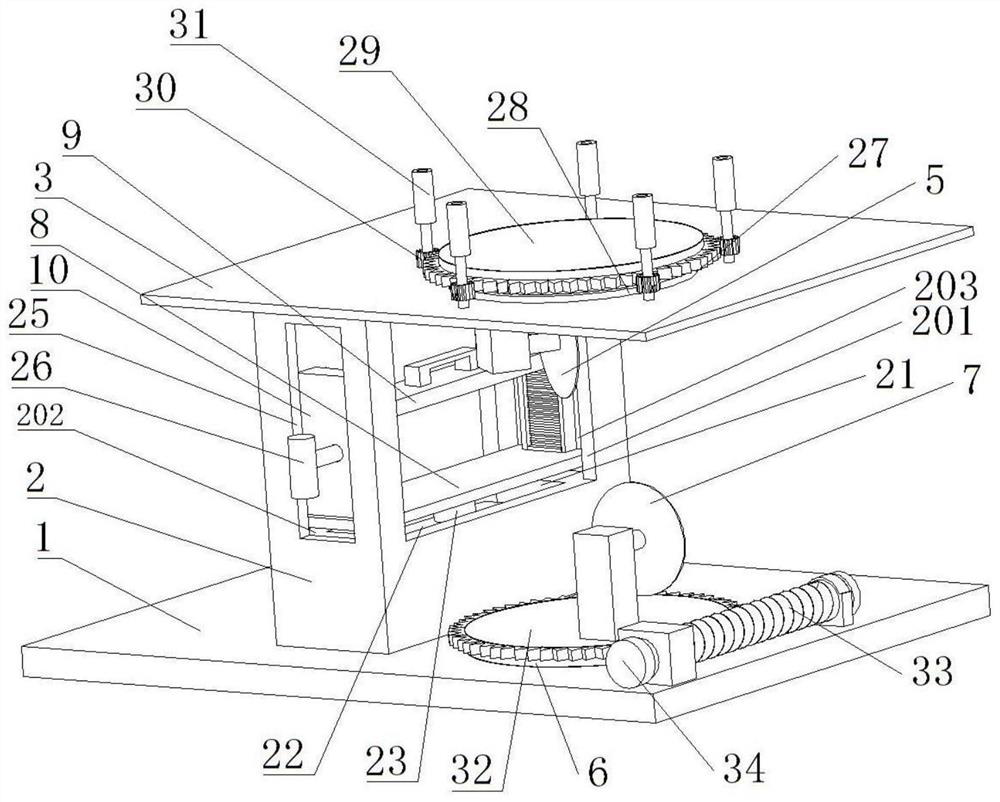

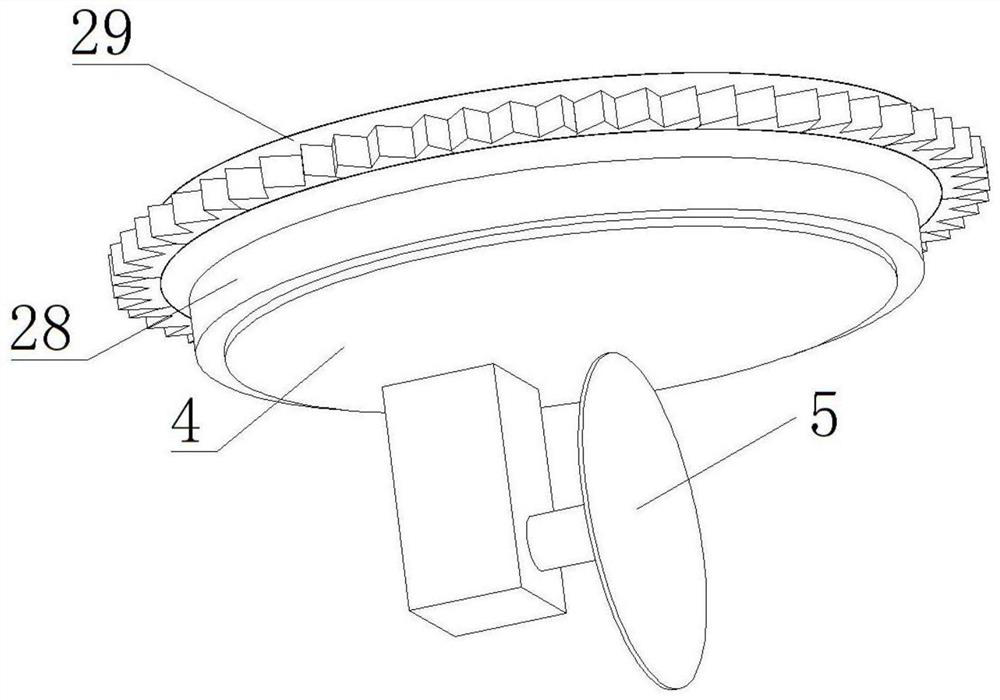

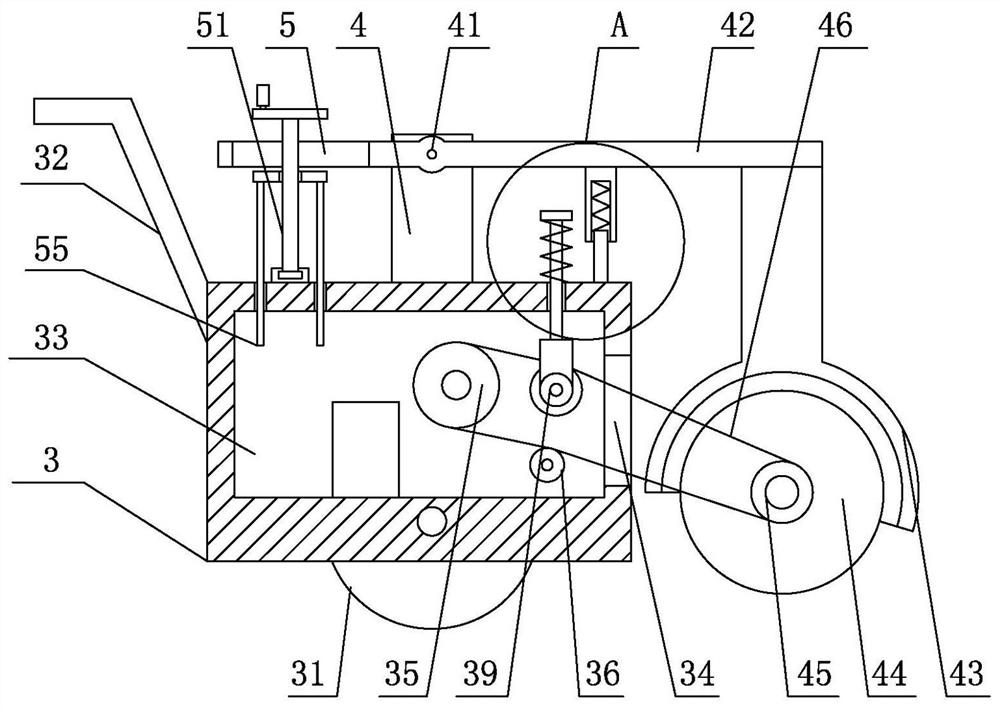

Lipomyoma excision robot

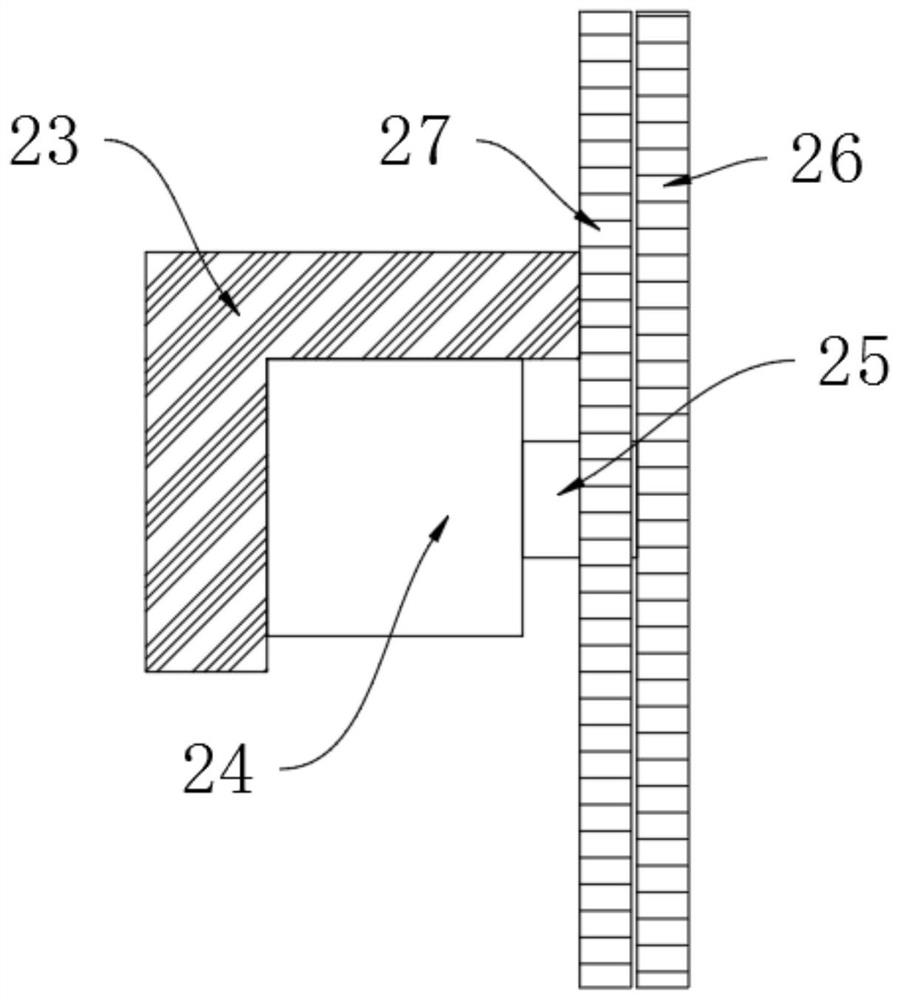

ActiveCN108714049AIncrease freedomWide range of cuttingExcision instrumentsSurgical manipulatorsMoving frameInjector

The invention provides a lipomyoma excision robot. The lipomyoma excision robot comprises a main body frame, a take-out part, an injection part, a cross-cutting part, an incision part and the like; the take-out part comprises a take-out part connecting rod, an electric cylinder base, a claw head, a needle seat and the like; the injection part comprises an injector, an injector holder, an injectionpart connecting rod and the like; the cross-cutting part comprises a cross-cutting part connecting rod, a telescopic electric cylinder seat, a lateral translation block, a cross-cutting cutter head and the like; the incision part comprises an incision cutter head, an incision cutter holder, an incision part connecting rod and the like; a main body of the robot is composed of the main body frame,a rotating rod, a sliding block moving frame and the like; the sliding block moving frame is provided with four mechanical arms of the take-out part, injection part, cross-cutting part and incision part; the injection part performs local anesthesia on the skin, the incision part cuts a part of the skin, a needle of the take-out part is inserted into a tumor body, and the claw head of the take-outpart and the cross-cutting part cut the periphery of the tumor body, so that the tumor body is separated, and the lipomyoma is removed.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Preparation method of diamond wire saw with composite coating

InactiveCN108166046AImprove cutting effectAvoid depositionElectrolytic coatingsChemical platingBiological activation

The invention discloses a preparation method of a diamond wire saw with a composite coating. The diamond wire saw is subject to rust removal, oil removal and activation treatment by a steel wire ropeto serve as a plated base body; a diamond adopting nickel plating / aluminum oxide or nickel plating / nickel oxide is used as grinding materials, a low-phosphorus nickel coating is prepared on the surface of the pretreated diamond through a chemical plating method, an aluminum oxide or nickel oxide layer is prepared on the surface of the nickel through a chemical precipitation method, and in a nickelelectroplating tank, the diamond wire saw with the composite coating is prepared through the sand feeding and thickening process. The preparation method is effective, high in yield, high in wire-making speed and high in production efficiency; the diamond wire saw with the composite coating has the advantages of being good in cutting edge performance, good in cutting performance, long in service life, high in utilization rate of diamond wire saw, wide in cutting range, capable of machining planes and curved surfaces and the like, and can be widely applied to the fields of military, civilian and other precise machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

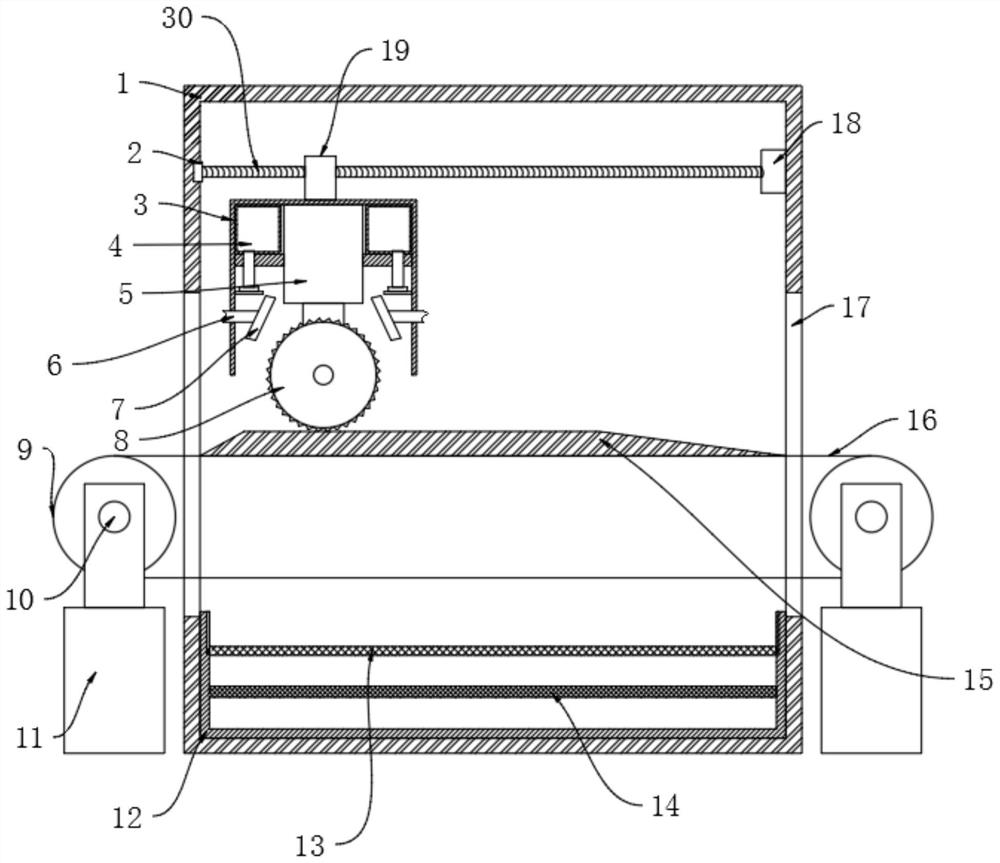

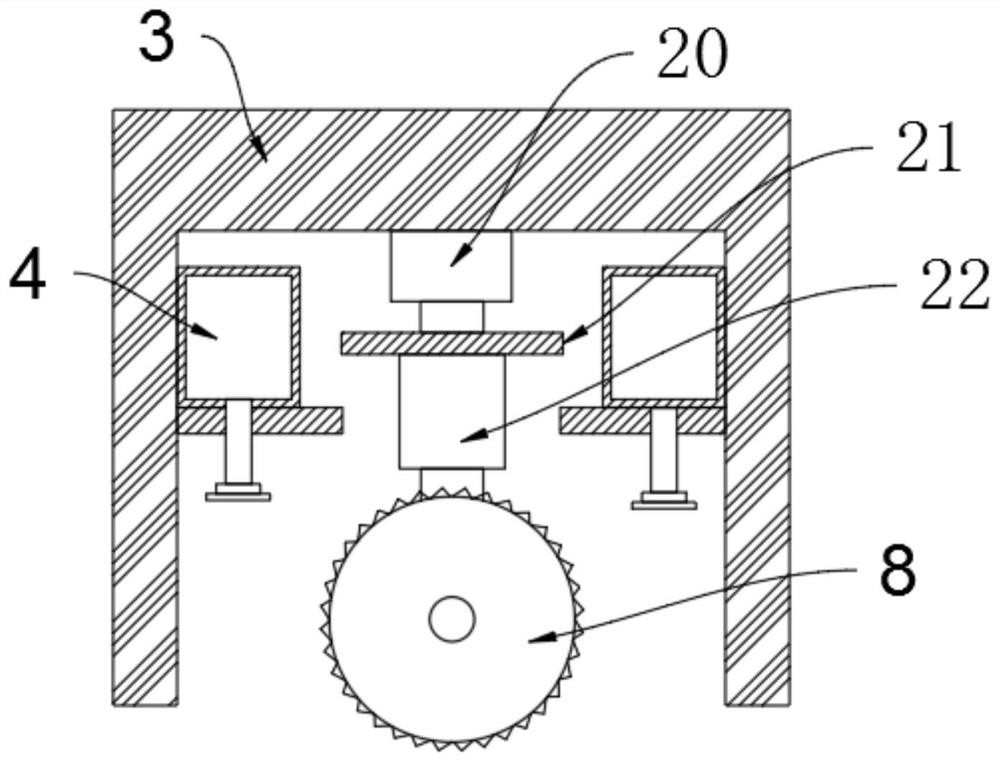

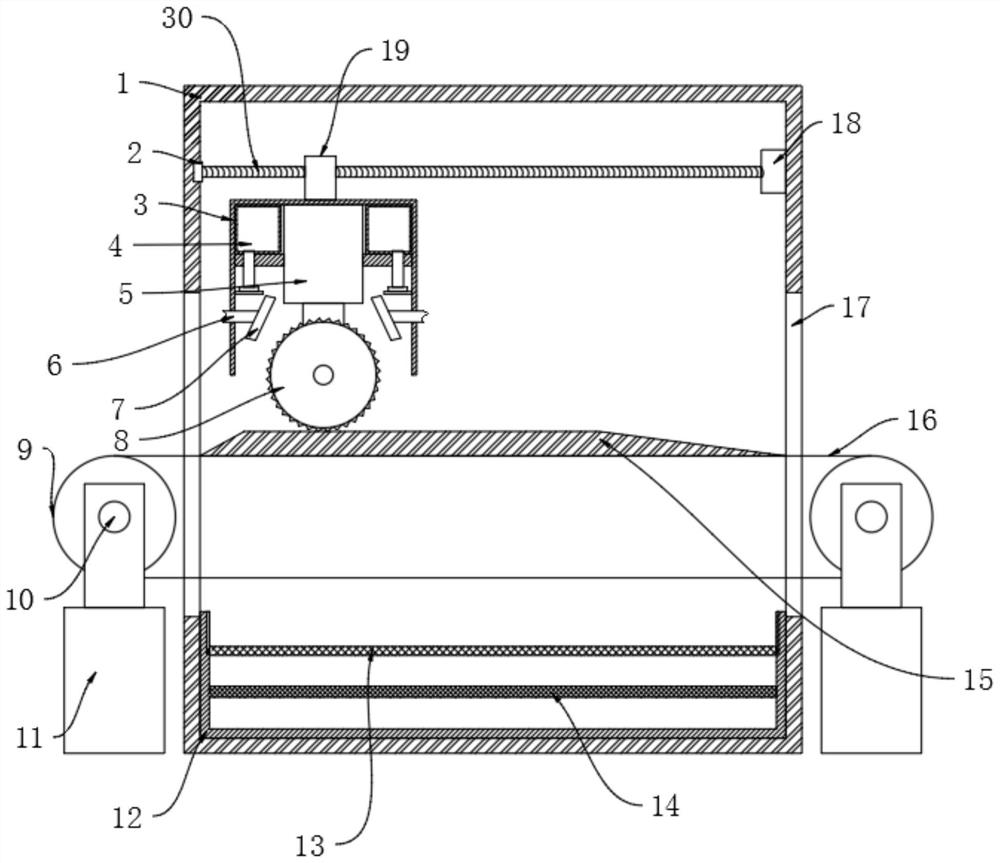

Novel intelligent telescopic pipeline cutting machine

InactiveCN106975843AWide range of cuttingMove away quicklyWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelGear wheel

The invention discloses a novel intelligent telescopic pipe cutting machine, which includes a body frame, a control panel, a transmission motor, a transmission wheel, a driven wheel, a pipe pulley and a laser cutting knife, and a sliding lifting bracket is arranged on the right side of the body frame. A laser generator is arranged on the sliding lifting bracket, the laser cutting knife is installed under the laser generator, an infrared sensing device is arranged on the laser generator, the control panel is installed on the left side of the body frame, and the A track is arranged on the right side of the bottom of the body frame, a transmission platform is arranged above the track, the transmission motor is installed on the transmission platform, and the transmission wheel is installed on the bottom of the transmission platform. The invention has a scientific and reasonable structure, safe and convenient operation, the cut pipe can be quickly removed through the transmission platform, and the cutting can be quickly completed through the pipe rotating motor, so as to avoid incomplete pipe cutting or pipe damage caused by the movement of the laser cutting knife.

Owner:王连福

A non-explosive metal pipe annular cutting device

The invention discloses a non-explosive annular cutting device for metal pipes. The device uses the high temperature generated by the burning of scorching agent as the power source, and can cut the metal pipes along the circumferential direction. It is mainly composed of upper joint, charging chamber, fluid distribution deflector, steering gear, sealing sliding sleeve and tailstock and other structures. After the burning agent in the charging chamber is ignited, the generated high-temperature fluid flows along the axial direction of the device to the direction of the fluid distribution deflector. After the high-temperature fluid passes through the fluid distribution deflector, it is turned by the diverter, and its moving direction smoothly changes to vertical In the radial direction of the axial direction of the device, and under the action of pressure, the sealing sliding sleeve slides to the rear of the device to open the cutting channel. The high-temperature fluid directly acts on the inner surface of the metal pipe to be cut, thereby realizing the cutting operation. It can be applied to downhole accident handling when the construction pipe string of oil and gas wells is stuck.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

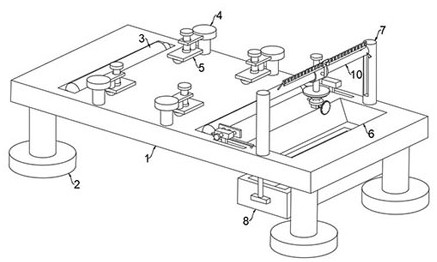

Cutting device for die part production

ActiveCN113210708AWon't shakeFirmly clampedShearing machinesLarge fixed membersCircular discEngineering

The invention discloses a cutting device for die part production. The cutting device comprises an operating platform fixedly mounted on a plurality of supporting columns, a disc and a fixing plate are fixedly mounted on the operating platform, a plurality of straight plates are fixedly mounted on the disc through a plurality of fixing rods, a pressing plate is mounted on each straight plate through a pressing mechanism, two side plates are fixedly installed on the operating platform through a plurality of vertical rods, a collecting mechanism is jointly installed among the fixing plate, the disc, the two side plates and the operating platform, and a cutting assembly is installed on the operating platform. The cutting device has the advantages that strip-shaped, square or circular parts can be cut, the cutting range is wide, the parts can be firmly and stably fixed, the parts cannot shake during cutting, the cutting angle, length and position can be flexibly adjusted, and the cutting efficiency is high.

Owner:南通维益机电有限公司

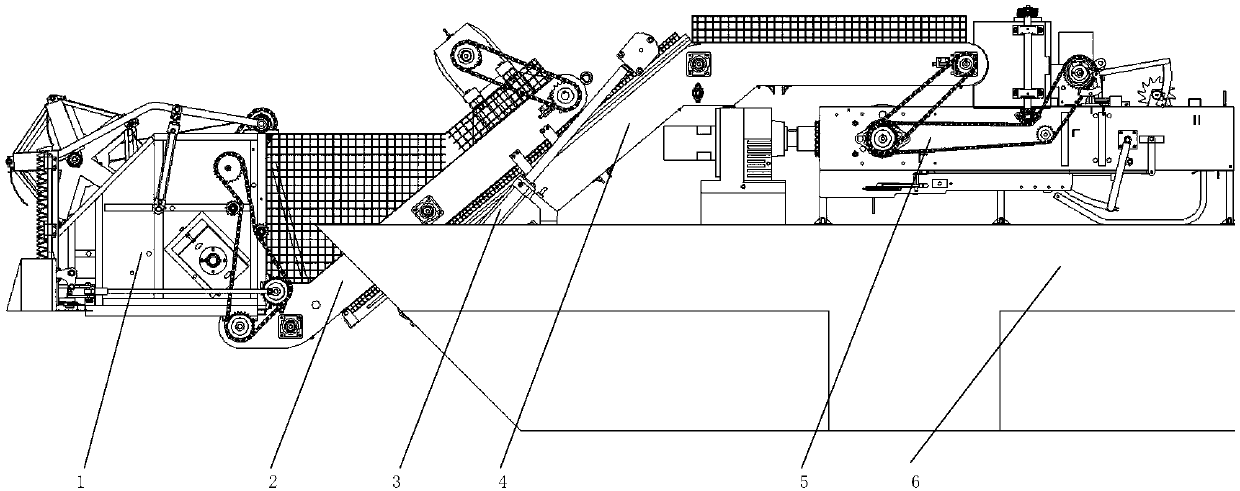

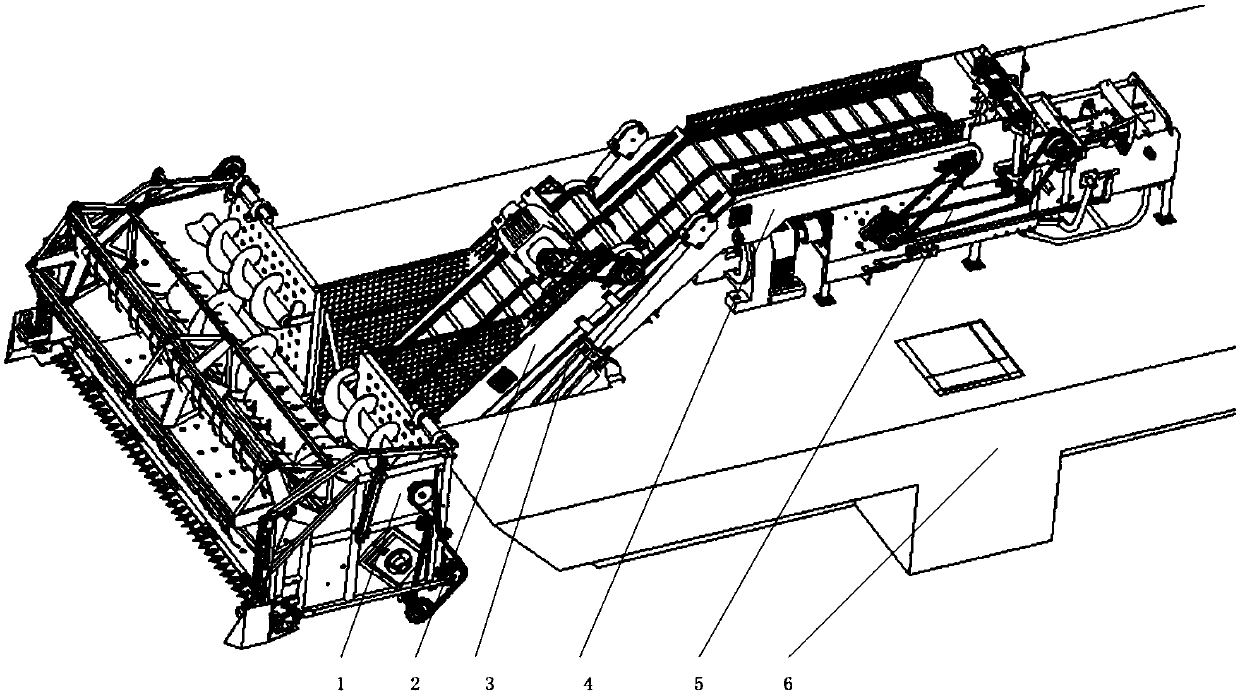

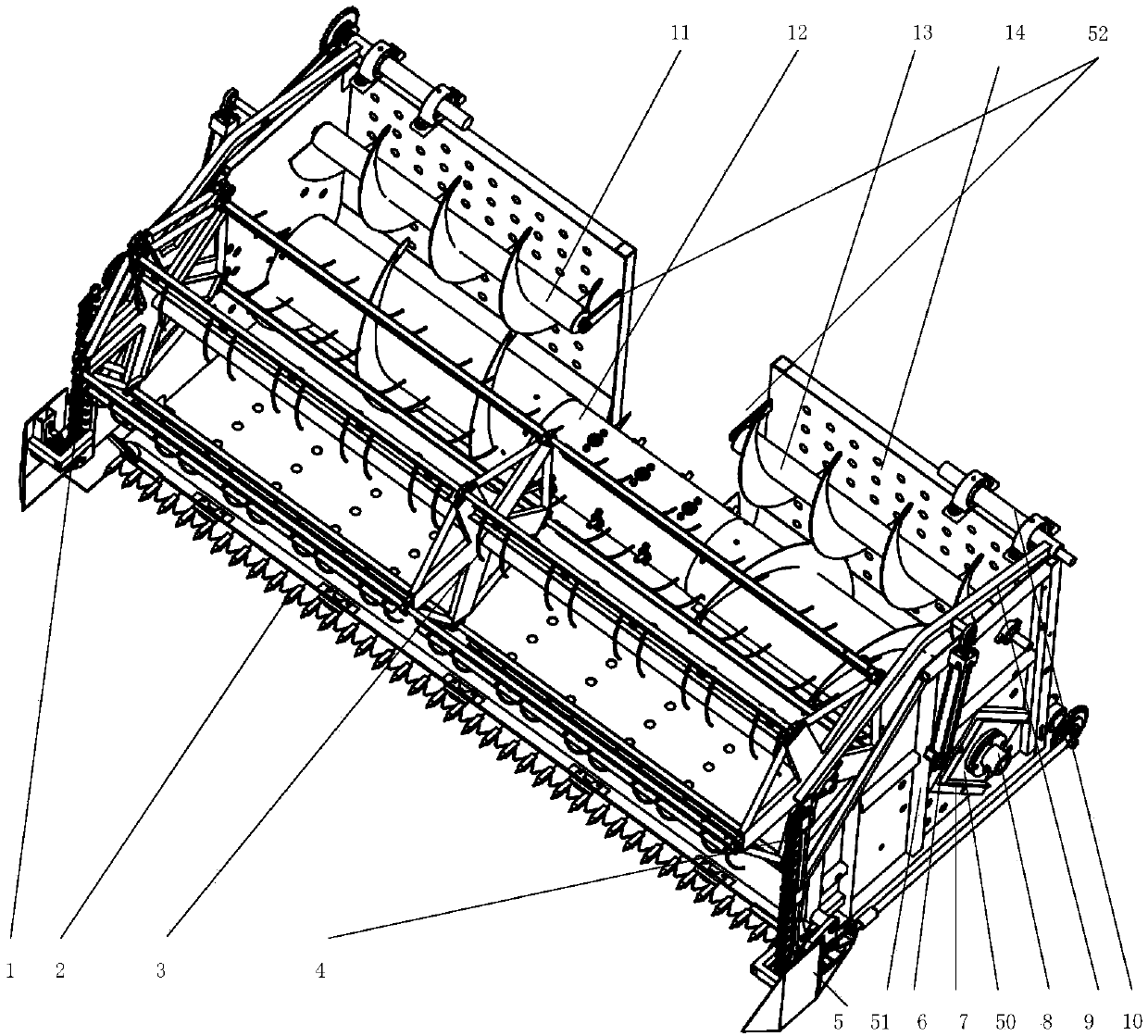

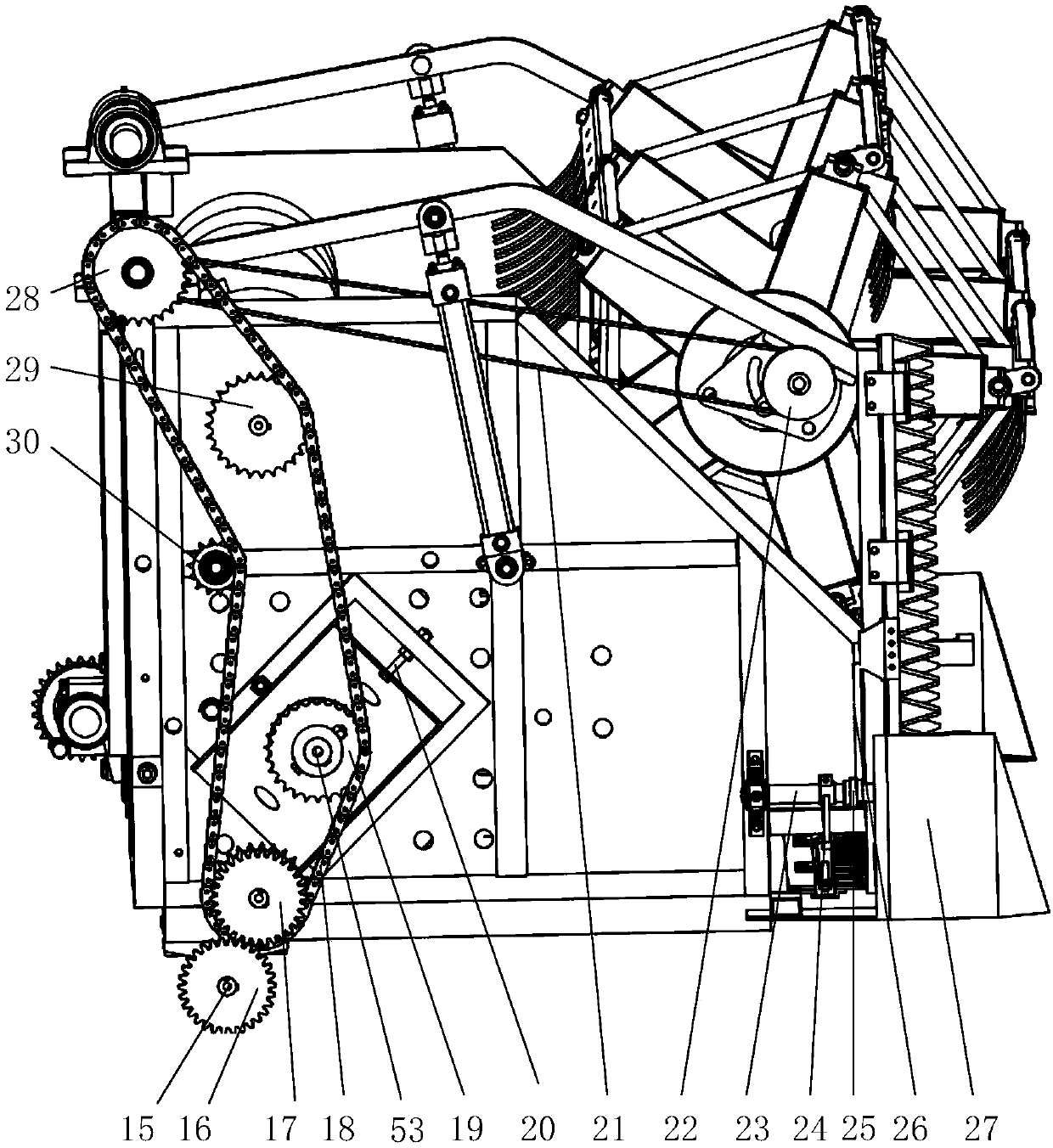

Aquatic weed cutting, conveying and bundling system and ship

The invention provides an aquatic weed cutting, conveying and bundling system and a ship. The system comprises a cutting table assembly, a primary conveying assembly, a cutting depth adjustment system, a secondary conveying assembly and a compressing and bundling system; the front portion of the primary conveying assembly is connected with the cutting table assembly, and the rear portion of the primary conveying assembly is in sliding connection with the front portion of the secondary conveying assembly through the cutting depth adjustment system; the compressing and bundling system is installed at the tail end of the rear portion of the secondary conveying assembly. The system can serve as a working part carried on the amphibious ship to effectively control water grass pollution in rivers, lakes and main canals. When the ship drives on land, the primary conveying assembly and a front-end cutting platform are stored through a hydraulic oil cylinder, and the occupied space of a hull isreduced; when the ship works in water, the primary conveying assembly and a cutting platform are put down through the hydraulic oil cylinder to adjust the cutting depth, and the aquatic weed cutting,conveying and bundling functions are achieved. The cutting table assembly of the aquatic weed cutting, conveying and bundling system can push aquatic weeds on the upper portion and the lower portion of the two sides to a cutting table notch for conveying the conveying parts behind, and thus efficient harvesting of the aquatic weeds can be achieved.

Owner:泰州市力鼎机械设备有限公司

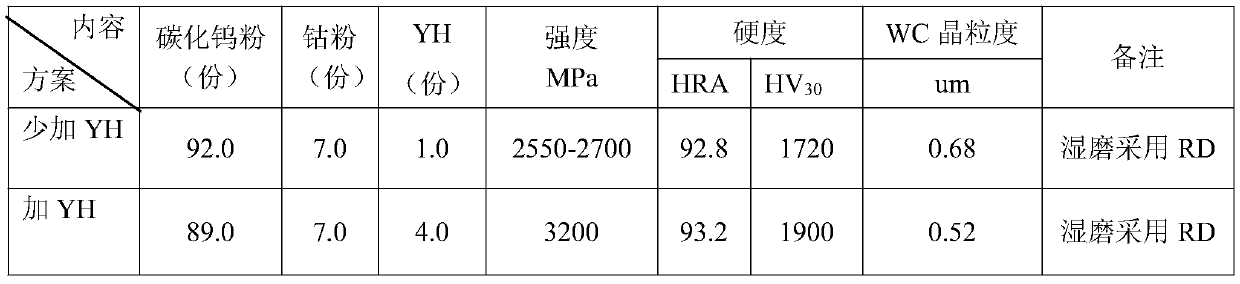

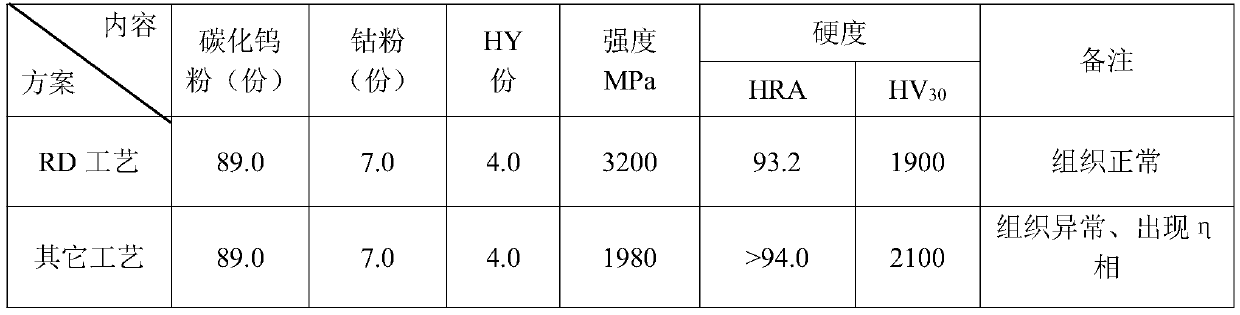

Microcrystalline GW10u hard alloy and preparation method thereof

InactiveCN111057929AAddressing disorganizationSolution to grain growthPtru catalystChemical composition

The invention discloses microcrystalline GW10u hard alloy. The microcrystalline GW10u hard alloy is prepared from the following raw materials in parts by mass: 89-93 parts of tungsten carbide powder,5-7 parts of cobalt powder and 2-4 parts of catalyst YH. According to the microcrystalline GW10u hard alloy, the superfine tungsten carbide powder and the cobalt powder are used as main raw materials,a trace grain inhibitor Y, a metal activator H and a combination of the trace grain inhibitor Y and the metal activator H are added, and the mixture is mixed under a unique wet grinding RD oxygen barrier medium, so that the defects of unstable performance caused by uneven structure, grain growth and unstable chemical composition of the mixture in the preparation process of the superfine hard alloy material are effectively overcome, and the GW10u hard alloy which has stable structure microcosmically and high strength and hardness macroscopically is prepared. The grade can be simultaneously suitable for machining K, N, S and H hard cutting metals, has a wide cutting range and completely covers the range specified by the existing national standard GB / T18376.1. In addition, the process is mature and simple, the product stability is good and the performance is excellent.

Owner:成都金钨硬质合金有限公司

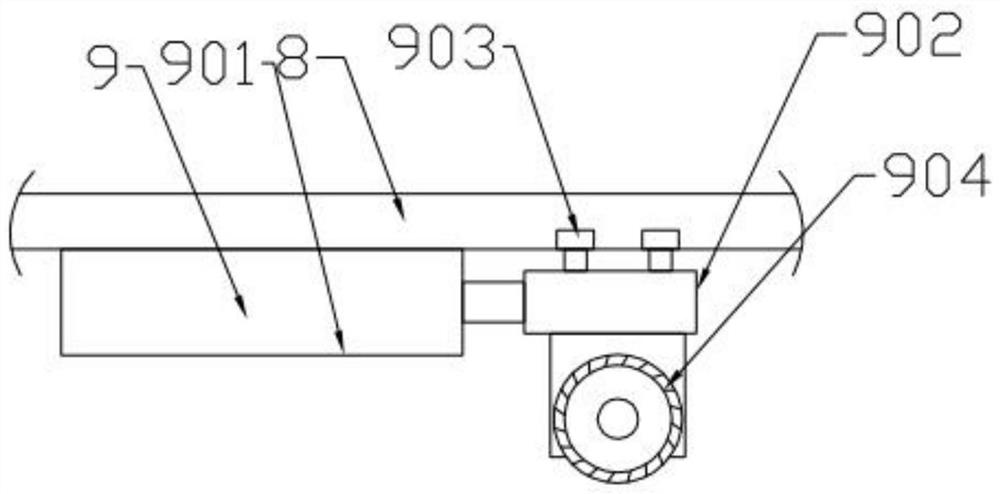

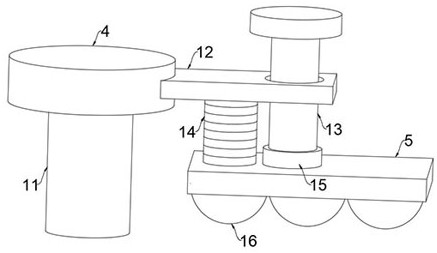

Positioning, marking and cutting device for lathe machining and implementation method of positioning, marking and cutting device

InactiveCN113000866AEasy to slideWide range of cuttingAutomatic/semiautomatic turning machinesAuxillary equipmentWire cuttingElectric machinery

The invention discloses a positioning, marking and cutting device for lathe machining and an implementation method of the positioning, marking and cutting device. The positioning, marking and cutting device comprises a lathe workbench, wherein a supporting frame set is arranged on one side of the upper end face of the lathe workbench, the bottom end of the supporting frame set is welded to the lathe workbench, a top plate is vertically connected to one side of the top end of the supporting frame set, and a sliding groove is transversely formed in the center of the surface of the top plate. According to the positioning, marking and cutting device for lathe machining and the implementation method of the positioning, marking and cutting device, the sliding groove is convenient for the front-back sliding of a cutting mechanism in the sliding groove, multi-directional cutting is achieved, the cutting range is wide, high practicability of equipment is achieved, a positioning and marking mechanism is used for marking the surface of a large-size metal steel plate, the steel plate is cut into various shapes according to production requirements, the operation is easy and flexible, the working efficiency is improved. A first air cylinder drives a first piston rod to drive a lifting plate to move up and down at a constant speed, a cutting tool apron is driven to move up and down, and then a motor is started, so that the effect that a cutting tool precisely cuts the metal steel plate is achieved.

Owner:定南县沃土园林养护有限公司

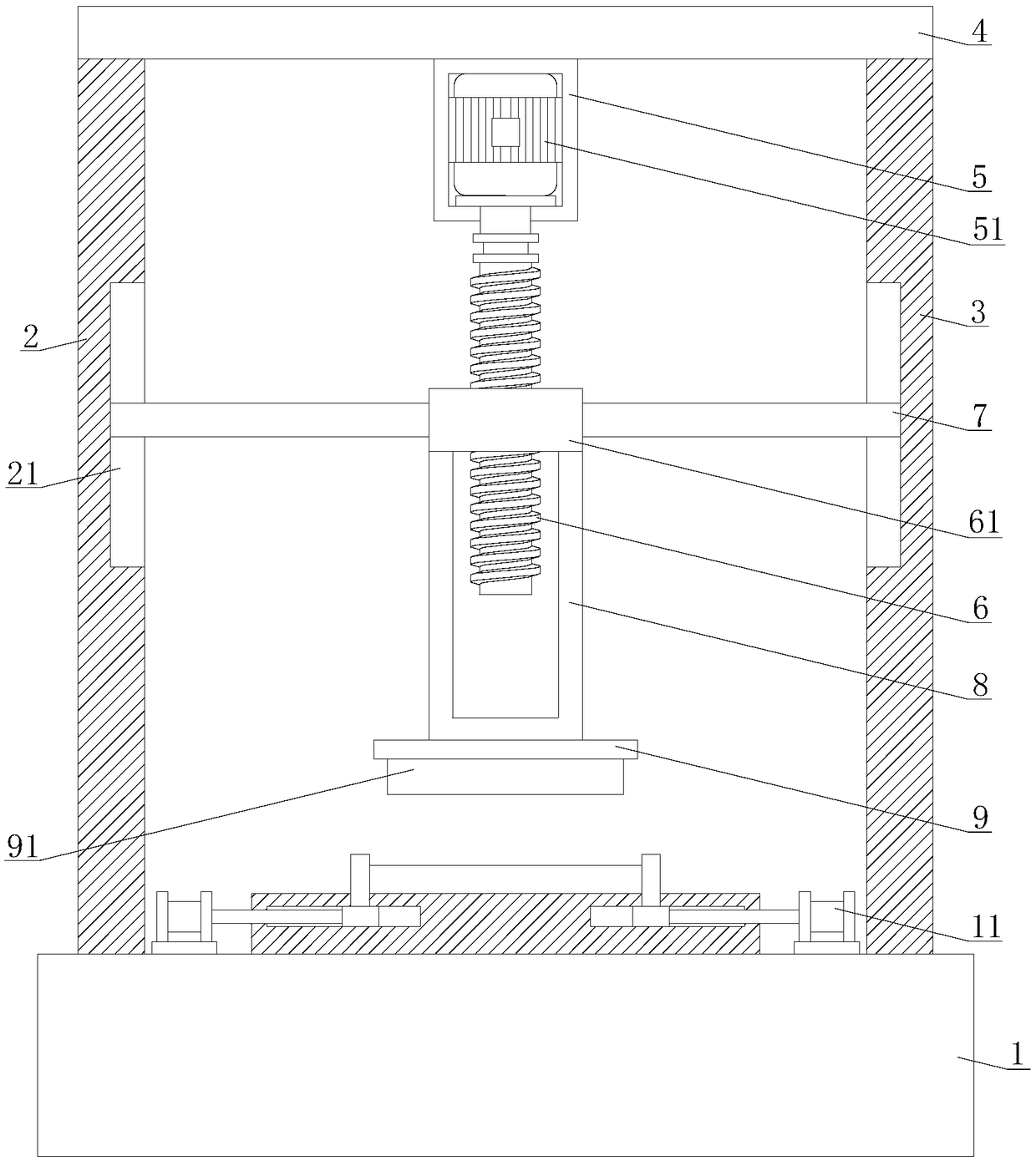

Surface cutting device for metal casting machining

ActiveCN114589529AEasy clampingEasy to cutFeeding apparatusPositioning apparatusEngineeringStructural engineering

The surface cutting device for metal casting machining comprises a machining box, a clamping mechanism is fixed to the bottom end of the interior of the machining box through supporting legs, the clamping mechanism comprises a base, moving plates are slidably connected to the two sides of the top of the base, and side plates are slidably connected to the tops of the moving plates; overturning rods are rotationally connected to the sides, close to each other, of the two side plates, overturning plates are fixed to the ends, away from the side plates, of the overturning rods, a cutting mechanism is arranged above the clamping mechanism, a recycling mechanism is fixed to the bottom end of the interior of the machining box, and cooling mechanisms are fixed to the two sides of the interior of the machining box. The problems that in an existing patent, after a metal casting is clamped, the metal casting cannot be driven to move and rotate in multiple directions, repeated dismounting and clamping are needed when different positions of the metal casting are cut, and the time cost is increased are solved; and meanwhile, when the cutting fluid is recycled, chippings in the cutting fluid cannot be separated, and environmental protection and recycling of the cutting fluid cannot be achieved.

Owner:江苏诺丰科技有限公司

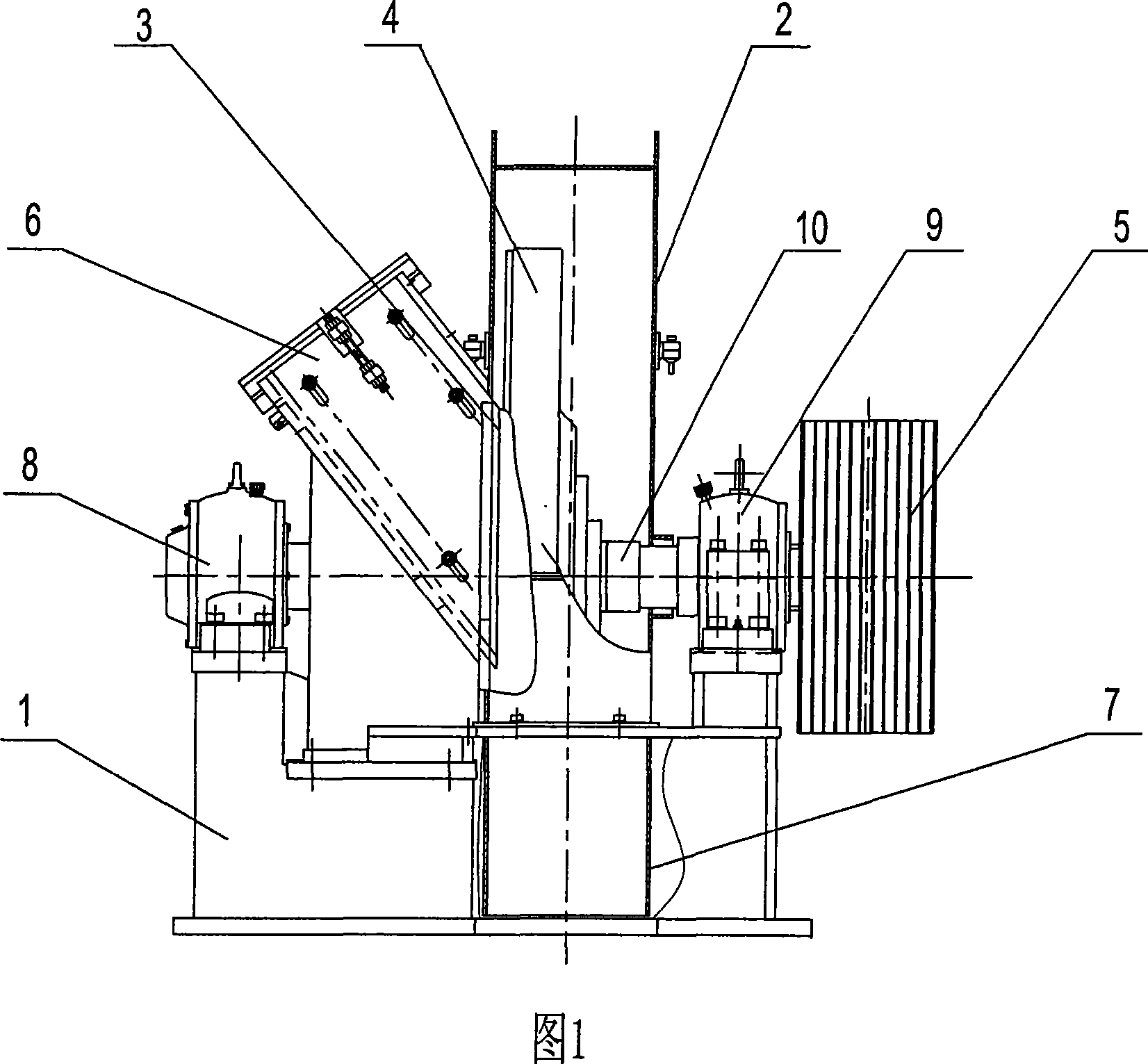

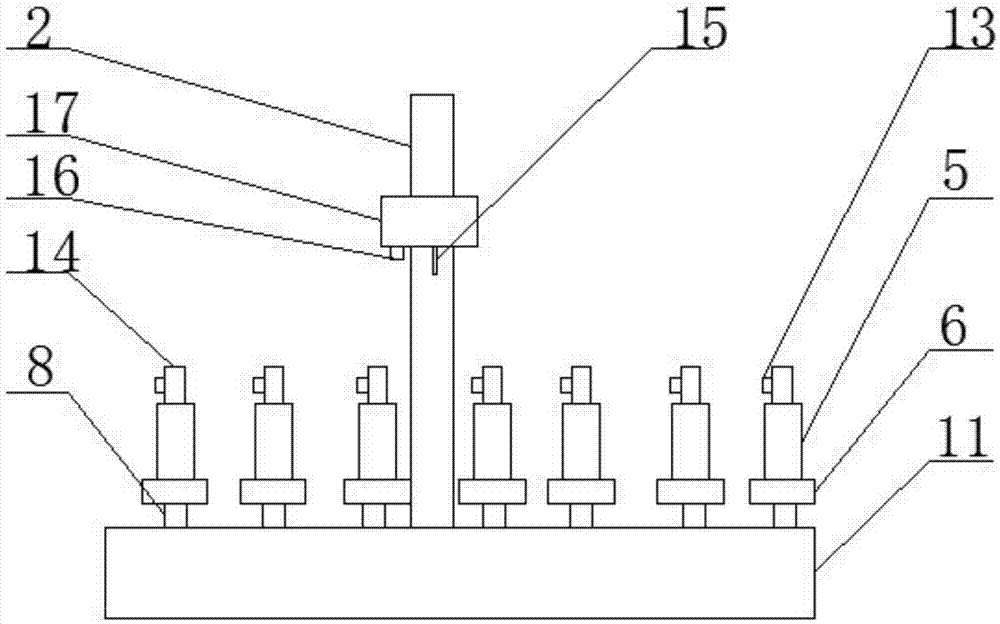

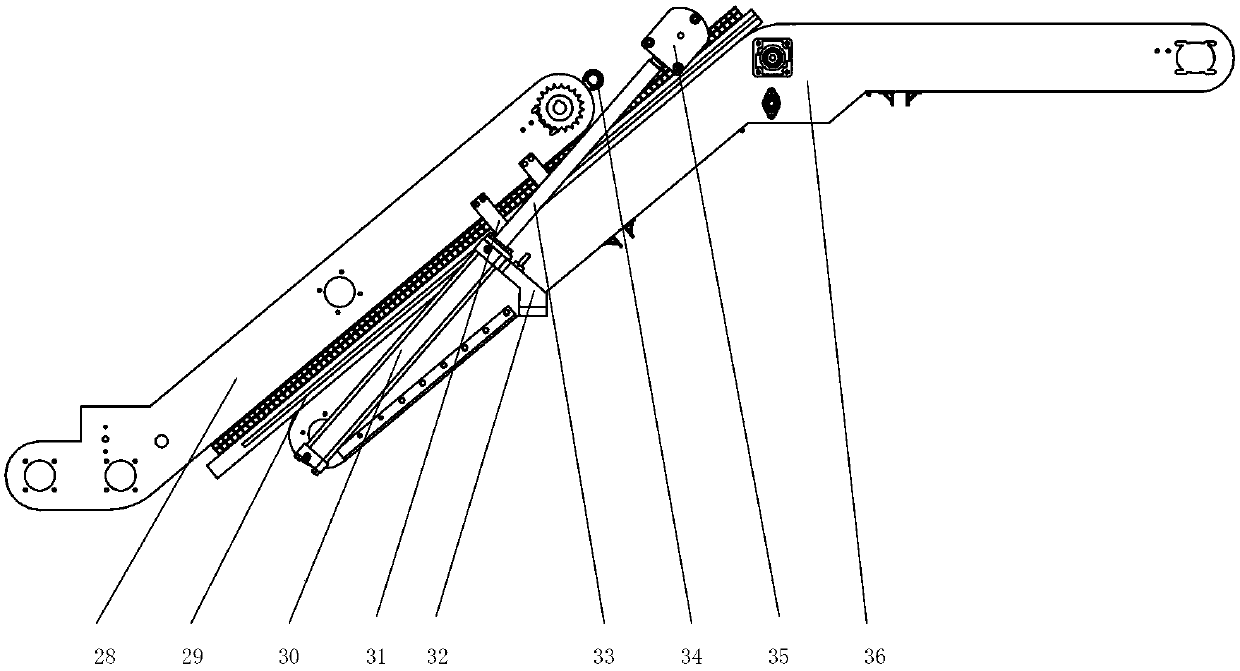

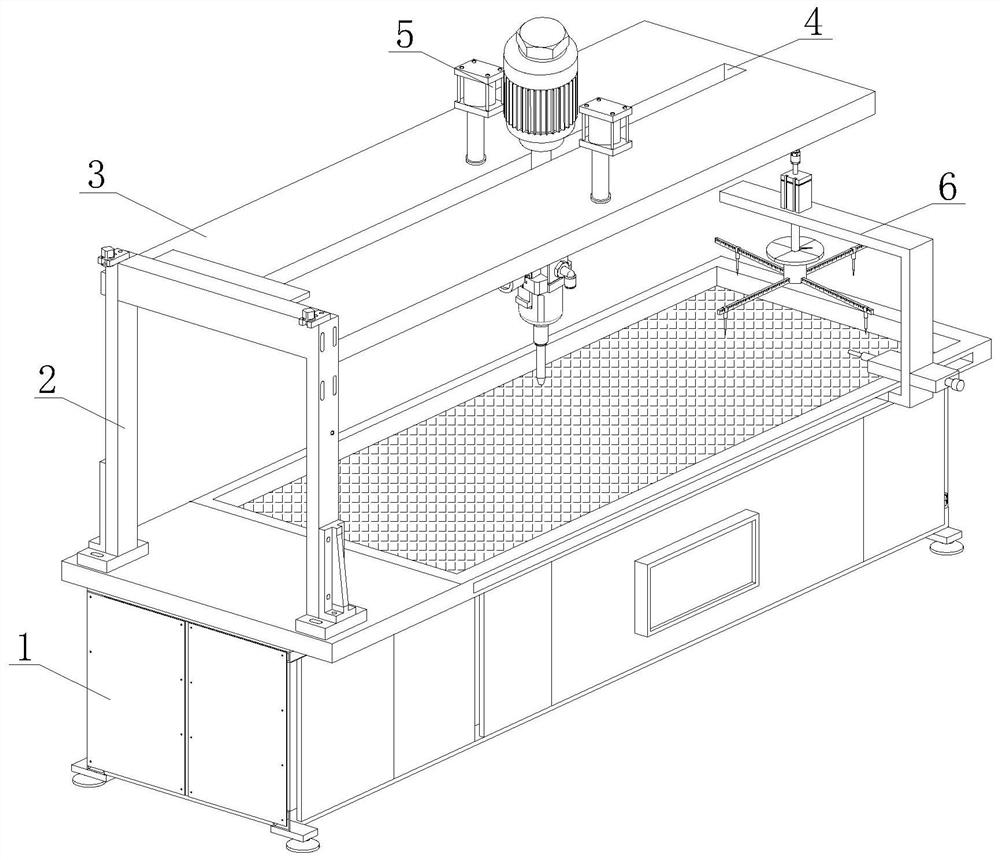

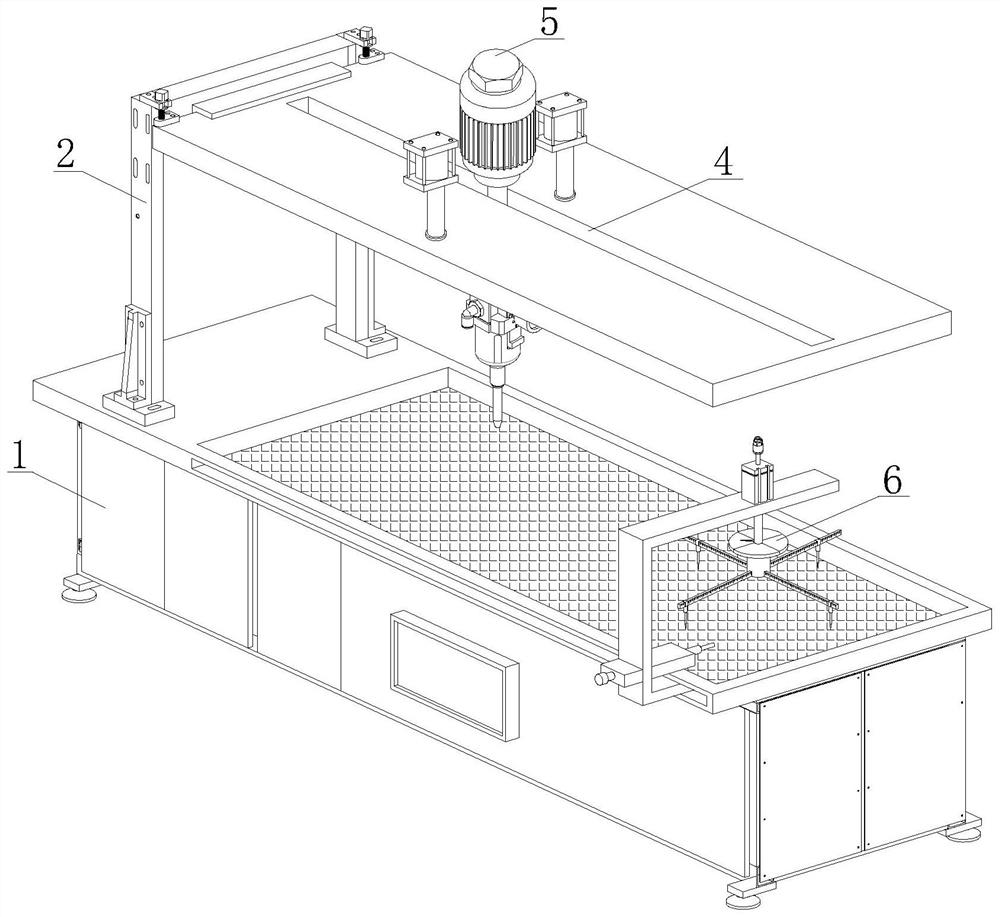

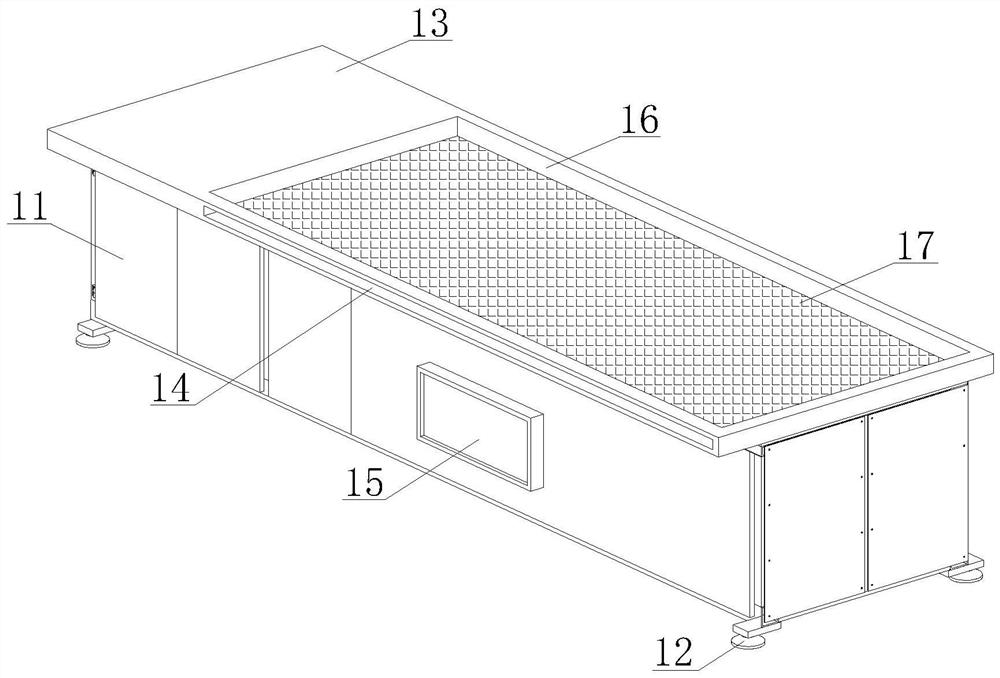

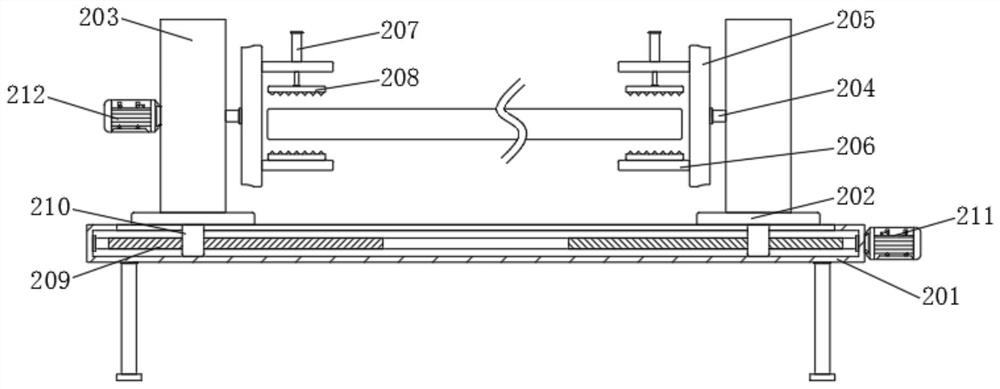

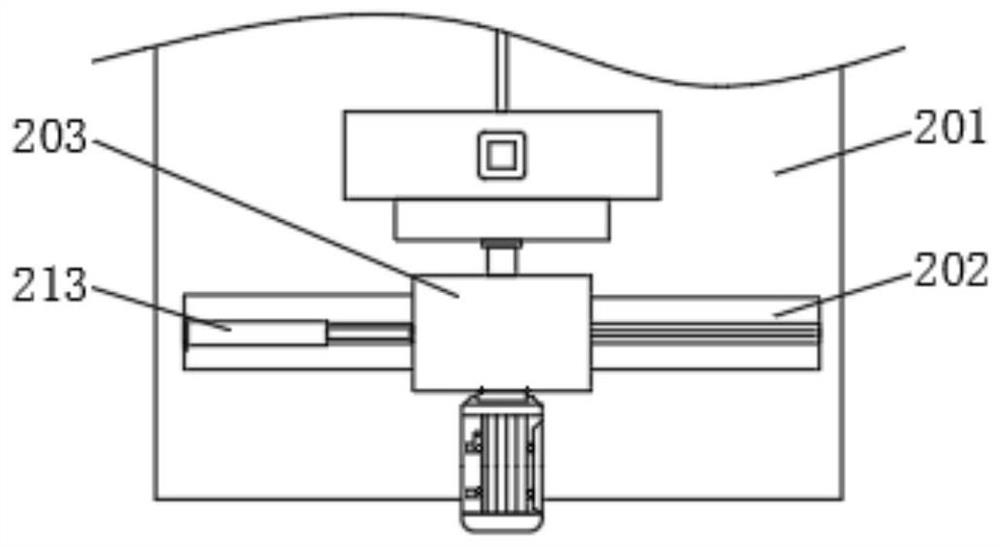

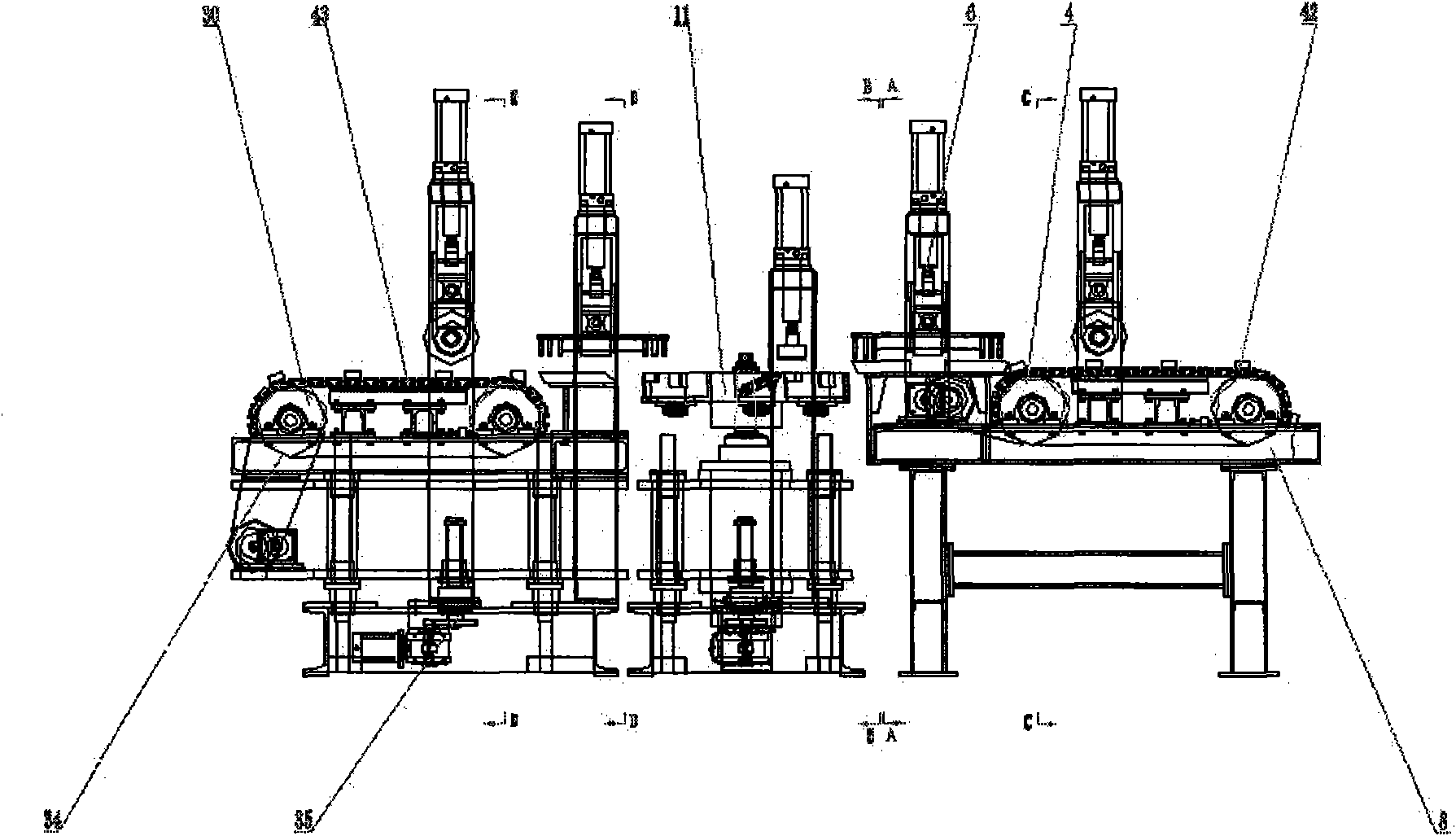

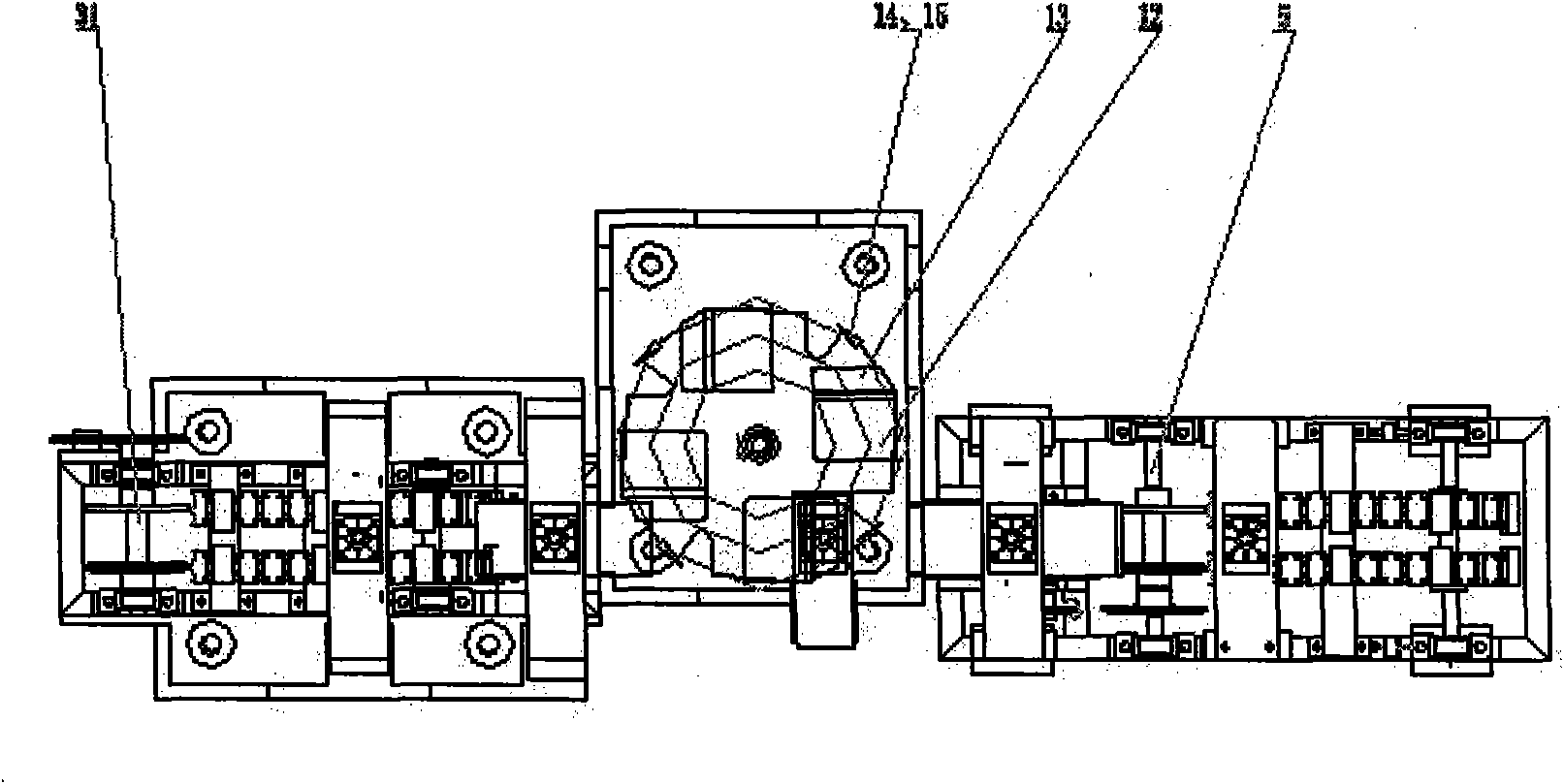

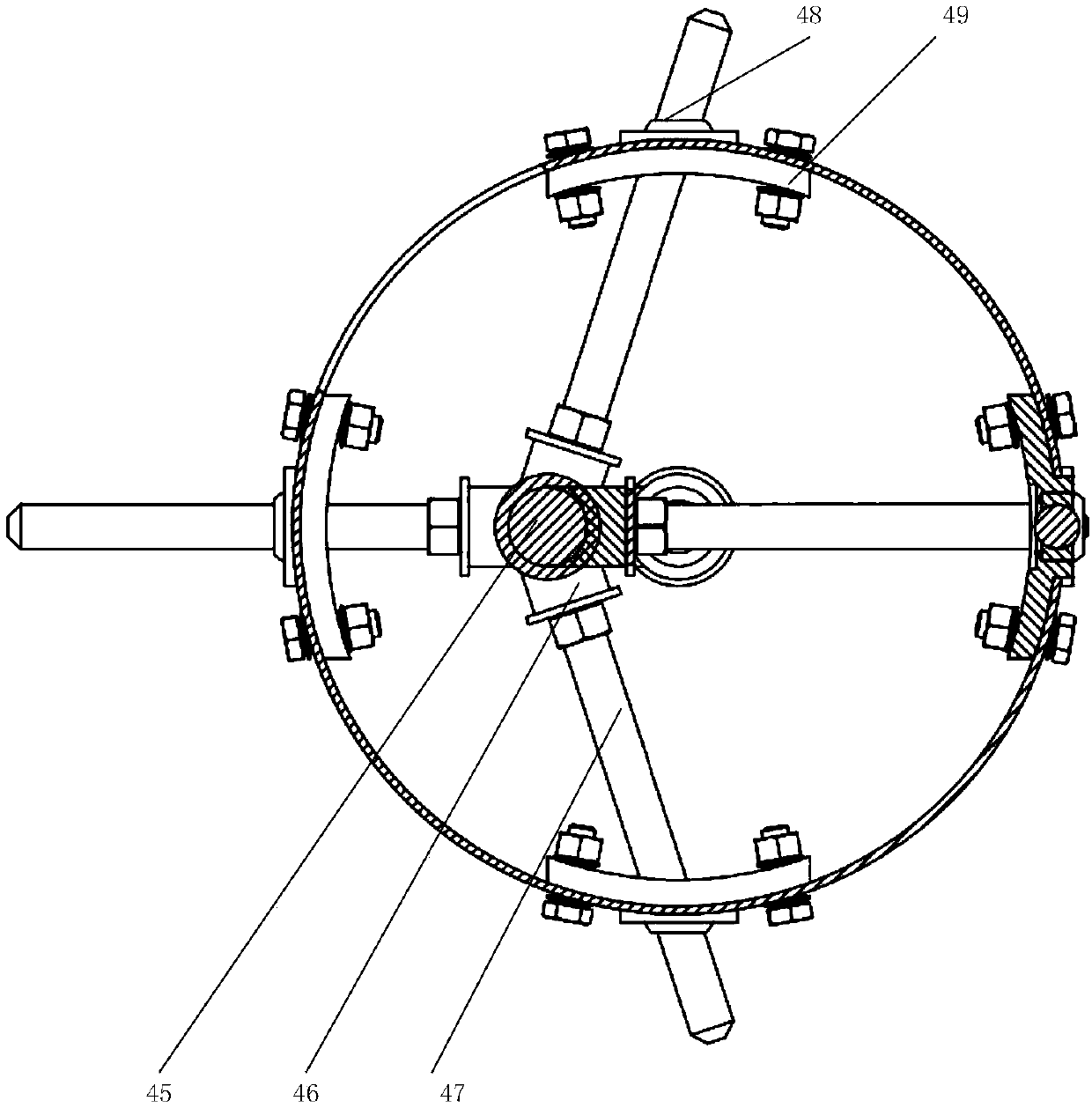

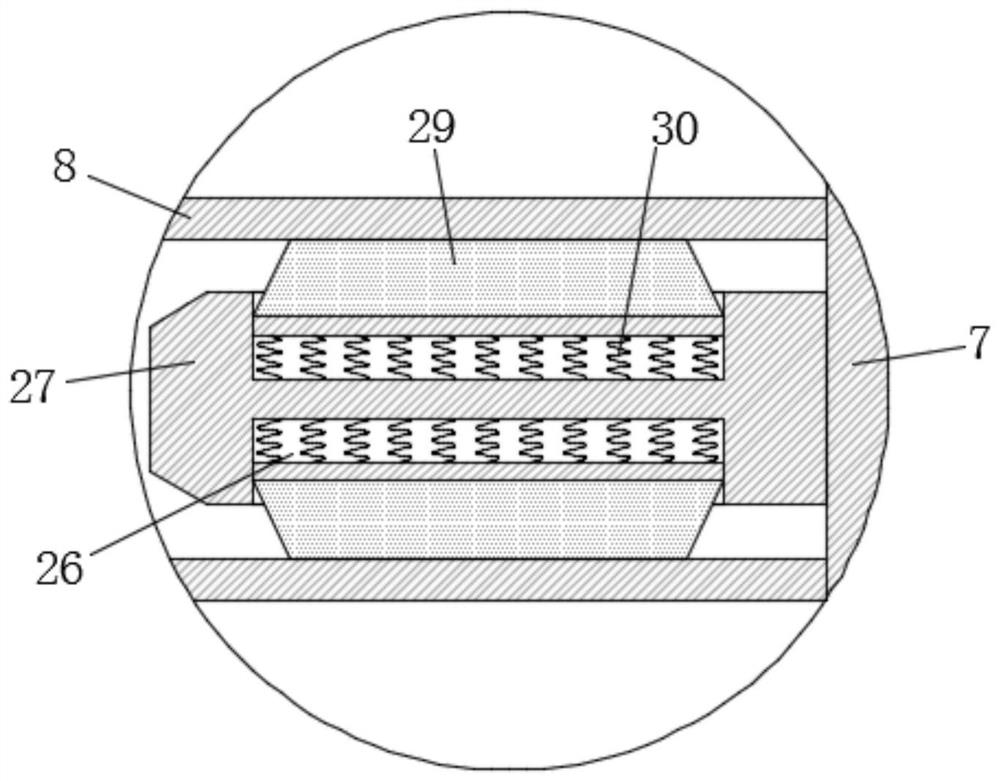

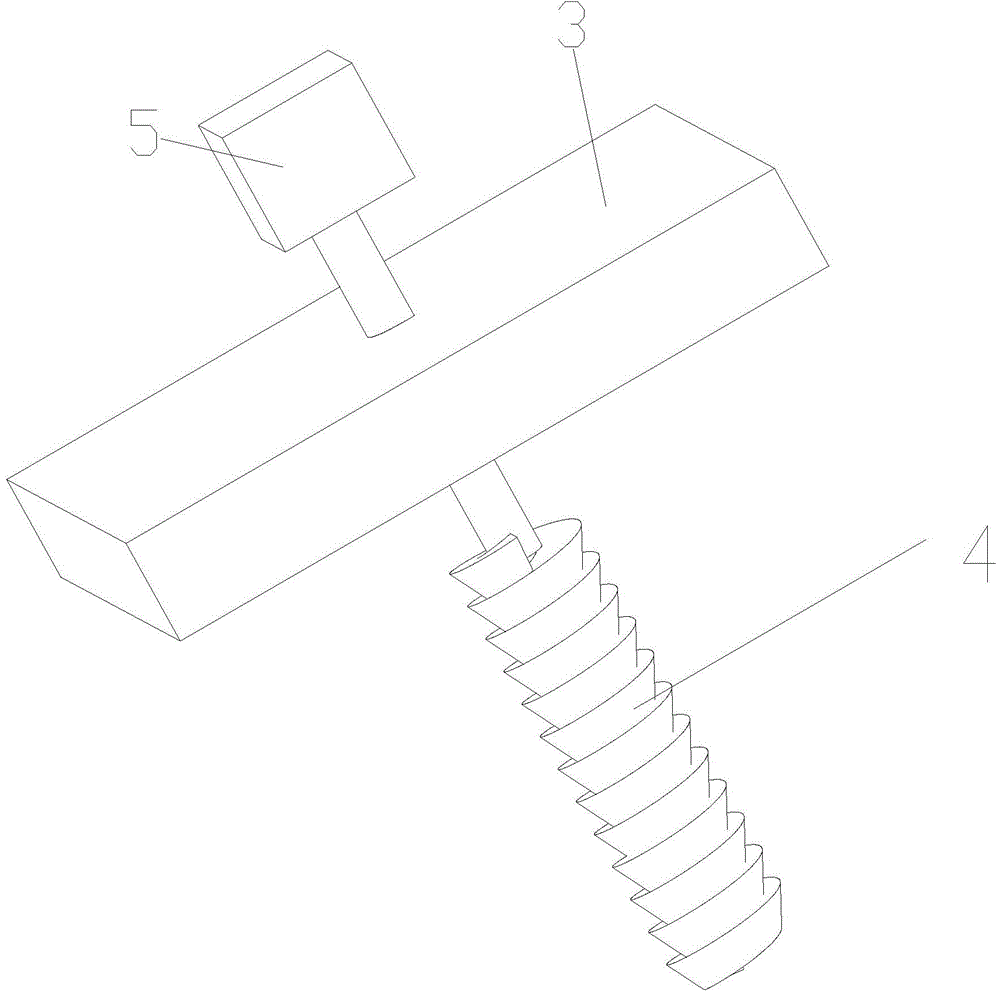

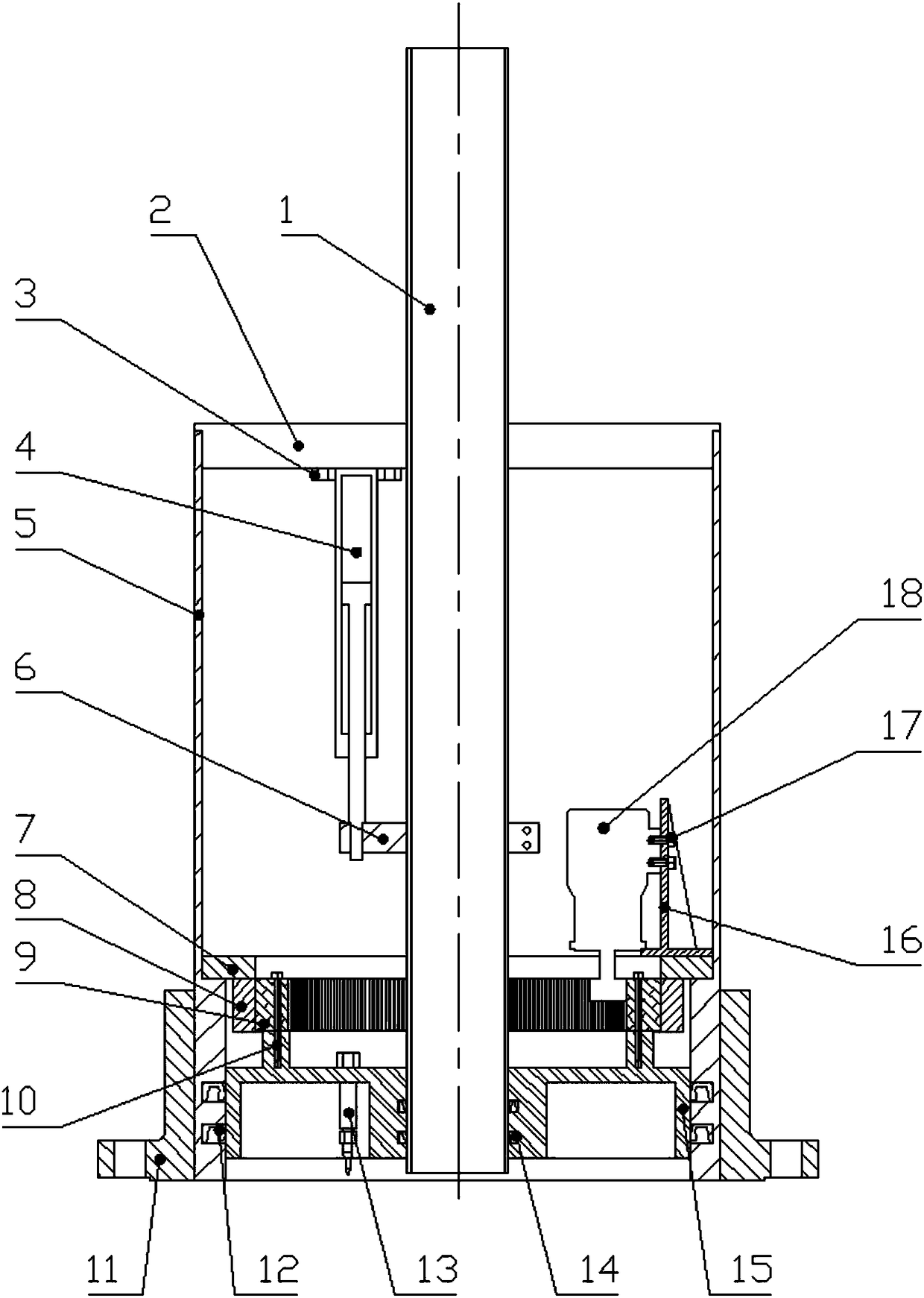

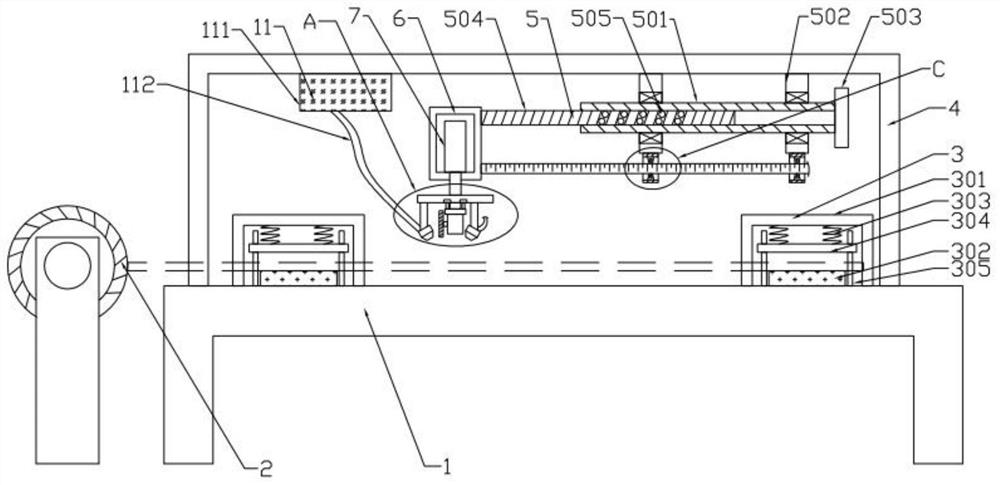

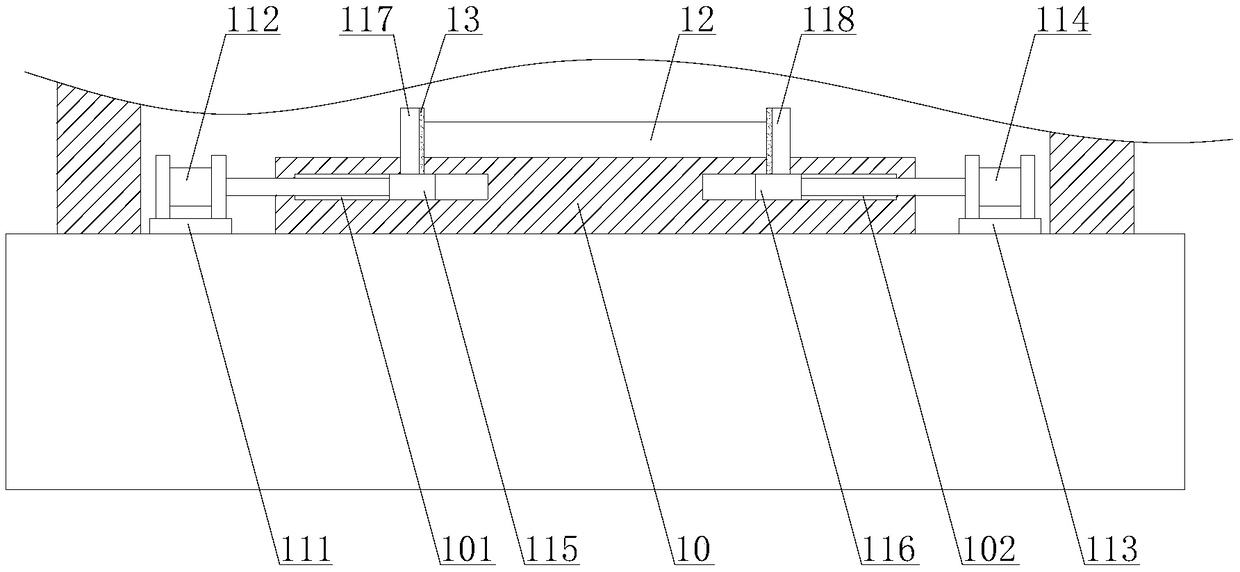

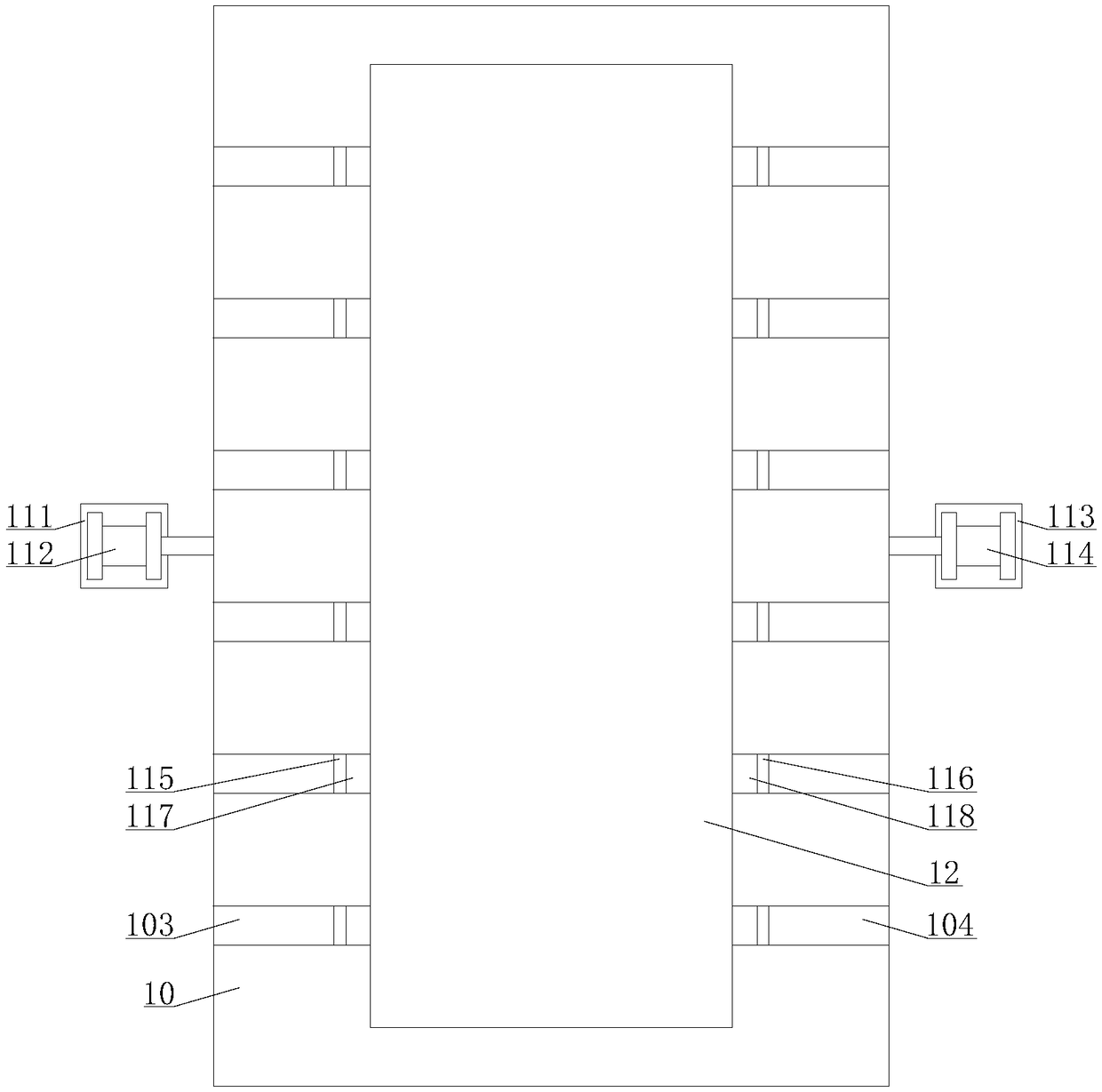

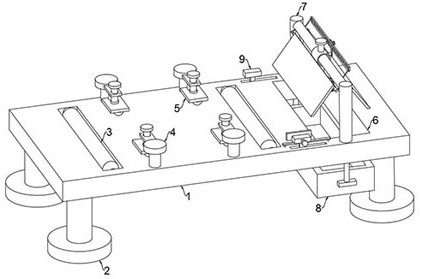

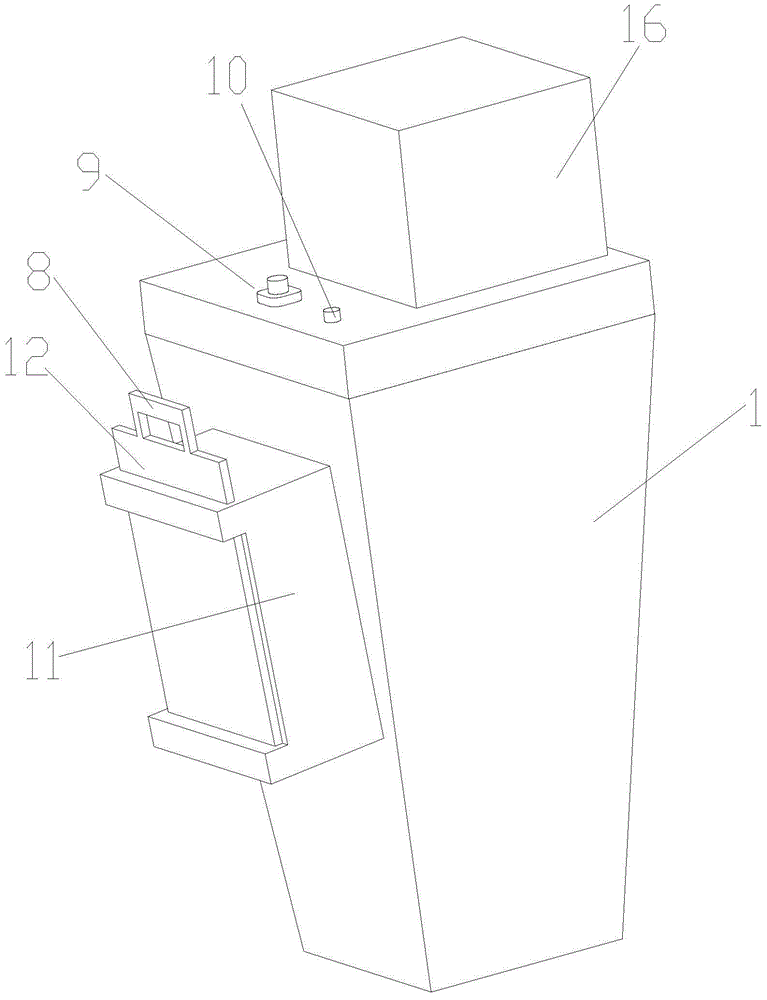

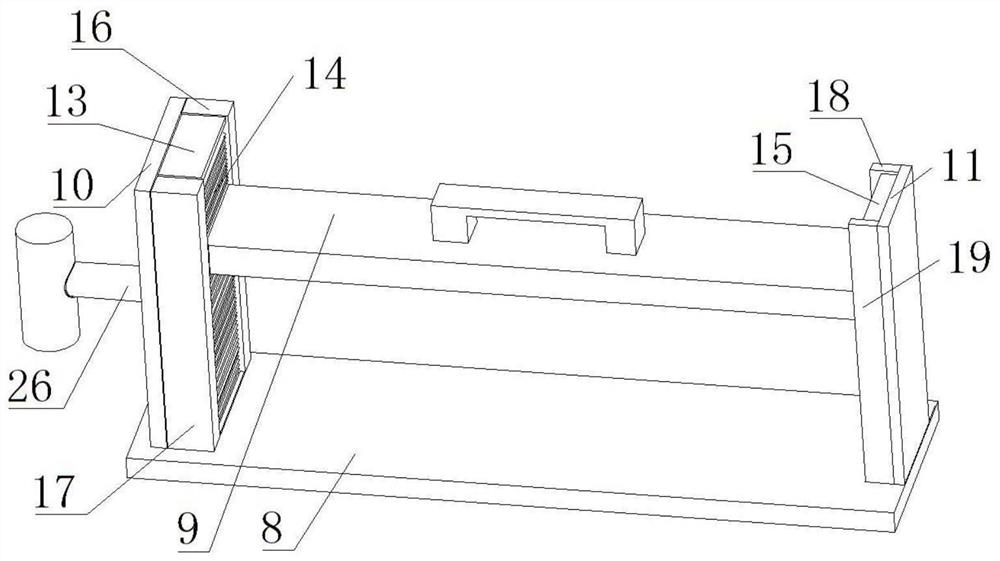

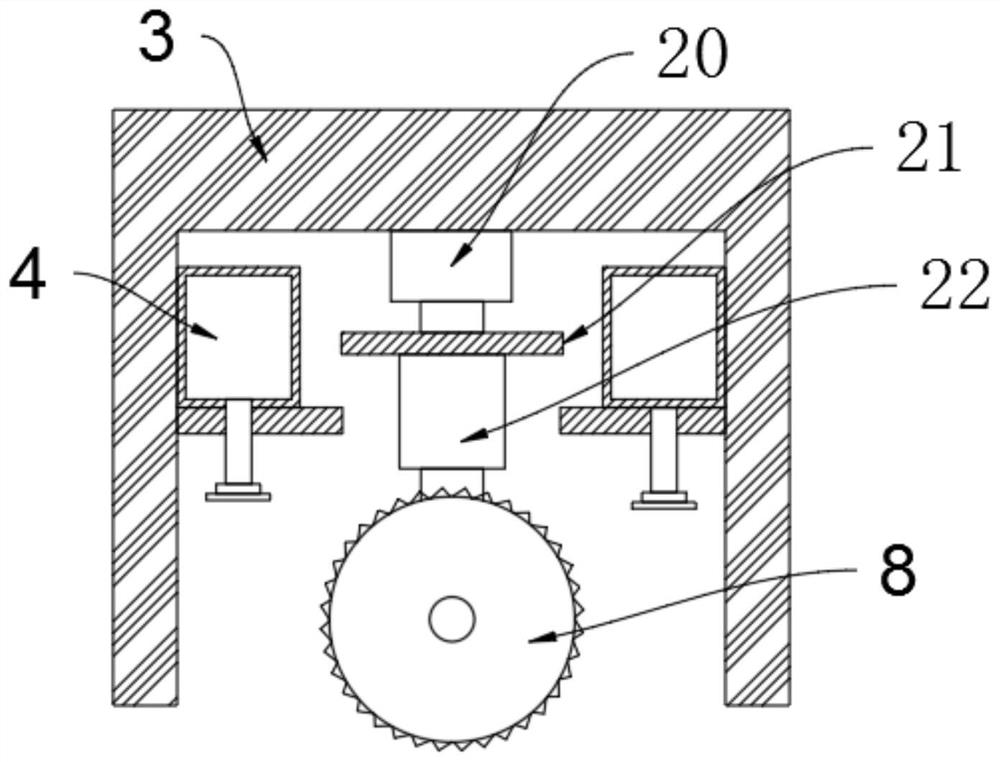

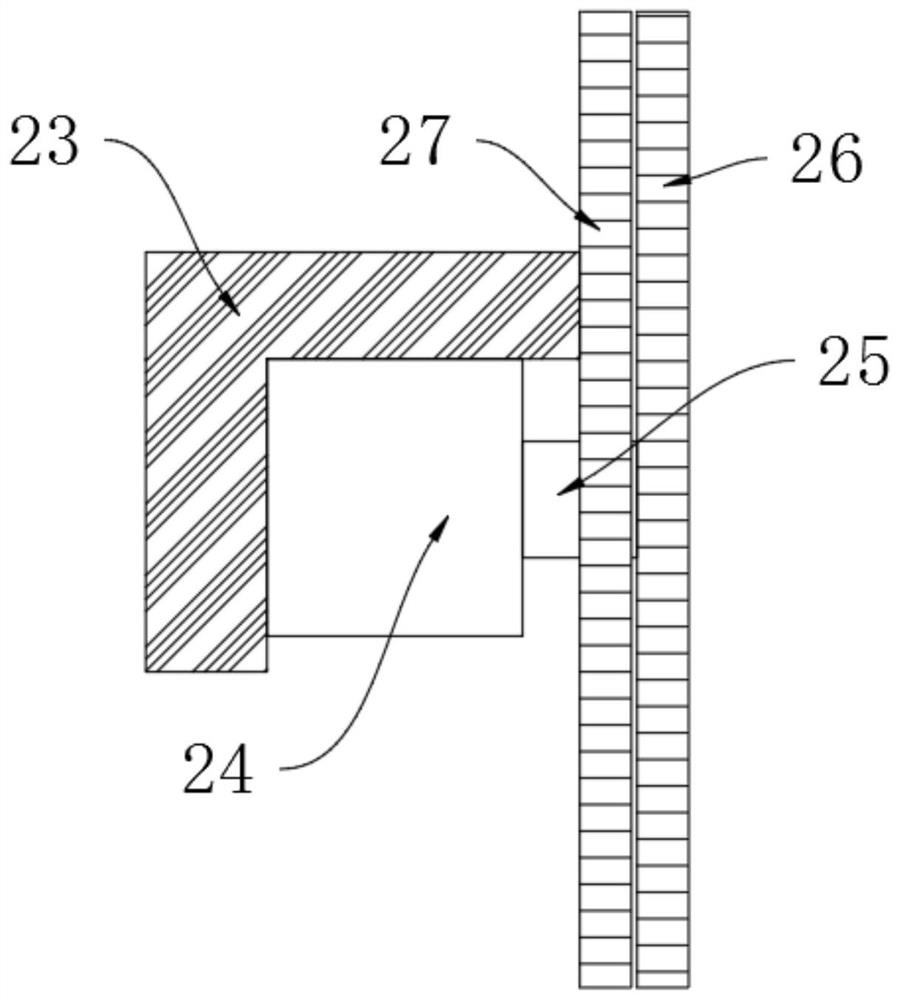

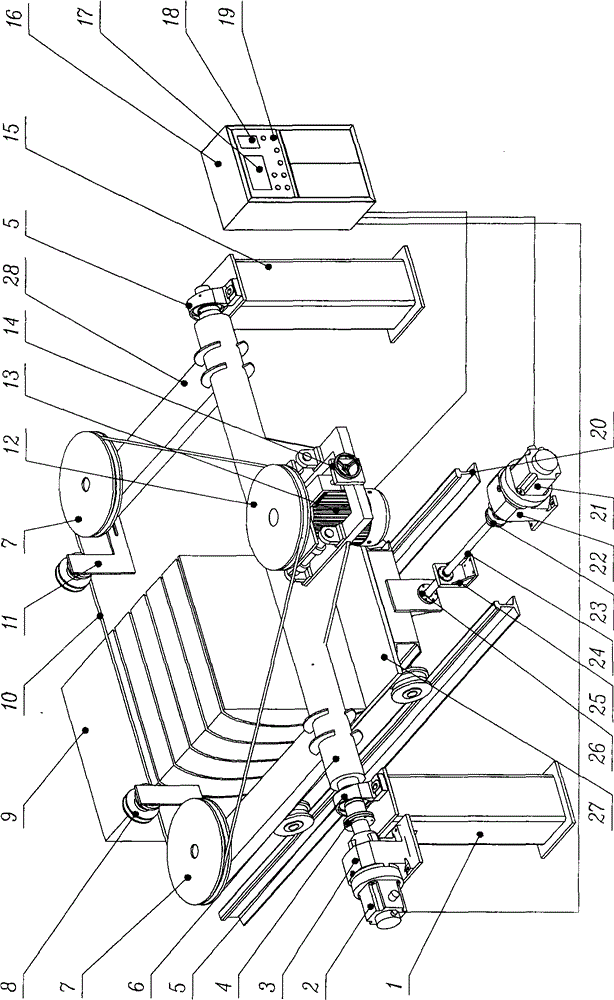

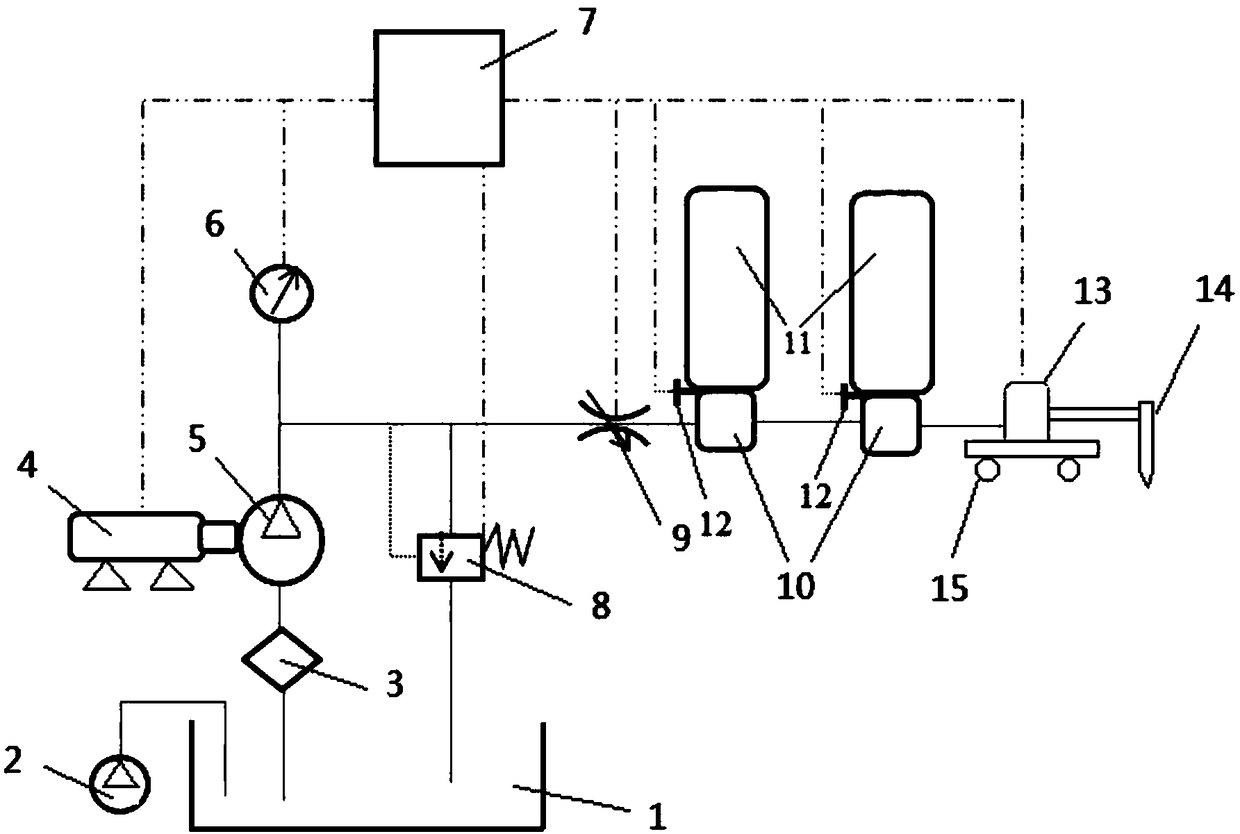

Disc chipper for micrometer long fibers

The invention relates to a disc chipper for micrometer long fibers, which mainly utilizes a blade in a disc structure for cutting, and realizes optimum cutting process by adjusting the rotating speed of a cutter head and the feeding speed of an electric spindle. The whole disc chipper comprises a feeding mechanism 1, a cutter head lifting mechanism 2, a cutter head compression mechanism 3, a cutter head assembly 4 and a discharging mechanism 5. The feeding mechanism 1 is powered by a motor 9 and feeds by means of chain transmission, the feeding amount of the feeding mechanism 1 is controlled by controlling the speed of the chain transmission, compression cylinders 10 and 11 are used for fixing materials, the cutter head lifting mechanism 2 is used for adjusting the height of the cutter head, the cutter head compression mechanism 3 with a compression cylinder is used for fixing materials on a worktable top, a stepping motor 8 is used for controlling the height of the cutter head, and cutters on the cutter assembly 4 are used for cutting. Residual materials are fixed by compression cylinders 12 and 13 on the discharging mechanism 5 powered by a motor 6. The disc chipper for the micrometer long fibers has the advantages of adjustability in cutting thickness and high operating efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY

Aquatic weed harvesting table and harvester

PendingCN109566076AEfficient HarvestingAvoid the situation of missed cutting in deep waterHeadersEngineeringAquatic weeds

The invention provides an aquatic weed harvesting table and a harvester. The aquatic weed harvesting table comprises a cutting table frame, a cutter, a first auger, a second auger, a third auger, a transmission mechanism and a reel; a rear plate of the cutting table frame is provided with a notch; the cutter is installed at the front end of the cutting table frame; the two ends of the reel are mounted on two side plates of the cutting table frame and located behind the cutter; the two ends of the first auger are mounted on the two side plates of the cutting table frame and located behind the reel; the second auger and the third auger are installed on the two sides of the notch of the cutting table frame respectively; the transmission mechanism is connected with the cutter, the reel, the first auger, the second auger and the third auger separately. The first auger and the small augers of the aquatic weed harvesting table gather aquatic weeds on the two sides of the upper portion and thelower portions to the notch behind the cutting table separately, the phenomenon of deep water miss cutting is avoided, and efficient harvesting of the aquatic weeds can be achieved.

Owner:泰州市力鼎机械设备有限公司

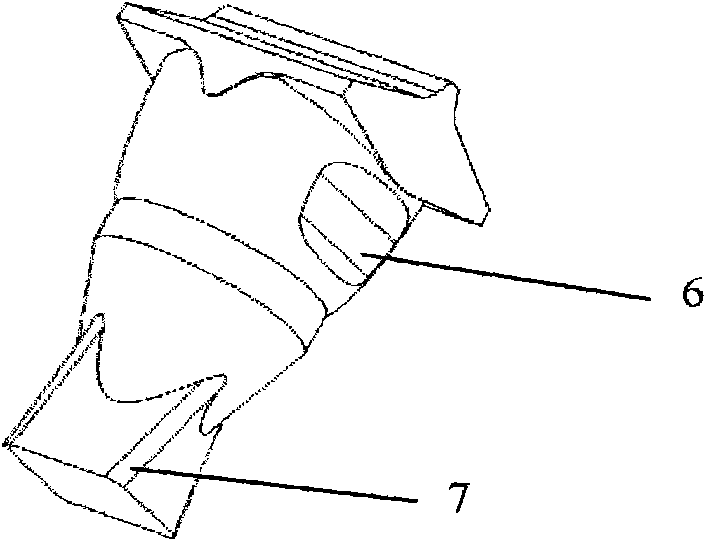

Rake tooth with sharp ridge and curved surface

ActiveCN102242547AIncrease ground pressureImprove digging abilityMechanical machines/dredgersEngineeringRidge

The invention provides a rake tooth with a sharp ridge and a curved surface, relating to a rake head accessory of a drag suction dredger, wherein the provided rake tooth can be used for improving digging depth when a rake head is used for dredging loam and clay. In a technical scheme provided by the invention, the adopted rake tooth is formed by integrally casting a tooth root and a tooth tops; aconical hole is formed on the upper end of the tooth root; one side of the upper end of the tooth root is provided with a hook-shaped body used for assembly with a rake tooth seat keyway; the rake tooth is characterized in that the cross section of the tooth top is of a triangle shape that is opened at a backside; and the tooth surfaces of two sides of the tooth top is machined into an arc shape,and the tooth surfaces of the two sides are crossed to form a tooth ridge.

Owner:SHANGHAI WATERWAY ENG DESIGN & CONSULTING

Operation tool for rail transit

InactiveCN112496435AStable clampingIncrease frictionTube shearing machinesMaintainance and safety accessoriesScrew threadRail transit

The invention discloses an operation tool for rail transit. The operation tool comprises a base and a vertical plate, the vertical plate is vertically and fixedly installed on the upper end surface ofthe base, a top plate is fixedly installed on the side wall of the vertical plate, a connecting plate is fixedly installed on the side wall of the top plate, a limiting rod is transversely fixed to the side wall of the connecting plate, the other end of the limiting rod is fixedly installed on the side wall of the vertical plate, a threaded rod is arranged below the limiting rod, a threaded blockis in threaded connection with the threaded rod, a limiting block is fixedly installed at the upper end of the threaded block, the limiting block is glidingly connected to the limiting rod, a cuttingmechanism is arranged below the threaded block, and the left end of the threaded rod penetrates through the side wall of the vertical plate and is provided with an adjusting mechanism. According to the tool, pipe bodies with different lengths can be stably clamped, the cutting range is wide, and the application range is large.

Owner:刘杰

Cup of juicer

The invention relates to a cup of a juicer. A cup body is connected with an upper cover integrally; the bottom of the upper cover is provided with a spiral cutting shaft; the spiral cutting shaft is connected with a motor located over the upper cover; an adapter plate is arranged on one side of the motor; a lifting cylinder fixedly arranged on the upper cover is arranged under the adapter plate; the motor can move in the axial direction of the upper cover through the lifting cylinder; the upper cover is provided with an opening button and a lifting button which are respectively connected with the motor and the lifting cylinder; the bottom of the cup body is provided with a cutting mechanism; a feeding rack is arranged on one side of the cup body; a feeding opening is arranged in the feeding rack; a retaining plate capable of moving up and down is arranged on the feeding opening; a juice outlet is arranged on the lower portion of one side, opposite to the feeding rack, of the cup body; a glass plug is arranged in the juice outlet. The cup of the juicer is wide in cutting range and has good practical and promotional values, and the cutting depth of the spiral cutting shaft at the upper end can be adjusted automatically as required.

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

Water-jet-based underwater tapping and pumping unit

The invention relates to a water-jet-based underwater tapping and pumping unit and relates to the field of recycling of oil spill from shipwrecks, in particular to a tapping and pumping unit for underwater residual oil chambers of shipwrecks. The water-jet-based underwater tapping and pumping unit comprises a connecting supporting mechanism, a tapping mechanism, a pumping mechanism, seals and a motor; the tapping mechanism and the pumping mechanism are mounted on the connecting supporting mechanism; the motor is mounted on the connecting supporting mechanism and is connected with the tapping mechanism so as to drive the same to rotate to carry out tapping; the tapping mechanism and the connecting supporting mechanism are sealed via the seal; the pumping mechanism and the connecting supporting mechanism are sealed via the seal; the connecting supporting mechanism is connected with a shipwreck to be pumped. The water-jet-based underwater tapping and pumping unit has the advantages of novel structure, good processing simplicity, excellent cutting quality, good applicability, wide cutting range, good cleanliness and environmental friendliness and the like; therefore, the water-jet-based underwater tapping and pumping unit is a novel water-jet-based underwater tapping and pumping unit having both good economy and practicality.

Owner:DALIAN MARITIME UNIVERSITY

Adjustable textile fabric equal-width cutting device

InactiveCN112411163AEasy to adjust the widthPrecise cuttingSevering textilesMetal working apparatusTextile technologyStructural engineering

The invention discloses an adjustable textile fabric equal-width cutting device, and belongs to the technical field of textiles. The adjustable textile fabric equal-width cutting device comprises a workbench, clamping mechanisms are correspondingly installed at the left end and the right end of the top of the workbench, a bracket is installed on the workbench, a width adjusting mechanism is installed on the bracket, the width adjusting mechanism is connected with a frame, a first hydraulic rod is installed on the frame, a telescopic rod of the first hydraulic rod is connected with a lifting plate, a cutting device is installed on the lifting plate, and a measuring device connected with the frame is installed on the width adjusting mechanism. The measuring device comprises a sleeve, limiting cams and a measuring ruler, the sleeve is connected with a bearing seat, the measuring ruler extending to the outside of the sleeve is installed in the sleeve, the multiple limiting cams are installed on the inner walls of the sleeve on the upper side and the lower side of the measuring scale, and a dust suction device extending to the lifting plate is installed on the bracket. The cutting widthis convenient to adjust, and the cutting size is accurate.

Owner:湖南亚瑞特运动用品有限公司

Cutting device for building material machining and operation method of cutting device

InactiveCN109129658AEffectively fixedImprove cutting accuracyMetal working apparatusSection planeCoupling

The invention discloses a cutting device for building material machining and an operation method of the cutting device and belongs to the technical field of building materials. The cutting device comprises a base. A first supporting vertical plate and a second supporting vertical plate are arranged on the upper surface of the base. A supporting transverse plate is installed on the top of the firstsupporting vertical plate and the top of the second supporting vertical plate. A motor seat is installed on the lower surface of the supporting transverse plate. A motor is arranged on the inner sideof the motor seat. An output shaft of the motor is connected with a screw rod through a coupler. A sliding block is installed at the middle end of the screw rod. A supporting frame is installed on the lower surface of the sliding block, a cutter rest is installed on the lower surface of the supporting frame, and a cutter is installed on the cutter rest. By means of the cutting device for buildingmaterial machining and an operation method of the cutting device, building materials are fixed through a first stop block and a second stop block, the phenomenon that the cutting sections of the building materials are not located on the same horizontal plane due to motion during cutting is prevented, the cutting precision is high, after the building materials are fixed, the motor drives the cutter to move downwards gradually to cut the building materials, safety is high, and the cutting efficiency is high.

Owner:ANHUI NVISION TECH DEV

A plate cutting device

ActiveCN111843038BLarge cutting areaImprove cutting efficiencyMetal sawing devicesHydraulic cylinderGear wheel

Owner:江西千多多家具有限公司

A high-precision furniture board fixed-length cutting device

ActiveCN113681651BShort cutting timeEasy to controlProfiling/shaping machinesBark-zones/chip/dust/waste removalOblique cuttingElectrical and Electronics engineering

The invention discloses a high-precision fixed-length cutting device for furniture boards, which includes a platform, on which an auxiliary mechanism and a storage mechanism are installed, on which two upright poles are fixedly installed, and between the two upright poles The lifting rod is installed through the sliding mechanism, the sliding sleeve on the lifting rod is provided with a sleeve, and a scale cross bar is installed between the sleeve and the lifting rod through a positioning mechanism, and a telescopic rod is fixedly installed on the sleeve through a fixed plate A cutting disk is installed on the telescopic rod through the cooperation of the magnetic disk and the servo motor, and a magnetic ring matching the magnetic disk is fixedly installed on the fixed disk. The advantages are: the furniture board can be precisely cut vertically and horizontally without moving or flipping it over, and it can also be cut at multi-angle obliquely. The overall cutting efficiency is high and the cutting range is wide.

Owner:南通弈驰新型建材科技有限公司

Pipe beveling machine

InactiveCN102962521BReduce labor intensityIncrease motivationFeeding apparatusPositioning apparatusEngineeringPower output

The invention relates to a pipeline facing machine, which comprises a main supporting shaft and an enclosure, wherein the main supporting shaft is provided with a main shaft sleeve; the main shaft sleeve is movably connected with the main supporting shaft via a bearing; the main shaft sleeve is provided with a transmission gear and a cutterhead; a hydraulic cutting and feeding device and a hydraulic expansion device are respectively arranged on two ends of the main supporting shaft; a driving device is meshed with the transmission gear via a power output gear; the driving device is fixedly arranged on the enclosure; and the enclosure is movably connected with the main shaft sleeve via a main enclosure supporting bearing. According to the pipeline facing machine disclosed by the invention, the facing machine and the a pipeline can be fixed and the cutterhead can be fed and retracted by the hydraulic expansion device and the hydraulic cutting and feeding device, the automatic degree and the manpower labor intensity are improved, and the pipeline facing machine has the advantages of high expansion speed, big expansion force, stability in feeding, compact equipment structure, small volumesize, wide pipeline applicable range and convenience in carrying. According to a proper device, one person can easily finish installing and disassembling the machine on the pipeline.

Owner:上海油威液压成套设备有限公司

A cup body for a fruit juice machine

Owner:广州玖荣包装制品有限公司

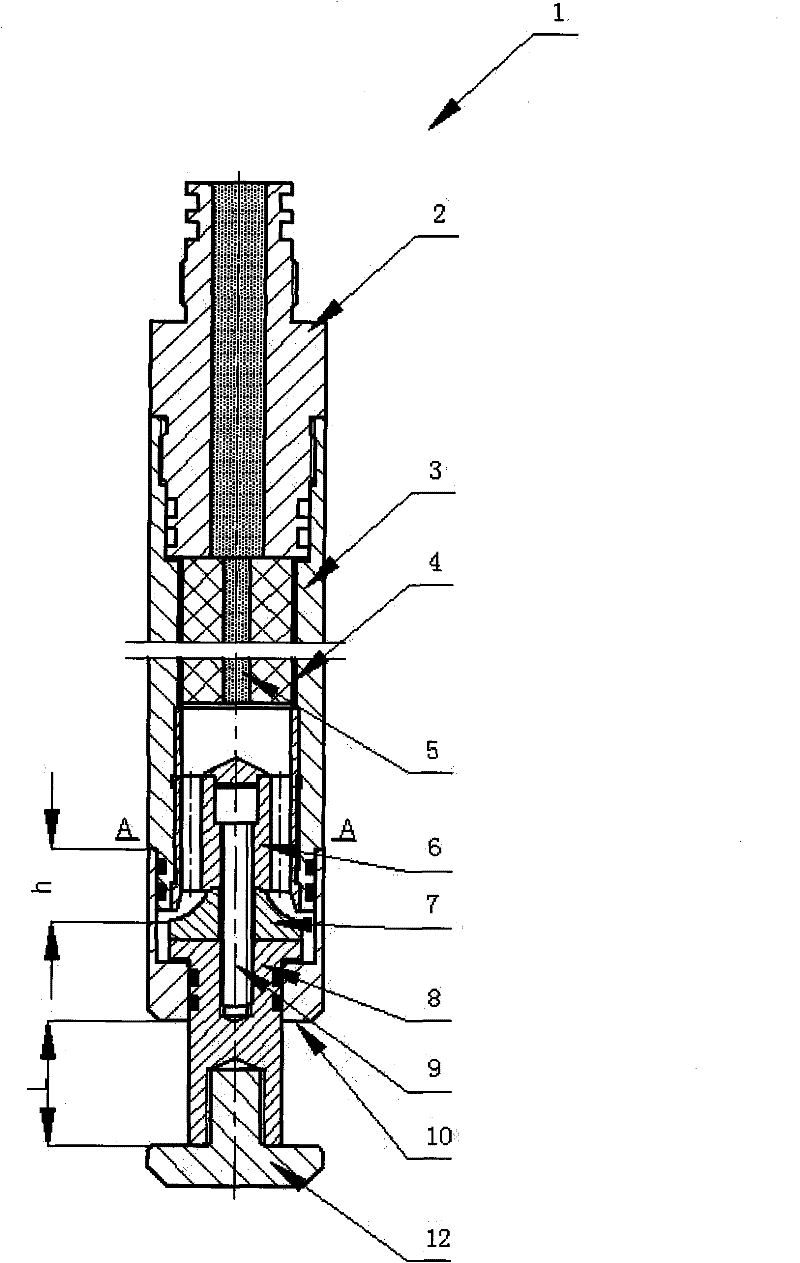

Disposable guide type anorectal hemorrhoid anastomat

ActiveCN103462667BWide range of cuttingHigh strengthSurgical staplesArchitectural engineeringTorsion spring

The invention relates to a disposable guiding type anorectal hemorrhoid stapler, which is suitable for anorectal hemorrhoid excision and suturing surgical instruments. Including nail anvil, spacer ring, nail anvil, nail magazine, ring knife, needle push piece, needle magazine sleeve, positioning shaft, connecting tube, aluminum tube, locking ring, return spring, push tube, screw, indicator cover , indicating block, indicating pull piece, spring 1, screw, adjusting tube, fixed handle, adjusting knob, insurance card, spring 2, top column, moving block, safety block, positioning pin 1, support rod, sounding block, positioning pin 3 , Movable handle, positioning pin 2, torsion spring, suture nail and movable handle cover; the left end of the movable handle is movably connected with the right end of the support rod, the left end of the support rod is movably connected with the fixed handle, the moving block is fixed on the screw rod, and the adjustment tube passes through the top column and the The threaded section at the left end of the screw rod is matched and connected, the adjustment knob is fixed at the left end of the adjustment tube, the sounding block is fixed in the mounting groove of the sounding block of the fixed handle, and the safety block is movably connected with the fixed handle.

Owner:WUXI SHENKANG MEDICAL INSTR EQUIP

Numerical control corner cutting machine

InactiveCN111660192AGood for corner cuttingWide range of cuttingGrinding carriagesGrinding drivesNumerical controlStructural engineering

The invention provides a numerical control corner cutting machine, and belongs to the technical field of machinery. The numerical control corner cutting machine solves the problem that an existing corner cutting machine cannot completely cut off corners of a workpiece at a time. The numerical control corner cutting machine comprises a bottom plate, a supporting block arranged on the bottom plate and a top plate arranged on the supporting block; a clamping mechanism is arranged on the supporting block, a lifting mechanism is further arranged on the supporting block, a first rotary disc is arranged at the bottom of the top plate, a first driving assembly is connected between the top plate and the first rotary disc, and a first grinding wheel is arranged below the first rotary disc; and a second rotary disc coaxial with the first rotary disc is arranged on the bottom plate, a second driving assembly is connected between the bottom plate and the second rotary disc, and a second grinding wheel is arranged on the second rotary disc. The numerical control corner cutting machine can completely cut out corners with specified angles, and has the advantages of being wide in cutting range, good in cutting effect and the like.

Owner:重庆小马智诚科技有限责任公司

Plate cutting device

ActiveCN111843038ALarge cutting areaImprove cutting efficiencyMetal sawing devicesHydraulic cylinderElectric machine

The invention discloses a plate cutting device. The plate cutting device comprises a box body, a conveying structure and a cutting structure, wherein the cutting structure comprises a transverse moving mechanism, an internal control structure, a splash-proof shell, a dust collection structure, a side water pipe, a spray head and a cutting roller; the cutting roller comprises a cutting gear and a fixed gear; the conveying structure comprises hydraulic cylinders, rollers, rotary shafts, a guide plate, a conveying belt and a fixing column; two groups of gears are adopted, namely one group of fixed gear and one group of rotating gear, so that the cutting area between the adjacent gears and a plate is enlarged, the cutting efficiency is higher, a cutting support frame is arranged on the device,the transverse moving mechanism can be used for driving the plate to be transversely cut, a rotating motor can be used for enabling the plate to be longitudinally cut, and the cutting range is wider.

Owner:江西千多多家具有限公司

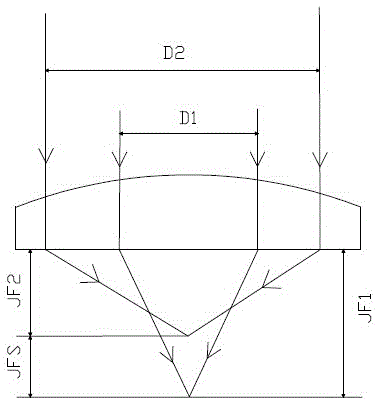

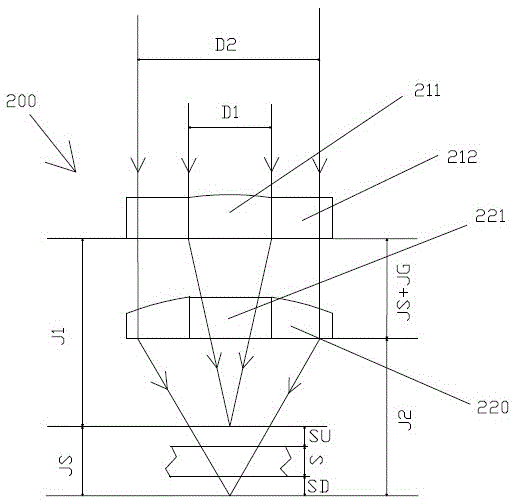

Focusing device and laser cutting device with the same

ActiveCN103722290BSimple manufacturing processAdjustable distanceLaser beam welding apparatusManufacturing technologyOptical axis

A focusing device used in a laser cutting device is provided with a lens and an adjusting mechanism which adjusts the position of the lens. The lens comprises a center focusing piece and an annular focusing lens. The center focusing piece is provided with a center focusing lens and an annular plane mirror which surrounds the center focusing lens and is used for fixing the center focusing lens. The outer diameter and the ring width of the annular focusing lens are the same as those of the annular plane mirror. The adjusting mechanism comprises a centering device and a distance adjusting device. The centering device is used for adjusting the focuses of the center focusing lens and the annular focusing lens, so that the focuses are placed on the same optical axis. The distance adjusting device adjusts the distance between the focuses of the center focusing lens and the annular focusing lens. According to the focusing device, the manufacturing technology of focusing lens with different curvature radiuses is simplified, adjusting of the distance between the two focuses is convenient, the cutting range is wide, and cost is low.

Owner:江苏亚威创科源激光装备有限公司

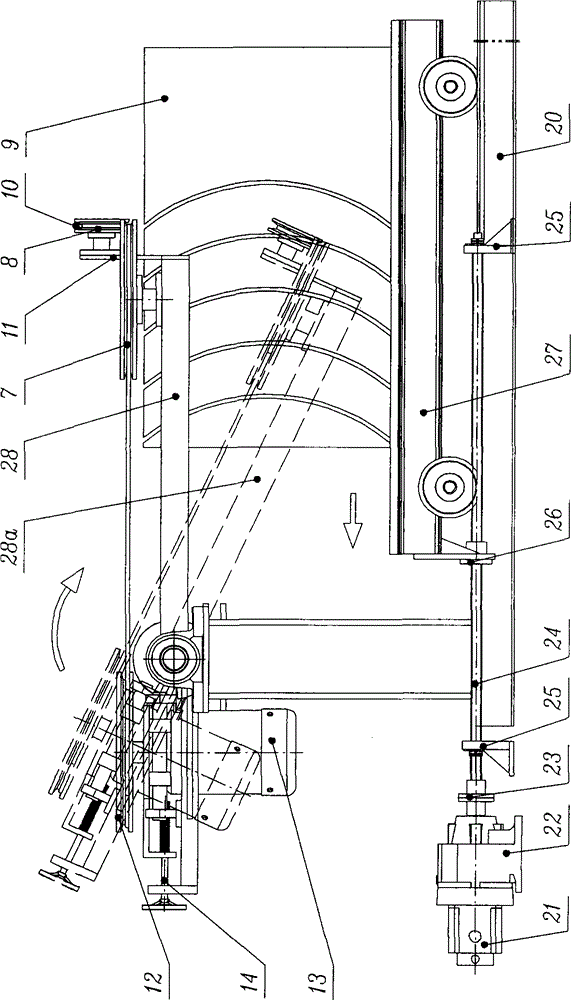

Multifunctional computer rope saw

InactiveCN102626948BReduce processing costsIncrease profitWorking accessoriesStone-like material working toolsFailure rateLow noise

The invention discloses a multifunctional computer rope saw. The multifunctional computer wire saw comprises a cutting mechanism, a rotation feed mechanism, a skip car feed mechanism and a control system, wherein one end of a rotation shaft in the rotation feed mechanism is connected with a first drive device; one side of the rotation shaft is fixedly connected with one end of a pair of rotation arms, while the other side is fixedly connected with a tensioning mechanism mounting seat; a pair of driven wheels in the cutting mechanism are rotatably arranged at the other end of the pair of rotation arms; during working hours, a cutting rope does horizontal cutting motions, and meanwhile, the cutting rope does rotation feed motions by taking the rotation shaft as a rotation center and the length of the rotation arms as a radius; and a difference supplement operation is formed by the rotation feed motions with horizontal transverse feed motions of the skip car so as achieve shape cutting motions. The multifunctional computer rope saw has the advantages of simple and unique structure, low equipment manufacturing cost, simple and reliable mounting, low noise and low power consumption during cutting, low stone processing cost, low failure rate and high working efficiency and can be used for cutting out all graphs expressed by first-order equations and quadratic equations.

Owner:LAIZHOU HONGTAI STONE MACHINERY

Road cutting machine for road construction

ActiveCN108894090BEnsure safety and efficiencyAvoid offset misalignmentRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a road surface cutting machine for road construction. The cutting machine comprises a guiding plate, connecting holes are formed in the two ends in the guiding plate, and a fixing bolts is slidably connected to the surfaces on the inner sides of the connecting holes; a locating head is arranged on the lower surface of the fixing bolt, a compressing nut is in threaded connection to the upper end of the outer surface of the fixing bolt, and a connecting groove is formed in the surface of the front end of the guiding plate; a locating block is arranged on the bottom surface in the connecting groove, a connecting plate is slidably connected to the outer surface of the locating block through a locating groove, the outer surface of the connecting plate is slidably connected to the surface on the inner side of the connecting groove, and the surfaces on the two sides of the connecting plate are fixedly installed on the surface on the inner side of the connecting groovethrough connecting screws. According to the road surface cutting machine for road construction, the guiding plate structure with a guiding groove is combined with the guiding block to make contact with a rack, therefore the convenience and stability of the using are greatly improved, and the safe and efficient maintenance of highways are ensured.

Owner:广东恒大路桥建设有限公司

A split type abrasive water jet cutting equipment

ActiveCN105751079BWide range of cuttingImprove efficiencyAbrasive feedersElectric machineControl system

The invention relates to a split type grinding material water-jet cutting apparatus, comprising a power system, a water supply system, a sand supply system, an action system and a control system, wherein the power system comprises a motor, a plunger pump and a pressure regulating valve; the water supply system comprises a water tank, a water suction pump and a filter; the sand supply system comprise a material storage tank, a mixing bin and a grinding control valve, the material storage tank is connected with the mixing bin by the grinding control valve, and the mixing bin is disposed under the material storage tank and is connected with the pressure regulating valve and the action system by a high pressure rubber hose; and the action system comprises a waterproof stepping motor, a cutting nozzle and a cutting track, and the waterproof stepping motor is arranged above the cutting track and drives the cutting nozzle to work along the track. The split type grinding material water-jet cutting apparatus has the beneficial effects of wide cutting range and high efficiency, can be assembled in a split combined manner, can work under water and on the ground, and can play a role of fast emergency.

Owner:CHINA OCEAN ENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com