Water-jet-based underwater tapping and pumping unit

A water jet and oil pumping technology, applied in the field of oil spill recovery from sunken ships, can solve the problems of inconvenient monitoring and control, low safety, complex transmission mechanism, etc., and achieve the effects of significant economic benefits, strong adaptability and clean operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

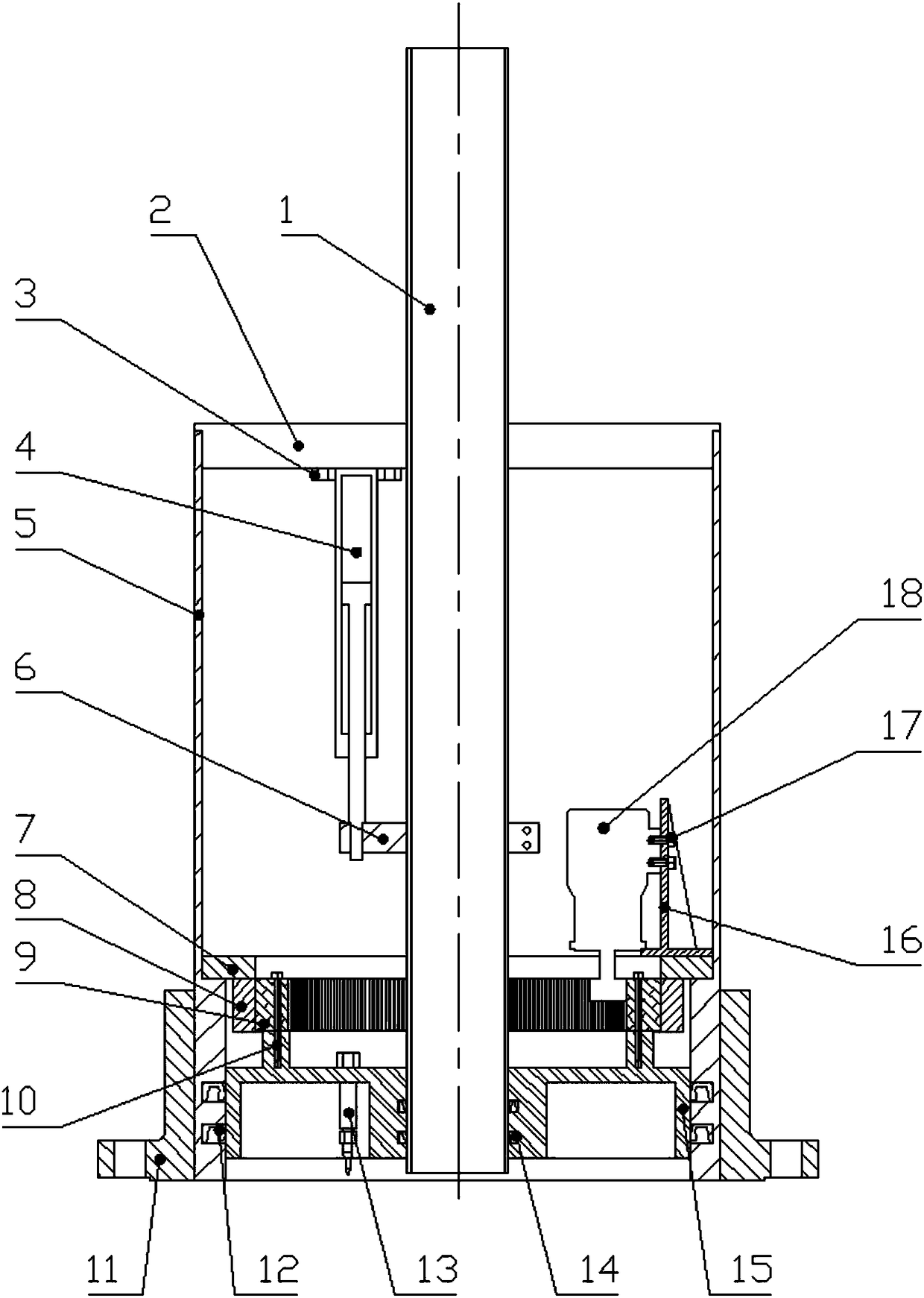

[0034] The specific embodiment of the present invention is shown in the accompanying drawings, the underwater perforated oil pumping device includes: an oil pumping pipe 1, an outer cylinder end cover 2, a hydraulic cylinder end face fixing flange 3, a hydraulic cylinder 4, an outer cylinder 5, an oil suction pipe locking Block 6, slewing support fixing flange 7, inner gear slewing bearing outer ring 8, inner gear slewing bearing inner ring 9, connecting screw 10, flange 11, oil seal 12, water jet nozzle and holder 13, lip The sealing ring 14, the rotating block 15, the motor fixing seat 16, the fixing screw 17, and the motor 18 are characterized in that: the flange 11 connects the whole device with the ship wall to be drilled. After the meshing of the inner ring 9 of the turntable bearing is decelerated, the rotating block 15 is driven to rotate, and the water jet nozzle and the holder 13 fixed on the rotating plate also complete the rotating opening movement. After the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com