FRP tank perforating device

A tank and cup-shaped technology, which is applied in the field of FRP tank opening devices, can solve the problems of low processing quality, low positioning accuracy, labor-intensive and other problems, and achieve high-quality opening, high positioning accuracy, and labor intensity reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

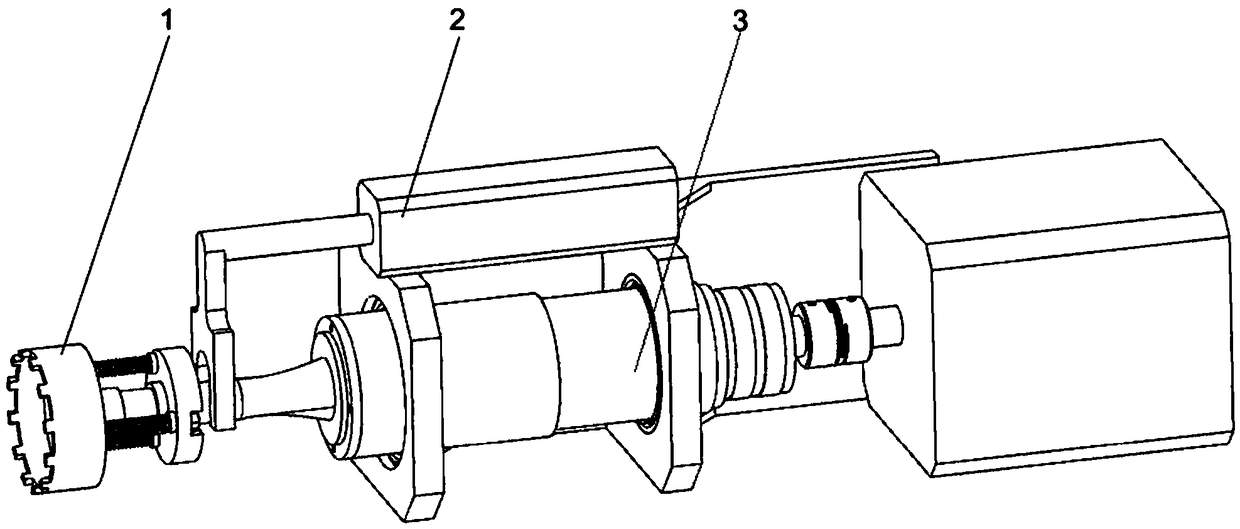

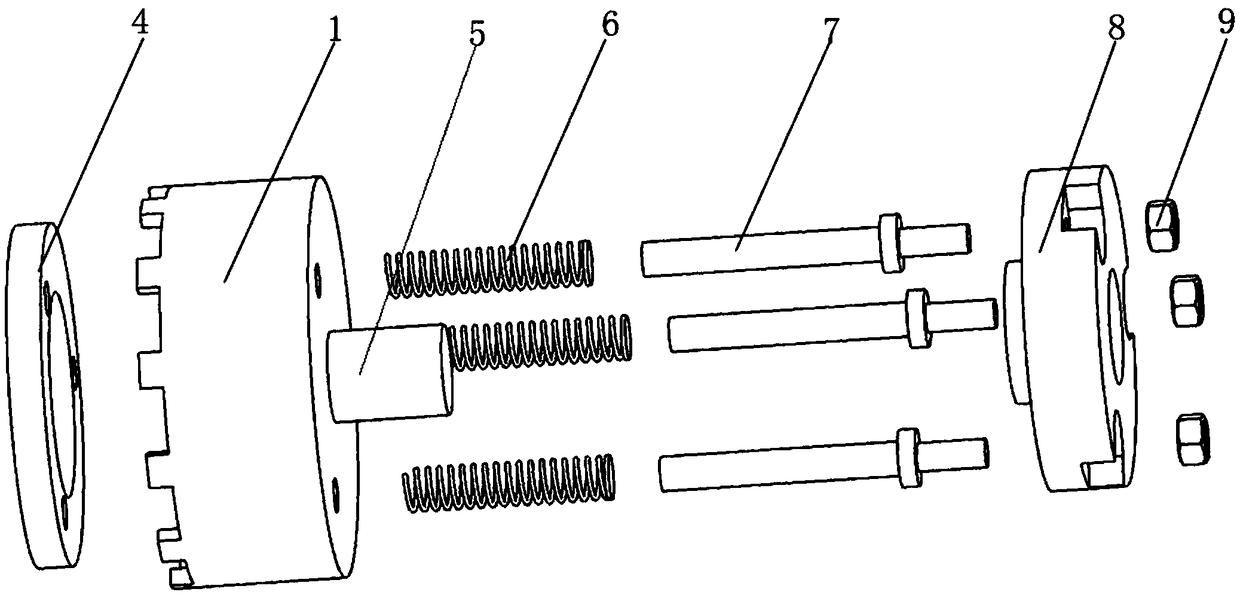

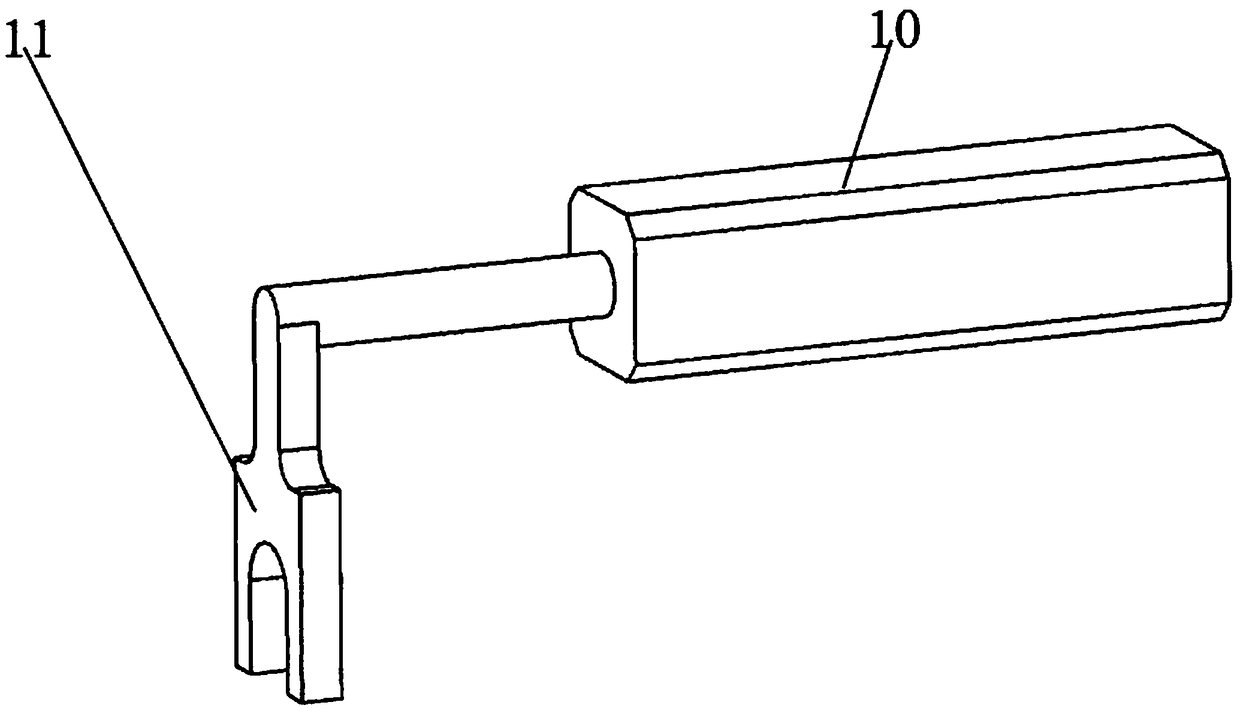

[0021] Such as Figure 1 to Figure 5 As shown, an FRP tank opening device is used in conjunction with a propulsion device and a positioning fixture, and includes a cup-shaped cutter 1, an ultrasonic rotating spindle 3 and a waste discharge mechanism 2. The waste discharge mechanism 2 includes a cup-shaped cutter 1 inner cavity The ejector ring 4, at least two ejector rods 7 connected to the ejector ring 4 after vertically passing through the end face of the cup-shaped cutter 1 (this embodiment is three evenly distributed ejector rods 7, in fact, it can also be 2, 4, 5, etc.), a synchronous plate 8 connected to the end of all ejector rods 7 away from the ejector ring 4, a drive element for driving the linear motion of the synchronous plate 8 to drive the ejector ring 4 to eject 10. The spring 6 that is set on the ejector rod 7 and can realize the reset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com