Plate cutting device

A technology for cutting devices and plates, applied in sawing devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of low efficiency and slow speed of cutting gears, and achieve the effect of wide cutting range and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

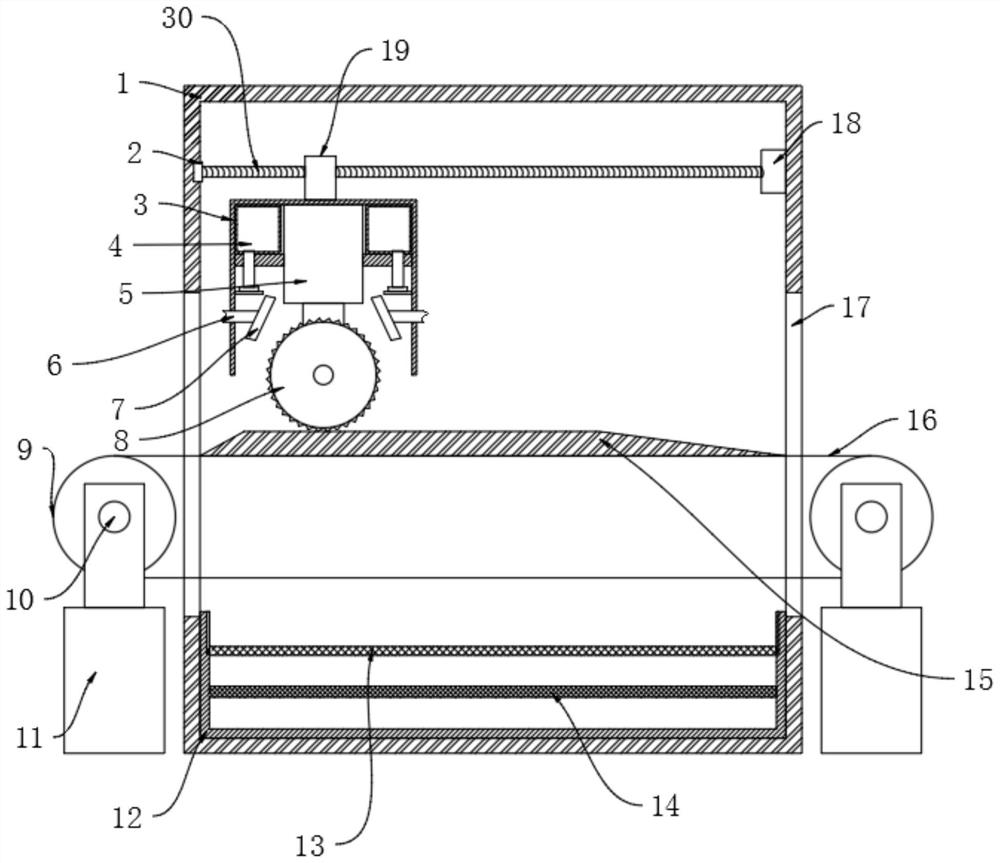

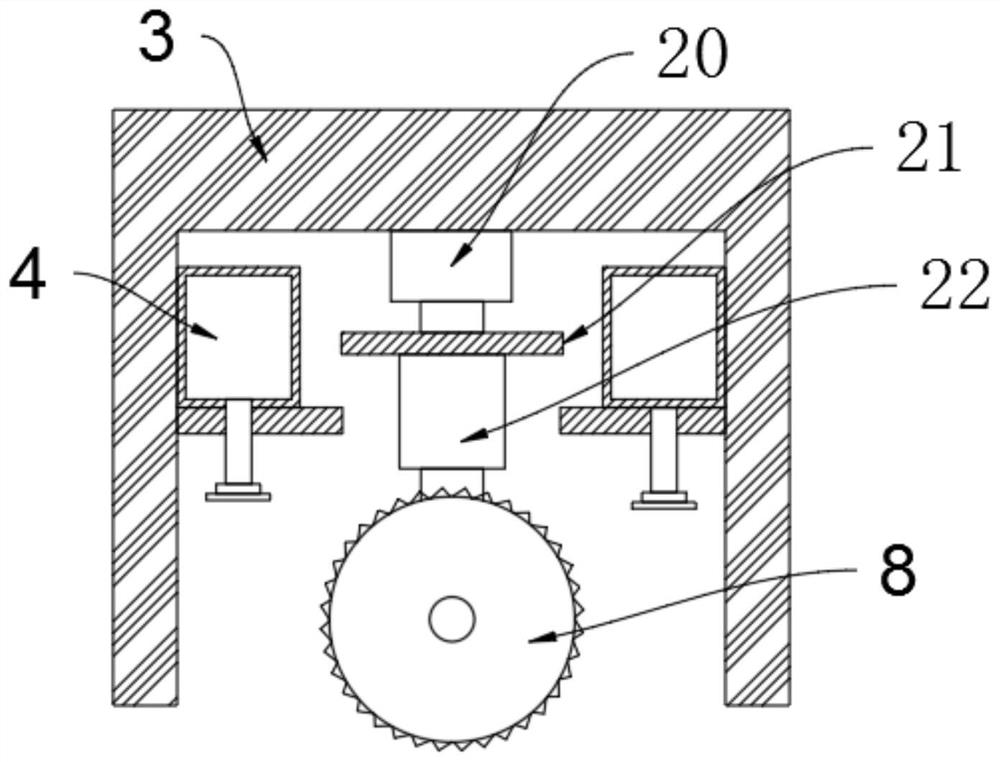

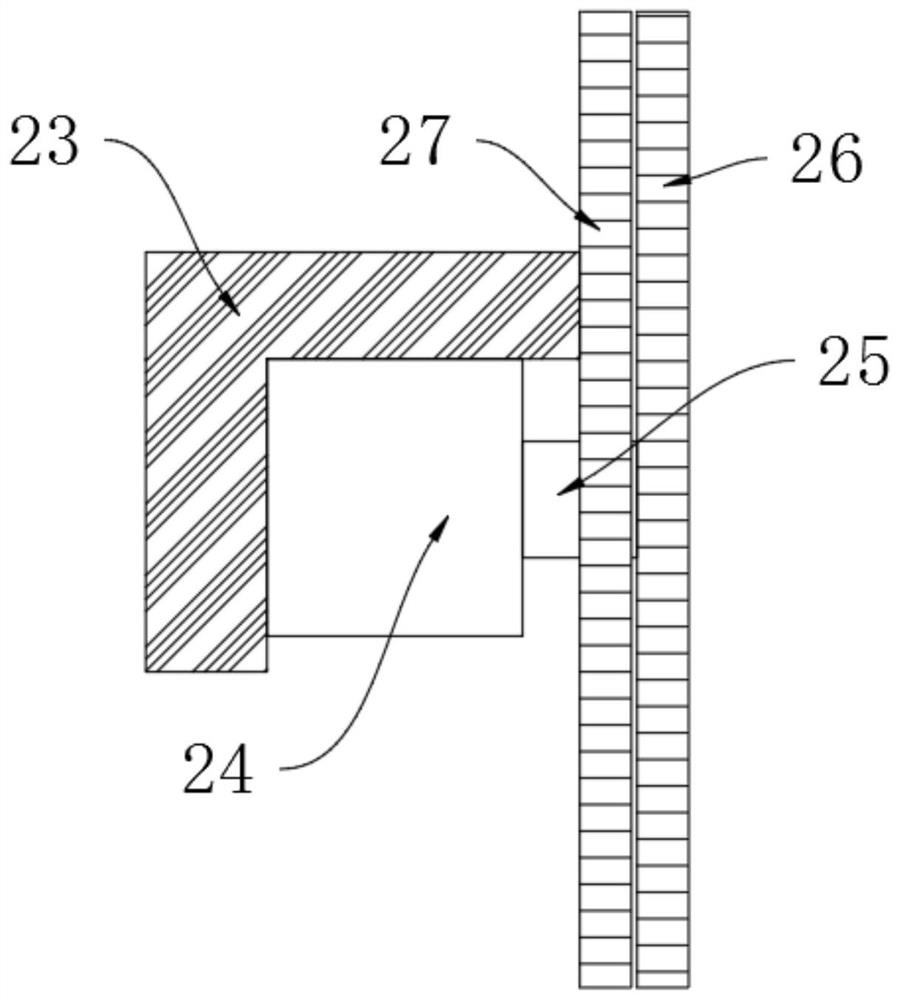

[0021] see Figure 1-5 , a plate cutting device, including a box 1, a transmission structure and a cutting structure, the inside of the box 1 is provided with a transmission structure, the inside of the box 1 is provided with a cutting structure, and the cutting structure includes a lateral movement mechanism , internal control structure 5, anti-splash housing 3, dust suction structure 4, side water pipe 6, spray head 7 and cutting roller 8, a lateral movement mechanism is fixed inside the box 1, and the lateral movement mechanism drives Connect the anti-splash housing 3, the inner end of the anti-splash housing 3 is fixed with an internal control structure 5, the side of the internal control structure 5 is fixed with a dust suction structure, and the side of the anti-splash housing 3 A side water pipe 6 is fixed, a spray head 7 is fixed at the output end of the side water pipe 6, a cutting roller 8 is fixed at the end of the internal control structure 5, and the cutting rolle...

Embodiment 2

[0028] Compared with Embodiment 1, the improvement of this embodiment is that: the bottom collection box 12 is fixed with a solid collection net plate 13 and a magnetic net plate 14, and the solid collection net plate 13 and magnetic net plate 14 are detachable. Firstly, the solids collection screen 13 is used to collect bulky solids, and then the magnetic screen 14 is used to collect finely divided metal residues.

[0029]The working principle of the present invention is: first, drive the connecting roller 9 through the transmission power mechanism, so that the transmission belt 16 transmits the plate to move, and through the guide plate 15, the plate is gradually raised until it reaches the cutting position, and at the same time the fixed column on the transmission belt 16 Push the plate to continue to move forward on the guide plate 15, then use the hydraulic cylinder 11 to lower the conveyor belt 16, and use the cutting structure to cut, that is, use the electric telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com