Multi-cutter vertical-type stone material sheet cutting machine

A cutting machine and sheet technology, used in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problem that the stone aluminum honeycomb panel cannot be cut accurately, multiple stone sheets cannot be cut at the same time, and it is difficult to accurately control the cutting width and Thickness and other issues, to achieve the effect of low production cost, high work efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

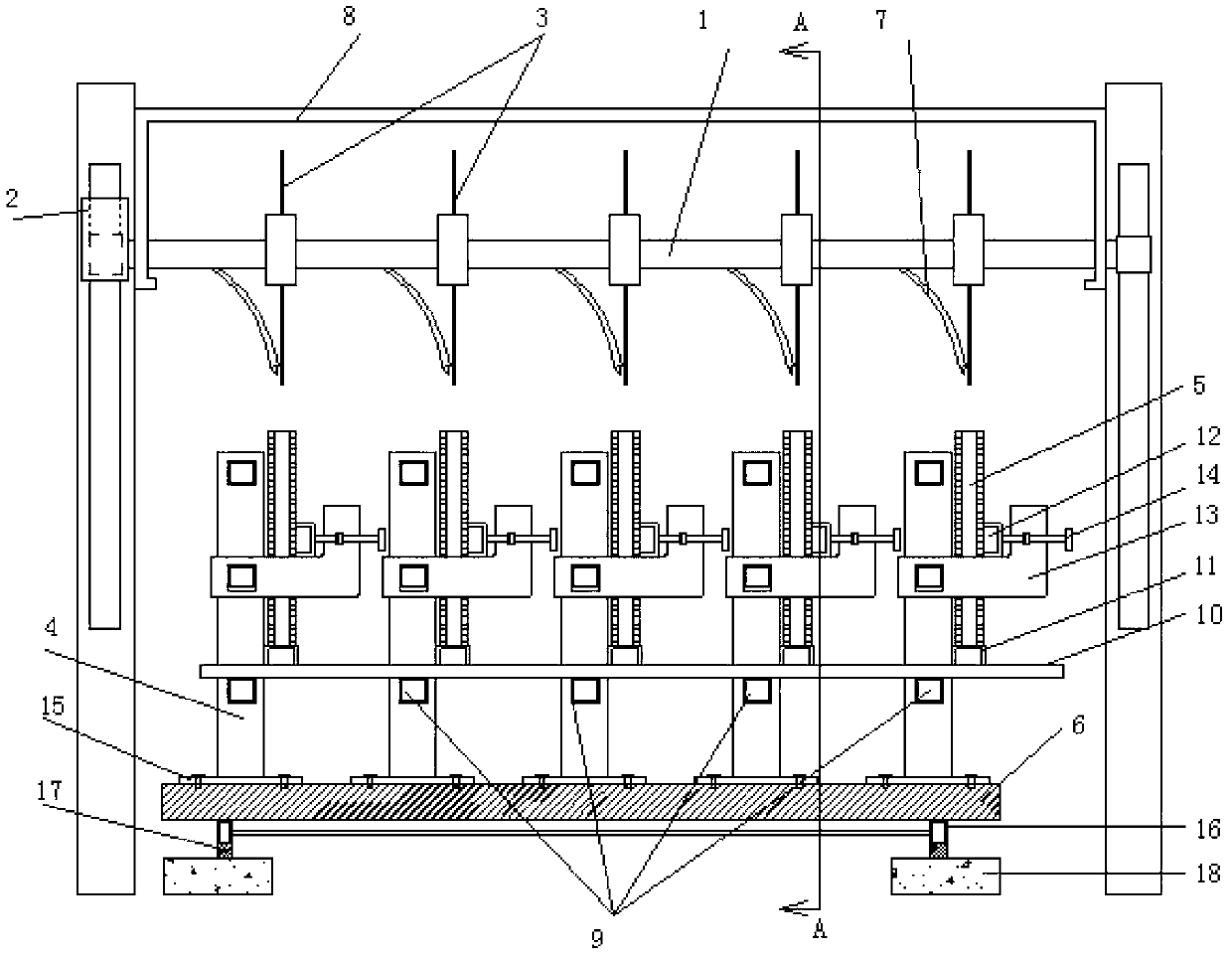

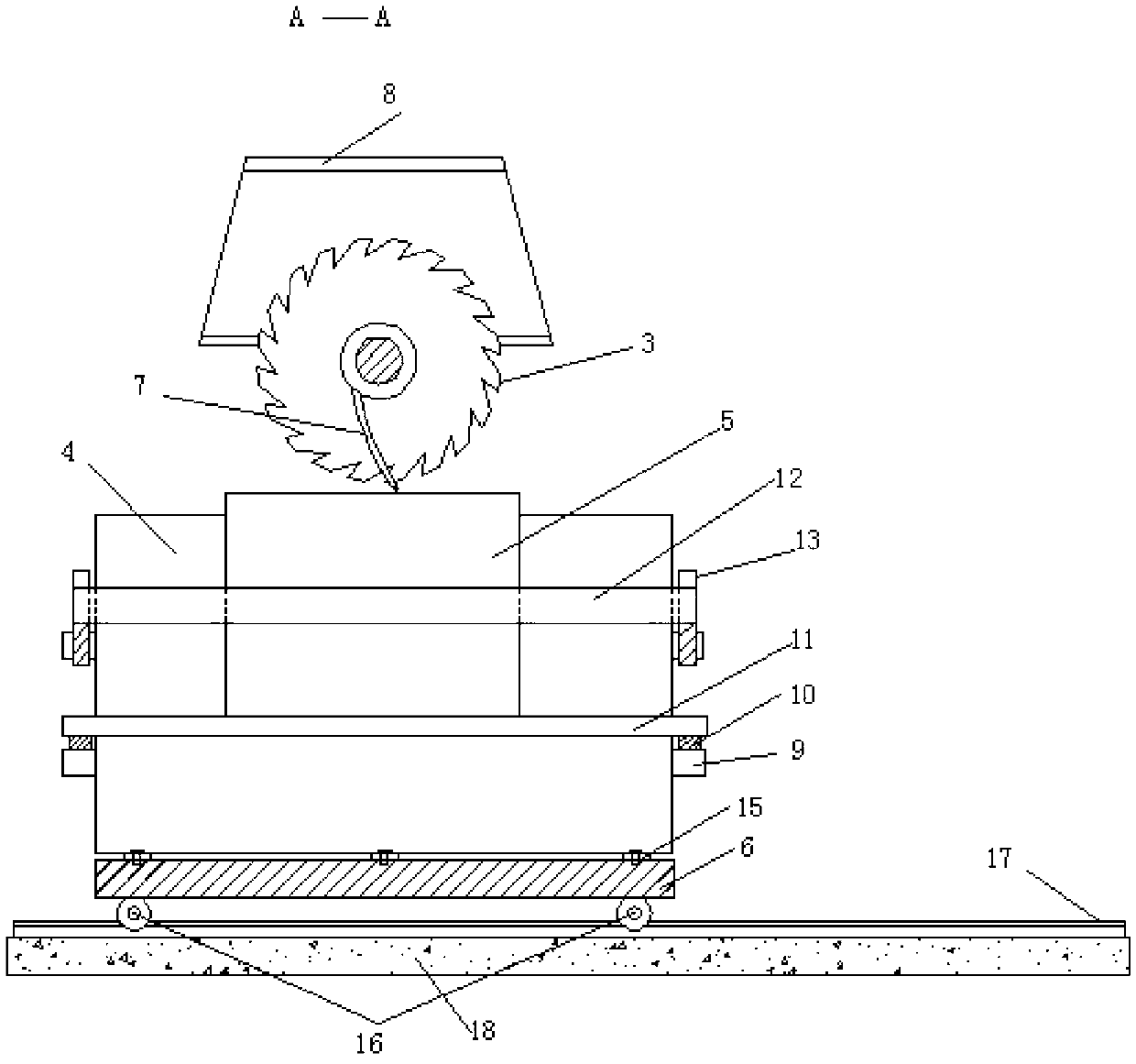

[0023] Please refer to figure 1 , figure 2 , the present invention provides a multi-cutter vertical stone plate cutting machine, comprising: a cutter wheel shaft 1, which is a round rod body, the two ends of the cutter wheel shaft 1 are connected to the support in a manner of moving up and down, and the cutter One end of the wheel shaft 1 is connected to the motor 2; a plurality of cutting knives 3 are a plurality of circular slices, and the plurality of cutting knives 3 are equidistantly fixed on the cutter wheel shaft 1, and the plurality of cutting knives 3 are connected to the The cutter wheel shaft 1 is coaxially arranged; a plurality of backers 4 are a plurality of vertically placed flat plate structures, and one side of the plurality of backers 4 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com