Detachable drill bit

A technology of drill bits and drill blades, which is applied in the field of detachable drill bits, can solve the problems of scrapped bits, cost reduction, and poor concentricity, etc., and achieves the effects of easy use, enlarged cutting area, and improved mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

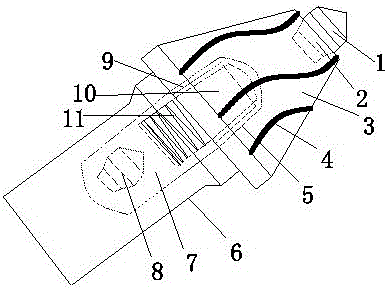

[0021] In view of the above problems, the object of the present invention is to provide a detachable drill bit. By adopting modular thinking, the traditional integrated drill bit is divided into three parts: a detachable drill blade, a drill shoulder, and a drill shank. When one part is damaged, it can be replaced separately. A spare drill edge is placed in the inner space of the drill shank, which is more convenient to use.

[0022] In order to achieve the above object, the present invention adopts the following technical solutions

[0023] Removable drill bit, which includes, drill edge 1, first mounting hole 2, drill shoulder 3, blade 4, second mounting hole 5, drill shank 6, fixing hole 7, spare drilling edge 8, fixing collar 9, fixing Shaft 10, external thread 11.

[0024] The upper part of the drill shoulder 3 is provided with a first installation hole 2, and the drill edge 1 is fixedly connected with the drill shoulder 3 through the first installation hole 2. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com